EN 203-1:2021+A1:2023

(Main)Gas heated catering equipment - Part 1: General safety requirements

Gas heated catering equipment - Part 1: General safety requirements

This document specifies the requirements and test methods for the construction and operating

characteristics relating to safety and rational use of energy for gas heated commercial catering and

bakery appliances intended to be used indoor.

This document applies to all professional cooking and bakery appliances using gas for preparing food and

drink.

Only appliances of types A1, A2, A3, B1 and B2, as defined in Clause 4, are considered in this document.

Only the net calorific value (Hi) and net Wobbe index (Wi) are used.

The requirements concerning specific types of appliances are given in the relevant Part 2.

Annex C (informative) lists the main types of equipment covered by the scope of this document.

Appliances covered by this document are not intended to use gases containing carbon monoxide or other

toxic components.

NOTE For appliances intended to be used in vehicles, in trailers or on-board ships, additional requirements

can be necessary.

Großküchengeräte für gasförmige Brennstoffe - Teil 1: Allgemeine Sicherheitsanforderungen

Dieses Dokument legt die Anforderungen und Prüfverfahren für die Bauweise und Bedienung bezüglich Sicherheit, sowie die rationelle Energienutzung für Großküchen- und Bäckereigeräte für gasförmige Brennstoffe fest, die für die Verwendung in Innenräumen bestimmt sind.

Dieses Dokument ist anwendbar für alle gewerblichen Koch- und Backgeräte, die Gas für die Zubereitung von Speisen und Getränken verwenden.

Nur Geräte der Arten A1, A2, A3, B1 und B2, wie in Abschnitt 4 definiert, werden in diesem Dokument berücksichtigt.

Es werden nur der Heizwert (Hi) und der untere Wobbeindex (Wi) verwendet.

Die Anforderungen an bestimmte Gerätetypen sind in dem entsprechenden Teil 2 aufgeführt.

Im informativen Anhang C sind die wesentlichen Gerätetypen des Anwendungsbereiches dieses Dokuments aufgelistet.

Geräte, die unter dieses Dokument fallen, sind nicht für die Verwendung von Gasen vorgesehen, die Kohlenstoffmonoxid oder andere toxische Komponenten enthalten.

ANMERKUNG Geräte, die für die Nutzung in Fahrzeugen, in Anhängern oder an Bord von Schiffen gedacht sind, können zusätzliche Anforderungen notwendig sein.

Appareils de cuisine professionnelle utilisant les combustibles gazeux - Partie 1 : Exigences générales de sécurité

Plinske naprave za gostinstvo - 1. del: Splošna varnostna pravila (vključno z dopolnilom A1)

Ta dokument določa zahteve in preskusne metode za konstrukcijske značilnosti in značilnosti delovanja v povezavi z varnostjo in racionalno rabo energije za komercialne plinske naprave za gostinstvo in peko, namenjene za uporabo v zaprtih prostorih.

Ta dokument se uporablja za vse profesionalne naprave za gostinstvo in peko, ki za pripravo hrane in pijače uporabljajo plin.

Ta dokument obravnava samo naprave tipov A1, A2, A3, B1 in B2 iz točke 4.

Uporabljata se samo neto kalorična vrednost (Hi) in neto Wobbejev indeks (Wi).

Zahteve glede posebnih tipov naprav so podane v ustreznem 2. delu.

V (informativnem) dodatku C so navedeni glavni tipi opreme, ki spada na področje uporabe tega dokumenta.

Naprave, zajete v tem dokumentu, ne uporabljajo plinov, ki vsebujejo ogljikov monoksid ali druge strupene sestavine.

OPOMBA: Za naprave, ki so namenjene za uporabo v vozilih, prikolicah ali na krovu ladij, so morda potrebne dodatne zahteve.

General Information

- Status

- Published

- Publication Date

- 12-Dec-2023

- Technical Committee

- CEN/TC 106 - Large kitchen appliances using gaseous fuels

- Drafting Committee

- CEN/TC 106/WG 1 - Security

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 13-Dec-2023

- Completion Date

- 13-Dec-2023

Relations

- Effective Date

- 18-Oct-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

Overview

EN 203-1:2021+A1:2023 (Gas heated catering equipment - Part 1: General safety requirements) defines safety, construction and test requirements for indoor gas heated commercial catering and bakery appliances. It applies to professional cooking and bakery appliances of types A1, A2, A3, B1 and B2 (see Clause 4) and covers requirements for safe operation and the rational use of energy. The standard uses only the net calorific value (Hi) and net Wobbe index (Wi) for gas characterization and excludes appliances intended to burn gases containing carbon monoxide or other toxic components. Annex C lists the main equipment types covered; Part 2 documents give additional, appliance‑specific requirements.

