EN 16211:2015

(Main)Ventilation for buildings - Measurement of air flows on site - Methods

Ventilation for buildings - Measurement of air flows on site - Methods

This European Standard specifies simplified methods for the measurement of air flows on site. It provides a description of the air flow methods and how measurements are performed within the margins of stipulated method uncertainties.

One measurement method is to take point velocity measurements across a cross-section of a duct to obtain the air flow. This simplified method is an alternative to the method described in ISO 3966 and EN 12599. This European Standard requests certain measurement conditions (length of straight duct and uniform velocity profile) to be met to achieve the stipulated measurement uncertainties for the simplified method.

Lüftung von Gebäuden - Luftvolumenstrommessung in Lüftungssystemen - Verfahren

Diese Norm gilt für die Messung von Luftvolumenströmen in Lüftungssystemen. Sie legt eine Beschreibung der Verfahren für Luftvolumenströme dar und wie Messungen innerhalb der für das Verfahren vorgeschriebenen Toleranzen durchgeführt werden.

Ein Messverfahren beruht auf der Messung von Punktgeschwindigkeiten über einen Querschnitt einer Luftleitung, um die Luftvolumenströmung zu bestimmen. Dieses vereinfachte Verfahren ist eine Alternative zu demn in ISO 3966 und EN 12599 beschriebenen Verfahren. Diese Norm setzt bestimmte Messumgebungen voraus (Länge gerader Luftleitungen und einheitliches Geschwindigkeitsprofil), die eingehalten werden müssen, um die vorgeschriebenen Toleranzen des vereinfachten Verfahrens zu erreichen.

Systèmes de ventilation pour les bâtiments - Mesurages de débit d'air dans les systèmes de ventilation - Méthodes

La présente Norme européenne spécifie des méthodes simplifiées pour le mesurage des débits d’air sur site. Elle fournit une description des méthodes de débit d’air et indique la façon dont les mesurages sont réalisés dans les marges d'incertitude de la méthode stipulée.

Une méthode de mesurage consiste en la prise de mesurages de la vitesse des points sur une section transversale d’un conduit afin d’obtenir le débit d’air. Cette méthode simplifiée est une variante de la méthode décrite dans l’ISO 3966 et l’EN 12599. La présente Norme européenne nécessite que certaines conditions de mesure (longueur de conduit droit et profil de vitesse uniforme) soient satisfaites afin d’obtenir les incertitudes de mesure spécifiées pour la méthode simplifiée.

Prezračevanje stavb - Meritve pretoka zraka v sistemu prezračevanja - Metode

Ta evropski standard določa poenostavljene metode za meritve pretoka zraka v sistemu prezračevanja. Podaja opis načinov pretoka zraka in kako se izvajajo meritve znotraj mejnih vrednosti negotovosti predpisane metode.

Pri eni merilni metodi je treba za izračun pretoka zraka meritve hitrosti točke prenesti prek preseka cevi. Ta poenostavljena metoda je alternativa metodi, opisani v standardih ISO 3966 in EN 12599. Ta evropski standard zahteva, da so izpolnjeni nekateri merilni pogoji (dolžina ravne cevi in enoten hitrostni profil), da je mogoče doseči predpisane merilne negotovosti za poenostavljeno metodo.

General Information

- Status

- Withdrawn

- Publication Date

- 30-Jun-2015

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 156 - Ventilation for buildings

- Drafting Committee

- CEN/TC 156/WG 4 - Air terminal devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 13-Nov-2024

- Completion Date

- 14-Apr-2025

Relations

- Replaced By

EN 16211:2024 - Ventilation for buildings - Measurement of air flow rates on site - Methods - Effective Date

- 19-Jan-2023

Frequently Asked Questions

EN 16211:2015 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ventilation for buildings - Measurement of air flows on site - Methods". This standard covers: This European Standard specifies simplified methods for the measurement of air flows on site. It provides a description of the air flow methods and how measurements are performed within the margins of stipulated method uncertainties. One measurement method is to take point velocity measurements across a cross-section of a duct to obtain the air flow. This simplified method is an alternative to the method described in ISO 3966 and EN 12599. This European Standard requests certain measurement conditions (length of straight duct and uniform velocity profile) to be met to achieve the stipulated measurement uncertainties for the simplified method.

