EN 17446:2021+A1:2024

(Main)Fire extinguishing systems in commercial kitchens - System design, documentation, and test requirements

Fire extinguishing systems in commercial kitchens - System design, documentation, and test requirements

This document establishes the minimum requirements applicable to the design, installation, functioning, test and maintenance of fixed automatic fire extinguishing systems for kitchen protection that covers the cooking appliances, the hood, the plenum and the air extract ducts. This document also provides requirements for the construction and components performance as applicable to specific types, designs, sizes and arrangements of pre-engineered kitchen fire-extinguishing systems.

This document does not cover household kitchens or industrial food production equipment.

The detailed test procedures for the plenum and air extract ducts are contained in CEN/TS 17749.

Closed plenum type ventilated ceilings designed similar to standard hoods are included in this document. Open plenum type ventilated ceilings are excluded and require an engineered solution for the plenum protection. Protection for appliances below open or closed plenum ventilated ceilings are included.

Brandbekämpfungsanlagen in Großküchen - Planung, Dokumentation und Prüfanforderungen

Dieses Dokument legt die Mindestanforderungen fest, die für die Konstruktion, Montage, Inbetriebnahme, Funktion, Prüfung und Instandhaltung von ortsfesten automatischen Feuerlöschanlagen zum Schutz von Küchen gelten, welcher die Kochgeräte, die Haube, dem Plenum und die Abluftkanäle abdeckt. Diese Norm stellt auch Anforderungen an den Aufbau und die Leistungsfähigkeit von Bauteilen bereit, die für bestimmte Arten, Ausführungen, Größen und Anordnungen von vorgeplanten Küchen Feuerlöschanlagen gelten.

Dieses Dokument behandelt keine Küchen in Privathaushalten oder Ausrüstungen der industriellen Lebensmittelproduktion.

Die ausführlichen Prüfverfahren für das Plenum und die Abluftkanäle sind in CEN/TS 17749 enthalten.

Geschlossene Lüftungsdecken, die in ähnlicher Weise wie Standard Hauben ausgeführt sind, sind in diesem Dokument enthalten. Offene Lüftungsdecken sind nicht enthalten und erfordern eine technische Lösung für den Schutz des Plenums. Der Schutz von Geräten unterhalb offener oder geschlossener Lüftungsdecken ist enthalten.

Systèmes d'extinction d'incendie dans les cuisines professionnelles - Conception du système, documentation et exigences d'essai

Le présent document établit les exigences minimales applicables à la conception, à l’installation, au fonctionnement, aux essais et à l’entretien des installations fixes automatiques de lutte contre l’incendie pour les appareils de cuisson, la hotte, le plénum et les conduits d’extraction d’air. Le présent document fournit également les exigences relatives à la construction et aux performances des composants applicables aux types, conceptions, dimensions et dispositions spécifiques des systèmes d’extinction d’incendie de cuisine standardisés.

Le présent document ne s’applique pas aux cuisines ménagères ni aux équipements industriels de production alimentaire.

Les modes opératoires d’essais détaillés pour le plénum et les conduits d’extraction d’air sont présentés dans le document CEN/TS 17749.

Les plafonds ventilés du type à plénum fermé de conception similaire aux hottes normalisées sont inclus dans le présent document. Les plafonds ventilés du type à plénum ouvert sont exclus et exigent une solution technique pour la protection du plénum. La protection des appareils sous des plafonds ventilés à plénum ouvert ou fermé est incluse.

Gasilni sistemi v profesionalnih kuhinjah - Načrtovanje sistema, dokumentacija in preskusne zahteve (vključno z dopolnilom A1)

Ta dokument določa minimalne zahteve za načrtovanje, namestitev, delovanje, preskušanje in vzdrževanje vgrajenih samodejnih gasilnih sistemov za zaščito kuhinje, kar zajema kuhalne naprave, napo, komoro in kanale za odvod zraka. Ta dokument določa tudi zahteve za izdelavo in delovanje sestavnih delov, ki veljajo za posamezno vrsto, zasnovo, velikost in ureditev predhodno oblikovanih kuhinjskih sistemov za gašenje požara.

Ta dokument ne zajema gospodinjskih kuhinj ali opreme za industrijsko proizvodnjo hrane.

Podrobni preskusni postopki za komoro in kanale za odvod zraka so zajeti v standardu CEN/TS 17749.

V ta dokument so vključeni prezračevani stropi s komoro zaprtega tipa, zasnovani podobno kot standardne nape. Prezračevani stropi s komoro odprtega tipa so izključeni; pri tem je za zaščito komore potrebna tehnična rešitev. Vključena je zaščita za naprave pod prezračevanimi stropi s komoro odprtega oziroma zaprtega tipa.

General Information

- Status

- Published

- Publication Date

- 29-Oct-2024

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 6 - Gas extinguishing Systems and components

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 30-Oct-2024

- Completion Date

- 30-Oct-2024

Relations

- Effective Date

- 11-Sep-2024

- Effective Date

- 11-Sep-2024

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 17446:2021+A1:2024 (CEN)

EN 17446:2021+A1:2024 is a European standard published by CEN that defines minimum requirements for the design, installation, operation, testing and maintenance of fixed automatic fire extinguishing systems in commercial kitchens. The standard covers protection of cooking appliances, the hood, the plenum and the air extract ducts and applies to pre‑engineered kitchen fire‑extinguishing systems. It supersedes EN 17446:2021 and includes Amendment 1 (approved September 2024). Household kitchens and industrial food‑production equipment are excluded.