Key Topics and Technical Requirements

The standard groups requirements into constructional, performance and test provisions. Major technical topics include:

Constructional requirements

- Materials and methods of construction, cleanability and food contact surfaces

- Gas connections, soundness of gas circuits and combustion circuits

- Provision for combustion air, evacuation of combustion products and flame visibility

- Electrical safety, stability, mechanical safety and fire risk prevention

- Design and safety of LPG cylinder compartments

Components and controls

- Burners, gas rate control and shut‑off devices, gas rate adjusters

- Auxiliary equipment such as ignition devices and flame supervision devices

- Air‑proving devices and gas/air ratio controls

Performance requirements

- Obtaining and verifying nominal, full and reduced gas rates

- Ignition, cross‑lighting, flame stability and temperature limits

- Combustion performance and tests for sooting limits

- Rational use of energy (efficiency considerations) and behavior under auxiliary energy fluctuations

Test methods and conditions

- Specified test gases, test room set‑up, test pressures and measurement accuracy

- Detailed test procedures for soundness, operational safety and combustion

- Special tests (pressurized parts, overheating of LPG cylinders, appliances with heat‑bearing fluids)

Practical Applications - Who Uses This Standard

SIST EN 203-1 is essential for:

- Manufacturers of professional gas cooking and bakery equipment (design, compliance and CE marking)

- Testing laboratories and conformity assessment bodies performing safety and performance tests

- Safety engineers, product designers and R&D teams ensuring gas appliance safety and energy efficiency

- Procurement, installers and facility managers specifying compliant appliances for commercial kitchens

- Regulators and certification bodies referencing harmonized European safety requirements

This standard helps reduce risks associated with gas combustion, ensures reliable operation in indoor commercial settings, and supports consistent energy‑efficient appliance performance.

Related Standards

- Part 2 documents of the EN 203 series contain appliance‑specific requirements.

- SIST EN 203-1 aligns with the European EN 203 series and national adoptions; users should consult the applicable Part 2 and other EN gas appliance standards and national regulations for vehicle, trailer or ship installations where additional requirements may apply.

Frequently Asked Questions

EN 203-1:2021+A1:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas heated catering equipment - Part 1: General safety requirements". This standard covers: This document specifies the requirements and test methods for the construction and operating characteristics relating to safety and rational use of energy for gas heated commercial catering and bakery appliances intended to be used indoor. This document applies to all professional cooking and bakery appliances using gas for preparing food and drink. Only appliances of types A1, A2, A3, B1 and B2, as defined in Clause 4, are considered in this document. Only the net calorific value (Hi) and net Wobbe index (Wi) are used. The requirements concerning specific types of appliances are given in the relevant Part 2. Annex C (informative) lists the main types of equipment covered by the scope of this document. Appliances covered by this document are not intended to use gases containing carbon monoxide or other toxic components. NOTE For appliances intended to be used in vehicles, in trailers or on-board ships, additional requirements can be necessary.

This document specifies the requirements and test methods for the construction and operating characteristics relating to safety and rational use of energy for gas heated commercial catering and bakery appliances intended to be used indoor. This document applies to all professional cooking and bakery appliances using gas for preparing food and drink. Only appliances of types A1, A2, A3, B1 and B2, as defined in Clause 4, are considered in this document. Only the net calorific value (Hi) and net Wobbe index (Wi) are used. The requirements concerning specific types of appliances are given in the relevant Part 2. Annex C (informative) lists the main types of equipment covered by the scope of this document. Appliances covered by this document are not intended to use gases containing carbon monoxide or other toxic components. NOTE For appliances intended to be used in vehicles, in trailers or on-board ships, additional requirements can be necessary.