This European Standard specifies simplified methods for the measurement of air flows on site. It provides a description of the air flow methods and how measurements are performed within the margins of stipulated method uncertainties. One measurement method is to take point velocity measurements across a cross-section of a duct to obtain the air flow. This simplified method is an alternative to the method described in ISO 3966 and EN 12599. This European Standard requests certain measurement conditions (length of straight duct and uniform velocity profile) to be met to achieve the stipulated measurement uncertainties for the simplified method.

EN 16211:2015 is classified under the following ICS (International Classification for Standards) categories: 17.120.10 - Flow in closed conduits; 91.140.30 - Ventilation and air-conditioning systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16211:2015 has the following relationships with other standards: It is inter standard links to EN 16211:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase EN 16211:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Lüftung von Gebäuden - Luftvolumenstrommessung in Lüftungssystemen - VerfahrenSystèmes de ventilation pour les bâtiments - Mesurages de débit d'air dans les systèmes de ventilation - MéthodesVentilation for buildings - Measurement of air flows on site - Methods91.140.30VLVWHPLVentilation and air-conditioningICS:Ta slovenski standard je istoveten z:EN 16211:2015SIST EN 16211:2015en,fr,de01-september-2015SIST EN 16211:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16211

July 2015 ICS 17.120.10; 91.140.30 English Version

Ventilation for buildings - Measurement of air flows on site - Methods

Systèmes de ventilation pour les bâtiments - Mesurages de débit d'air dans les systèmes de ventilation - Méthodes

Lüftung von Gebäuden - Luftvolumenstrommessung in Lüftungssystemen - Verfahren This European Standard was approved by CEN on 5 March 2015.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2015 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 16211:2015 ESIST EN 16211:2015

.......................................................................................................................................... 7 4.4 Dynamic pressure, pd ............................................................................................................................ 7 4.5 Corrections for air density,