Key topics and technical requirements

- Scope and exclusions: Applies to commercial kitchens (restaurants, hotels, hospitals) and includes closed plenum ventilated ceilings; open plenums require engineered solutions. Detailed plenum/duct test procedures are in CEN/TS 17749.

- System design principles: Systems must be designed per the manufacturer’s system manual and provide hazard‑focused protection rather than mandating a single system type.

- Mandatory system elements:

- Extinguishing agent storage and actuation mechanism (mechanical/electrical)

- Discharge nozzles and piping

- Detection and automatic/manual actuation

- Fuel/power shut‑down functions

- Component control: Only components used in the system’s type‑testing and listed in the system manual may be used - no substitutions.

- Performance and environment: Equipment should be suitable for an ambient temperature range (specified in the standard as typically +5 °C to +60 °C) and operate reliably under fire conditions; secondary power supplies are recommended where primary power is essential.

- Testing and verification: The standard defines test methods covering extinguishing tests for appliances, splash tests, hood and duct entrance tests, plenum tests and agent distribution tests, plus requirements for test reports.

- Commissioning, maintenance and documentation: Requires system commissioning, periodic maintenance, full system manual and a full review when kitchen equipment is changed.

- Safety: Addresses hazards to personnel, safety in occupied zones and electrostatic discharge considerations.

Applications - who uses this standard

- Fire protection engineers and system designers specifying kitchen suppression systems

- Manufacturers of pre‑engineered kitchen extinguishing systems and components

- Installation contractors and commissioning agents

- Testing laboratories performing appliance, hood, plenum and duct tests

- Facilities managers, building owners, and compliance officers in commercial hospitality, healthcare and institutional kitchens

- Regulatory bodies and inspectors assessing conformity with CEN standards

Related standards

- CEN/TS 17749 - detailed test procedures for plenums and air extract ducts

- EN 3-7, EN 3-8 - portable fire extinguisher requirements (referenced)

- EN 1860-2 - barbecue fuel/appliance testing (referenced)

Using EN 17446:2021+A1:2024 ensures consistent, hazard‑based protection of commercial cooking risks and supports safe, test‑verified kitchen fire suppression system design, installation and maintenance.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 17446:2021+A1:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fire extinguishing systems in commercial kitchens - System design, documentation, and test requirements". This standard covers: This document establishes the minimum requirements applicable to the design, installation, functioning, test and maintenance of fixed automatic fire extinguishing systems for kitchen protection that covers the cooking appliances, the hood, the plenum and the air extract ducts. This document also provides requirements for the construction and components performance as applicable to specific types, designs, sizes and arrangements of pre-engineered kitchen fire-extinguishing systems. This document does not cover household kitchens or industrial food production equipment. The detailed test procedures for the plenum and air extract ducts are contained in CEN/TS 17749. Closed plenum type ventilated ceilings designed similar to standard hoods are included in this document. Open plenum type ventilated ceilings are excluded and require an engineered solution for the plenum protection. Protection for appliances below open or closed plenum ventilated ceilings are included.

This document establishes the minimum requirements applicable to the design, installation, functioning, test and maintenance of fixed automatic fire extinguishing systems for kitchen protection that covers the cooking appliances, the hood, the plenum and the air extract ducts. This document also provides requirements for the construction and components performance as applicable to specific types, designs, sizes and arrangements of pre-engineered kitchen fire-extinguishing systems. This document does not cover household kitchens or industrial food production equipment. The detailed test procedures for the plenum and air extract ducts are contained in CEN/TS 17749. Closed plenum type ventilated ceilings designed similar to standard hoods are included in this document. Open plenum type ventilated ceilings are excluded and require an engineered solution for the plenum protection. Protection for appliances below open or closed plenum ventilated ceilings are included.

EN 17446:2021+A1:2024 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17446:2021+A1:2024 has the following relationships with other standards: It is inter standard links to EN 17446:2021/FprA1, EN 17446:2021, EN 1860-2:2023, EN 3-8:2021, EN 3-7:2004+A1:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17446:2021+A1:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2024

Nadomešča:

SIST EN 17446:2021

Gasilni sistemi v profesionalnih kuhinjah - Načrtovanje sistema, dokumentacija in

preskusne zahteve (vključno z dopolnilom A1)

Fire extinguishing systems in commercial kitchens - System design, documentation, and

test requirements

Brandbekämpfungsanlagen in Großküchen - Planung, Dokumentation und

Prüfanforderungen

Systèmes d'extinction d'incendie dans les cuisines professionnelles - Conception du

système, documentation et exigences d'essai

Ta slovenski standard je istoveten z: EN 17446:2021+A1:2024

ICS:

13.220.20 Požarna zaščita Fire protection

97.040.99 Druga kuhinjska oprema Other kitchen equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17446:2021+A1

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2024

EUROPÄISCHE NORM

ICS 13.220.20 Supersedes EN 17446:2021

English Version

Fire extinguishing systems in commercial kitchens -

System design, documentation, and test requirements

Systèmes d'extinction d'incendie dans les cuisines Brandbekämpfungsanlagen in Großküchen - Planung,

professionnelles - Conception du système, Dokumentation und Prüfanforderungen

documentation et exigences d'essai

This European Standard was approved by CEN on 4 July 2021 and includes Amendment 1 approved by CEN on 30 September

2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17446:2021+A1:2024 E

worldwide for CEN national Members.

