EN 16351:2015

(Main)Timber structures - Cross laminated timber - Requirements

Timber structures - Cross laminated timber - Requirements

This European Standard sets out provisions regarding the performance characteristics for straight and curved structural cross laminated timber (X-Lam) both without and with large finger joints as a material for the manufacture of structural elements to be used in buildings and bridges.

This European Standard applies to cross laminated timber:

- to be used in service class 1 or 2 according to EN 1995 1 1;

- made of coniferous species and poplar listed in 5.1.5 of this standard;

- built up of at least three orthogonally bonded layers (at least two of them timber layers);

- having, depending on the number of layers, adjacent layers which may be bonded parallel to the grain;

- made of timber layers which are made of strength graded timber according to EN 14081 1;

- made of timber layers having thicknesses between 6 mm and 60 mm (including) taking into account the layup requirements given in this European standard;

- made of timber layers which may be edge bonded or which are not bonded and have spacing less than 6 mm between adjacent laminations;

- which may comprise wood based panel layers made of structural wood based panels specified in this European standard, fulfilling the requirements for use in service class 2 or 3 according to EN 1995 1 1, having no structural joints between the single panels and having thicknesses between 6 mm and 45 mm (including);

- bonded with adhesives, fulfilling the requirements given in this European standard;

- having overall thicknesses up to 500 mm;

- which is not made from reused timber or wood based panels comprising reused timber.

This European Standard also applies to cross laminated timber with large finger joints:

- made from cross laminated timber pieces having the same cross section and layup;

- made from cross laminated timber pieces having cross sectional thicknesses from 51 mm up to 345 mm (inclusive) and minimum thicknesses of the outermost layers not less than 17 mm.

- made from cross laminated timber pieces solely comprising timber layers;

- made from plane cross laminated timber pieces jointed so that no regular change between the grain directions of the layers occurs;

- with finger joints having a finger length of at least 45 mm and fingers which are visible at the two narrow sides of the components.

This European Standard applies to cross laminated timber treated against biological attack. Cross laminated timber treated with fire retardants is not covered.

It also sets out minimum production requirements and procedures for Assessment and Verification of Constancy of Performance.

Holzbauwerke - Brettsperrholz - Anforderungen

Diese Europäische Norm enthält Festlegungen hinsichtlich der Leistungsmerkmale von ebenem und gekrümmtem Brettsperrholz (X Lam) für tragende Zwecke mit und ohne Universal Keilzinkenverbindungen zur Herstellung von Elementen für tragende Zwecke, die im Hochbau und im Brückenbau zu verwenden sind.

Diese Europäische Norm gilt für Brettsperrholz,

- das in der Nutzungsklasse 1 oder 2 nach EN 1995-1-1 angewendet wird;

- das aus Nadelholzarten oder aus Pappel besteht, die in Abschnitt 5.1.5 dieser Norm aufgeführt sind;

- das aus mindestens drei rechtwinklig zueinander verklebten Lagen (mindestens zwei Lagen sind Brettlagen) besteht;

- bei dem je nach Anzahl der Lagen aneinander grenzende Lagen parallel zur Faser verklebt werden dürfen;

- das aus Lagen aus Vollholz (Bretter oder Bohlen, im Folgenden als Bretter bezeichnet) besteht, das entsprechend EN 14081-1 nach Festigkeit sortiert ist;

- das aus Brettlagen mit Dicken von 6 mm bis (einschließlich) 60 mm besteht, wobei die in dieser Europäischen Norm angegebenen Anforderungen an den Aufbau zu berücksichtigen sind;

- das aus Brettlagen mit oder ohne Schmalseitenverklebungen mit einem Abstand zwischen aneinander grenzenden Lamellen von weniger als 6 mm besteht;

- das Lagen aus Holzwerkstoffen aus den in dieser Europäischen Norm festgelegten Holzwerkstoffen für tragende Zwecke enthalten darf, die die Anforderungen an die Nutzungsklasse 2 oder 3 nach EN 1995-1-1 erfüllen, keine tragenden Verbindungen zwischen einzelnen Platten aufweisen und Dicken von 6 mm bis (einschließlich) 45 mm besitzen;

- das mit Klebstoffen verklebt ist, die den in dieser Europäischen Norm angegebenen Anforderungen entsprechen;

- das Gesamtdicken bis 500 mm hat;

- das nicht aus Altholz oder aus Holzwerkstoffen besteht, die Altholz enthalten.

