EN 13824:2004

(Main)Sterilization of medical devices - Aseptic processing of liquid medical devices - Requirements

Sterilization of medical devices - Aseptic processing of liquid medical devices - Requirements

This document specifies requirements for the design and operation of aseptic processing facilities and the validation and routine control of aseptic processes for the preparation of sterile liquid medical devices. It is not applicable to those pharmaceutical products where the requirements of the relevant good manufacturing practices are applicable.

NOTE Many of the principles included in this document can be applied to certain aseptically processed sterile solid medical devices.

Sterilisation von Medizinprodukten - Aseptische Herstellung flüssiger Medizinprodukte - Anforderungen

Dieses Dokument legt Anforderungen an die Gestaltung und den Betrieb aseptischer Verarbeitungs-

einrichtungen und an die Validierung und Routinekontrolle der aseptischen Herstellungsverfahren für sterile

flüssige Medizinprodukte fest. Es gilt nicht für pharmazeutische Produkte, für die Anforderungen an die

einschlägige Gute Herstellungspraxis anzuwenden sind.

ANMERKUNG Viele der in diesem Dokument enthaltenen Prinzipien können auf bestimmte unter aseptischen

Bedingungen hergestellte Medizinprodukte im festen Zustand angewendet werden.

Stérilisation des dispositifs médicaux - Traitement aseptique des dispositifs médicaux liquides - Exigences

Le présent document spécifie les exigences relatives à la conception et au fonctionnement des installations de traitement aseptique et à la validation et au contrôle de routine des procédés aseptiques en vue de la préparation de dispositifs médicaux liquides stériles. Elle ne s'applique pas aux produits pharmaceutiques pour lesquels les exigences relatives aux bonnes pratiques de fabrication appropriées s'appliquent.

NOTE De nombreux principes spécifiés dans cette Norme peuvent être appliqués à certains dispositifs médicaux solides traités dans des conditions d'asepsie.

Sterilizacija medicinskih pripomočkov – Aseptična proizvodnja tekočih medicinskih pripomočkov - Zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 23-Nov-2004

- Withdrawal Date

- 28-Jun-2011

- Technical Committee

- CEN/TC 204 - Sterilization of medical devices

- Drafting Committee

- CEN/TC 204/WG 8 - Aseptic processing of medical devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Jun-2011

- Completion Date

- 29-Jun-2011

- Directive

- 93/42/EEC - Medical devices

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 13824:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sterilization of medical devices - Aseptic processing of liquid medical devices - Requirements". This standard covers: This document specifies requirements for the design and operation of aseptic processing facilities and the validation and routine control of aseptic processes for the preparation of sterile liquid medical devices. It is not applicable to those pharmaceutical products where the requirements of the relevant good manufacturing practices are applicable. NOTE Many of the principles included in this document can be applied to certain aseptically processed sterile solid medical devices.

This document specifies requirements for the design and operation of aseptic processing facilities and the validation and routine control of aseptic processes for the preparation of sterile liquid medical devices. It is not applicable to those pharmaceutical products where the requirements of the relevant good manufacturing practices are applicable. NOTE Many of the principles included in this document can be applied to certain aseptically processed sterile solid medical devices.

EN 13824:2004 is classified under the following ICS (International Classification for Standards) categories: 11.080.01 - Sterilization and disinfection in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13824:2004 has the following relationships with other standards: It is inter standard links to EN ISO 13408-5:2011, EN ISO 13408-2:2011, EN ISO 13408-4:2011, EN ISO 13408-1:2011, EN ISO 13408-3:2011, EN ISO 13408-6:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13824:2004 is associated with the following European legislation: EU Directives/Regulations: 90/385/EEC, 93/42/EEC; Standardization Mandates: M/023. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13824:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sterilization of medical devices - Aseptic processing of liquid medical devices - RequirementsRþLKStérilisation des dispositifs médicaux - Traitement aseptique des dispositifs médicaux liquides - ExigencesSterilisation von Medizinprodukten - Aseptische Herstellung flüssiger Medizinprodukte - AnforderungenTa slovenski standard je istoveten z:EN 13824:2004SIST EN 13824:2005en11.080.01Sterilizacija in dezinfekcija na splošnoSterilization and disinfection in generalICS:SLOVENSKI