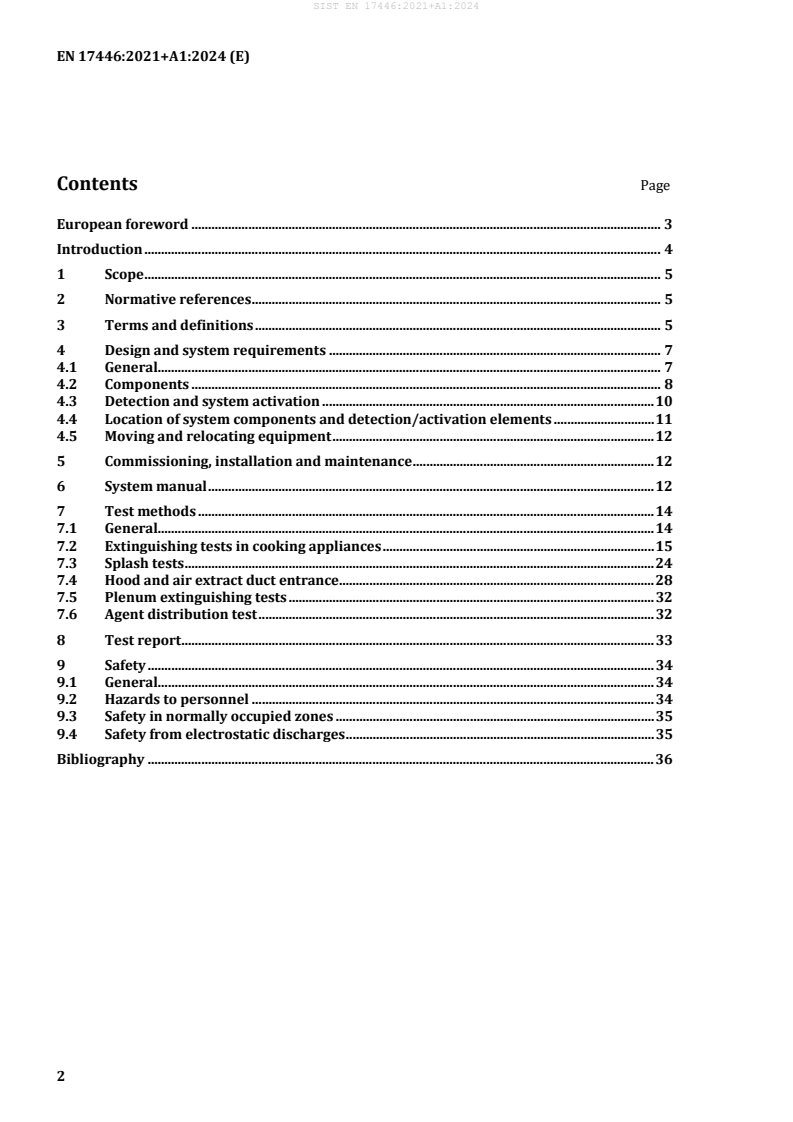

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Design and system requirements . 7

4.1 General. 7

4.2 Components . 8

4.3 Detection and system activation . 10

4.4 Location of system components and detection/activation elements . 11

4.5 Moving and relocating equipment . 12

5 Commissioning, installation and maintenance . 12

6 System manual . 12

7 Test methods . 14

7.1 General. 14

7.2 Extinguishing tests in cooking appliances . 15

7.3 Splash tests . 24

7.4 Hood and air extract duct entrance . 28

7.5 Plenum extinguishing tests . 32

7.6 Agent distribution test . 32

8 Test report . 33

9 Safety . 34

9.1 General. 34

9.2 Hazards to personnel . 34

9.3 Safety in normally occupied zones . 35

9.4 Safety from electrostatic discharges . 35

Bibliography . 36

European foreword

This document (EN 17446:2021+A1:2024) has been prepared by Technical Committee CEN/TC 191

“Fixed firefighting systems”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2025, and conflicting national standards shall be

withdrawn at the latest by April 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

!This document supersedes EN 17446:2021".

This document includes Amendment 1 approved by CEN on 30 September 2024.

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document has been developed with the purpose of establishing a common base for fire protection

of commercial kitchens (for example, the ones used in restaurants, hotels and hospitals), attending to the

appliances usually found in them and independently from the typology of the fire extinguishing system

used. This approach focused in hazard protection rather than in the definition of the system, allows

achieving a same fire hazard protection level independently from the type of system used.

This document does not consider the requirements for the components that constitute the different types

of fire extinguishing systems to which it applies. This circumstance does not reduce the importance to

the need that components are designed to ensure functionality and reliability of the system, both for those

having existing standards and for those that at this moment do not count with them.

Summarizing, this document offers a full set of requirements to carry out the design, installation and

maintenance of fire protection systems for kitchens, together with test protocols applicable to any

system, which shall be completed when required, with specific requirements in relationship with the

components constituting a system for each typology.

