EN 203-1:2005+A1:2008

(Main)Gas heated catering equipment - Part 1: General safety rules

Gas heated catering equipment - Part 1: General safety rules

This document specifies the general requirements and the constructional and operating characteristics relating to safety ), marking, and the associated test methods for gas heated commercial catering and bakery appliances.

The specific requirements are given in Part 2.

Only appliances of types A1, A2, A3, B1 and B2, as defined in Clause 4, are considered in this document.

This document applies to all professional cooking and bakery appliances using gas for preparing food and drink.

This document covers type tests only, and only the net calorific value (Hi) and net Wobbe number (Wi) are used.

Annex C, informative, lists the main types of equipment entering into the field of application of this document.

NOTE This document does not really deal with rational use of energy. This aspect is mentioned in 6.10 only for the coherency with associated Part 2 (clauses numbering) and to remind that in case of not any Part 2 exist for a specific product, rational use of energy has however to be considered.

Großküchengeräte für gasförmige Brennstoffe - Teil 1: Allgemeine Sicherheitsanforderungen

Appareils de cuisine professionnelle utilisant les combustibles gazeux - Partie 1: Règles générales de sécurité

Ce document définit les exigences générales et les caractéristiques de construction et de fonctionnement relatives

à la sécurité 1), au marquage et les techniques d’essais associées des appareils de cuisson professionnelle et de

boulangerie artisanale utilisant les combustibles gazeux.

Les exigences spécifiques sont données dans les parties 2.

Seuls les appareils des types A1, A2, A3, B1 et B2 définis à l’article 4, sont étudiés dans cette norme.

Ce document s'applique à tous les appareils de cuisson professionnelle et de boulangerie artisanale utilisant les

combustibles gazeux destinés à la préparation et à la cuisson des aliments et des boissons.

Ce document couvre uniquement les essais de type, et seuls le pouvoir calorifique inférieur (Hi) et l'indice de

Wobbe inférieur (Wi) sont utilisés.

L’Annexe C, informative, donne une liste des principaux types d’appareils entrant dans le champ d’application de la

présente norme.

NOTE Ce document ne traite pas réellement de l’utilisation rationnelle de l’énergie. Cet aspect est mentionné en 6.10

seulement pour la cohérence avec les parties 2 associées (numérotation des paragraphes) et pour rappeler que dans les cas

où il n’existe pas de partie 2 pour un produit spécifique, l’utilisation rationnelle de l’énergie doit cependant être considérée.

Plinske naprave za gostinstvo - 1. del: Splošna varnostna pravila (vključno z dopolnilom A1)

General Information

- Status

- Withdrawn

- Publication Date

- 06-May-2008

- Withdrawal Date

- 25-Feb-2014

- Technical Committee

- CEN/TC 106 - Large kitchen appliances using gaseous fuels

- Drafting Committee

- CEN/TC 106/WG 1 - Security

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Feb-2014

- Completion Date

- 26-Feb-2014

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Jan-2023

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 203-1:2005+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas heated catering equipment - Part 1: General safety rules". This standard covers: This document specifies the general requirements and the constructional and operating characteristics relating to safety ), marking, and the associated test methods for gas heated commercial catering and bakery appliances. The specific requirements are given in Part 2. Only appliances of types A1, A2, A3, B1 and B2, as defined in Clause 4, are considered in this document. This document applies to all professional cooking and bakery appliances using gas for preparing food and drink. This document covers type tests only, and only the net calorific value (Hi) and net Wobbe number (Wi) are used. Annex C, informative, lists the main types of equipment entering into the field of application of this document. NOTE This document does not really deal with rational use of energy. This aspect is mentioned in 6.10 only for the coherency with associated Part 2 (clauses numbering) and to remind that in case of not any Part 2 exist for a specific product, rational use of energy has however to be considered.

This document specifies the general requirements and the constructional and operating characteristics relating to safety ), marking, and the associated test methods for gas heated commercial catering and bakery appliances. The specific requirements are given in Part 2. Only appliances of types A1, A2, A3, B1 and B2, as defined in Clause 4, are considered in this document. This document applies to all professional cooking and bakery appliances using gas for preparing food and drink. This document covers type tests only, and only the net calorific value (Hi) and net Wobbe number (Wi) are used. Annex C, informative, lists the main types of equipment entering into the field of application of this document. NOTE This document does not really deal with rational use of energy. This aspect is mentioned in 6.10 only for the coherency with associated Part 2 (clauses numbering) and to remind that in case of not any Part 2 exist for a specific product, rational use of energy has however to be considered.

