EN 12916:2019+A1:2022

(Main + Amendment)Petroleum products - Determination of aromatic hydrocarbon types in middle distillates - High performance liquid chromatography method with refractive index detection

Petroleum products - Determination of aromatic hydrocarbon types in middle distillates - High performance liquid chromatography method with refractive index detection

This document specifies a test method for the determination of the content of mono-aromatic, di-aromatic and tri+-aromatic hydrocarbons in diesel fuels, paraffinic diesel fuels and petroleum distillates.

This document defines two procedures, A and B.

Procedure A is applicable to diesel fuels that may contain fatty acid methyl esters (FAME) up to 30 % (V/V) (as in [1], [2] or [3]) and petroleum distillates in the boiling range from 150 °C to 400 °C (as in [4].

Procedure B is applicable to paraffinic diesel fuels with up to 7 % (V/V) FAME. This procedure does not contain a dilution of the sample in order to determine the low levels of aromatic components in these fuels.

The polycyclic aromatic hydrocarbons content is calculated from the sum of di-aromatic and tri+-aromatic hydrocarbons and the total content of aromatic compounds is calculated from the sum of the individual aromatic hydrocarbon types.

Compounds containing sulfur, nitrogen and oxygen can interfere in the determination; mono-alkenes do not interfere, but conjugated di-alkenes and poly-alkenes, if present, can do so.

NOTE 1 For the purpose of this European Standard, the terms "% (m/m)" and "% (V/V)" are used to represent the mass fraction, µ, and the volume fraction, φ, of a material respectively.

NOTE 2 By convention, the aromatic hydrocarbon types are defined on the basis of their elution characteristics from the specified liquid chromatography column relative to model aromatic compounds. Their quantification is performed using an external calibration with a single aromatic compound for each of them, which may or may not be representative of the aromatics present in the sample. Alternative techniques and test methods may classify and quantify individual aromatic hydrocarbon types differently.

NOTE 3 Backflush is part of laboratory-internal maintenance.

WARNING - The use of this standard can involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of users of this standard to take appropriate measures to ensure the safety and health of personnel prior to application of the standard, and fulfil statutory and regulatory requirements for this purpose.

Mineralölerzeugnisse - Bestimmung von aromatischen Kohlenwasserstoffgruppen in Mitteldestillaten - Hochleistungsflüssigkeitschromatographie-Verfahren mit Brechzahl-Detektion

Produits pétroliers - Détermination des familles d'hydrocarbures aromatiques dans les distillats moyens - Méthode par chromatographie liquide à haute performance avec détection par réfractométrie différentielle

Le présent document prescrit une méthode pour déterminer la teneur en hydrocarbures mono-aromatiques, di-aromatiques, et tri+-aromatiques des carburants diesel, des carburants diesel paraffiniques et des distillats pétroliers.

Le présent document définit deux modes opératoires, A et B.

La procédure A est applicable aux carburants diesel, qui peuvent contenir des esters méthyliques d’acides gras (EMAG) jusqu’à 30 % (V/V) (comme ceux prescrits dans [1], [2] ou [3]), et distillats pétroliers d'intervalle d'ébullition de 150 °C à 400 °C (comme ceux prescrits dans [4]).

La procédure B est applicable aux carburants diesel paraffiniques qui peuvent contenir jusqu’à 7 % (V/V) d’EMAG. Cette procédure n’implique pas d’étape de dilution de l’échantillon afin de déterminer les faibles teneurs en aromatiques dans ces carburants.

La teneur en hydrocarbures aromatiques polycycliques est calculée à partir de la somme des di-aromatiques, et tri+-aromatiques, et la teneur totale en composés aromatiques est calculée à partir de la somme des teneurs des différentes familles de composés aromatiques. !Les intervalles de mesure qui s’appliquent à cette méthode sont donnés dans les Tableaux 2 et 3."