STANDARDSIST EN 13824:200501-marec-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13824November 2004ICS 11.080.01English versionSterilization of medical devices - Aseptic processing of liquidmedical devices - RequirementsStérilisation des dispositifs médicaux - Traitementaseptique des dispositifs médicaux liquides - ExigencesSterilisation von Medizinprodukten - Aseptische Herstellungflüssiger Medizinprodukte - AnforderungenThis European Standard was approved by CEN on 14 October 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13824:2004: E

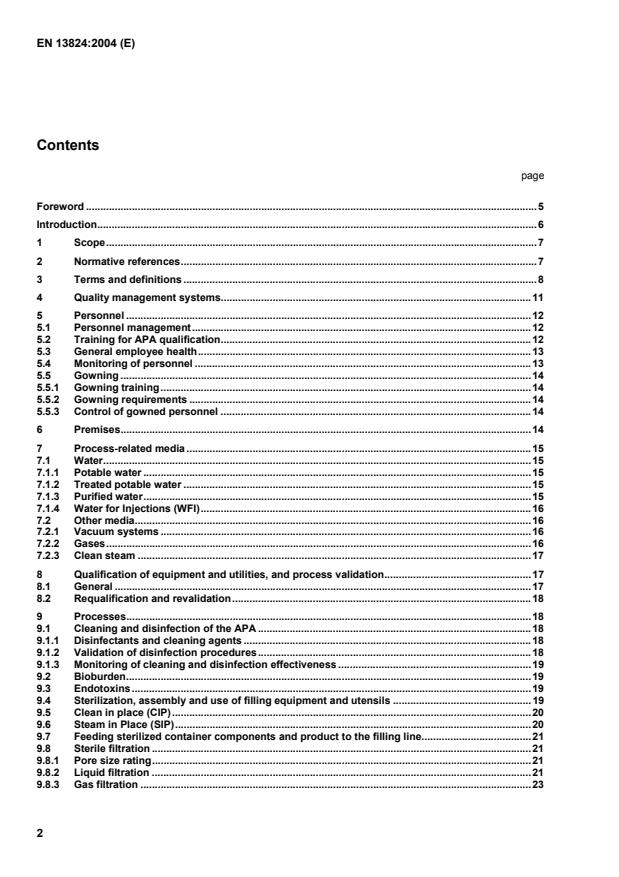

Conventional cleanrooms.28 A.1 Facility design features.28 A.2 Facility design review.29 A.3 Material flow.29 A.4 Aseptic processing area (APA).29 A.5 Critical processing zones.29 A.6 Other processing zones within the APA.30 A.7 Support areas outside the APA.30 A.8 Environmental air systems and controls.30 A.8.1 Temperature and humidity.31 A.8.2 Air.31 A.8.3 HEPA filter integrity.31 A.8.4 Air handling.32 A.9 Facility design.32 A.10 Preparation areas.32 Annex B (normative)

Isolator technology.33 B.1 Types of isolator.33 B.1.1 General.33 B.1.2 Transfer devices used with isolators.33 B.2 Transfer devices.33 B.2.1 General.33 B.2.2 Classification system for transfer devices.33 B.3 Surrounding area.34 B.3.1 General.34 B.3.2 Siting of Isolators.34 B.4 Gloves, gauntlets, half suits and full suits.35 B.4.1 General.35 B.4.2 Use of gloves/gauntlets.35 B.4.3 Changing gloves/gauntlets.36 B.4.4 Use of half suits, full suits.36 B.5 Pressure differentials.36 B.6 Cleaning of isolators.36 B.7 Filtration of air in isolators.36 B.8 Pressure differential.36 B.9 Air change rate.36

Aseptically-prepared suspensions.41 C.1 General.41 C.2 Media fill considerations.41 Annex D (normative)

