EN 15967:2011

(Main)Determination of maximum explosion pressure and the maximum rate of pressure rise of gases and vapours

Determination of maximum explosion pressure and the maximum rate of pressure rise of gases and vapours

The European Standard test method is designed to produce measurements of explosion pressure and the maximum explosion pressure, the rate of explosion pressure rise and the maximum rate of explosion pressure rise of a quiescent flammable gas/air/inert mixture in closed volume at ambient temperature and pressure. In this European Standard, the term "gas" includes vapours but not mists. Detonation and decomposition phenomena are not considered in this European Standard.

The pressures and rates of pressure rise measured by the procedures specified in this European Standard are not applicable to flameproof enclosures, that is enclosures intended to withstand an internal explosion and not to transmit it to an external explosive atmosphere, or any other closed volume where the internal geometry can result in pressure piling. Even in an enclosure of relatively simple geometry the disposition of the internal components can lead to rates of pressure rise significantly higher than those measured using this European Standard. This European Standard does not apply to the design and testing of flameproof enclosures in conformity with EN 13463-6 (for non-electrical equipment) and EN 60079-1 (for electrical equipment).

Verfahren zur Bestimmung des maximalen Explosionsdruckes und des maximalen zeitlichen Druckanstieges für Gase und Dämpfe

Diese Europäische Norm legt ein Verfahren zur Bestimmung des Explosionsdrucks und des maximalen Explosionsdrucks sowie des zeitlichen Explosionsdruckanstieges und des maximalen zeitlichen Explosionsdruckanstieges eines ruhenden Gemischs aus brennbarem Gas (Brennstoff), Luft und Inertgas bei Umgebungsbedingungen in geschlossenen Behältern ohne Einbauten fest. In dieser Europäischen Norm schließt der Begriff „Gas“ auch Dämpfe, jedoch keine Nebel, ein. Diese Europäische Norm gilt nicht für Bedingungen, unter denen Detonations- und Zersetzungsphänomene auftreten können. Die nach den in der vorliegenden Europäischen Norm festgelegten Verfahren gemessenen Drücke und zeitlichen Druckanstiege sind für die Auslegung von druckfesten Kapselungen, das sind Umschließungen, die konstruktiv so ausgelegt sind, dass sie einer im Innern stattfindenden Explosion standhalten und diese nicht in eine äußere explosionsfähige Atmosphäre übertragen, oder anderen geschlossenen Behältern, deren innere Geometrie zu einer Drucküberhöhung führen kann, nicht anwendbar. Selbst in einer Umschließung von relativ einfacher Geometrie können Einbauten zu wesentlich höheren Explosionsdrücken als den nach dieser Europäischen Norm gemessenen führen. Diese Europäische Norm gilt nicht für die Konstruktion und Prüfung von druckfesten Kapselungen nach den Anforderungen von EN 13463-6 (für nicht elektrische Betriebsmittel) und EN 60079-1 (für elektrische Betriebsmittel).

Détermination de la pression maximale d'explosion et de la vitesse maximale de montée en pression des gaz et des vapeurs

La présente Norme européenne spécifie une méthode d'essai conçue pour fournir des mesures de la pression d'explosion et de la pression maximale d'explosion, ainsi que des mesures de la vitesse de montée en pression et de la vitesse maximale de montée en pression d'un mélange gaz inflammable/air/gaz inerte, dans un volume clos, à température et pression ambiantes. Dans la présente Norme européenne, le terme « gaz » inclut les vapeurs mais n'inclut pas les brouillards. Les phénomènes de détonation et de décomposition explosive ne sont pas pris en compte dans la présente Norme européenne. Les pressions et les vitesses de montée en pression mesurées selon les modes opératoires spécifiés dans la présente Norme européenne ne sont pas applicables aux enveloppes antidéflagrantes, c'est-à-dire aux enveloppes destinées à résister à une explosion interne et à ne pas la transmettre à l'atmosphère explosive externe ou à tout autre volume fermé où la géométrie interne peut entraîner une accumulation de pression. Même dans une enveloppe dont la géométrie est relativement simple, la disposition des éléments internes peut conduire à des vitesses de montée en pression nettement supérieures à celles mesurées selon la présente Norme européenne. La présente Norme européenne ne s’applique pas à la conception et aux essais des enveloppes antidéflagrantes conformes à l’EN 13463-6 (pour le matériel non électrique) et à l’EN 60079-1 (pour le matériel électrique).