Les composés soufrés, azotés et oxygénés peuvent interférer dans la mesure. Les mono-oléfines n'interfèrent pas, au contraire des dioléfines conjuguées et des polyoléfines qui peuvent interférer, si elles sont présentes.

NOTE 1 Pour les besoins de la présente Norme européenne, les expressions « % (m/m) » et « % (V/V) » sont utilisées pour désigner respectivement les fractions massiques, µ, et les fractions volumiques, φ, d’un produit.

NOTE 2 Par convention, la présente Norme définit les familles d’hydrocarbures aromatiques à partir de leurs caractéristiques d’élution dans la colonne de chromatographie liquide prescrite, et par comparaison aux temps d'élution des composés aromatiques servant de modèle. La quantification est effectuée par étalonnage externe avec un seul composé aromatique par famille d’hydrocarbures aromatiques, ce composé pouvant être ou non représentatif des aromatiques présents dans l’échantillon. Il est possible que des techniques et méthodes alternatives classent et quantifient différemment les familles d'hydrocarbures aromatiques.

!NOTE 3 Le rétrobalayage fait partie de la maintenance interne au laboratoire."

AVERTISSEMENT — L'utilisation de la présente norme peut impliquer la mise en œuvre de produits, d'opérations et d'équipements à caractère dangereux. La présente norme n'est pas censée aborder tous les problèmes de sécurité concernés par son usage. Il est de la responsabilité des utilisateurs de cette norme de prendre les mesures appropriées pour assurer la sécurité et préserver la santé du personnel avant son application, et pour répondre aux exigences réglementaires et statutaires à cette fin.

Naftni proizvodi - Določevanje aromatskih ogljikovodikov v srednjih destilatih - Metoda tekočinske kromatografije visoke ločljivosti z detekcijo lomnega količnika

Ta dokument določa preskusno metodo za določevanje vsebnosti aromatskih ogljikovodikov z enim, dvema, tremi ali več aromatskimi obroči v dizelskih gorivih, parafinskih dizelskih gorivih in naftnih destilatih.

Ta dokument določa dva postopka, A in B.

Postopek A se uporablja za dizelska goriva, ki lahko vsebujejo do 30 % (V/V) metilnih estrov maščobnih kislin (FAME) (kot v delih [1], [2] ali [3]), in naftne destilate z vreliščem med 150 °C in 400 °C (kot v delu [4]).

Postopek B se uporablja za parafinska dizelska goriva z vsebnostjo metilnih estrov maščobnih kislin do 7 % (V/V). Ta postopek ne vključuje redčenja vzorca za namene ugotavljanja nizke vsebnosti aromatskih snovi v teh gorivih.

Vsebnost policikličnih aromatskih ogljikovodikov se izračuna s seštevanjem aromatskih ogljikovodikov z dvema obročema in aromatskih ogljikovodikov s tremi ali več obroči, skupna vsebnost aromatskih spojin pa na podlagi seštevka posameznih vrst aromatskih ogljikovodikov.

Spojine, ki vsebujejo žveplo, dušik in kisik, lahko povzročajo motnje pri določevanju; monoalkeni ne povzročajo motenj, konjugirani dialkeni in polialkeni pa jih lahko povzročajo, če so prisotni.

OPOMBA 1: V tem evropskem standardu sta uporabljeni oznaki »% (m/m)« in »% (V/V)«, ki označujeta masni delež (µ) oziroma prostorninski delež (φ) materiala.

OPOMBA 2: Po dogovoru so vrste aromatskih ogljikovodikov opredeljene na podlagi njihovih elucijskih lastnosti iz določene kolone tekočinske kromatografije v primerjavi z modelnimi aromatskimi spojinami. Njihova kvantifikacija se izvede z uporabo zunanjega umerjanja z enojno aromatsko spojino za posamezno vrsto aromatskih ogljikovodikov, ki je lahko reprezentativna za aromatske spojine iz vzorca ali pa tudi ne. Druge tehnike in preskusne metode lahko drugače razvrstijo in kvantificirajo posamezne vrste aromatskih ogljikovodikov.