Freeze-drying.42 D.1 General.42 D.2 Validation.42 D.3 Gases used during the freeze-drying process.42 D.4 Process routing.43 D.5 Open containers and stoppers.43 D.6 Transport to freeze-dryer.43 D.7 Unloading and transport to sealing equipment.43 D.8 Cleaning and disinfection of freeze dryer.44 D.9 Biodecontamination of the freeze dryer.44 D.9.1 Frequency.44 D.9.2 Methods.44 D.10 Vent filter system.44 D.11 Environmental monitoring and controls.44 D.12 Media fills for freeze-drying.45 D.13 Maintenance.45 Annex E (normative)

Media fills (process simulation tests).46 E.1 Performance qualification.46 E.2 Performance requalification.47 E.3 Repeat of performance qualification.47 E.4 Media fill procedures.48 E.5 Media selection and growth support.48 E.6 Incubation and inspection of media filled units.48 E.7 Acceptance criteria.49 E.7.1 General.49 E.7.2 Acceptance criteria tables.49 E.8 Contamination with media.53 E.9 Data required for media fills.53 E.10 Media fill runs for which action levels are exceeded.54 E.10.1 Investigation.54 E.10.2 Further actions.55 Annex F (informative)

Contamination rate calculations for a given number of media filled units.56 Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of Council Directive 90/385/EEC relating to active implantable medical devices.59 Annex ZB (informative)

Clauses of this European Standard addressing essential requirements or other provisions of Council Directive 93/42/EEC relating to medical devices.60 Bibliography.61

(environmental monitoring) established microbial or particulate levels giving early warning of potential drift from normal operating conditions which are not necessarily grounds for definitive corrective action but which could require follow-up investigation 3.4 alert level (media fill) number of positive media fill units that, if exceeded, requires immediate investigation of the cause, but that are not necessarily grounds for definitive corrective action 3.5 aseptic filling part of aseptic processing where a pre-sterilized product, or a solution passed through a product sterilizing filter, is filled and/or packaged into sterile containers

that are then closed 3.6 aseptic filling line manufacturing structure or arrangement where

containers are aseptically-filled with the liquid medical device 3.7 aseptic processing handling and filling of sterile containers and devices, or their components, in a controlled environment in which the air supply, materials, equipment and personnel are regulated to control microbial and particulate contamination to acceptable levels NOTE Aseptic processing can include formulation (compounding), filtration and filling into pre-sterilized containers. 3.8 aseptic processing area (APA) controlled environment for handling the aseptic filling of containers

with liquid medical devices in which the air supply, materials, equipment and personnel are regulated to control and minimize/remove any potential risk of microbial/ particulate contamination to within pre-determined levels 3.9 batch defined quantity of starting material, packaging material or product processed in one process or series of processes so that it could be expected to be homogeneous

Qualification of equipment and/or processes generally includes installation qualification, operational qualification, and performance qualification. • Installation qualification - demonstrates that the unit or process under test is in compliance with all relevant design criteria and safety standards, and is calibrated. • Operational qualification - testing demonstrates that the equipment and/or process functions as intended, that procedures exist describing operation of the equipment, and that personnel have been trained to set-up, operate and maintain the equipment. • Performance qualification - testing involves actual challenges to the system to substantiate its effectiveness and reproducibility. 3.28 shift scheduled period of work or production staffed by a single defined group of workers 3.29 sterile condition of a medical device that is free from viable microorganisms

with a steady velocity and approximately parallel streamlines NOTE This type of airflow results in a directed transport of particles from the clean zone. 3.35 validation documented procedure for obtaining, recording and interpreting the results required to establish that a process will consistently yield product complying with predetermined specifications 3.36 vent filter porous material capable of removing non-viable particles and microorganisms from gases passing in and out of a closed vessel 4 Quality management systems A documented quality management system shall be established and maintained to control activities affecting aseptic processing. NOTE 1 Guidance on the application of quality systems for medical devices is included in EN ISO 13485. NOTE 2 The quality management system should normally include, in addition to the product, components and process specifications, written procedures and specifications for: a) environmental conditions in the aseptic processing area (APA); b) cleaning and disinfection of the APA; c) sterilization of the product, equipment, and container/closure system; d) aseptic processing of bulk products, e.g., freeze-drying, aseptic crystallization, powder drying, etc.; e) introduction of items into the aseptic processing area or critical processing zone;

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...