EN 203-1:2021+A1:2023 is classified under the following ICS (International Classification for Standards) categories: 97.040.20 - Cooking ranges, working tables, ovens and similar appliances. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 203-1:2021+A1:2023 has the following relationships with other standards: It is inter standard links to EN 203-1:2021, EN 60335-1:2012/A2:2019, EN IEC 60730-2-9:2019/A1:2019, EN 61770:2009, EN 60335-1:2012/A14:2019, EN 61770:2009/A1:2019, EN 60730-1:2016/A1:2019, EN 60335-1:2012/A11:2014, EN IEC 60730-2-9:2019/A2:2020, EN 60335-1:2012/A1:2019, EN 60335-1:2012/A13:2017, EN 60335-1:2012, EN 60335-2-102:2016, EN 60730-1:2016, EN 61770:2009/A11:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 203-1:2021+A1:2023 is associated with the following European legislation: EU Directives/Regulations: 2016/426; Standardization Mandates: M/595. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 203-1:2021+A1:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2024

Nadomešča:

SIST EN 203-1:2022

Plinske naprave za gostinstvo - 1. del: Splošna varnostna pravila (vključno z

dopolnilom A1)

Gas heated catering equipment - Part 1: General safety requirements

Großküchengeräte für gasförmige Brennstoffe - Teil 1: Allgemeine

Sicherheitsanforderungen

Appareils de cuisine professionnelle utilisant les combustibles gazeux - Partie 1 :

Exigences générales de sécurité

Ta slovenski standard je istoveten z: EN 203-1:2021+A1:2023

ICS:

97.040.20 Štedilniki, delovni pulti, Cooking ranges, working

pečice in podobni aparati tables, ovens and similar

appliances

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 203-1:2021+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 97.040.20 Supersedes EN 203-1:2021

English Version

Gas heated catering equipment - Part 1: General safety

requirements

Appareils de cuisine professionnelle utilisant les Großküchengeräte für gasförmige Brennstoffe - Teil 1:

combustibles gazeux - Partie 1 : Exigences générales de Allgemeine Sicherheitsanforderungen

sécurité

This European Standard was approved by CEN on 3 October 2021 and includes Amendment approved by CEN on 11 October

2023.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 203-1:2021+A1:2023 E

worldwide for CEN national Members.