Ugotavljanje najvišjega tlaka eksplozije in največje hitrosti naraščanja tlaka plinov in hlapov

Ta standardna preskusna metoda je zasnovana za določevanje tlaka eksplozije in najvišjega tlaka eksplozije vnetljive mešanice plin-zrak-inertni plin pri sobni temperaturi in tlaku.

Ta standardna preskusna metoda je zasnovana za merjenja stopnje tlaka eksplozije in najvišjega tlaka eksplozije vnetljive mešanice plin-zrak-inertni plin pri sobni temperaturi in tlaku.

V tem evropskem standardu izraz »plin« vključuje hlape, vendar ne meglic. Pojava detonacije in dekompozicije nista obravnavana v tem evropskem standardu.

General Information

- Status

- Withdrawn

- Publication Date

- 02-Aug-2011

- Withdrawal Date

- 08-Feb-2026

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 19-Jan-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 06-Aug-2011

- Effective Date

- 31-Jan-2018

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 15967:2011 is a standard published by the European Committee for Standardization (CEN). Its full title is "Determination of maximum explosion pressure and the maximum rate of pressure rise of gases and vapours". This standard covers: The European Standard test method is designed to produce measurements of explosion pressure and the maximum explosion pressure, the rate of explosion pressure rise and the maximum rate of explosion pressure rise of a quiescent flammable gas/air/inert mixture in closed volume at ambient temperature and pressure. In this European Standard, the term "gas" includes vapours but not mists. Detonation and decomposition phenomena are not considered in this European Standard. The pressures and rates of pressure rise measured by the procedures specified in this European Standard are not applicable to flameproof enclosures, that is enclosures intended to withstand an internal explosion and not to transmit it to an external explosive atmosphere, or any other closed volume where the internal geometry can result in pressure piling. Even in an enclosure of relatively simple geometry the disposition of the internal components can lead to rates of pressure rise significantly higher than those measured using this European Standard. This European Standard does not apply to the design and testing of flameproof enclosures in conformity with EN 13463-6 (for non-electrical equipment) and EN 60079-1 (for electrical equipment).

The European Standard test method is designed to produce measurements of explosion pressure and the maximum explosion pressure, the rate of explosion pressure rise and the maximum rate of explosion pressure rise of a quiescent flammable gas/air/inert mixture in closed volume at ambient temperature and pressure. In this European Standard, the term "gas" includes vapours but not mists. Detonation and decomposition phenomena are not considered in this European Standard. The pressures and rates of pressure rise measured by the procedures specified in this European Standard are not applicable to flameproof enclosures, that is enclosures intended to withstand an internal explosion and not to transmit it to an external explosive atmosphere, or any other closed volume where the internal geometry can result in pressure piling. Even in an enclosure of relatively simple geometry the disposition of the internal components can lead to rates of pressure rise significantly higher than those measured using this European Standard. This European Standard does not apply to the design and testing of flameproof enclosures in conformity with EN 13463-6 (for non-electrical equipment) and EN 60079-1 (for electrical equipment).

EN 15967:2011 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15967:2011 has the following relationships with other standards: It is inter standard links to EN 13673-1:2003, EN 13673-2:2005, EN 15967:2022, EN 13237:2024, EN 14373:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15967:2011 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 2014/34/EU, 94/9/EC; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15967:2011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Verfahren zur Bestimmung des maximalen Explosionsdruckes und des maximalen zeitlichen Druckanstieges für Gase und DämpfeDétermination de la pression maximale d'explosion et de la vitesse maximale de montée en pression des gaz et des vapeursDetermination of maximum explosion pressure and the maximum rate of pressure rise of gases and vapours13.230Varstvo pred eksplozijoExplosion protectionICS:Ta slovenski standard je istoveten z:EN 15967:2011SIST EN 15967:2011en,fr,de01-oktober-2011SIST EN 15967:2011SLOVENSKI