OPOMBA 3: Povratno izpiranje je del vzdrževanja laboratorijske opreme.

OPOZORILO: Pri uporabi tega standarda so lahko prisotni nevarni materiali, postopki in oprema. Ta standard ne obravnava vseh varnostnih težav, ki se navezujejo na njegovo uporabo. Za sprejetje ustreznih ukrepov za zagotavljanje varnosti in zdravja osebja pred uporabo standarda ter izpolnjevanje zakonskih in regulativnih zahtev za ta namen so odgovorni uporabniki tega standarda.

General Information

- Status

- Withdrawn

- Publication Date

- 02-Aug-2022

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 19 - Petroleum products, lubricants and related products

- Drafting Committee

- CEN/TC 19/WG 9 - Chromatographic test methods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Mar-2024

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 25-May-2022

- Effective Date

- 15-Mar-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 12916:2019+A1:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Petroleum products - Determination of aromatic hydrocarbon types in middle distillates - High performance liquid chromatography method with refractive index detection". This standard covers: This document specifies a test method for the determination of the content of mono-aromatic, di-aromatic and tri+-aromatic hydrocarbons in diesel fuels, paraffinic diesel fuels and petroleum distillates. This document defines two procedures, A and B. Procedure A is applicable to diesel fuels that may contain fatty acid methyl esters (FAME) up to 30 % (V/V) (as in [1], [2] or [3]) and petroleum distillates in the boiling range from 150 °C to 400 °C (as in [4]. Procedure B is applicable to paraffinic diesel fuels with up to 7 % (V/V) FAME. This procedure does not contain a dilution of the sample in order to determine the low levels of aromatic components in these fuels. The polycyclic aromatic hydrocarbons content is calculated from the sum of di-aromatic and tri+-aromatic hydrocarbons and the total content of aromatic compounds is calculated from the sum of the individual aromatic hydrocarbon types. Compounds containing sulfur, nitrogen and oxygen can interfere in the determination; mono-alkenes do not interfere, but conjugated di-alkenes and poly-alkenes, if present, can do so. NOTE 1 For the purpose of this European Standard, the terms "% (m/m)" and "% (V/V)" are used to represent the mass fraction, µ, and the volume fraction, φ, of a material respectively. NOTE 2 By convention, the aromatic hydrocarbon types are defined on the basis of their elution characteristics from the specified liquid chromatography column relative to model aromatic compounds. Their quantification is performed using an external calibration with a single aromatic compound for each of them, which may or may not be representative of the aromatics present in the sample. Alternative techniques and test methods may classify and quantify individual aromatic hydrocarbon types differently. NOTE 3 Backflush is part of laboratory-internal maintenance. WARNING - The use of this standard can involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of users of this standard to take appropriate measures to ensure the safety and health of personnel prior to application of the standard, and fulfil statutory and regulatory requirements for this purpose.

This document specifies a test method for the determination of the content of mono-aromatic, di-aromatic and tri+-aromatic hydrocarbons in diesel fuels, paraffinic diesel fuels and petroleum distillates. This document defines two procedures, A and B. Procedure A is applicable to diesel fuels that may contain fatty acid methyl esters (FAME) up to 30 % (V/V) (as in [1], [2] or [3]) and petroleum distillates in the boiling range from 150 °C to 400 °C (as in [4]. Procedure B is applicable to paraffinic diesel fuels with up to 7 % (V/V) FAME. This procedure does not contain a dilution of the sample in order to determine the low levels of aromatic components in these fuels. The polycyclic aromatic hydrocarbons content is calculated from the sum of di-aromatic and tri+-aromatic hydrocarbons and the total content of aromatic compounds is calculated from the sum of the individual aromatic hydrocarbon types. Compounds containing sulfur, nitrogen and oxygen can interfere in the determination; mono-alkenes do not interfere, but conjugated di-alkenes and poly-alkenes, if present, can do so. NOTE 1 For the purpose of this European Standard, the terms "% (m/m)" and "% (V/V)" are used to represent the mass fraction, µ, and the volume fraction, φ, of a material respectively. NOTE 2 By convention, the aromatic hydrocarbon types are defined on the basis of their elution characteristics from the specified liquid chromatography column relative to model aromatic compounds. Their quantification is performed using an external calibration with a single aromatic compound for each of them, which may or may not be representative of the aromatics present in the sample. Alternative techniques and test methods may classify and quantify individual aromatic hydrocarbon types differently. NOTE 3 Backflush is part of laboratory-internal maintenance. WARNING - The use of this standard can involve hazardous materials, operations and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of users of this standard to take appropriate measures to ensure the safety and health of personnel prior to application of the standard, and fulfil statutory and regulatory requirements for this purpose.