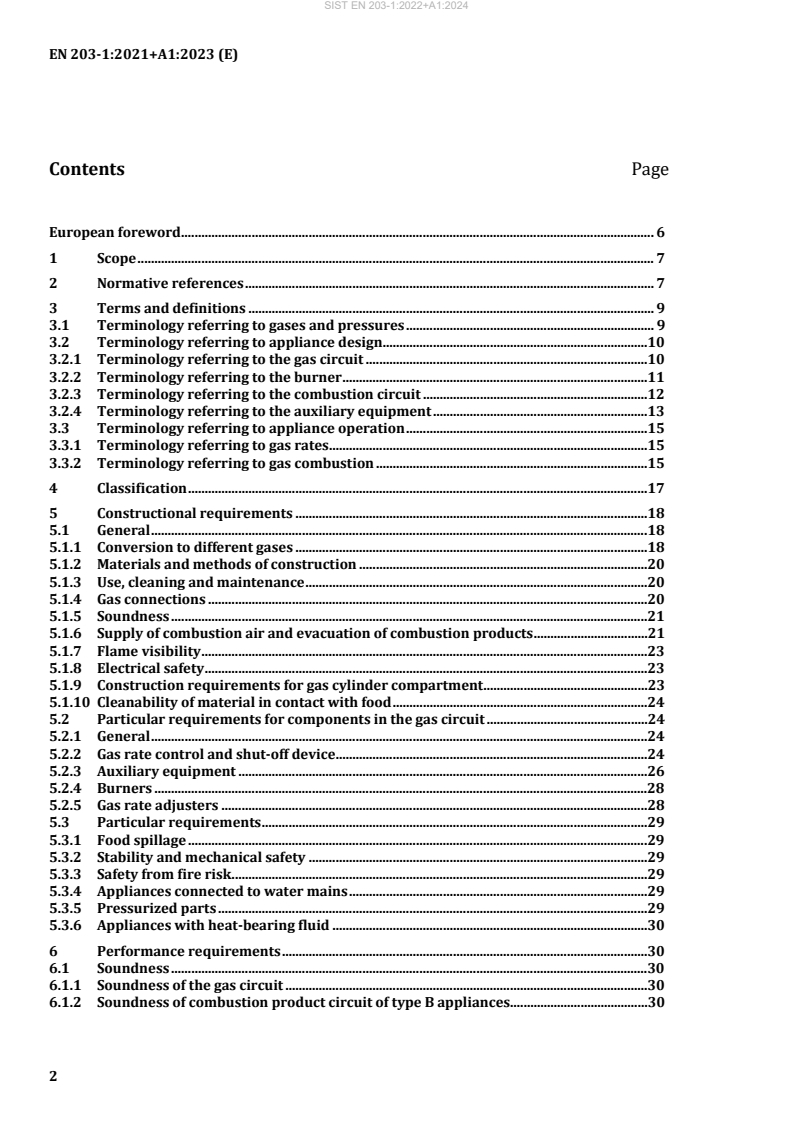

Contents Page

European foreword . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

3.1 Terminology referring to gases and pressures . 9

3.2 Terminology referring to appliance design .10

3.2.1 Terminology referring to the gas circuit .10

3.2.2 Terminology referring to the burner .11

3.2.3 Terminology referring to the combustion circuit .12

3.2.4 Terminology referring to the auxiliary equipment .13

3.3 Terminology referring to appliance operation .15

3.3.1 Terminology referring to gas rates.15

3.3.2 Terminology referring to gas combustion .15

4 Classification .17

5 Constructional requirements .18

5.1 General .18

5.1.1 Conversion to different gases .18

5.1.2 Materials and methods of construction .20

5.1.3 Use, cleaning and maintenance .20

5.1.4 Gas connections .20

5.1.5 Soundness .21

5.1.6 Supply of combustion air and evacuation of combustion products .21

5.1.7 Flame visibility .23

5.1.8 Electrical safety .23

5.1.9 Construction requirements for gas cylinder compartment .23

5.1.10 Cleanability of material in contact with food .24

5.2 Particular requirements for components in the gas circuit .24

5.2.1 General .24

5.2.2 Gas rate control and shut-off device .24

5.2.3 Auxiliary equipment .26

5.2.4 Burners .28

5.2.5 Gas rate adjusters .28

5.3 Particular requirements .29

5.3.1 Food spillage .29

5.3.2 Stability and mechanical safety .29

5.3.3 Safety from fire risk .29

5.3.4 Appliances connected to water mains .29

5.3.5 Pressurized parts .29

5.3.6 Appliances with heat-bearing fluid .30

6 Performance requirements .30

6.1 Soundness .30

6.1.1 Soundness of the gas circuit .30

6.1.2 Soundness of combustion product circuit of type B appliances .30

6.2 Obtaining the gas rate . 31

6.2.1 Nominal heat input (Q ) . 31

n

6.2.2 Full gas rate . 31

6.2.3 Reduced gas rate . 31

6.2.4 Ignition burner heat input . 31

6.3 Safety of operation . 32

6.3.1 Burners . 32

6.3.2 Temperature limits . 32

6.3.3 Ignition – cross-lighting - flame stability . 34

6.3.4 Combustion products discharge safety devices for type B appliances . 34

11BS

6.3.5 Pre-purge . 34

6.4 Influence of burners on each other . 35

6.5 Auxiliary equipment . 35

6.5.1 Flame supervision device . 35

6.5.2 Ignition device . 36

6.6 Air proving device . 36

6.6.1 General . 36

6.6.2 Supervision of the combustion air or combustion products rate . 36

6.6.3 Supervision of the combustion air pressure or combustion products pressure . 37

6.6.4 Gas/air ratio controls . 37

6.7 Combustion . 37

6.7.1 All appliances (in calm air) . 37

6.7.2 Special conditions . 37

6.8 Auxiliary energy . 38

6.8.1 Electrical energy fluctuation . 38

6.8.2 Electrical energy shut off . 38

6.8.3 Other types of auxiliary energy . 38

6.9 Rational use of energy. 38

6.10 Operating requirements - Temperature of the LPG cylinder and its compartment . 38

6.10.1 Temperature of the walls of the compartment . 38

6.10.2 Temperature of the LPG cylinder . 38

7 Test conditions . 39

7.1 General . 39

7.1.1 Characteristics of the test gases . 39

7.1.2 Requirements for making up test gases . 39

7.1.3 Test room . 39

7.1.4 Preparation of the appliance . 39

7.1.5 Practical method of test. 40

7.1.6 Test pressures. 40

7.1.7 Carrying out the tests . 41

7.1.8 Accuracy of measuring instruments . 41

7.2 Soundness . 42

7.2.1 Soundness of the gas circuit . 42

7.2.2 Soundness of the combustion circuit and correct evacuation of the combustion

products for type B appliances . 42

7.3 Obtaining gas rates . 43

7.3.1 General . 43

7.3.2 Nominal heat input . 43

7.3.3 Full gas rate . 45

7.3.4 Reduced gas rate . 45

7.3.5 Ignition device . 46

7.4 Operational safety . 46

7.4.1 Burners .46

7.4.2 Limit temperatures .46

7.4.3 Ignition – cross - lighting - flame stability .47

7.5 Auxiliary equipment .52

7.5.1 Flame supervision device .52

7.6 Combustion .53

7.6.1 General .53

7.6.2 Tests carried out under normal conditions .54

7.6.3 Specific test for type B appliances .56