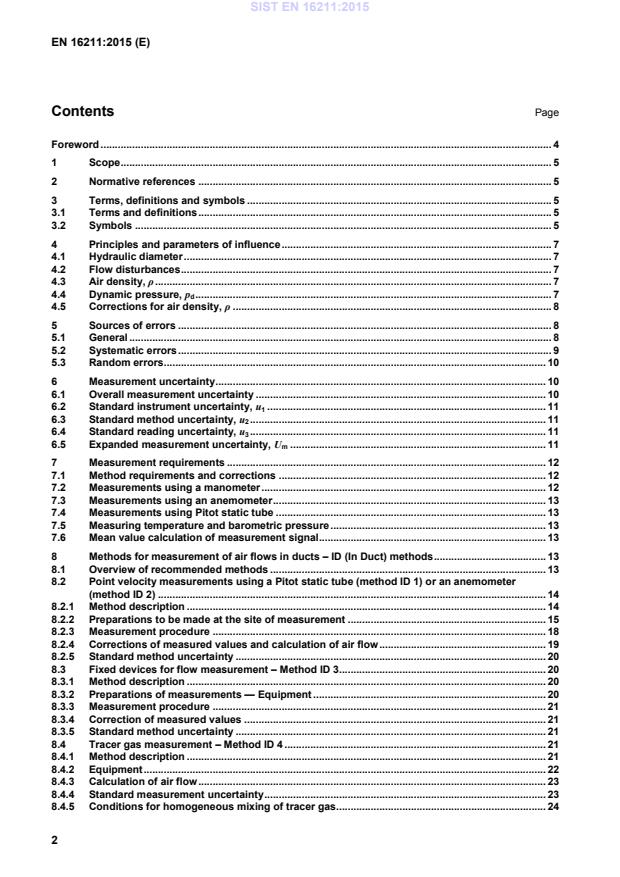

............................................................................................................... 8 5 Sources of errors .................................................................................................................................. 8 5.1 General ................................................................................................................................................... 8 5.2 Systematic errors .................................................................................................................................. 9 5.3 Random errors ..................................................................................................................................... 10 6 Measurement uncertainty ................................................................................................................... 10 6.1 Overall measurement uncertainty ..................................................................................................... 10 6.2 Standard instrument uncertainty, u1 ................................................................................................. 11 6.3 Standard method uncertainty, u2 ....................................................................................................... 11 6.4 Standard reading uncertainty, u3 ....................................................................................................... 11 6.5 Expanded measurement uncertainty, Um ......................................................................................... 11 7 Measurement requirements ............................................................................................................... 12 7.1 Method requirements and corrections ............................................................................................. 12 7.2 Measurements using a manometer ................................................................................................... 12 7.3 Measurements using an anemometer ............................................................................................... 13 7.4 Measurements using Pitot static tube .............................................................................................. 13 7.5 Measuring temperature and barometric pressure ........................................................................... 13 7.6 Mean value calculation of measurement signal ............................................................................... 13 8 Methods for measurement of air flows in ducts – ID (In Duct) methods ....................................... 13 8.1 Overview of recommended methods ................................................................................................ 13 8.2 Point velocity measurements using a Pitot static tube (method ID 1) or an anemometer (method ID 2) ....................................................................................................................................... 14 8.2.1 Method description ............................................................................................................................. 14 8.2.2 Preparations to be made at the site of measurement ..................................................................... 15 8.2.3 Measurement procedure .................................................................................................................... 18 8.2.4 Corrections of measured values and calculation of air flow .......................................................... 19 8.2.5 Standard method uncertainty ............................................................................................................ 20 8.3 Fixed devices for flow measurement – Method ID 3 ........................................................................ 20 8.3.1 Method description ............................................................................................................................. 20 8.3.2 Preparations of measurements — Equipment ................................................................................. 20 8.3.3 Measurement procedure .................................................................................................................... 21 8.3.4 Correction of measured values ......................................................................................................... 21 8.3.5 Standard method uncertainty ............................................................................................................ 21 8.4 Tracer gas measurement – Method ID 4 ........................................................................................... 21 8.4.1 Method description ............................................................................................................................. 21 8.4.2 Equipment ............................................................................................................................................ 22 8.4.3 Calculation of air flow ......................................................................................................................... 23 8.4.4 Standard measurement uncertainty .................................................................................................. 23 8.4.5 Conditions for homogeneous mixing of tracer gas ......................................................................... 24 SIST EN 16211:2015

Uncertainties . 37 A.1 Examples of calculations . 37 A.2 Compound uncertainties . 38 A.3 Example of applications . 38 Bibliography . 39

Density kg/m3 p Pressure Pa s Standard conditions air density = 1,2 kg/m3 pd Dynamic pressure Pa r Real density kg/m3 ps Static pressure Pa ¡ tracer Tracer gas density kg/m3 pt Total pressure Pa ¡ duct Duct air density kg/m3 pu Measured pressure Pa A Cross-section Area m2 ûp Differential pressure Pa a, b, c, etc. Dimensions of length mm ûpu Measured differential pressure Pa L Mixing length mm q Air flow m3/s, l/s H Height of duct mm qk Corrected air flow m3/s, l/s W Width of duct mm qs Tracer gas flow m3/s, l/s B Barometric pressure hPa qs¡duct Tracer gas flow at duct temperature m3/s, l/s C Contaminant concentration ppm qstracer Tracer gas flow at rotameter temperature m3/s, l/s Ci Initial tracer gas concentration ppm qt Total air flow m3/s, l/s Cs Tracer gas concentration in stationary condition ppm qu Measured air flow m3/s, l/s D Diameter mm Ç Temperature °C Dh Hydraulic diameter mm Çduct Temperature in duct °C kc coverage factor - Çtracer=Temperature of tracer gas °C k1 Correction factor for density - V Volume m3 k2 Correction factor for duct shape - v Air velocity m/s k Flow factor - vs Standard air velocity m/s L1 Smaller dimension of a rectangular duct mm vr Real air velocity m/s L2 Larger dimension of a rectangular duct mm vm Air velocity, mean value m/s u1 Standard Instrument uncertainty -

u2 Standard Method uncertainty -

u3 Standard Reading uncertainty -

um Standard measurement uncertainty -

Um Expanded measurement uncertainty -

(1) For a rectangular duct this becomes: Dh = 2 „ L1 „ L2 / (L1+ L2)