EN 12916:2019+A1:2022 is classified under the following ICS (International Classification for Standards) categories: 75.080 - Petroleum products in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12916:2019+A1:2022 has the following relationships with other standards: It is inter standard links to EN 12916:2019/prA1, EN 12916:2019, EN 12916:2024, EN ISO 3171:1999, EN ISO 1042:1999, EN ISO 3170:2025, EN 14214:2012+A2:2019, EN 15940:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12916:2019+A1:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2022

Naftni proizvodi - Določevanje aromatskih ogljikovodikov v srednjih destilatih -

Metoda tekočinske kromatografije visoke ločljivosti z detekcijo lomnega količnika

Petroleum products - Determination of aromatic hydrocarbon types in middle distillates -

High performance liquid chromatography method with refractive index detection

Mineralölerzeugnisse - Bestimmung von aromatischen Kohlenwasserstoffgruppen in

Mitteldestillaten - Hochleistungsflüssigkeitschromatographie-Verfahren mit Brechzahl-

Detektion

Produits pétroliers - Détermination des familles d'hydrocarbures aromatiques dans les

distillats moyens - Méthode par chromatographie liquide à haute performance avec

détection par réfractométrie différentielle

Ta slovenski standard je istoveten z: EN 12916:2019+A1:2022

ICS:

71.040.50 Fizikalnokemijske analitske Physicochemical methods of

metode analysis

75.080 Naftni proizvodi na splošno Petroleum products in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12916:2019+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2022

EUROPÄISCHE NORM

ICS 75.080 Supersedes EN 12916:2019

English Version

Petroleum products - Determination of aromatic

hydrocarbon types in middle distillates - High

performance liquid chromatography method with

refractive index detection

Produits pétroliers - Détermination des familles Mineralölerzeugnisse - Bestimmung von aromatischen

d'hydrocarbures aromatiques dans les distillats Kohlenwasserstoffgruppen in Mitteldestillaten -

moyens - Méthode par chromatographie liquide à Hochleistungsflüssigkeitschromatographie-Verfahren

haute performance avec détection par réfractométrie mit Brechzahl-Detektion

différentielle

This European Standard was approved by CEN on 15 April 2019 and includes Amendment 1 approved by CEN on 20 May 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12916:2019+A1:2022 E

worldwide for CEN national Members.