7.6.4 Test with sooting limit gas .56

7.7 Air-proving device .56

7.7.1 General .56

7.7.2 Supervision of the combustion air or the combustion products rate .57

7.7.3 Supervision of the combustion air or the combustion products pressure .57

7.8 Special tests .58

7.8.1 Stability and mechanical safety .58

7.8.2 Pressurized parts .58

7.8.3 Appliances with heat-bearing fluid .58

7.9 Test method - Overheating of the LPG cylinder and its compartment .58

7.10 Rational use of energy .59

8 Marking and instructions .59

8.1 General requirements for marking and instructions .59

8.2 Marking on the appliance .59

8.2.1 Data plates, labels and packaging .59

8.2.2 Additional marking on the appliance and packaging .60

8.3 Instructions for installation and adjustment .60

8.3.1 Requirements for installation and adjustment .60

8.3.2 Additional requirements for installation and adjustment.62

8.4 Instructions for use and maintenance .62

8.4.1 Requirements for instructions for use and maintenance .62

8.4.2 Additional requirements for instructions for use and maintenance .63

Annex A (informative) National situations .70

A.1 Connection requirements in force in various countries (see 5.1.4) .70

A.2 Requirements for flue connection in force in various countries (see 5.1.6.5).71

A.3 Categories, test gases and test pressures .72

Annex B (normative) Use of symbols on appliances and packaging .73

B.1 General .73

B.2 Electric power supply .73

B.3 Type of gas .73

B.4 Gas supply pressure .73

B.5 Country of destination .74

B.6 Category .74

B.7 Other optional information .74

B.8 Nominal heat input of burner .74

B.9 Nominal heat input of set of burners on appliance .74

Annex C (informative) Trilingual list of appliances in the scope of EN 203-1 and

corresponding Part 2 . 75

Annex D (informative) Configuration of the gas circuit . 77

D.1 Minimum requirements for appliances with or without fan, but with permanent or

alternating ignition burner and appliances with fan and pre-purge . 77

D.2 Minimum requirements for appliances with fan, without permanent or alternating

ignition burner and without pre-purge . 78

Annex E (normative) Material in contact with food . 79

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2016/426 aimed to be covered . 82

Bibliography . 85

European foreword

This document (EN 203-1:2021+A1:2023) has been prepared by Technical Committee CEN/TC 106

“Large kitchen appliances using gaseous fuels”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2024, and conflicting national standards shall be

withdrawn at the latest by June 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes !EN 203-1:2021".

This document includes Amendment 1, approved by CEN on 2023-10-11.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !"

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

This document constitutes Part 1 of EN 203, Gas heated catering equipment. Particular requirements are

given in the relevant Part 2: Specific requirements.

!deleted paragraphs"

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document specifies the requirements and test methods for the construction and operating

characteristics relating to safety and rational use of energy for gas heated commercial catering and

bakery appliances intended to be used indoor.

This document applies to all professional cooking and bakery appliances using gas for preparing food and

drink.

Only appliances of types A , A , A , B and B , as defined in Clause 4, are considered in this document.

1 2 3 1 2

Only the net calorific value (Hi) and net Wobbe index (Wi) are used.

The requirements concerning specific types of appliances are given in the relevant Part 2.

Annex C (informative) lists the main types of equipment covered by the scope of this document.

Appliances covered by this document are not intended to use gases containing carbon monoxide or other

toxic components.

NOTE For appliances intended to be used in vehicles, in trailers or on-board ships, additional requirements

can be necessary.