STANDARDSIST EN 13673-2:2006SIST EN 13673-1:20031DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15967

August 2011 ICS 13.230 Supersedes EN 13673-1:2003, EN 13673-2:2005English Version

Determination of maximum explosion pressure and the maximum rate of pressure rise of gases and vapours

Détermination de la pression maximale d'explosion et de la vitesse maximale de montée en pression des gaz et des vapeurs

Verfahren zur Bestimmung des maximalen Explosionsdruckes und des maximalen zeitlichen Druckanstieges für Gase und Dämpfe This European Standard was approved by CEN on 1 July 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2011 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15967:2011: ESIST EN 15967:2011

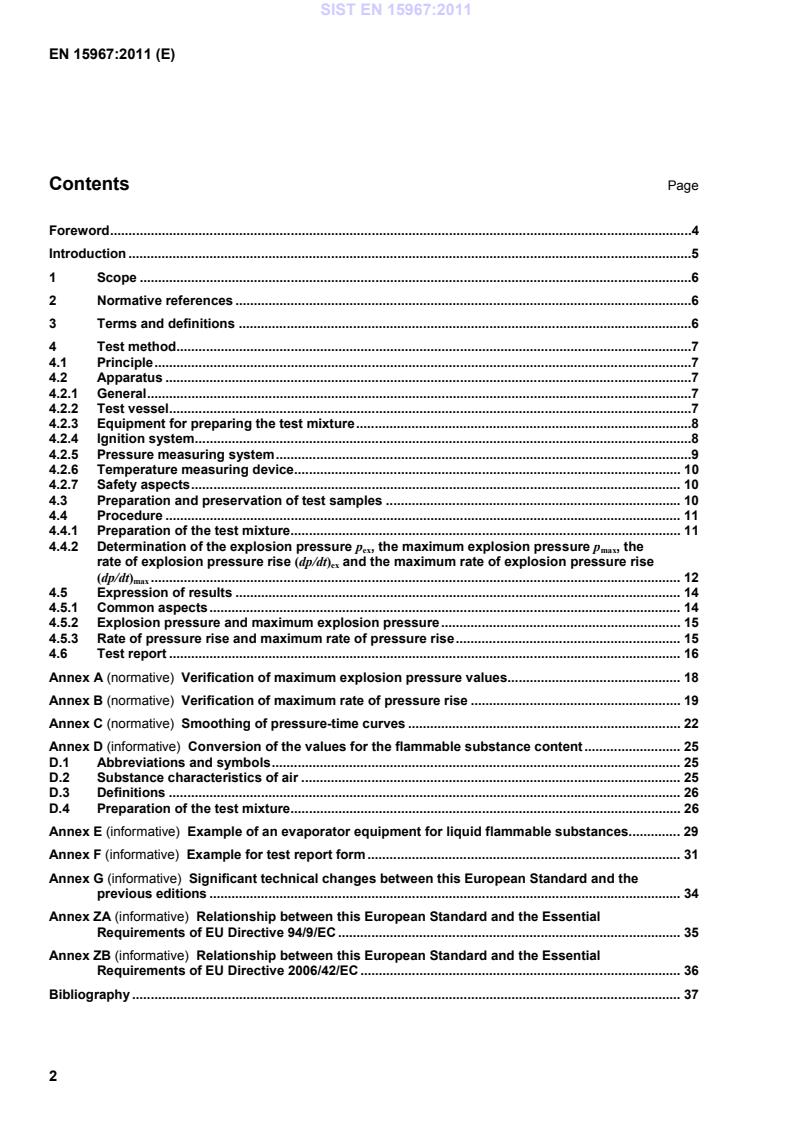

Verification of maximum explosion pressure values . 18Annex B (normative)

Verification of maximum rate of pressure rise . 19Annex C (normative)

Smoothing of pressure-time curves . 22Annex D (informative)

Conversion of the values for the flammable substance content . 25D.1 Abbreviations and symbols . 25D.2 Substance characteristics of air . 25D.3 Definitions . 26D.4 Preparation of the test mixture . 26Annex E (informative)