Diese Europäische Norm gilt auch für Brettsperrholz mit Universal Keilzinkenverbindungen, das

- aus Brettsperrholzstücken mit gleichem Querschnitt und Aufbau besteht;

- aus Brettsperrholzstücken mit Querschnittsdicken von 51 mm bis (einschließlich) 345 mm besteht, wobei die Mindestdicken der äußersten Lagen mindestens 17 mm betragen;

- aus Brettsperrholzstücken besteht, die ausschließlich Brettlagen enthalten;

- aus ebenen Brettsperrholzstücken besteht, die so miteinander verbunden sind, dass zwischen den verbundenen Lagen keine regelmäßige Änderung der Faserrichtung auftritt;

- Keilzinkenverbindungen mit einer Keilzinkenlänge von mindestens 45 mm enthält, wobei die Keilzinken an den beiden Schmalseiten der Komponenten sichtbar sind.

Diese Europäische Norm gilt für Brettsperrholz, das gegen biologischen Befall behandelt wurde. Mit Feuerschutzmittel behandeltes Brettsperrholz ist nicht Gegenstand dieser Norm.

In dieser Europäischen Norm werden auch Mindestanforderungen an die Fertigung und Verfahren zur Bewertung und Überprüfung der Leistungsbeständigkeit (AVCP) festgelegt.

Structures en bois - Bois lamellé croisé - Exigences

La présente Norme européenne spécifie les dispositions concernant les caractéristiques de performance du bois lamellé croisé (CLT) de structure, droit ou courbe, avec ou sans aboutages à entures multiples de grandes dimensions, en tant que matériau pour la fabrication d'éléments de structure devant être utilisés dans les bâtiments et les ponts.

La présente Norme européenne s'applique au bois lamellé croisé :

- destiné à être utilisé en classe de service 1 ou 2 conformément à l'EN 1995-1-1 ;

- constitué d'essences de bois de résineux et de peuplier énumérés en 5.1.5 de la présente norme ;

- constitué d'au moins trois couches collées orthogonalement (au moins deux d'entre elles étant des couches de bois) ;

- comportant, en fonction du nombre de couches, des couches contigües qui peuvent être collées parallèlement au fil ;

- comportant des couches de bois constituées de bois classé pour sa résistance mécanique conformément à l'EN 14081-1 ;

- comportant des couches de bois ayant des épaisseurs comprises entre 6 mm et 60 mm (inclus) en tenant compte des exigences de combinaison spécifiées dans la présente Norme européenne ;

- constitué de couches de bois qui peuvent être collées ou non sur leschants et ayant un espacement entre lamelles contigües inférieur à 6 mm ;

- qui peut comprendre des couches en panneaux à base de bois pour usage structurel tels que spécifiés dans la présente Norme européenne, satisfaisant aux exigences relatives à une utilisation en classe de service 2 ou 3 conformément à l'EN 1995-1-1, n'ayant pas d'assemblages de structure entre les panneaux individuels et ayant des épaisseurs comprises entre 6 mm et 45 mm (inclus) ;

- collé à l'aide d'adhésifs satisfaisant aux exigences spécifiées dans la présente Norme européenne ;

- ayant des épaisseurs totales inférieures ou égales à 500 mm ;

- qui n'est pas constitué de bois réutilisé ou de panneaux à base de bois contenant du bois réutilisé.

La présente Norme européenne s'applique également au bois lamellé croisé avec aboutages à entures multiples de grandes dimensions :

- constitué de pièces de bois lamellé croisé ayant la même section transversale et la même combinaison ;

- constitué de pièces de bois lamellé croisé ayant des épaisseurs de section transversale comprises entre 51 mm et 345 mm (inclus) et des épaisseurs minimales des couches extérieures supérieures ou égales à 17 mm ;

- constitué de pièces de bois lamellé croisé comprenant uniquement des couches de bois ;

- constitué de pièces de bois lamellé croisé planes assemblées de telle sorte qu'aucun changement régulier n'apparaisse entre les sens du fil ;

- avec des aboutages à entures multiples ayant une longueur d'au moins 45 mm et des entures qui sont visibles au niveau des deux faces étroites des composants.

La présente Norme européenne s'applique également au bois lamellé croisé traité contre les attaques biologiques. Le bois lamellé croisé traité par des produits ignifuges n'est pas couvert.

Elle spécifie également les exigences minimales relatives à la fabrication ainsi que les procédures d'évaluation et de vérification de la constance des performances.

Lesene konstrukcije - Križno lamelirani les - Zahteve

Ta dokument določa zahteve za križno lameliran les s pravokotnimi preseki, narejen z žaganjem, oblanjem ali drugimi metodami. Ta evropski standard zajema križno lameliran les, nezaščiten ali zaščiten pred biološkimi dejavniki. Ta dokument ne zajema lesa, obdelanega z ognjevarnimi izdelki.