2 Normative references

The following documents are referred to in the text in such a way that some or all their content constitutes

requirements of this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 88-1:2011+A1:2016, Pressure regulators and associated safety devices for gas appliances - Part 1:

Pressure regulators for inlet pressures up to and including 50 kPa

EN 88-2:2007, Pressure regulators and associated safety devices for gas appliances - Part 2: Pressure

regulators for inlet pressures above 500 mbar up to and including 5 bar

EN 125:2010+A1:2015, Flame supervision devices for gas burning appliances - Thermoelectric flame

supervision devices

EN 126:2012, Multifunctional controls for gas burning appliances

EN 161:2011+A3:2013, Automatic shut-off valves for gas burners and gas appliances

EN 257:2010, Mechanical thermostats for gas-burning appliances

EN 298:2012, Automatic burner control systems for burners and appliances burning gaseous or liquid fuels

EN 437:2021, Test gases - Test pressures - Appliance categories

EN 549:2019, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 751-1:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases

and hot water - Part 1: Anaerobic jointing compounds

EN 751-2:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases

and hot water - Part 2: Non-hardening jointing compounds

EN 1106:2010, Manually operated taps for gas burning appliances

EN 1672-2:2005+A1:2009, Food processing machinery – Basic concepts – Part 2: Hygiene requirements

EN 1717:2000, Protection against pollution of potable water in water installations and general

requirements of devices to prevent pollution by backflow

EN 10226-1:2004, Pipe threads where pressure tight joints are made on the threads - Part 1: Taper external

threads and parallel internal threads - Dimensions, tolerances and designation

EN 10226-2:2005, Pipe threads where pressure tight joints are made on the threads - Part 2: Taper external

threads and taper internal threads - Dimensions, tolerances and designation

EN 12067-2:2004, Gas/air ratio controls for gas burners and gas burning appliances - Part 2: Electronic

types

EN 13611:2019, Safety and control devices for burners and appliances burning gaseous and/or liquid fuels

- General requirements

EN 16340:2014, Safety and control devices for burners and appliances burning gaseous or liquid fuels -

Combustion product sensing devices

EN 60335-1:2012 , Household and similar electrical appliances - Safety - Part 1: General requirements (IEC

60335-1:2010, modified)

EN 60335-2-102:2016, Household and similar electrical appliances - Safety - Part 2-102: Particular

requirements for gas, oil and solid-fuel burning appliances having electrical connections (IEC 60335-2-

102:2004, modified)

EN 60730-1:2016 , Automatic electrical controls for household and similar use - Part 1: General

requirements (IEC 60730-1:2013, modified)

EN IEC 60730-2-9:2019 , Automatic electrical controls - Particular requirements for temperature sensing

control (IEC 60730-2-9:2015)

EN 61770:2009 , Electric appliances connected to the water mains - Avoidance of backsiphonage and

failure of hose-sets (IEC 61770:2008)

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads - Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

As impacted by EN 60335-1:2012/AC:2014, EN 60335-1:2012/A11:2014, EN 60335-1:2012/A13:2017,

EN 60335-1:2012/A1:2019, EN 60335-1:2012/A2:2019 and EN 60335-1:2012/A14:2019.

As impacted by EN 60730-1:2016/A1:2019.

As impacted by EN IEC 60730-2-9:2019/A1:2019 and EN IEC 60730-2-9:2019/A2:2020.

As impacted by EN 61770:2009/AC:2011, EN 61770:2009/A11:2018 and EN 61770:2009/A1:2019.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1 Terminology referring to gases and pressures

3.1.1

gas family

group of gaseous fuels with similar burning behaviour linked together by a range of Wobbe indices

[SOURCE: EN 437:2021, 3.18]

3.1.2

gas group

specified range of Wobbe index within that of the family concerned

Note 1 to entry: See EN 437:2021, Table 1.

Note 2 to entry: This range is determined on the general principle that appliances utilizing this gas group would

operate safely when burning all gases within this range without adjustment.

Note 3 to entry: Adjustment of the appliance may be permitted in accordance with the special national or local

conditions that apply in some countries.

[SOURCE: EN 437:2021, 3.19]

3.1.3

appliance category

means of identifying the gas families and/or gas groups for which a gas appliance is designed to operate

safely and to the desired performance level

[SOURCE: EN 437:2021, 3.20]

3.1.4

gas supply pressure

p

difference between the pressure measured at the inlet connection of the appliance, with the appliance in

operation, and atmospheric pressure

Note 1 to entry: Gas supply pressure is expressed in millibars (mbar).

