EN 14336:2004

(Main)Heating systems in buildings - Installation and commissioning of water based heating systems

Heating systems in buildings - Installation and commissioning of water based heating systems

This European Standard specifies the requirements for the installation and commissioning of water-based heating systems in buildings with a maximum operating temperature of 110 oC and a maximum operating pressure of 6 bar.

This standard covers the system's requirements for the installation and commissioning of individual components of the system (e.g. heat generators, pumps, controls). It does not cover the specific commissioning requirements for these components.

This standard does not cover the installation or commissioning of attached systems (e.g. air conditioning, domestic hot water or ventilation systems).

This standard covers only the technical requirements, and does not cover any commercial or contractual arrange-ments between parties.

Heizungsanlagen in Gebäuden - Installation und Abnahme der Warmwasser-Heizungsanlagen

Diese Norm legt Anforderungen für die Installation und die Abnahme von Warmwasserheizungsanlagen in Gebäuden mit einer maximalen Betriebstemperatur bis 110°C und einem maximalen Betriebsdruck von 6 bar fest.

Diese Norm gilt nicht für die Installation und die Abnahme von zugeschalteten Anlagen (z. B. Klimaanlagen, Hauswasseranlagen oder Lüftungsanlagen).

Diese Norm legt nur die technischen Voraussetzungen fest und regelt nicht das vertragliche Verhältnis zwischen Auftraggeber und Auftragnehmer (Planer und Ausführenden).

Systèmes de chauffage dans les bâtiments - Installation et commissionnement des systèmes de chauffage à eau

Le présent document spécifie les exigences relatives à l'installation et au commissionnement des systèmes de chauffage à eau des bâtiments fonctionnant avec une température maximale de 110 °C et une pression maximale de fonctionnement de 6 bars.

Le présent document couvre les spécifications pour l'installation et le commissionnement des composants du système (par exemple les générateurs, circulateurs, régulateurs). Il ne concerne pas les opérations de commissionnement spécifiques à ces composants.

La présente norme ne couvre pas l'installation ou le commissionnement des systèmes connexes (p.ex. systèmes de conditionnement d'air, de production d'eau chaude domestique ou de ventilation).

Le présent document couvre les spécifications techniques, il ne concerne pas les accords contractuels ou commerciaux entre les parties.

Ogrevalni sistemi v stavbah - Vgradnja in zagon toplovodnih sistemov

General Information

- Status

- Withdrawn

- Publication Date

- 05-Oct-2004

- Withdrawal Date

- 22-Sep-2025

- Technical Committee

- CEN/TC 228 - Heating systems in buildings

- Drafting Committee

- CEN/TC 228/WG 2 - Installation and commissioning

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 04-Jun-2025

- Completion Date

- 23-Sep-2025

Relations

- Effective Date

- 05-Apr-2023

- Effective Date

- 29-Aug-2018

Frequently Asked Questions

EN 14336:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Heating systems in buildings - Installation and commissioning of water based heating systems". This standard covers: This European Standard specifies the requirements for the installation and commissioning of water-based heating systems in buildings with a maximum operating temperature of 110 oC and a maximum operating pressure of 6 bar. This standard covers the system's requirements for the installation and commissioning of individual components of the system (e.g. heat generators, pumps, controls). It does not cover the specific commissioning requirements for these components. This standard does not cover the installation or commissioning of attached systems (e.g. air conditioning, domestic hot water or ventilation systems). This standard covers only the technical requirements, and does not cover any commercial or contractual arrange-ments between parties.

This European Standard specifies the requirements for the installation and commissioning of water-based heating systems in buildings with a maximum operating temperature of 110 oC and a maximum operating pressure of 6 bar. This standard covers the system's requirements for the installation and commissioning of individual components of the system (e.g. heat generators, pumps, controls). It does not cover the specific commissioning requirements for these components. This standard does not cover the installation or commissioning of attached systems (e.g. air conditioning, domestic hot water or ventilation systems). This standard covers only the technical requirements, and does not cover any commercial or contractual arrange-ments between parties.

EN 14336:2004 is classified under the following ICS (International Classification for Standards) categories: 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14336:2004 has the following relationships with other standards: It is inter standard links to EN 14336:2025, prEN 14336. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14336:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ogrevalni sistemi v stavbah - Vgradnja in zagon toplovodnih sistemovHeizungsanlagen in Gebäuden - Installation und Abnahme der Warmwasser-HeizungsanlagenSystemes de chauffage dans les bâtiments - Installation et commissionnement des systemes de chauffage a eauHeating systems in buildings - Installation and commissioning of water based heating systems91.140.10Sistemi centralnega ogrevanjaCentral heating systemsICS:Ta slovenski standard je istoveten z:EN 14336:2004SIST EN 14336:2005en01-marec-2005SIST EN 14336:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14336October 2004ICS 91.140.10 English versionHeating systems in buildings - Installation and commissioning ofwater based heating systemsSystèmes de chauffage dans les bâtiments - Installation etmise en systèmes de chauffage à eauHeizungsanlagen in Gebäuden - Installation und Abnahmeder Warmwasser-HeizungsanlagenThis European Standard was approved by CEN on 29 July 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14336:2004: ESIST EN 14336:2005