(2) where

L1 and L2

are the sides of the duct. For a circular duct this becomes: Dh = D

(3) 4.2 Flow disturbances Flow disturbances in ducts result in irregular velocity profiles. NOTE Flow seldom has a symmetrical appearance except after long straight sections. The symmetry is often disturbed by varying resistance, for example after a bend, an area decrease or an area increase. The velocity profile also becomes disturbed by a damper and T-piece as well as before and after a fan. 4.3 Air density,

The density of dry air varies with air pressure and temperature in accordance with the following approximating formula: 27315129310132527315,,,,Bρϑ=⋅⋅+ (4) NOTE The relative humidity of the air (RH) has very little influence on the density of air at room temperature. The density of air at 20 °C and 1 013,25 hPa which is saturated with water vapour is only approximately 1 % less than equivalent dry air. In a low-pressure system it is hardly necessary to consider the influence of static pressure on air density. In a high-pressure system, however, it can be necessary. The calculation is then performed as follows: 00127315129310132527315,,,,,sBpρϑ+⋅=⋅⋅+ (5) 4.4 Dynamic pressure, pd When measuring with a Pitot static tube a dynamic pressure is measured. The dynamic pressure can be used to calculate the air velocity by the use of the following formula: 22dp⋅= (6) SIST EN 16211:2015

When presenting a measured air flow or velocity, it should be stated if it is the real air flow or the flow converted to standard conditions that is presented. The measurements should correspond to the designed air flow values of the system (real or standard air flow). The methods in this standard present the measurements as real air flow. How to convert between standard and real velocity is described in 4.5. The same conversion is also valid for air flow. The real flow rate of air is as it is at the present temperature and barometric pressure of the air. Standard air flow is used to present the air flow at standard condition of 1 013,25 hPa and 20 °C. A fan transports approximately the same amount of air independent of air density. The amount of standard flow changes with air density. The instrument in use can measure real or standard air flow or it could require calibration conditions to display correctly. Compensate accordingly, especially when used for other conditions than calibration condition or standard conditions of 1 013,25 hPa and 20 °C. The barometric pressure will decrease with altitude and also vary with weather. Convert real flow or velocity to standard flow or velocity by using the following formula: vs = vr „ r / s (7) 5 Sources of errors 5.1 General There are many factors which affect the measurement results which shall be checked in connection with measuring. These factors are for example: a)

calibration equipment, which shall be regularly compared with a traceable norm (calibration unit); b)

calibrated measurement instruments; c)

calibration intervals; d)

examination of instruments’ long term stability; e)

instruments’ temperature or density compensation; f)

random instrument uncertainties; g)

random reading uncertainties; h)

variations in the measured quantity; i)

measurement methods adapted to different installation cases; j)

random uncertainties in measurement methods; k)

measurement methods’ influence on the flow rate; l)

variations in the exterior climate; m)

air flow stability. SIST EN 16211:2015

Key 1 systematic Error X time Y value Figure 1 — Explanation of systematic error The circles represent measured numbers which lie randomly spread around the true value and which according to the definition are thus free from systematic errors. The crosses represent results of measurements where the measured numbers lie too high, for example as a result of an uncalibrated measuring instrument being used. This error can easily be rectified by calibrating the instrument and determining a correction. The following applies to a correction: Correction = (estimate of true value) – (read value) or (Read value) + (correction) = estimate of true value Estimates of true values are also often called measured values. To make corrections it is recommended to add a correction value (positive or negative) instead of multiplying with a correction factor. Calibration is a part of the determination of the systematic errors of an instrument, which allows the understanding of the calibration uncertainty, to eventually set up the instrument or correct the measurements and by its repetition to assess the drift uncertainty. SIST EN 16211:2015

(8) where

u1, u2 and u3

are random standard uncertainties with a coverage probability of approximately 68 %; u1 is the standard instrument uncertainty, such as hysteresis, temperature compensation, drift, etc. The instrument uncertainty is normal distributed; u2 is the standard method uncertainty, resulting from deviations from the calibration method for the measurement method. In this type are also included deviations from the calibration curve for series-produced measurement devices, dampers or terminals with in-built measurement outlets. The method uncertainty is normal distributed; u3 is the standard reading uncertainty. The reading uncertainty is rectangular distributed for digital instruments. SIST EN 16211:2015