3.1.5

relative density

d

ratio of the masses of equal volumes of dry gas and dry air under the same conditions of temperature and

pressure: 15 °C or 0 °C and 1 013,25 mbar

3.1.6

calorific value

quantity of heat produced by the complete combustion, of a unit volume or mass of dry gas, the

constituents of the combustible mixture being taken at reference conditions of 15 °C, 1 013,25 mbar and

the products of combustion being brought back to the same conditions

Note 1 to entry: A distinction is made between:

— the gross calorific value H : the water produced by combustion is assumed to be condensed;

s

— the net calorific value H : the water produced by combustion is assumed to be in the vapour state.

i

Note 2 to entry: The calorific value is expressed:

— either in megajoules per cubic metre (MJ/m ) of dry gas under the reference conditions of 15 °C, 1 013,25 mbar;

— or in megajoules per kilogram (MJ/kg) of dry gas.

3.1.7

Wobbe index

gross Wobbe index Ws: net Wobbe index Wi ratio of the calorific value of a dry gas per unit volume and

the square root of its relative density under the reference conditions of 15 °C, 1 013,25 mbar

Note 1 to entry: The Wobbe index is said to be gross or net according to whether the calorific value used is the

gross or net calorific value.

Note 2 to entry: The Wobbe indices are expressed:

— either in megajoules per cubic metre (MJ/m ) of dry gas under the reference conditions of 15 °C, 1 013,25 mbar;

— or in megajoules per kilogram (MJ/kg) of dry gas.

3.2 Terminology referring to appliance design

3.2.1 Terminology referring to the gas circuit

3.2.1.1

gas circuit

part of an appliance, between the gas inlet connection and the burner(s), which conveys or contains the

gas

3.2.1.2

inlet connection

part of the appliance which is intended to be connected to the gas supply

3.2.1.3

mechanical joint (or mechanical means of obtaining soundness)

assembly of several parts, generally metallic, which achieves soundness by use of mechanical means such

as metal-to-metal joints, toroidal sealing rings (O rings) or flat joints

3.2.1.4

restrictor

device with one or more orifices that is placed in the path of the gas flow between the appliance inlet

connection and the burner to create a pressure drop, and thus reduces the gas pressure at the burner to

a predetermined value for a given supply pressure and rate

3.2.1.5

gas rate adjuster

component which allows the gas input to each burner to be set at a predetermined value according to

supply conditions by continuous (screw adjuster) or discontinuous (changing restrictors) action

Note 1 to entry: The operation of setting this device is known as “setting the gas rate”.

3.2.1.6

pressure regulator

device which maintains a constant downstream pressure within a fixed range, independent of the

upstream pressure and/or the gas rate

Note 1 to entry: Only appliances with pressure regulator are considered regulated appliances.

3.2.1.7

gas rate control

tap or equivalent component which allows the gas supply to one or more burners to be opened or closed,

and possibly, the burner or burners to be adjusted to a gas input lower than the nominal heat input

3.2.1.8

touch control

indirect manual burner control resulting from finger contact or light touch, with or without movement

on the contact surface

3.2.1.9

indirect control

control that commands a shut-off or gas regulating device via some auxiliary energy (e.g. electric,

pneumatic, etc.)

3.2.1.10

primary air

air entrained in the burner by gas flow and which is mixed upstream of the burner

3.2.1.11

primary aeration adjuster

device which allows the primary air rate to be set at a desired value, according to the supply conditions

Note 1 to entry: The operation of changing the setting of the device is called “adjusting the primary aeration”.

3.2.1.12

injector

component which admits gas into a burner

3.2.1.13

heat bearing fluid

intermediary fluid that indirectly conveys the heat from a burner to the food or cooking container

3.2.2 Terminology referring to the burner

3.2.2.1

main burner

burner which performs the heating function of the appliance and is often called simply “burner”

3.2.2.2

auxiliary burner

burner which allows, by means of an ignition burner or pilot, ignition of a main burner

3.2.2.3

ignition burner or pilot

burner intended to ignite the main burner or at first an auxiliary burner

Note 1 to entry: If a burner operates independently of the main burners, it is called “pilot”.

3.2.2.4

alternating ignition burner

ignition burner which goes off as soon as the main burner is ignited and is ignited from the main burner

just before the main burner is extinguished

3.2.2.5

permanent ignition burner

ignition burner which remains ignited even when the main burner is in use

3.2.3 Terminology referring to the combustion circuit

3.2.3.1

combustion circuit

circuit including the air supply duct, if it exists, the combustion chamber, the heat exchanger and the

combustion products evacuation duct, if it exists

3.2.3.2

combustion products circuit

circuit including the combustion chamber, the heat exchanger and the combustion products evacuation

duct if it exists

3.2.3.3

combustion chamber

enclosure in which the air/gas mixture burns

3.2.3.4

flue outlet

part of an appliance intended to be connected to a combustion products evacuation duct