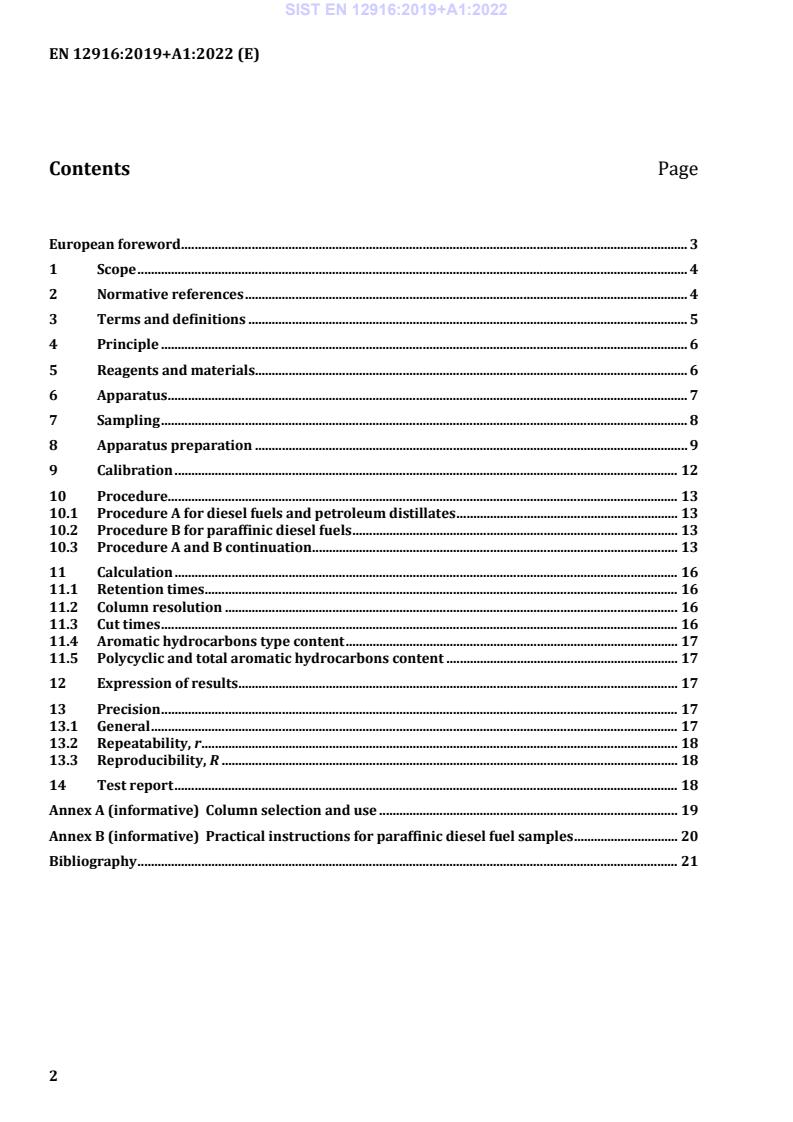

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 5

4 Principle . 6

5 Reagents and materials . 6

6 Apparatus . 7

7 Sampling . 8

8 Apparatus preparation . 9

9 Calibration . 12

10 Procedure. 13

10.1 Procedure A for diesel fuels and petroleum distillates . 13

10.2 Procedure B for paraffinic diesel fuels . 13

10.3 Procedure A and B continuation . 13

11 Calculation . 16

11.1 Retention times . 16

11.2 Column resolution . 16

11.3 Cut times . 16

11.4 Aromatic hydrocarbons type content . 17

11.5 Polycyclic and total aromatic hydrocarbons content . 17

12 Expression of results . 17

13 Precision . 17

13.1 General . 17

13.2 Repeatability, r . 18

13.3 Reproducibility, R . 18

14 Test report . 18

Annex A (informative) Column selection and use . 19

Annex B (informative) Practical instructions for paraffinic diesel fuel samples . 20

Bibliography . 21

European foreword

This document (EN 12916:2019+A1:2022) has been prepared by Technical Committee CEN/TC 19

“Gaseous and liquid fuels, lubricants and related products of petroleum, synthetic and biological origin”,

the secretariat of which is held by NEN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2023, and conflicting national standards

shall be withdrawn at the latest by February 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 20 May 2022.

This document supersedes !EN 12916:2019".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies a test method for the determination of the content of mono-aromatic, di-

aromatic and tri+-aromatic hydrocarbons in diesel fuels, paraffinic diesel fuels and petroleum

distillates.

This document defines two procedures, A and B.

Procedure A is applicable to diesel fuels that may contain fatty acid methyl esters (FAME) up to

30 % (V/V) (as in [1], [2] or [3]) and petroleum distillates in the boiling range from 150 °C to 400 °C (as

in [4].