EN 203-1:2005+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 97.040.20 - Cooking ranges, working tables, ovens and similar appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 203-1:2005+A1:2008 has the following relationships with other standards: It is inter standard links to EN 203-1:2005, EN 203-1:2005/prA1, EN 203-1:2014, EN 161:2022+A1:2025, EN 88-2:2022+A1:2024, EN 1106:2022+A1:2023, EN 15502-2-2:2024, EN 88-1:2022+A1:2023, EN 125:2022+A1:2024, EN 257:2022+A1:2023, prEN 15116, EN 88-3:2022+A1:2024, EN 415-6:2013, EN 203-2-7:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 203-1:2005+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2009/142/EC, 90/396/EEC; Standardization Mandates: M/BC/CEN/89/6. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 203-1:2005+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Großküchengeräte für gasförmige Brennstoffe - Teil 1: Allgemeine SicherheitsanforderungenAppareils de cuisine professionnelle utilisant les combustibles gazeux - Partie 1: Règles générales de sécuritéGas heated catering equipment - Part 1: General safety rules97.040.20Cooking ranges, working tables, ovens and similar appliancesICS:Ta slovenski standard je istoveten z:EN 203-1:2005+A1:2008SIST EN 203-1:2006+A1:2008en01-november-2008SIST EN 203-1:2006+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 203-1:2005+A1

May 2008 ICS 97.040.20 Supersedes EN 203-1:2005 English Version

Gas heated catering equipment - Part 1: General safety rules

Appareils de cuisine professionnelle utilisant les combustibles gazeux - Partie 1: Règles générales de sécurité

Großküchengeräte für gasförmige Brennstoffe - Teil 1: Allgemeine Sicherheitsanforderungen This European Standard was approved by CEN on 21 April 2005 and includes Amendment 1 approved by CEN on 5 March 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 203-1:2005+A1:2008: ESIST EN 203-1:2006+A1:2008

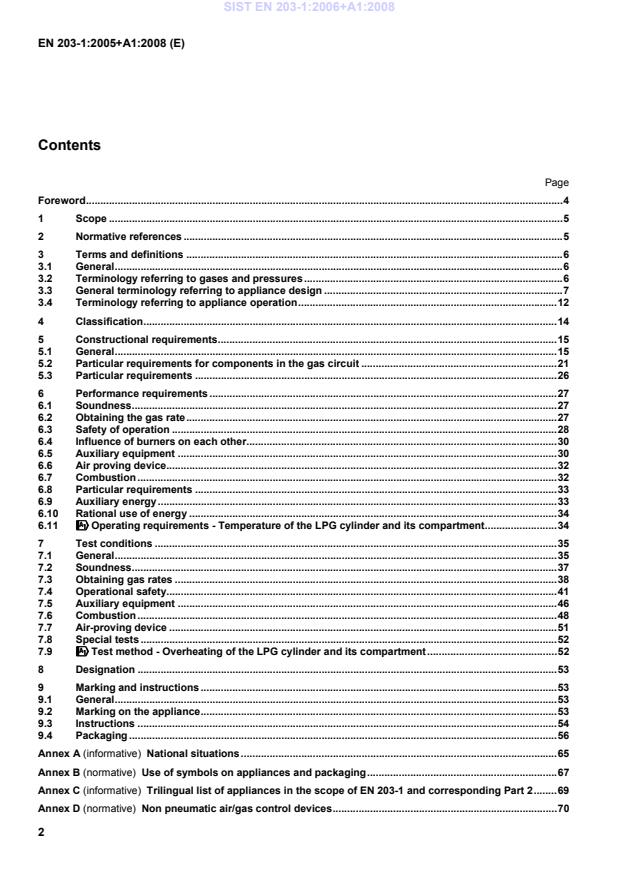

National situations.65 Annex B (normative)

Use of symbols on appliances and packaging.67 Annex C (informative)

Trilingual list of appliances in the scope of EN 203-1 and corresponding Part 2.69 Annex D (normative)

Non pneumatic air/gas control devices.70 SIST EN 203-1:2006+A1:2008

Composition of the gas circuit.73 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives.75 Bibliography.78

(IEC 60335-1:2001, modified)

1) The term "safety" includes not only the safety of the appliance gas line but also that of the overall cooking appliance during its normal use in catering. SIST EN 203-1:2006+A1:2008