It is important to understand that the protection of the cooking areas only without including the hood,

plenum or the air extract ducts may become incomplete because of the possibility of fire causing the

ignition of the grease present in them, and to which an extinguishing agent discharge not including these

points, will not be capable to extinguish it. The existence of fire in the air extract ducts can cause its

propagation to other parts of the building.

1 Scope

This document establishes the minimum requirements applicable to the design, installation, functioning,

test and maintenance of fixed automatic fire extinguishing systems for kitchen protection that covers the

cooking appliances, the hood, the plenum and the air extract ducts. This document also provides

requirements for the construction and components performance as applicable to specific types, designs,

sizes and arrangements of pre-engineered kitchen fire-extinguishing systems.

This document does not cover household kitchens or industrial food production equipment.

The detailed test procedures for the plenum and air extract ducts are contained in CEN/TS 17749.

Closed plenum type ventilated ceilings designed similar to standard hoods are included in this document.

Open plenum type ventilated ceilings are excluded and require an engineered solution for the plenum

protection. Protection for appliances below open or closed plenum ventilated ceilings are included.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 3-7:2004+A1:2007, Portable fire extinguishers — Part 7: Characteristics, performance requirements

and test methods

EN 3-8, Portable fire extinguishers — Part 8: Requirements for the construction, pressure resistance and

mechanical tests for extinguishers with a maximum allowable pressure equal to or lower than 30 bar, which

comply with the requirements of EN 3-7

EN 1860-2, Appliances, solid fuels and firelighters for barbecuing — Part 2: Barbecue charcoal and

barbecue charcoal briquettes — Requirements and test methods

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

extinguishing agent

substance whose action causes the extinguishment of a fire

3.2

cooking appliance

cooking device that has, or is capable of having, a surface of liquid grease or one in which cooking with

grease is involved

EXAMPLE Deep fat fryer, griddle, range, chain-broiler, electric char-broiler, charcoal broiler, mesquite broiler,

gas radiant char broiler, wok, tilt skillet/braising pan and similar appliances.

Note 1 to entry: The protected area is limited to the cooking area of the appliance only.

3.3

hood

device part of an exhaust system that directs and captures grease and oil vapours and also the combustion

gases from a cooking appliance

3.4

deep fat fryer

cooking appliance where the food is fried submerged in a fixed vat filled with oil exposed to an intense

radiant or convective heat source

3.4.1

multiple vat fryer

fryer that incorporates vats that are mechanically joined together, where each vat incorporates a

separately controlled heating source

3.4.2

split-vat deep fat fryer

fryer that incorporates a divided partition which splits the fryer in sections, where each split-vat fryer

incorporates a separately controlled heating source

Note 1 to entry: It may have one or several vats arranged adjoining each other.

3.5

expellant gas

means used to discharge the extinguishing agent from its container

3.6

grease

melted animal fat, vegetable shortening, or other type of oily substance used in, or as a result from, the

preparation of foods

3.7

range top

cooking appliance where the food is cooked and is directly exposed to a heat source

3.8

system manual

manufacturer’s documentation where the design, installation, functioning and maintenance of the system

are defined

3.9

griddle

cooking appliance where the food is not directly exposed to the fire but on a flat surface intensely heated

by radiation or convection

3.10

broiler

cooking appliance where the food is on a grill, directly exposed to an intense heat source by radiation,

and perhaps by convection, where neither the food nor the radiation source have to be necessarily in the

horizontal position

3.11

plenum

hood space behind the filters

3.12

tested hazard

kitchen appliance, hood or plenum where the fire is generated, and the air extract duct during the tests

described in this document and that will determine the scope of the obtained results

3.13

tilt skillet

cooking appliance consisting in a large dimension vessel exposed to an intense heat source, which can

move from one side to the other tilting on an axis, where the food is cooked, boiled, sautéed or fried

3.14

extinguishing system

components fitted to each other forming a fixed system that discharges an extinguishing agent for the

purpose of extinguishing fires in kitchens

3.15

discharge time

time during which the discharge of the extinguishing agent occurs without interruptions in it, without

including the residual expellant gas discharge, if applicable

3.16

wok

bottom domed round frying pan

3.17

protected kitchen area

surface enclosing all the cooking appliances located under the projection of a hood, including the

associated filters, plenum and air extract ducts

3.18

pre-engineered kitchen fire-extinguishing system

performance tested system in accordance with the limitations prescribed by the manufacturer and

included in the system manual

4 Design and system requirements

4.1 General

The system shall be designed according to the fire extinguishing system manual. The system manual shall

be based on the parameters determined from the requirements of this document.

A full system review shall be conducted to the fire extinguishing system prior to any change which could

affect the operation and/or efficacy of the kitchen equipment.

Each system shall consist of at least the following elements:

— extinguishing agent storage unit plus actuation mechanism (mechanical or electrical);

— nozzles;

— detection system associated to the actuation mechanism;

— manual actuation mechanism;

— pipe layout to feed the extinguishing agent discharge nozzles;

— fuel/power supply shut down.

The system shall be dedicated to the protected equipment.

Where power supplies are essential to maintain the operation of the system, a secondary power supply

should be provided independent of the primary supply.