(11) where

kc = 2 7 Measurement requirements 7.1 Method requirements and corrections The measurement methods which are used shall have small method uncertainties. The requirements for method uncertainties shall be to some extent related to the requirement for flow tolerances. A measurement shall be based on a well-defined method, in which both measurement points as well as the measuring instrument shall be decided. This does not mean that certain selected instruments should be standardized, but that there is a decided procedure with norms for the instrument to be used. Measurement values are evaluated in a specified way for the method chosen, after which the values are corrected for the method. A correction factor is commonly used at this point, from which: Correct value = (measured value) · (correction factor for the method) 7.2 Measurements using a manometer When measuring with a manometer, minimum resolution and maximum uncertainty should apply, in accordance with Table 1. Table 1 — Resolution for the ranges of manometers Range Pa Resolution Pa Uncertainty Up to and including 50 Above 50 0,1 1 0,5 Pa ± 0,5 % of reading The lowest acceptable measured pressure is 3 Pa if the manometer has not lower uncertainty than stated in Table 1. The manometer should be:

a) zeroed before each measurement; or

b) equipped with a function which automatically zeroes the instrument: 1) after a certain time period; or 2) before each measurement; or 3) compensates the measurement with the offset checked with a following auto zero. SIST EN 16211:2015

It is linked to the minimum acceptable pressure measurement (see 7.2). Any other tube with equivalent or higher accuracy can also be used in conjunction with this standard. 7.5 Measuring temperature and barometric pressure To make the measurement use, for example, a resistance thermometer or thermo-couples. Instruments shall have a resolution better than 0,1 °C and be calibrated to an accuracy of ± 0,3 °C or better. To take measurements of barometric pressure a barometer with a resolution of 1 hPa and an accuracy of ± 5 hPa or better should be used. No corrections for air density are required during the proportional balancing of terminals and branch ducts providing that the entire installation is balanced under the same running conditions. For this reason, heaters in terminals and branch ducts, for example, shall be switched off. Heating or cooling devices in the duct between the fan and the place of measurement shall be switched off while measuring air flow or air velocity. 7.6 Mean value calculation of measurement signal In order to eliminate reading uncertainties as much as possible, instruments with a mean value calculation function should be used. The instrument shall calculate the mean value from a minimum of 15 readings that are a minimum of 0,1 s apart. 8 Methods for measurement of air flows in ducts – ID (In Duct) methods 8.1 Overview of recommended methods An overview of recommended methods is given in Table 2. SIST EN 16211:2015

1) Circular cross-section ID 11

4 % (case A) – 6 % (case B) 2) Rectangular cross-section ID 12

4 % Point measurement using hot-wire anemometer or mechanical anemometer: ID 2 8.2

1)

Circular cross-section ID 21

4 % (case A) – 6 % (case B) 2)

Rectangular cross-section ID 22

4 % Fixed flow measurement devices: ID 3 8.3 5 % (Applies generally using the installation measurements obtained with testing method) 1) Without damper ID 31

2) With damper ID 32

Tracer gas ID 4 8.4 5 % or 10 % depending on mixing length 8.2 Point velocity measurements using a Pitot static tube (method ID 1) or an anemometer (method ID 2) 8.2.1 Method description This method involves the flow being calculated from a series of velocity measurements in the duct cross-section. The determination of velocity is carried out using a Pitot static (Prandtl) tube or anemometer. For the Pitot static tube the velocity is calculated from the differential pressure measurement. Any other tube for air velocity measurement with equivalent or higher accuracy than a Pitot static tube can also be used. A Pitot static tube measures both total and static pressure. It consists in principle of a tube placed inside another tube. Both the static and the dynamic pressure enter the orifice of the inner tube. In order for the measurement result to be correct, the orifice shall point directly into the axis of flow. The static pressure is measured through holes in the mantle surface of the outer tube. The principles involved in making measurements with a Pitot static tube are illustrated in Figure 2. SIST EN 16211:2015