3.3.1.1 gas circuit part of an appliance between the gas inlet connection and the burner(s) which conveys or contains the gas 3.3.1.2 inlet connection part of the appliance which is intended to be connected to the gas supply 3.3.1.3 mechanical soundness joint (or mechanical means of obtaining soundness) assembly of several parts, generally metallic, which achieves soundness by use of mechanical means such as metal-to-metal joints, toroidal sealing rings (O rings) or flat joints 3.3.1.4 restrictor or calibrated orifice device with one or more orifices that is placed in the path of the gas flow between the appliance inlet connection and the burner so as to create a pressure drop, and thus reduce the gas pressure at the burner to a predetermined value for a given supply pressure and rate 3.3.1.5 gas rate adjuster component which allows the gas input to each burner to be set at a predetermined value according to supply conditions. Adjustment may be continuous (screw adjuster) or discontinuous (changing restrictors). The adjusting device of an adjustable governor is regarded as a gas rate adjuster. SIST EN 203-1:2006+A1:2008

3.3.2.1 atmospheric induction burner burner in which part of the air necessary for combustion, called primary air, is entrained by the gas flow and is mixed upstream of the burner. The remainder of the air, called secondary air, is taken up downstream of the burner 3.3.2.2 main burner burner which affects the heating function of the appliance and is often called simply a “burner” 3.3.2.3 auxiliary burner burner which allows, by means of an ignition burner or pilot, ignition of a main burner 3.3.2.4 ignition burner or pilot

burner intended to ignite the main burner. If a burner operates independently of the main burners, it is called a “pilot” 3.3.2.5 alternating ignition burner ignition burner which goes off as soon as the main burner is ignited and is ignited from the main burner just before the main burner is extinguished 3.3.2.6 forced draught burner burner in which the combustion air is introduced by means of a fan SIST EN 203-1:2006+A1:2008

3.3.6.1 combustion circuit circuit including the air supply duct, if it exists, the combustion chamber, the heat exchanger and the combustion products evacuation duct, if it exists 3.3.6.2 combustion products circuit circuit including the combustion chamber, the heat exchanger and the combustion products evacuation duct if exists 3.3.6.3 combustion chamber enclosure in which the air/gas mixture burns 3.3.6.4 flue outlet part of an appliance intended to be connected to a combustion products evacuation duct 3.3.6.5 draught diverter device placed in the combustion products circuit of type B1 appliances, which is intended to reduce the influence of the flue pull and down draught on the burner performance and combustion 3.3.6.6 combustion products outlet or flueway extension part of an appliance not connected to a flue, through which products of combustion are discharged into a room 3.3.6.7 combustion products discharge safety device device that at least shuts off the main burner when there is an unacceptable spillage of combustion products at the draught diverter of type B11BS

appliances 3.3.7 auxiliary equipment all the accessory devices of an appliance which act directly or indirectly on the gas rate: e.g. gas rate control, flame supervision device, governor, thermostat, etc. SIST EN 203-1:2006+A1:2008

safety shut-down of the burner, such that a restart can only be accomplished by either a manual reset of the burner, or an interruption of the electrical supply and its subsequent restoration 3.3.7.3 pressure governor device which maintains a constant downstream pressure within a fixed range, independent of the upstream pressure and/or the gas rate 3.3.7.4 temperature regulator (thermostat) device which controls performance of the appliance (by on/off, on/low or modulating control), maintaining a predetermined temperature within the given limits of operation SIST EN 203-1:2006+A1:2008

3.4.1.1 heat input, Q quantity of energy used in unit time corresponding to the volumetric or mass gas flow rates, the calorific value to be considered in this document being the net calorific value NOTE Heat input is expressed in kilowatts (kW). 3.4.1.2 nominal heat input Qn value of the heat input declared by the manufacturer NOTE Nominal heat input is expressed in kilowatts (kW). 3.4.1.3 mass flow rate M mass of gas consumed by the appliance divided by the operating time NOTE The mass flow rate is expressed in kilograms per hour (kg/h) or grams per hour (g/h). 3.4.1.4 volumetric flow rate V volume of the gas consumed by the appliance divided by the operating time, the gas being taken under reference conditions NOTE Volumetric flow rate is expressed in cubic metres per hour (m3/h), litres per minute (l/m), cubic decimetres per hour (dm3/h) or cubic decimetres per second (dm3/s). SIST EN 203-1:2006+A1:2008