3.2.3.5

draught diverter

device placed in the combustion products circuit of type B appliances, which is intended to reduce the

influence of the flue pull and down draught on the burner performance and combustion

3.2.3.6

combustion products outlet or flueway extension

part of an appliance not connected to a flue, through which products of combustion are discharged into a

room

3.2.3.7

combustion products discharge safety device

device that at least shuts off the main burner when there is an unacceptable spillage of combustion

products at the draught diverter of type B appliances

11BS

3.2.3.8

purging

act of forcing air into the combustion circuit to expel any remaining gas/air mixture or products of

combustion

Note 1 to entry: Pre-purging is a purging that takes place between the starting demand and the activation of the

ignition device.

3.2.3.9

control device for aeration or evacuation of combustion products

device which causes shutdown in the event of abnormal aeration or combustion products evacuation

conditions

3.2.3.10

gas/air ratio device

device which automatically adjusts the combustion air flow to the gas flow and vice versa

3.2.4 Terminology referring to the auxiliary equipment

3.2.4.1

auxiliary equipment

all the devices of an appliance which act directly or indirectly on the gas rate (e.g. gas rate control, flame

supervision device, governor, thermostat, etc.)

3.2.4.2

ignition device

means used to light gas admitted to the ignition burner, auxiliary burner or main burner, which may or

may not be fixed to the appliance

3.2.4.3

flame supervision device

device which, on the extinguishment of the supervised flame, shuts off the gas supply

Note 1 to entry: It is described as having “simple control” if it shuts off the gas supply to the main burner only.

Note 2 to entry: It is described as having “complete control” if it shuts off the gas supply to the main burner and

to the ignition burner.

3.2.4.3.1

ignition time

time interval between the ignition of the supervised flame and the moment when the force thus produced

is sufficient to keep the valve open

3.2.4.3.2

ignition safety time

TSA

time that elapses between the input to open the gas supply to the burner and the gas supply being shut

off in the event no flame has been detected

3.2.4.3.3

flame detector

part of the flame supervision device sensing element on which the supervised flame acts directly and

transforms the flame effect into a signal which is transmitted directly or indirectly to a shut off valve

3.2.4.3.4

extinction safety time

TSE

time that elapses between extinguishment of the supervised flame and the input to shut off the gas supply

to the burner

3.2.4.3.5

closing time

time interval between the interruption of the auxiliary energy or the voltage and the achievement of the

closed position

3.2.4.3.6

ignition rate

Q

ign

average heat input during the ignition safety time, expressed as a percentage of the nominal heat input

3.2.4.3.7

spark restoration

automatic process by which, following flame failure, the ignition device is switched on again without total

interruption of the gas supply

3.2.4.3.8

recycling

automatic process by which, after loss of flame during operation, the gas supply is interrupted, and the

full start procedure is re-initiated automatically

3.2.4.3.9

non-volatile lockout of the appliance

safety shutdown such that a restart can only be accomplished by manual reset and by no other means

3.2.4.3.10

volatile lock-out of the appliance

safety shutdown such that a restart can only be accomplished by either the manual reset, or an

interruption of the electrical supply and its subsequent restoration

3.2.4.4

temperature regulator (thermostat)

device which controls the operation of the appliance (by on/off, on/low or modulating control),

maintaining a predetermined temperature within the given limits of operation

3.2.4.5

overheat limit device

manually reset device which ensures that temperature is limited to a predetermined safety value

Note 1 to entry: Overheat limit device is not a regulating device.

3.2.4.6

control knob

component which is moved by hand and operates an appliance control device (e.g. tap, thermostat, etc.)

3.2.5

functional surface

part of the appliance which is hot for the appliance to fulfil its function

3.2.6

marking

permanent indication on the appliance

3.2.7

removable part

part that can be removed or opened without the aid of a tool, a part that is removed or opened in

accordance with the instructions for use, even if a tool is needed for removal

3.3 Terminology referring to appliance operation

3.3.1 Terminology referring to gas rates

3.3.1.1

heat input

Q

quantity of energy used in unit time corresponding to the volumetric or mass flow rates, the calorific

value to be considered in this document being the net calorific value

Note 1 to entry: Heat input is expressed in kilowatts (kW).

3.3.1.2

nominal heat input

Q

n

value of the heat input declared by the manufacturer

Note 1 to entry: Nominal he

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...