Key 1 connection for static pressure 2 connection for total pressure Figure 2 — Measurements with Pitot static tubes The following relationship can be established for the pressure conditions at the connections for total and static pressure: Connection for total pressure: 22sdspppp⋅=+=+ (12) Connection for static pressure: p = ps (13) The differential pressure obtained by connecting both outlets to a manometer is: 22dp⋅= (14) The air velocity can be determined from this dynamic pressure: 2dpv⋅= (15) 8.2.2 Preparations to be made at the site of measurement 8.2.2.1 Equipment For this method a manometer with Pitot static tube for use above 2,5 m/s or anemometer, both with indication of insertion length and a thermometer and barometer are needed. SIST EN 16211:2015

200 250 315 400 a = 0,10·D b = 0,50·D c = 0,90·D 20 25 32 40 100 125 158 200 180 225 283 360

500 630 800 1 000 1 250 a = 0,043·D b = 0,290·D c = 0,710·D d = 0,957·D 22 27 34 43 54 145 185 230 290 360 355 445 570 710 890 478 603 766 957 1 196

a According to duct standard. Table 5 — Measurement points for rectangular ducts related to the longer dimension: L2 150 ≤ L2 ≤ 300 mm 300 < L2 ≤ 2 000 mm a = 0,08·L2 c = 0,57·L2 b = 0,43·L2

d = 0,92·L2 a = 0,06·L2

d = 0,57·L2 b = 0,235·L2 e = 0,765·L2

c = 0,43·L2 f = 0,94·L2 Table 6 — Measurements points for rectangular ducts related to the longer dimension — Values recalculated in accordance with L2 L2 150 200 250 300 400 500 600 800 1 000 1 200 1 400 1 600 1 800 2 000 a 13 16 20 25 25 30 35 50 60 70 85 95 110 120 b 65 85 110 130 95 120 140 190 235 280 330 375 420 470 c 85 115 140 170 170 215 260 345 430 515 600 690 775 860 d 137 184 230 275 230 285 340 455 570 685 800 910 1 025 1 140 e - - - - 305 380 460 610 765 920 1 070 1 225 1 380 1 530 f - - - - 380 470 565 750 940 1 130 1 315 1 505 1 690 1 880 SIST EN 16211:2015

3) Ensure that the lighting is good at the place of measurement. 4) Drill holes in the duct so that measurements can be made along lines in a cross-section. The cross-section shall be perpendicular to the axis of the duct. For circular ducts: The two lines shall be perpendicular to each other. In case A, one of the lines of points is placed in the same plane as the axis of the duct and the centre of the bent upstream the duct. If this is impossible (e.g. access restriction) use two other perpendicular lines in the cross-section case B. Note that the uncertainty is higher in case B. The reasons for the increase of uncertainty in case B is that the flow profile is different from case A and that the location of the probe is more difficult in comparison with case A. In Figure 3, cases A and B are shown for a horizontal duct with horizontal and/or vertical ducts upstream.

Figure 3 — Cases A and B — Cross-section of a horizontal duct — A bent upstream is in a horizontal or vertical plane 8.2.3 Measurement procedure It is important that the Pitot static tube is kept parallel to the direction of flow (if oblique to the flow, this results in either too low or too high readings) and at the correct point of measurement. First determine the velocity distribution as described: Measure the dynamic pressure in the centre of the cross-section. Search for the position of highest dynamic pressure and note both its value and location. If this maximum pressure is located further from the duct wall than 0,1 D (0,1 Dh) and the maximum dynamic pressure is less than two times the dynamic pressure in the centre (anemometer: the maximum velocity is less than 1,4 × the velocity in the centre), and if no backflow is detected in the cross-section, the plane of measurement is approved. Measurement points are selected as in Table 4 for circular ducts and as in Tables 5 to 7 for rectangular ducts and the measurement is made. If these three criteria are not met, a new plane of measurement is selected. If no plane of measurement is found that meets these three criteria, measurements should not be made according to this method (ID 2) whether by means of a Pitot static tube or by means of an anemometer. SIST EN 16211:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...