The secondary power supply should be of sufficient capacity and resilience to maintain the system for at

least the operation time identified in the manufacturer’s manual and be capable of operating safely in fire

conditions for the appropriate period of time.

Extinguishing media supply shall be permanently available to the kitchen fire protection system. Where

the agent supply is external to the equipment, e.g. mains water supply, it shall not be possible to reduce

the supply when the system is in operation. During installation it has to be established that sufficient

water flow and water pressure (with all possible demand on the same source in use) is available. The

extinguishing system needs to be connected directly into the water main or sprinkler system supply and

a test connection included to allow routine testing to confirm adequate flow and pressure.

The equipment shall be suitable for use within the minimum ambient temperature range of (+5, +60) °C.

The equipment operating temperature range shall be specified in the manufacturer’s design manual.

The system shall be designed to provide simultaneous discharge to the protected appliances, the hood

and air extract duct entrances.

For hoods with an inner physical separation, both sides of the separation shall be protected.

Hoods that are connected without an inner physical separation, as they are vulnerable to fire spread, shall

be protected with a simultaneous system activation and discharge to all hazard areas.

The protected length of duct from the cooking appliance ignition source shall be specified in the

manufacturer’s design manual.

4.2 Components

4.2.1 General

The system shall only use components as used in the testing and as specified in the manufacturer’s

manual. There shall be no substitution of components.

All system components shall be designed to function under the intended conditions and within their

range of temperatures of utilization.

4.2.2 Agent container assembly

Where containers are used in these systems they shall be designed to meet the requirements of relevant

national standards.

Agent container, valve and seals shall be made of material suitable for use with:

— the agent in terms of corrosion and chemical compatibility.

When tested in accordance with EN 3-7:2004+A1:2007, Clause 14:

— external corrosion.

When tested in accordance with EN 3-7:2004+A1:2007, Clause 14:

— pressure resistance.

When tested in accordance with EN 3-8.

Where applicable, means shall be provided to indicate that each container is correctly charged.

Each container shall have a permanent nameplate or other permanent marking specifying the

extinguishant, tare and gross mass, and the super pressurization level (where applicable) of the

container.

The containers used in these systems shall be designed to meet the requirements of relevant national

standards.

4.2.3 Discharge nozzles

Nozzles shall be manufactured from non-combustible materials and they shall withstand the intended

fire exposure without observed deformation or without its extinguishing performances being reduced.

Nozzles shall be designed to prevent clogging, or other means within the system shall be employed.

Nozzles shall be resistant to:

— corrosion;

— extinguishing agent;

— environmental conditions;

— temperature conditions and fire.

When tested in accordance with design manual.

Open nozzles shall be provided with a protective cover protecting the nozzle opening against grease

migration.

The protective cover shall not interfere in the agent discharge in a way that affects the performance of

the system and shall be included in the fire testing. Additionally, it shall not create an increased danger

of fire spread or to the people, due to splashing.

The protective cover shall be made of material suitable for use with:

— agent in terms of corrosion;

— temperature conditions and fire resistance;

— blow-off pressure;

— vibration;

— stress corrosion.

4.2.4 Pipe and fittings

Pipe and fittings shall be of non-combustible material and with physical and chemical characteristics

compatible with the extinguishing agent. They shall withstand the maximum operating pressures (at

maximum storage temperature) occurring during the discharge.

Pipework and fittings shall comply with the appropriate national standards.

4.2.5 Hose and hose fittings

Hoses and hose fittings, shall not be used where they are exposed to the fire and be of materials having

physical and chemical characteristics compatible with the extinguishing agent. They shall withstand the

maximum operating pressures (at maximum storage temperature) occurring during the discharge. Hoses

and hose fittings used in the system shall be installed as described in the system manual.

4.2.6 Extinguishing agent

The extinguishing agent used shall be defined in the fire test report. Extinguishing agents with different

formulations or provided by different manufacturers shall not be used or mixed. The instructions

provided in the system manual shall be followed.

4.2.7 Manual activation device(s)

4.2.7.1 General

Each system shall be equipped with at least one manual activation device (see 4.4.4). Operation of the

manual activation device shall lead to immediate activation and complete discharge (in accordance with

the system design manual) of the system.

The construction and materials used for the manual activation device (including the marking - see 4.4.5)

shall be suitable for the typical commercial kitchen environment including frequent cleaning.

4.2.7.2 Mechanical activation devices

The operating mechanism of the manual activation device (pull ring, handle, lever, push button or strike

knob) shall be suitable for manual operation.

The operating mechanism shall be provided with a safety device to prevent inadvertent operation. The

release of the safety device shall involve an operation distinct from that of the operating mechanism.

The manual activation device shall be fitted with an indicating element which clearly shows whether the

manual activation device may have been operated. It shall not be possible to restore, re-insert or re-install

the indicating element. Wire seals and frangible elements are examples of acceptable indicating elements.

4.2.7.3 Electrical activation devices

For systems with an electrical manual push button actuation system, it shall be fitted with a protective

cover to prevent inadvertent operation. The protective cover shall have a wire seal or equivalent

indicating element. The manual activation device shall have an Ingress Protection (IP) rating of 54 or

higher.

4.2.8 Special requirements

For all penetrations through a protected air extract duct or hood an appropriate oil tight fitting shall be

used.