General Information

- Status

- Withdrawn

- Publication Date

- 13-Oct-2015

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 124 - Timber structures

- Drafting Committee

- CEN/TC 124/WG 3 - Glued laminated timber

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Mar-2021

- Completion Date

- 14-Apr-2025

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 21-Nov-2017

Frequently Asked Questions

EN 16351:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Timber structures - Cross laminated timber - Requirements". This standard covers: This European Standard sets out provisions regarding the performance characteristics for straight and curved structural cross laminated timber (X-Lam) both without and with large finger joints as a material for the manufacture of structural elements to be used in buildings and bridges. This European Standard applies to cross laminated timber: - to be used in service class 1 or 2 according to EN 1995 1 1; - made of coniferous species and poplar listed in 5.1.5 of this standard; - built up of at least three orthogonally bonded layers (at least two of them timber layers); - having, depending on the number of layers, adjacent layers which may be bonded parallel to the grain; - made of timber layers which are made of strength graded timber according to EN 14081 1; - made of timber layers having thicknesses between 6 mm and 60 mm (including) taking into account the layup requirements given in this European standard; - made of timber layers which may be edge bonded or which are not bonded and have spacing less than 6 mm between adjacent laminations; - which may comprise wood based panel layers made of structural wood based panels specified in this European standard, fulfilling the requirements for use in service class 2 or 3 according to EN 1995 1 1, having no structural joints between the single panels and having thicknesses between 6 mm and 45 mm (including); - bonded with adhesives, fulfilling the requirements given in this European standard; - having overall thicknesses up to 500 mm; - which is not made from reused timber or wood based panels comprising reused timber. This European Standard also applies to cross laminated timber with large finger joints: - made from cross laminated timber pieces having the same cross section and layup; - made from cross laminated timber pieces having cross sectional thicknesses from 51 mm up to 345 mm (inclusive) and minimum thicknesses of the outermost layers not less than 17 mm. - made from cross laminated timber pieces solely comprising timber layers; - made from plane cross laminated timber pieces jointed so that no regular change between the grain directions of the layers occurs; - with finger joints having a finger length of at least 45 mm and fingers which are visible at the two narrow sides of the components. This European Standard applies to cross laminated timber treated against biological attack. Cross laminated timber treated with fire retardants is not covered. It also sets out minimum production requirements and procedures for Assessment and Verification of Constancy of Performance.

This European Standard sets out provisions regarding the performance characteristics for straight and curved structural cross laminated timber (X-Lam) both without and with large finger joints as a material for the manufacture of structural elements to be used in buildings and bridges. This European Standard applies to cross laminated timber: - to be used in service class 1 or 2 according to EN 1995 1 1; - made of coniferous species and poplar listed in 5.1.5 of this standard; - built up of at least three orthogonally bonded layers (at least two of them timber layers); - having, depending on the number of layers, adjacent layers which may be bonded parallel to the grain; - made of timber layers which are made of strength graded timber according to EN 14081 1; - made of timber layers having thicknesses between 6 mm and 60 mm (including) taking into account the layup requirements given in this European standard; - made of timber layers which may be edge bonded or which are not bonded and have spacing less than 6 mm between adjacent laminations; - which may comprise wood based panel layers made of structural wood based panels specified in this European standard, fulfilling the requirements for use in service class 2 or 3 according to EN 1995 1 1, having no structural joints between the single panels and having thicknesses between 6 mm and 45 mm (including); - bonded with adhesives, fulfilling the requirements given in this European standard; - having overall thicknesses up to 500 mm; - which is not made from reused timber or wood based panels comprising reused timber. This European Standard also applies to cross laminated timber with large finger joints: - made from cross laminated timber pieces having the same cross section and layup; - made from cross laminated timber pieces having cross sectional thicknesses from 51 mm up to 345 mm (inclusive) and minimum thicknesses of the outermost layers not less than 17 mm. - made from cross laminated timber pieces solely comprising timber layers; - made from plane cross laminated timber pieces jointed so that no regular change between the grain directions of the layers occurs; - with finger joints having a finger length of at least 45 mm and fingers which are visible at the two narrow sides of the components. This European Standard applies to cross laminated timber treated against biological attack. Cross laminated timber treated with fire retardants is not covered. It also sets out minimum production requirements and procedures for Assessment and Verification of Constancy of Performance.