Example of an evaporator equipment for liquid flammable substances. 29Annex F (informative)

Example for test report form . 31Annex G (informative)

Significant technical changes between this European Standard and the previous editions . 34Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC . 35Annex ZB (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 36Bibliography . 37SIST EN 15967:2011

Figures Figure B.1 — Plot of the rate of explosion pressure rise (dp/dt)ex as a function of the test vessel volume V for H2-air mixtures (xH2 ≅ 35 mol %) . 20 Figure B.2 — Plot of the rate of explosion pressure rise (dp/dt)ex as a function of the test vessel volume V for CH4-air mixtures (xCH4 ≅ 10 mol %) . 20 Figure B.3 — Plot of the rate of explosion pressure rise (dp/dt)ex as a function of the test vessel volume V for NH3-air mixtures (xNH3 ≅ 23 mol %) . 21 Figure C.1 — Example of a raw p(t) curve showing oscillations . 23 Figure C.2 — Example of a raw p(t) curve showing oscillations . 23 Figure C.3 — Schematic diagram showing the variation of (dp/dt)ex as a function of a smoothing parameter . 24 Figure E.1 — Evaporator equipment for producing test mixtures from liquid flammable substances . 29 Tables Table 1 — Rules for rounding up (dp/dt)ex and (dp/dt)max values . 16Table A.1 — Valuesa for verification of the apparatus . 18Table B.1 — Valuesa for verification of the apparatusb . 19Table D.1 — Formulas for the conversion . 28Table G.1 — The significant changes with respect to EN 13673-1:2003 and EN 13673-2:2005 . 34Table ZA.1 — Correspondence between this European Standard and Directive 94/9/EC . 35Table ZB.1 — Correspondence between this European Standard and Directive 2006/42/EC . 36 SIST EN 15967:2011

pex highest pressure occurring in a closed vessel during the explosion of a specific mixture of flammable substances with air or air and inert gases determined under specified test conditions NOTE pex is expressed as absolute pressure with gases and vapour and as overpressure with dusts. 3.2 maximum explosion pressure

pmax maximum value of explosion pressure measured in the tests for explosion pressure when the content of the flammable substances in the mixture is varied NOTE pmax is expressed as absolute pressure with gases and vapour and as overpressure with dusts. 3.3 rate of explosion pressure rise (dp/dt)ex highest value of the slope (first derivative) of the pressure-time curve (smoothed if necessary), measured in a closed vessel during the explosion of a specific mixture of flammable substances with air or air and inert substances determined under specified test conditions SIST EN 15967:2011

To reduce the time required for replacing the fusing wire after a test, the rods may be mounted in a plug that can be screwed into the test vessel wall.

The cross-section of the wires connecting the transformer to the rods shall be between 2,5 mm2 and 7 mm2. The length of the wires shall be less than 5 m. The diameter of the rods shall be between 1,5 mm and 5 mm.

If, for practical reasons, the diameter of the rods has to be less than 3 mm additional mechanical support may be necessary. 4.2.5 Pressure measuring system The pressure measuring system consists of: a) a pressure transducer;

1) The pressure transducer(s) shall be fitted in the test vessel, with the head flush with the internal wall. 2) The pressure transducer(s) shall be able to measure pressures up to 20 bar. Pressure transducers of lower range may be used if lower explosion pressures are expected. b) an amplifier; c) a data recording system.

1) The data recording system shall have a resolution of at least 12 bit and either a sampling rate of 20 kHz, or a sampling rate of 500/t ex samples per second.

2) tex is the time from ignition to the maximum explosion pressure. (see Figure C.1 and Figure C.2). d) The pressure measuring system shall have a bandwidth of at least 10 kHz To ensure reliability, two pressure measuring systems may be used.