Simultaneously to the system activation, all fuel or electrical power sources generating heat at the

protected equipment shall be disconnected.

4.3 Detection and system activation

All systems shall have both automatic and manual activation methods. These activation methods shall be

independent from each other in order to avoid the failure of one of them preventing the functioning of

the system.

The automatic detection and manual activation system shall be in accordance with the system manual.

All activation devices shall be designed, located, installed or protected in such a way that they are not

subjected to adverse mechanical or environmental conditions that may render the system inoperative or

that may cause an unwanted activation of the system. The system shall have the necessary electrical

switches to be able to integrate the following signals and actions:

— output to audible and visual fire alarm;

— output to control and indicating equipment;

— output to shut off the electric power and/or gas supply for the cooking appliances;

— output to shut off ventilation fans, and close ventilations dampers.

A readily accessible means for the manual activation of the system shall be located in the evacuation

route.

4.4 Location of system components and detection/activation elements

4.4.1 Extinguishing agent storage

Extinguishing agent and expellant gas containers shall be located in places where the range of ambient

temperature is within the specified values in the system manual, avoiding those locations where wide

and continuous variations of temperature are foreseen that may result in a premature degradation of the

extinguishing agent and therefore, in a considerable decrease of its extinguishing capacity.

In the event the extinguishing agent might freeze at low temperatures, it shall be conditioned so that the

container temperature is always at least 5 °C over the extinguishing agent freezing temperature.

Systems in which the extinguishing agent partially or wholly may be located in zones susceptible to be

exposed to high temperatures are not considered suitable (for example, inside the hood), provided this

situation may cause the degradation and therefore, loss of the extinguishing agent effectiveness.

In case the ambient temperature is expected to be out of the range of temperatures specified by the

manufacturer of the system, a protection system to keep the assembly temperature within that range

shall be provided.

Extinguishing agent and expellant gas containers shall not be located where they can be exposed to

mechanical and chemical damage, bad weather or direct sunlight. In case this is not possible, protection

systems such as cabinets or guards shall be provided. Likewise, the extinguishing agent and expellant gas

containers sets shall be readily accessible for their inspection, maintenance and recharge and shall be

located according to the system manual, and in no case where they may be exposed to fire.

If the extinguishing agent or any of its components may be degraded by continuous exposure to the usual

temperatures to which it may be subjected, automatic nozzles keeping the extinguishing agent

pressurized inside the distribution network, shall not be installed.

4.4.2 Discharge nozzles

All discharge nozzles shall be located so that damage and incorrect nozzle aiming are minimized and are

always to be installed within the limitations in the system manual.

4.4.3 Detection

The fire detection devices for cooking appliances shall be installed in accordance with the manufacturer’s

instructions.

Automatic fire detection devices shall be provided, as a minimum:

— along the entire length of the hood;

— in the hood plenum, at the entry of the air exhaust duct(s).

The detection system shall be suitable for kitchen environments and shall be located and installed in such

way that they are not subjected to adverse mechanical or environmental conditions that may render the

system inoperative or that may cause an unwanted activation of the system.

4.4.4 Manual activation devices

The manual activation device shall be installed in an easily accessible place and height and be in the path

of egress. If there are more than one means of egress, additional manual activation devices shall be

provided. The horizontal distance between the manual activation device and any of the protected cooking

appliances shall be at least 2 m, if technically possible. If necessary, protective measures against

mechanical damage shall be installed. Such protective measures shall in no way obstruct the operation of

the manual activation device.

4.4.5 Signage

Near each manual activation device, signage shall be placed with at least the following information:

— the text “kitchen fire extinguishing system”;

— operating instructions for the manual activation device, preferably with pictograms.

The signage shall be at least 100 cm , with contrasting colours. Text height shall be at least 12 mm,

pictograms shall be at least (25 × 25) mm. Any text shall be in the local language(s).

If more than one extinguishing system is installed, additional signage may be required to indicate which

system is activated by each manual activation device.

4.5 Moving and relocating equipment

To ensure correct nozzle aiming, cooking appliances shall have the appropriate means to ensure correct

positioning in relation to the discharge nozzles during the usual tasks in the kitchen. The protection

offered should be checked to ensure it is still applicable if appliances are permanently relocated.

5 Commissioning, installation and maintenance

The system is designed to be installed, commissioned and maintained in accordance with the system

manual, by competent persons trained by the manufacturer.

The maintenance shall be carried out in accordance with the system manual and shall include a system

review every six months or more frequently, if necessary. Where there is a change to any kitchen

equipment which could affect the operation and/or efficacy of the fire extinguishing system, then a

system review should be conducted.

6 System manual

A copy of the installation, operating, recharging, inspection and maintenance instruction manual is to be

furnished for use as a reference in the examination and testing of an automatic extinguishing unit or pre-

engineered extinguishing system unit.