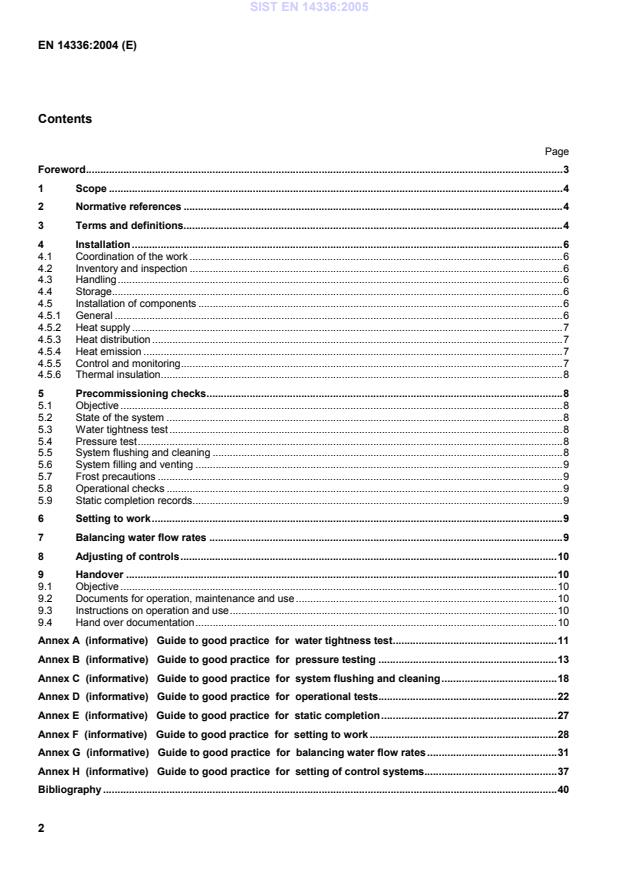

(informative)

Guide to good practice

for

water tightness test.11 Annex B

(informative)

Guide to good practice

for

pressure testing.13 Annex C

(informative)

Guide to good practice

for

system flushing and cleaning.18 Annex D

(informative)

Guide to good practice

for

operational tests.22 Annex E

(informative)

Guide to good practice

for

static completion.27 Annex F

(informative)

Guide to good practice

for

setting to work.28 Annex G

(informative)

Guide to good practice

for

balancing water flow rates.31 Annex H

(informative)

Guide to good practice

for

setting of control systems.37 Bibliography.40

EN 61082-3; — records about pressure and functional testing; — records about environmental testing, e.g. flue gas testing; — balancing report.

(informative)

Guide to good practice

for

water tightness test A.1 General The Contractor shall test the heating system for water tightness after installation but before insulating pipework, covering of shafts or openings in the walls and ceilings as well as before covering a floor heating system with screed or other coverings. A.2 Procedure For doing the water tightness test, the system shall be filled with filtered water starting from the lowest point (filling valve) up to the highest point and shall be vented. Having filled the system, the vents shall be shut and the system shall be checked for water tightness. In case of doing the water tightness test with inert gas, the safety requirements for each test shall be met and all connections to appliances and joints shall be checked for water tightness with soap water. The heating system is tight if no water is escaping or, in case of testing by inert gas, no bubbles can be seen or heard. A.3 Documentation After the water tightness test, a record shall be prepared containing the following information: — date of test; — data on the heating system, including position in the building and maximum operational pressure; — test pressure; — time period of water tightness test; — confirmation that the system is watertight and that no permanent deformation was found. See Typical Water Tightness Test Report, Form A1. These reports should be passed to the technical author of the OM&U instructions in accordance with the system designer's requirements. SIST EN 14336:2005

TYPICAL WATER TIGHTNESS TEST REPORT

FORM A1

PROJECT: . REF: . ADDRESS: .

...................................................................................................... CLIENT NAME: ...................................................................................................... ADDRESS: ......................................................................................................

...................................................................................................... SYSTEM TESTED: ...................................................................................................... SECTION OF SYSTEM TESTED: ...................................................................................................... PLANT TESTED: ...................................................................................................... TYPE OF TEST (HYDRAULIC OR PNEUMATIC): ...................................................................................................... TEST PRESSURE (BAR): ...................................................................................................... TIME PERIOD (HOURS): ...................................................................................................... WORKING PRESSURE (BAR): ...................................................................................................... TEMPERATURE (°°°°C): ......................................................................................................

RESULTS: .

......................................................................................................

...................................................................................................... CONFIRM SYSTEM/PLANT IS TIGHT AND WITHOUT DEFORMATION: ...................................................................................................... REMARKS: ......................................................................................................