EN 16351:2015 is classified under the following ICS (International Classification for Standards) categories: 79.060.10 - Plywood. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16351:2015 has the following relationships with other standards: It is inter standard links to EN 16351:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16351:2015 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/112. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16351:2015 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Lesene konstrukcije - Križno lamelirani les - ZahteveHolzbauwerke - Brettsperrholz - AnforderungenStructures en bois - Bois lamellé croisé - ExigencesTimber structures - Cross laminated timber - Requirements91.080.20Lesene konstrukcijeTimber structures79.060.10Vezan lesPlywoodICS:Ta slovenski standard je istoveten z:EN 16351:2015SIST EN 16351:2015en,fr,de01-december-2015SIST EN 16351:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16351

October

t r s w ICS

y {ä r x rä s r English Version

Timber structures æ Cross laminated timber æ Requirements Structures en bois æ Bois lamellé croisé æ Exigences

Holzbauwerke æ Brettsperrholz æ Anforderungen This European Standard was approved by CEN on

t { August

t r s wä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s w CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x u w sã t r s w ESIST EN 16351:2015

Release of Formaldehyde . 48 A.1 General . 48 A.2 Classification . 48 A.2.1 Cross laminated timber . 48 A.2.2 Cross laminated timber with large finger joints . 49 Annex B (normative)

Additional test methods and requirements for adhesives . 50 B.1 General . 50 B.2 Long-term sustained load test at cyclic climate conditions with specimens loaded perpendicular to the glue line for moisture curing one-component polyurethane and emulsion polymer isocyanate adhesives (glass house test) . 50 B.2.1 General description . 50 B.2.2 Production of the specimens . 50 B.2.3 Test procedure and climate conditions . 51 B.2.4 Requirements . 52 B.2.5 Test report . 52 Annex C (normative)

Delamination test of glue lines between layers . 53 C.1 Principle . 53 C.2 Apparatus . 53 C.2.1 Pressure vessel . 53 C.2.2 Drying duct . 53 C.2.3 Balance . 53 C.2.4 Metal wedge and hammer . 53 C.3 Sampling and preparation of test pieces . 53 C.4 Procedures . 54 C.4.1 General . 54 C.4.2 Measurement and evaluation of delamination . 54 C.4.3 Test cycle . 55 C.5 Results . 55 C.5.1 General . 55 C.5.2 Total delamination . 55 C.5.3 Maximum delamination . 56 C.5.4 Wood failure percentage . 56 C.6 Test report . 56 Annex D (normative)

Shear tests . 57 D.1 Principle . 57 D.2 Apparatus . 57 D.2.1 Testing machine . 57 D.2.2 Shearing tool . 57 D.3 Test pieces . 58 D.3.1 General . 58 D.3.2 Test pieces for edge bonds in timber layers . 58 D.3.3 Test pieces for glue lines between layers . 58 D.3.4 Test pieces for testing single glue lines within cross laminated timber . 60 D.3.5 Sampling of test pieces . 60 D.3.6 Marking of test pieces . 61 D.4 Procedure . 61 D.5 Results . 61 D.6 Test report . 62 SIST EN 16351:2015

Tests with laminations with or without finger joints (including compliance criteria) . 63 E.1 Sampling . 63 E.1.1 General . 63 E.1.2 For type testing . 63 E.1.3 For factory production control . 63 E.2 Testing . 63 E.2.1 General . 63 E.2.2 Additional requirements for type testing . 63 E.2.3 Additional requirements for factory production control . 63 E.3 Compliance criteria of finger joints in laminations . 64 E.3.1 For type testing . 64 E.3.2 For factory production control . 64 E.4 Report of tests with finger joints in laminations . 64 E.5 Tests with laminations without finger joints . 65 Annex F (normative)

Determination of strength, stiffness and density properties of cross laminated timber . 66 F.1 Indices . 66 F.2 General . 69 F.2.1 Sampling . 69 F.2.2 Specimens . 69 F.2.3 Testing . 69 F.2.4 Analysis of test results . 70 F.2.5 Test reports . 70 F.3 Characteristics determined by tests with loads perpendicular to the plane . 70 F.3.1 Bending test . 70 F.3.2 (Rolling) shear strength and stiffness derived from bending tests . 71 F.3.3 (Rolling) shear strength and stiffness derived from shear test (alternative test method) . 72 F.3.4 Compression perpendicular to the plane . 74 F.3.5 Large finger joint - Bending test . 74 F.4 Characteristics determined by tests with in-plane loads . 75 F.4.1 Bending . 75 F.4.2 Shear values within a layer – net cross section . 76 F.4.3 Shear values for glue lines between layers – torsional shear . 77 F.4.4 Shear stiffness for cross laminated timber in plane by bending test . 78 F.4.5 Large finger joint - Bending test . 79 Annex G (normative)