The instructions shall reference the requirements and limitations of each extinguishing system unit and

include at least the following items:

a) Description and operating details of each extinguishing system unit and all accessory equipment,

including identification of extinguishing system units or accessory equipment by part number or

model;

b) Freezing point of the extinguishing agent (if agent is a liquid);

c) Type of protection afforded by the system;

d) Type of pipe, hose, tubing and fittings to be used;

e) Typical system layout and specific limitations for correct system installation and effective protection,

e.g. tilt skillet/braising pan instructions indicating that the nozzle is to be placed toward the front of

the appliance to minimize potential interference to the nozzle discharge from, for example, a skillet

cover;

f) Specific information on piping limitations for correct system installation and effective protection;

g) Description of all variations of each extinguishing system, including the limitations for each variation;

h) Discharge nozzle limitations, including maximum dimensional and area coverage for each different

appliance, minimum and maximum height limitations, and nozzle location(s). When a system unit is

limited to a maximum volume, this information shall also be included;

i) Installation details of each extinguishing system unit, including accessory equipment;

j) Reference to the specific types of detection and control panels (where applicable) to be connected to

the equipment;

k) Specifications and instructions for the interconnection of multiple extinguishing system units, or a

caution statement to not use multiples of units, when a means for interconnecting is unavailable;

l) Operating pressure of the system if applicable;

m) Operating temperature limitations;

n) Information on inspection of system after installation;

o) Information intended for use by the competent person trained to carry out the system’s periodic

inspection. The periodic inspection which shall include at least the following:

1. An inspection to see that the hazard has not changed and the design remains compliant with the

hazard.

2. An examination of all detectors, the expellant gas container(s), the agent container(s), actuation

devices, hoses, nozzles, signals and all auxiliary equipment, including the shutdown devices.

3. An inspection of the extinguishing agent. This may include:

i. water flow and pressure requirements to ensure it meets demand for systems using mains

supply;

ii. checking for any contamination of agent;

iii. agent levels;

iv. if the agent is foam, that is not pre-mixed, any proportioning equipment to check if the foam

concentrate is being proportioned in accordance with manufacturer requirements.

4. A verification that the agent distribution piping is not damaged and not obstructed.

5. Hydrostatic testing, as applicable, in accordance with the recommendations of the manufacturer

or National requirements.

6. Operation of the detection systems, signals, and releasing devices, including the manual release

stations and other associated equipment.

7. Corrective actions, repairs and replacement of defective or damaged parts.

8. An inspection of temperature sensitive elements, other than fusible metal alloy type, clean or

replace according to manufacturer’s instructions. Replacement of glass bulbs shall in no case

exceed 5 years. Care should be taken to avoid the use of abrasive cleaning materials.

9. Replacement (at least annually) of fixed temperature sensing elements of the fusible metal alloy

type (the old sensing elements shall be permanently identified to avoid re-use when removed).

10. A maintenance report listing repairs and recommendations.

p) Recharging of all extinguishing system units after use or as indicated by the inspections and

maintenance procedures;

q) Flushing of the pipework and proportioner after any discharge;

r) Discarding of any agent removed from the storage containers, in an environmentally acceptable

manner;

s) Detailed information for recharging the system after operation, including the use of the intended

extinguishing media originally supplied;

t) Description of the requirements for maintenance of all equipment;

u) Name of the manufacturer or private labeller, or equivalent designation;

v) Date and manual designation on each page;

w) Material information, ‘safety data sheets’ and cautionary instructions.

An installation, operation and maintenance manual shall either be provided with each extinguishing

system unit or made available upon request. When these manuals are not included with each system, an

owner’s manual shall be shipped with each system.

7 Test methods

7.1 General

The extinguishing system shall be tested for each cooking appliance it is expected to be used with.

The type test should be conducted by an independent testing laboratory accredited to EN ISO/IEC 17025.

This clause specifies the methodology to follow for the tests the extinguishing system have to be subjected

to:

— fire extinguishing tests in cooking appliances (7.2);

— splash tests (7.3);

— hood and air extract duct extinguishing tests (7.4);

— plenum extinguishing tests (7.5);

— agent distribution test (7.6).

Unless otherwise specifically indicated, the scope of the results of each test is limited to the same or lesser

size and to the same tested hazard, as well as to the system characteristics affecting the distribution of

the extinguishing agent. In relation to dimensions, only the cooking area of the concerned cooking

appliance is considered.

Elements that may affect the distribution of the extinguishing agent are, among others, pressure losses in

the agent distribution network, discharge nozzle height and orientation over the hazard, obstructions in

the nozzles spray pattern, extinguishing agent storage characteristics, etc.

The hazards the system can act upon considered in this document and applicable tests are given in

Table 1:

Table 1 — Hazard and applicable tests

Hazard Applicable tests

deep fat fryer 7.2.2 7.3.2 7.3.3

griddle 7.2.3

range top 7.2.4 7.3.4 7.3.5

gas broiler 7.2.5

electric broiler 7.2.6

lava, pumice or synthetic rock broiler 7.2.7

charcoal broiler 7.2.8

wood broiler 7.2.9

upright broiler 7.2.10

chain broiler 7.2.11

woks 7.2.12 7.3.6 7.3.7

hood and duct 7.4

plenum 7.5

all other equipment not listed in table 7.2.2 7.3.2 7.3.3

A distribution test 7.6 is required for every hazard in the list.

The distribution test may be carried out before the fire tests.

7.2 Extinguishing tests in cooking appliances

7.2.1 General

The length and width of the tested hazard shall be in accordance with the coverage limitations of the

maximum area and size specified in the system manual.

The hazard to test shall be clean before its preparation.