The pressure measuring system shall have an accuracy such that the initial and explosion pressures are measured to ± 0,05 bar or better. SIST EN 15967:2011

b) to prevent rupture of the test vessel, it shall be designed to withstand a maximum pressure of at least 20 bar (see 4.2.2), as this can be assumed to be higher than the maximum explosion pressure likely to be generated during a test; c) if the test mixture is prepared in a separate vessel, this vessel and the connecting line shall be designed to withstand the maximum explosion pressure; d) to prevent injuries to the operator from flying fragments, all parts of the apparatus that may contain an explosive mixture shall be adequately shielded; e) adequate ventilation shall be provided to prevent the build up of an explosive atmosphere in the laboratory as a result 1) of purging of the apparatus; 2) exhaust from the vacuum pump;

3) or leaks from the apparatus. f) all electrical connections shall be adequately insulated to prevent electrocution or shock to personnel; g) measures shall be taken prior to preparing the mixture to ensure that the substances can be mixed without risk; h) measures shall be taken to prevent hazards arising from the handling of toxic flammables gases or combustion products; i) the handling of flammable liquids shall be carried out in such a manner that

the risk of a fire is minimised; j) the handling of gas cylinders shall be carried out in such a manner that the risk of an explosion is minimised; k) in the event of ignition system failure, the explosive mixture will still be present at the end of the test, purge and diltute to render non-flammable. 4.3 Preparation and preservation of test samples The components of the test mixture shall fulfil the following requirements: a) Air:

the air shall be free of water and oil. If synthetic air is used, it has to be stated in the

report.

the purity of the inert, or the mixture of inerts, shall be 99,8 % mol or better. If a mixture

of inerts is used, the composition of the mixture shall be stated in the test report.

c) Flammable gas:

the flammable gas may be derived from: 1) a single substance or a mixture of substances, 2) a process sample (of known or unknown composition). When a single substance or a mixture of substances is used, the purity of each substance shall be 99,8 % mol or better. In the case of a mixture of substances or a process sample of known composition, the precision of the composition shall be stated in the test report. In the case of a process sample of unknown composition, the sample shall be defined as well as possible (e.g. process conditions, lower explosion limit). If the flammable gas is derived from a liquid containing more than one component, the gas phase composition can differ from the composition of the liquid phase and when large quantities of the gas are drawn off, the composition of both the liquid and gas phases can change with time. For these reasons, the test sample shall be taken from the liquid phase. 4.4 Procedure 4.4.1 Preparation of the test mixture 4.4.1.1 General If liquefied gases or liquids are used, it is necessary to ensure that there is no condensation. NOTE Condensation can be prevented by checking the vapour pressure of the substances and by local heating to prevent cooling at certain parts of the apparatus (e.g. valves). The test mixture may be prepared by the method of partial pressures or by the method of mixing flows, either inside or outside the test vessel. 4.4.1.2 Preparation of the test mixture by partial pressures If the preparation of the test mixture includes evacuating the vessel, the amount of air remaining shall be taken into account when calculating the pressures of combustible substances and air required. In preparing the test mixture, precautions may be necessary to prevent condensation. The mixture components are sequentially introduced into the vessel to give the required partial pressure. The partial pressure measuring system shall have an accuracy of ± 0,005 bar or better. It is necessary to ensure that the mixture in the vessel is thoroughly mixed during the introduction of each component. If the volume of the feed lines is not negligible compared to the volume of the vessel, they also shall be evacuated or purged. NOTE For practical reasons, air is often introduced as the last component, especially if atmospheric air is used. 4.4.1.3 Preparation of the test mixture by mixing flows The test mixture is prepared by thoroughly mixing metered flows of the gaseous components. If liquid components are used, they shall be vaporised totally before mixing. NOTE It is recommended that if possible the composition of the test mixture is also measured, to check the metering devices are operating correctly and that there are no leaks in the mixing system. SIST EN 15967:2011

The test vessel and the feed lines shall be evacuated to a pressure of 5 mbar or less before filling. Purging shall be done in such a way that the test vessel atmosphere is totally replaced. This is achieved by purging with a volume that is at least ten times the vessel volume. Once the test mixture has been introduced into the test vessel, the inlet and outlet valves shall be closed. The test mixture shall be left for a period of at least two minutes to ensure it is quiescent. The test mixture is then ignited and the pressure-time curve of the explosion recorded. During a set of tests the temperature increase of the vessel (caused by the combustion after ignition) shall not be allowed to exceed 15 K (see 4.5.2) After the test residual overpressure shall be released from the test vessel. Following this, the vessel shall be purged with air to remove the combustion products. The combustion products and purge gas shall be discharged safely. The humidity of the gas mixture can influence the rate of pressure rise, so it is important to ensure that the test vessel and feed lines have been purged of all moisture before starting the next test. If soot is formed during the test, the test vessel and the igniter shall be cleaned. The whole test procedure shall be carried out five times for each composition of the test mixture.