Measurement of moisture content . 80 G.1 General . 80 G.2 Measurement of moisture content of boards during production . 80 G.3 Mean moisture content of cross laminated timber made from timber laminations . 80 Annex H (normative)

Separation tests with finger joints in laminations produced with contact-free application of adhesive . 81 Annex I (normative)

Minimum production requirements . 82 I.1 Personnel . 82 I.2 Production and storage facilities . 82 I.2.1 General . 82 I.2.2 Facilities for drying and storage of timber . 82 I.2.3 Facilities for processing and storage of adhesives . 82 I.2.4 Facilities for production and curing . 82 I.3 Equipment . 83 I.4 Finger joints in laminations . 83 SIST EN 16351:2015

Clauses of this European Standard addressing the requirements of the EU Construction Products Regulation . 90 Bibliography . 102

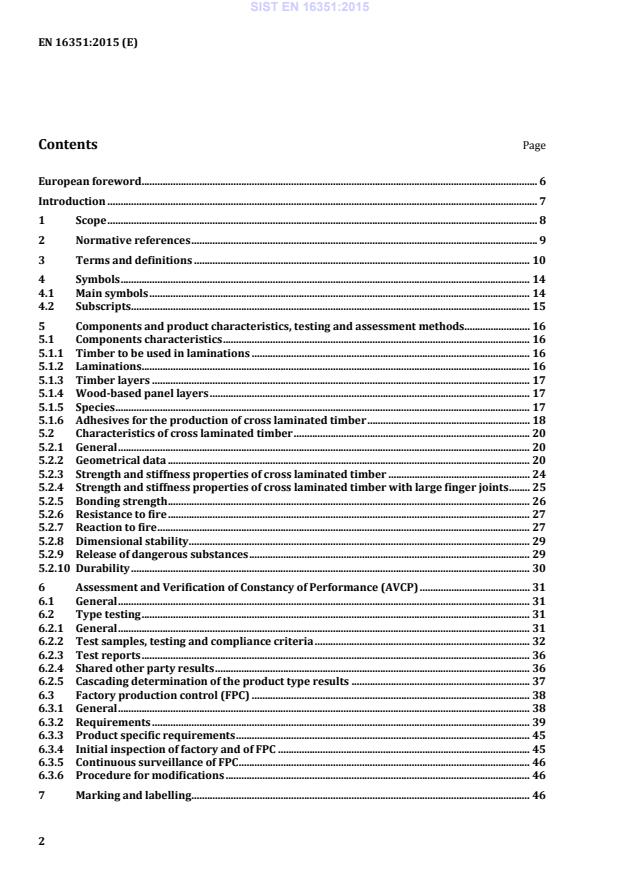

Key 1 boards 6 glued laminated timber (glulam) 2 is a component for 7 glulam with large finger joints 3 structural finger jointed timber 8 block glued glulam 4 glued laminated products 9 cross laminated timber (X-Lam) 5 glued solid timber 10 cross laminated timber (X-Lam) with large finger joints Figure 1 — Relation of European Standards prepared by CEN/TC 124 SIST EN 16351:2015

of each side of the fingers of a finger joint Note 1 to entry: See Figure 2. 3.9 finger joint interlocking end joint formed by machining a number of similar, tapered, symmetrical fingers in the ends of timber components using a finger joint cutter and then bonded together Note 1 to entry: In this European Standard the term finger joint is used for finger joints in laminations whereas finger joints between cross laminated timber are defined as large finger joints (see 3.13). SIST EN 16351:2015

Key lj finger length p pitch

finger angle lt tip gap bcut tip width of the cutter bt tip width 1 slot base Figure 2 — Typical profile of a finger joint 3.10 finger length distance lj between the finger base and the tip of the finger, measured along the centre line of the finger Note 1 to entry: See Figure 2. 3.11 finished thickness thickness after planing 3.12 laminations structural timber boards, finger jointed unless the length of a single board matches the lamination length, being part of timber layers in cross laminated timber 3.13 large finger joint finger joint through the full cross sectional area of two cross laminated timber pieces Note 1 to entry: See Figure 3.

Figure 3 — Cross laminated timber with large finger joints SIST EN 16351:2015

finger angle, in degree (see Figure 2);

density, in kg/m3; v reduction factor of a finger joint. 4.2 Subscripts a actual; c compression; cor corrected; dc declared value; j properties of finger joints in laminations; k characteristic; l properties of laminations; SIST EN 16351:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...