3.4.2.1 combustion oxidation phenomena of combustible gases by the oxygen of air, taking place throughout the burners The combustion may be: complete; in this case only traces of combustible constituents (hydrogen, carbon monoxide, carbon etc.) remain in the products of combustion. or incomplete; in this case at least one combustible constituent is present in significant proportions in the products of combustion. It is the amount of carbon monoxide (CO) in the dry air-free products of combustion which is used as the criterion to distinguish between complete and incomplete combustion. The maximum CO limits according to the circumstances of the test are defined in 6.7. In each case, combustion is regarded as complete (or hygienic) if the CO concentration is below the maximum allowed; if not, it is regarded as incomplete (or non hygienic). 3.4.2.2 aerated flame flame produced by the combustion of gas previously mixed with air 3.4.2.3 non-aerated flame flame produced by the combustion of gas which comes into contact with air at the moment of its combustion 3.4.2.4 flame stability condition of the flame firmly attached to the burner ports or the contact area provided by the design, with no risk of flame lift or light back 3.4.2.5 flame lift phenomenon characterized by the total or partial lifting of the base of the flame from the burner port or the flame contact area provided by the design. Flame lift may cause the extinction of the flame 3.4.2.6 light back phenomenon characterized by the return of the flame into the body of the burner 3.4.2.7 light back at the injector phenomenon characterized by the ignition of the gas at the injector, either as a result of the flame returning into the burner or by the propagation of a flame around the outside of the burner 3.4.2.8 sooting phenomenon appearing with incomplete combustion and characterized by the deposit of soot on the surfaces or parts of the appliance in contact with the products of combustion or with the flame 3.4.2.9 aeration rate ratio of the air rate entrained at the burner to the minimum air rate necessary for complete combustion SIST EN 203-1:2006+A1:2008

An appliance without a fan. Type A2:

An appliance with a fan downstream of the combustion chamber/heat exchanger. Type A3:

An appliance with a fan upstream of the combustion chamber/heat exchanger. Type B An appliance intended to be connected to a flue that evacuates the products of combustion to the outside of the room containing the appliance. The combustion air is drawn directly from the room. Type B1:

A type B appliance incorporating a draught diverter in the combustion products circuit. Type B11:

A natural draught type B1 appliance. Type B12:

A type B1 appliance designed for a natural draught flue incorporating a fan downstream of the combustion chamber / heat exchanger and upstream of the draught diverter. SIST EN 203-1:2006+A1:2008

A type B1 appliance designed for a natural draught flue incorporating a fan upstream of the combustion chamber / heat exchanger. Type B14:

A type B1 appliance having an integral fan downstream of both the combustion chamber / heat exchanger and the draught diverter. Type B2:

A type B appliance without a draught diverter. Type B22:

A type B2 appliance incorporating a fan downstream of the combustion chamber / heat exchanger. Type B23:

A type B2 appliance incorporating a fan upstream of the combustion chamber / heat exchanger. A supplementary classification for type B appliances is used to clarify the identification of such appliances when fitted with particular safety devices. The subscript letters “BS” (blocked safety) refer to a combustion products discharge safety device, which reacts to blockage or restriction of the flue system. Example: Type B11BS: A type B11 appliance fitted with a combustion products discharge safety device. A type B appliance intended to operate with a pressurized flue duct shall be identified by an extra subscript “P”. This subscript “P” is only used when installation in accordance with the appliance manufacturer’s instructions on a flue specified by the appliance manufacturer results in the flue operating at a positive pressure. 5 Constructional requirements 5.1 General 5.1.1 Conversion to different gases 5.1.1.1 General The only acceptable operations for converting from the gas of one group or family and/or for adapting to the different supply pressures of a gas are given below for each category. 5.1.1.2 Category I a) categories I2H, I2L, I2E, I2E+:

no adjustment to the appliance may be made; b) category I3B/P: no adjustment to the appliance may be made; c) category I3+: change of injectors or restrictors may be made but only to convert from one pressure couple to another (e.g. 28-30/37 mbar to/from 50/67 mbar). Adjustment of the primary aeration to convert from one pressure couple to another or to convert from one pressure couple to another within the same pressure couple can be made; d) category I3P: for a change of pressure, only a change of injectors, adjustment of gas rates and adjustment of the primary aeration may be made. 5.1.1.3 Category II 5.1.1.3.1 Categories of appliance designed for use with gases of the first and second families a) change of injectors or restrictors; b) adjustment of reduced rate; SIST EN 203-1:2006+A1:2008

Appliances shall be constructed so that, under normal conditions of use and maintenance, the supply of combustion air and the evacuation of combustion products are permanently ensured. The cross-section of the air passage to the combustion chamber and of the combustion products passage, fixed by construction, shall be neither adjustable nor obstructed during installation. 5.1.6.2 Appliances equipped with a fan 5.1.6.2.1 Fan The parts of the fan in contact with combustion products shall be effectively protected against corrosion unless they are of corrosion-resistant materials and they shall withstand the temperature of the combustion products. SIST EN 203-1:2006+A1:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...