......................................................................................................

...................................................................................................... QUALITY STANDARD: ......................................................................................................

......................................................................................................

SIGNED: . REPORT CARRIED OUT BY: . POSITION: . WITNESSED BY: . FOR: . DATE: .

(informative)

Guide to good practice

for

pressure testing B.1 General Pressure testing should be carried out normally by hydraulic testing using water, exceptionally by pneumatic testing using inert gas or air, and only under the carefully controlled conditions. The dangers of testing with compressible gases, such as nitrogen or air, are not always realised. At the pressure ranges normally encountered, the amount of energy stored in compressed air or gas is 200 times more than that contained in water at the same pressure and volume. This energy can be released with explosive force if a joint, pipe section, or other component fails under test pressure. For this reason, hydraulic pressure testing is by far the safer method and shall be used wherever practicable. In circumstances where pneumatic testing is unavoidable, e.g. where contamination of the interior of the vessel by water is not acceptable, stringent safety precautions shall be followed. The following procedures and safety precautions shall be observed when either pneumatic or hydraulic testing is being carried out. The testing procedures available can be summarised as follows: — hydraulic pressure test - this is the preferred method because it is the safest and should be used wherever practicable; — pneumatic leak test followed by hydraulic pressure test - this is used only where water leakage would cause unacceptable damage. Where pneumatic leak testing with air or nitrogen or by means of tracer gas is used, this testing should always be carried out before hydraulic pressure testing. B.2 Procedures B.2.1 Pre-test considerations Before beginning a particular test, the following questions shall be considered: a) Has the system been flushed? b) Is the specified test appropriate to the service and the building environment? c) Would it be advisable to test with compressed air at limited pressure before filling with water, in order to locate major faults? d) Will a water test leave undrained pockets subject to frost damage? e) Is the specified test pressure correct, e.g. in high buildings? The vertical pipework may have to be divided in order to limit pressures, but at all points a test pressure equal to 1,3 times the working pressure shall be applied. f) Have vulnerable items been blanked-off? SIST EN 14336:2005

TYPICAL PRESSURE TEST REPORT FORM B1

PROJECT: . REF: . ADDRESS: .

...................................................................................................... CLIENT NAME: ...................................................................................................... ADDRESS: ......................................................................................................

......................................................................................................

SYSTEM TESTED: . SECTION OF SYSTEM TESTED: . PLANT TESTED: . TYPE OF TEST (HYDRAULIC OR PNEUMATIC): . USED EQUIPMENT:

TEST PRESSURE (BAR): . TIME PERIOD (HOURS): . WORKING PRESSURE (BAR): . TEMPERATURE (°°°°C): .

RESULTS: .

......................................................................................................

...................................................................................................... REMARKS: ......................................................................................................

......................................................................................................

...................................................................................................... QUALITY STANDARD: ......................................................................................................

......................................................................................................

......................................................................................................

SIGNED: . REPORT CARRIED OUT BY: . POSITION: . WITNESSED BY: . FOR: . DATE: .

(informative)

Guide to good practice

for

system flushing and cleaning C.1 General Care shall be taken during construction to keep the internal surfaces of pipework systems clean. Serious blockages in equipment will prove damaging and expensive to rectify. It is, therefore, most important that the system is thoroughly cleaned of all detritus. On no account should any part of the system be drained and left empty for longer than 24 hours after cleaning, as this will promote rapid corrosion and possibly necessitate a re-clean. Frost protection systems shall be active after flushing or chemical cleaning in order to avoid damage and the loss of chemicals during cold periods. Water introduced into a building water system for commissioning purposes should be completely drained away unless the system is to be put into service immediately. It should be noted that for closed water systems, at low risk of disseminating Legionnaires' disease, this practice would be both costly and unnecessary. Chemicals for cleaning should not damage internal parts of the installation (e.g. elastomer parts) and /or trigger corrosion. C.2 Procedures C.2.1 Flushing Systems shall be cleaned and flushed in accordance with an agreed and approved method plan. Throughout the cleaning and flushing process, the carrying out of procedures in accordance with the method plan should be verified. Satisfactory compliance may be ensured by certification. Additionally, the commissioning specialist should be satisfied that the system has been adequately cleaned, by reference to the certification. The following procedure is recommended: a) flushing should be supervised only by qualified staff; b) a flushing schedule should be provided by the installation contractor and approved in accordance with the specifications, before the physical process commences; c) the schedule should be based on schematic drawings with all sub-circuits, branches, and terminals uniquely identified. All valves, coils, tubes, and other equipment liable to choking should be clearly identified; d) flushing should be carried out methodically from the top to the bottom of the system; e) equipment liable to choking should be by-passed, isolated, or completely removed and replaced by a spool piece to ensure system flow continuity; f) every effort should be made for the flushing water velocity to be generated, externally and not by use of the system pumps. It is recommended that system pumps be by-passed, isolated, or removed and the circuit completed; SIST EN 14336:2005

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...