Procedure B is applicable to paraffinic diesel fuels with up to 7 % (V/V) FAME. This procedure does not

contain a dilution of the sample in order to determine the low levels of aromatic components in these

fuels.

The polycyclic aromatic hydrocarbons content is calculated from the sum of di-aromatic and tri+-

aromatic hydrocarbons and the total content of aromatic compounds is calculated from the sum of the

individual aromatic hydrocarbon types. !The measurement ranges that apply to this method are

given in Table 2 and 3."

Compounds containing sulfur, nitrogen and oxygen can interfere in the determination; mono-alkenes do

not interfere, but conjugated di-alkenes and poly-alkenes, if present, can do so.

NOTE 1 For the purpose of this European Standard, the terms “% (m/m)” and “% (V/V)” are used to represent

the mass fraction, µ, and the volume fraction, φ, of a material respectively.

NOTE 2 By convention, the aromatic hydrocarbon types are defined on the basis of their elution characteristics

from the specified liquid chromatography column relative to model aromatic compounds. Their quantification is

performed using an external calibration with a single aromatic compound for each of them, which may or may not

be representative of the aromatics present in the sample. Alternative techniques and test methods may classify

and quantify individual aromatic hydrocarbon types differently.

NOTE 3 Backflush is part of laboratory-internal maintenance.

WARNING — The use of this standard can involve hazardous materials, operations and equipment. This

standard does not purport to address all of the safety problems associated with its use. It is the

responsibility of users of this standard to take appropriate measures to ensure the safety and health of

personnel prior to application of the standard, and fulfil statutory and regulatory requirements for this

purpose.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14214, Liquid petroleum products — Fatty acid methyl esters (FAME) for use in diesel engines and

heating applications — Requirements and test methods

EN ISO 1042, Laboratory glassware - One-mark volumetric flasks (ISO 1042:1998)

EN ISO 3170, Petroleum liquids - Manual sampling (ISO 3170:2004)

EN ISO 3171, Petroleum liquids - Automatic pipeline sampling (ISO 3171:1988)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1

non-aromatic hydrocarbon

compound having a shorter retention time on the specified polar column than the majority of mono-

aromatic hydrocarbons

3.2

mono-aromatic hydrocarbon

MAH

compound having a longer retention time on the specified polar column than the majority of non-

aromatic hydrocarbons, but a shorter retention time than the majority of di-aromatic hydrocarbons

3.3

di-aromatic hydrocarbon

DAH

compound having a longer retention time on the specified polar column than the majority of mono-

aromatic hydrocarbons, but a shorter retention time than the majority of tri+-aromatic hydrocarbons

3.4

tri+-aromatic hydrocarbon

T+AH

compound having a longer retention time on the specified polar column than the majority of di-

aromatic hydrocarbons including chrysene

3.5

polycyclic aromatic hydrocarbon

POLY-AH

sum of the di-aromatic hydrocarbons and tri+-aromatic hydrocarbons

3.6

total aromatic hydrocarbon

sum of the mono-aromatic hydrocarbons, di-aromatic hydrocarbons and tri+-aromatic hydrocarbons

Note 1 to entry: Published and unpublished data indicate that the major constituents for each hydrocarbon type

include:

a) non-aromatic hydrocarbons: cyclic and acyclic alkanes (paraffins and naphthenes), mono-alkenes (if

present),

b) MAHs: benzenes, tetralins, indanes and higher naphthenobenzenes (e.g. octahydrophenanthrenes),

thiophenes, styrenes, conjugated polyalkenes,

c) DAHs: naphthalenes, biphenyls, indenes, fluorenes, acenaphthenes, benzothiophenes and dibenzothiophenes,

d) T+AHs: phenanthrenes, pyrenes, fluoranthenes, chrysenes, triphenylenes, benzanthracenes.