When the tested hazard is a gas broiler, the field of applicability of results may be extended to electric

broilers, of the same dimensions and under the same test conditions.

When the tested hazard is a lava broiler, the field of applicability of results may be extended to pumice

broilers and synthetic rock broilers of the same dimensions and under the same test conditions.

Where a gas or electrically heated lava broilers, pumice broilers and synthetic rock broilers are used

either fuel source can be used for the testing.

Where the test hazard is a deep fat fryer, the field of applicability of results may be extended to griddle,

range top, electric or gas broiler, upright broiler and wok, of the same dimensions and under the same

test conditions.

NOTE Attention needs to be given to prevent spreading of embers and hot ashes in some types of charcoal or

solid fuel grills.

7.2.1.1 Compliance criteria for extinguishing tests

When performing an extinguishing test, the following shall be complied with:

a) the flame in the appliance being completely extinguished in one minute or less from the start of

discharge;

b) after 10 s from the start of the discharge of the extinguishing agent, the flames shall be no bigger than

those prior to the start of the discharge of the agent;

c) when the hazard is a deep fat fryer, a wok or a range top, there shall be no re-ignition:

1) during the 20 min following the extinguishment; and

2) until the temperature of the test oil decreases more than 30 °C from the measured auto-ignition

temperature; or if the fire is manually ignited (at 363 °C), until the temperature of the test oil

decreases below 333 °C.

d) when the hazard is not a deep fat fryer, wok or a range top, there shall be no re-ignition during the 5

min following the extinguishment;

e) after the fire has been extinguished, some fuel shall be remaining.

7.2.1.2 Minimum discharge flow test criteria

Extinguishing tests shall be carried out on a system discharging the minimum quantity of extinguishing

agent over the hazard with the minimum discharge flow per nozzle, with the hydraulically most

unfavourable distribution network, on each of the following:

a) with the nozzles located at the maximum allowed height in respect to the fire hazard and with the

most unfavourable orientation;

b) with the nozzles located at the minimum allowed height in respect to the fire hazard and with the

most unfavourable orientation.

Where used the storage unit of the extinguishing agent shall be filled to its rated capacity.

For systems using stored pressure to discharge the extinguishing agent, the pressurized element shall be

at the operating pressure. That element shall be conditioned for at least 16 h before the test at the

minimum temperature specified by the manufacturer (–5 °C, +0 °C), or filled at operating pressure (–5 %,

+5 %) equivalent to the one at the minimum temperature specified by the manufacturer.

For systems not using pressure to discharge the extinguishing agent, the storage unit of the extinguishing

agent shall be conditioned for at least 16 h before the test at the minimum temperature specified by the

manufacturer (–5 °C, +0 °C).

7.2.1.3 Cooking area limitations

If the area of the protected appliance exceeds the capacity of a single nozzle then multiple nozzles may

be used in modules, provided the area of coverage assigned to each discharge nozzle does not exceed the

tested area of coverage.

In addition:

a) in the case of a deep fat fryer the cooking area !shall not" exceed 0,55 m in surface area. The

0,55 m total surface cooking area requirement does not apply to tilt skillets;

b) deep fat fryers with a surface cooking area greater than 0,55 m !may" be protected when it has

been demonstrated that the nozzles have been tested on the specific model of appliance.

7.2.2 Extinguishing test on deep fat fryers

7.2.2.1 Tested hazard

The hazard to test is a natural gas, propane or butane, or electric deep fat fryer, at least 230 mm deep,

having a cooking surface area according to the hazard intended to cover with the system. In case the deep

fat fryer has drip boards, the surface area of the zone to protect shall be calculated taking into account

the system manual.

Multiple-vat and split-vat deep fat fryers shall be separately tested.

NOTE In the tests natural gas or propane or butane deep fat fryers are usually used due to the damage that can

occur in electric deep fat fryers during testing. Test results are applicable to all types of deep fat fryer independent

of the heat source used.

The deep fat fryer shall be such that, at an ambient temperature of (21 ± 5) °C:

a) adjusting the deep fat fryer to its maximum power setting, the average value of rise in temperature

per minute when the temperature of the oil goes from (260 ± 5) °C to (315 ± 5) °C, shall not be less

than 7 °C/min;

b) adjusting the deep fat fryer to its maximum power setting and shutting it off on reaching (325 ± 5) °C,

the average value of descent of temperature per minute when the temperature of the oil goes from

(315 ± 5) °C to (260 ± 5) °C, shall not exceed 3 °C/min.

For the verification of the deep fat fryer requirements, temperatures shall be continuously recorded with

a thermocouple located at the same position as during the tests.

7.2.2.2 Fuel

Fill the hazard with unused oil until the oil surface is at least 75 mm from the top of the vat. If the deep

fat fryer incorporates a drip board, the oil surface shall be at the height of the deep fat fryer/drip pan

interface, when it is between 175 °C and 190 °C.

The oil level shall not be more than 75 mm below the top of the vat when it is between 288 °C and 315 °C.

The auto-ignition reference temperature of the oil shall not be less than 363 °C.

+10

During the test; if auto-ignition occurs before 363 °C, the 120 s pre burn time would begin to count

on reaching 363 °C.

If the hazard is required to include split-vat deep fat fryers, one or more of the adjacent vats to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...