3.7

fatty acid methyl ester

FAME

mixture of fatty acid methyl esters derived from vegetable oil or animal fats and complying to the

specification defined in EN 14214

4 Principle

A known mass of sample is taken and a fixed volume of this sample is injected into a high performance

liquid chromatograph fitted with a polar column. Diesel fuels with a concentration of FAME up to

30 % (V/V) and petroleum distillates need to be diluted with heptane (Procedure A). Paraffinic diesel

fuels are injected neat (Procedure B).

This column has little affinity for non-aromatic hydrocarbons, while exhibiting a strong selectivity for

aromatic hydrocarbons. As a result of this selectivity, the aromatic hydrocarbons are separated from

the non-aromatic hydrocarbons and into distinct bands according to their ring structure, i.e. MAH, DAH

and T+AH compounds.

The column is connected to a refractive index detector which detects the components as they elute from

the column. The electronic signal from the detector is continually monitored by a data processor. The

amplitudes of the signals from the aromatics in the sample are compared with those obtained from

calibration standards in order to calculate the mass fraction of MAHs, DAHs and T+AHs in the sample.

The sum of the DAHs and T+AHs mass fractions is reported as the mass fraction of POLY-AH, and the

sum of the MAHs, DAHs and T+AHs mass fractions is reported as the mass fraction of total aromatic

hydrocarbons.

When following Procedure A, the column may be backflushed after the aromatics have eluted from the

column to allow any remaining components such as FAME to elute in a backflush peak. This will allow

for a better cleaning of the column but care should be taken as it can affect the lifetime of the column.

5 Reagents and materials

WARNING — Aromatic compounds can be volatile and flammable, their vapours can form explosive

mixtures with the air, and they can cause acute or chronicle harm when inhaled or in case of contact

with the skin. In addition, they can be water polluting.

5.1 General

The highest purity reagents and materials available should be used; those required to be of high

performance liquid chromatography (HPLC) grade are commercially available from major suppliers.

5.2 Cyclohexane, of 99 % (m/m) minimum purity (CAS registry number 110-82-7).

NOTE Cyclohexane can contain benzene as an impurity.

5.3 Heptane, HPLC analytical grade, as the mobile phase (CAS registry number 142-82-5).

Batch to batch variation of the solvent water content, viscosity, refractive index, and purity can cause

unpredictable column behaviour. Drying (for example, by standing over activated molecular sieve type

5A) and filtering the mobile phase can help reducing the effect of trace impurities present in the solvent.

It is recommended practice to de-gas the mobile phase before use; this can be done conveniently online

or off-line by helium sparging, vacuum degassing or ultrasonic agitation. A failure to de-gas the mobile

phase can lead to negative peaks.

5.4 1-Phenyldodecane, of 98 % (m/m) minimum purity (CAS registry number 123-01-3).

5.5 1,2-Dimethylbenzene (o-xylene), of 98 % (m/m) minimum purity (CAS registry number 95-47-

6).

5.6 Hexamethylbenzene, of 98 % (m/m) minimum purity (CAS registry number 87-85-4).

5.7 Naphthalene, of 98 % (m/m) minimum purity (CAS registry number 91-20-3).

5.8 Fluorene, of 98 % (m/m) minimum purity (CAS registry number 86-73-7).

5.9 Phenanthrene, of 98 % (m/m) minimum purity (CAS registry number 85-01-8).

5.10 Dibenzothiophene, of 95 % (m/m) minimum purity (CAS registry number 132-65-0).

5.11 9-Methylanthracene, of 95 % (m/m) minimum purity (CAS registry number 779-02-2).

5.12 Chrysene, of 95 % (m/m) minimum purity (CAS registry number 218-01-9).

5.13 FAME, compliant to EN 14214.

6 Apparatus

6.1 Liquid chromatograph, consisting of a high performance instrument capable of pumping the

mobile phase at flow rates from 0,5 ml/min to 1,5 ml/min, with a precision better than 0,5 % and a

pulsation of < 1 % full scale deflection under the test conditions described in Clause 8. Make sure that

the equipment for handling or testing the sample is not sensitive to FAME. Recommended materials are

Polytetrafluoroethylene, Viton® and Nylon.

6.2 Sample injection system, capable of nominally injecting 10 μl of sample solution with a

repeatability better than 1 %.

Equal and constant volumes of the calibration and sample solutions are injected into the

chromatograph. Both manual and automatic sample injection systems, using either complete or partial

filling of the sample loop, can meet these repeatability requirements when used correctly. When using

the partial filling mode, it is recommended that the injection volume is less than half the total loop

volume. For complete filling of the loop, best results are obtained by overfilling the loop at least six

times.

The repeatability of the injection system can be checked by comparing peak areas from at least four

injections of the system calibration standard (see 8.4).

Sample and calibration injection volumes different from 10 μl (typically in the range 3 μl to 20 μl) may

be used provided they meet the requirements for injection repeatability, refractive index sensitivity and

linearity (see 9.4), and column resolution (see 8.10).

6.3 Sample filter, if required (see 10.1 and 10.2), consisting of a microfilter of porosity 0,45 μm or

less, chemically inert towards hydrocarbon solvents, for the removal of particulate matter from the

sample solutions.

NOTE Polytetrafluorethylen (PTFE) filters have been found to be suitable.

Viton® is the trademark of a fluoroelastomer supplied by the Chemours Company, Wilmington, Delaware 19899

(USA). This information is given for the convenience of users of this document and does not constitute an

endorsement by CEN of the product named. Equivalent products may be used if they can be shown to lead to the

same results.

6.4 Column system, consisting of a stainless steel HPLC column(s) packed with a commercial 3 μm,

5 μm or 10 μm amino-bonded (or amino/cyano-bonded) silica stationary phase meeting the resolution

requirements given in 8.7, 8.8, 8.10 and 8.12 . See Annex A for guidance on the selection and use of

suitable column systems.

6.5 Temperature controls, for different parts of the apparatus (column, sample injection system,

solvent, refractive index detector). Maintain the sample injection system at the same temperature as the

sample solution, for the column a heating block or an air-circulating HPLC column oven may be used.

Also, a temperature-controlled laboratory, capable of maintaining a constant temperature in the range

(20 ± 1) °C to (40 ± 1) °C may be used.

The refractive index detector is sensitive to both sudden and gradual changes in the temperature of the

eluent. All necessary precautions should be taken to establish constant temperature conditions

throughout the liquid chromatograph system. The temperature should be optimized depending on the

stationary phase.

6.6 Refractive index detector, capable of being operated over the refractive index range 1,3 to 1,6

and giving a linear response over the calibration ranges with a suitable output signal for the data

system.

If the detector is equipped with a device for independent temperature control, it is recommended that it

is set at the same temperature as the column oven.

6.7 Computer or computing integrator, compatible with the refractive index detector, having a

minimum sampling rate of 1 Hz and capable of peak area and retention time measurements. It shall also

have minimum capabilities for post-analysis data processing such as baseline correction and re-

integration.

The ability to perform automatic peak detection and identification and to calculate sample

concentrations from peak area measurements is recommended, but is not essential.

6.8 Volumetric flasks, 10 ml and 100 ml capacity, conforming to grade A of EN ISO 1042.

6.9 Analytical balance, capable of weighing to the nearest 0,1 mg.

7 Sampling

Unless otherwise specified in the commodity specification, samples shall be taken as described in

EN ISO 3170 or EN ISO 3171 and/or in accordance with the requirements of national standards or

regulations for the sampling of the product under test.

A storage temperature of 19 °C ± 5 °C shall be maintained. If for some reason, the samples have been

exposed to temperatures above 25 °C for a long period during storage or in custody (that you are aware

of), this shall be reported.

At least 24 h before a test the blend shall be placed at ambient temperature.

After finishing the tests completely, replace the air by nitrogen or any noble gas before closing the

container tightly.

---------------------- Pa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...