For determination of pex the number of determinations may be reduced to three, provided the scatter in the three tests is not greater than 0,5 bar. For the determination of (dp/dt)ex the number of determinations can be reduced to three, provided the relative standard deviation is not greater than 10 %. 4.4.2.2 Determination of the explosion pressure pex The highest pressure on each of the pressure-time curves for a given composition measured by the procedure in 4.4.2.1 is determined by one of the following methods. a) Graphical method From a plot of pressure versus time, which may be the analogue output from a recording instrument, the highest pressure shall be determined. The precision of the data used for the plot and the scale of the graph shall be sufficient to allow the pressures to be resolved to the nearest 0,1 bar. b) Computational method A computer programme may be used to process the pressure-time data to determine the highest pressure. The precision of data used shall be sufficient to allow the pressures to be resolved to the nearest 0,1 bar. The explosion pressure pex is the highest value of these determinations. SIST EN 15967:2011

temperature of the mixture before ignition

in K T1: reference temperature in K p: pressure of the mixture before ignition

in bar p1: reference pressure in bar pmax(T,p): pmax for the mixture conditions T and p before ignition

in bar pmax(T1,p1): pmax at reference temperature T1 and reference pressure p1 in bar Similar dependences can be expected for pex, except for near limit mixtures. NOTE 2 As the values are obtained for safety purposes, the highest values of pressure are used instead of the mean values. The verification of the apparatus and procedure shall be carried out according to Annex A. 4.5.3 Rate of pressure rise and maximum rate of pressure rise In reporting results of these determinations, all the information specified in 4.6 shall be provided. The values for (dp/dt)ex and (dp/dt)max will depend on the volume and shape of the test vessel used for the determination. For example, (dp/dt)max decreases with increasing vessel volume. It is, therefore, the practice to quote a rate of explosion pressure rise normalised to a vessel volume of 1 m3 (KG), using the following equation: 31/maxGV)dt/dp(K= (1) where V is the vessel volume. SIST EN 15967:2011

in bar/s < 10 10 to 100 100 to 1 000 > 1 000 Rounding up to the nearest

in bar/s 0,1 1 10 100

The main contributing factors to the overall uncertainty of the rate of explosion pressure rise (dp/dt)ex measurements at a given flammable gas content are the uncertainty of the pressure measurements, the uncertainty of the flammable gas content values and the smoothing procedure used. To give a rough measure of the scatter of the measurements the lowest and highest values of rate of pressure rise shall be reported.

The additional contributing factor to the overall uncertainty of the maximum rate of explosion pressure rise (dp/dt)max is the increment used for the flammable gas content.

As the values are intended for use in safety applications the highest value of the rate of pressure rise shall be used for (dp/dt)max instead of the mean values. If the smoothing procedure is carried out according to the criteria given in Annex C, it should not have a significant effect on the calculated value of (dp/dt)ex. Verification of the test apparatus shall be carried out according to the procedure given in Annex B. 4.6 Test report The test report shall give the following information: a) laboratory name operator and date; b) reference to the applied standard c) test conditions: 1) ambient temperature and pressure of the test mixture before ignition; d) sample identification: SIST EN 15967:2011

2) composition, purity and amount of added inert; f) test vessel: 1) vessel shape; 2) vessel volume; g) ignition system; h) preparation of test mixture; method used (including inside or outside preparation) and accuracy; i) what is to be determined (pmax , pex

; (dp/dt)max , (dp/dt)ex); j) results: 1) in the case of pex or (dp/dt)ex: i) final explosion pressure; or final rate of explosion pressure rise, respectively i) flammable gas content and accuracy; ii) highest, lowest and average values; 2) in the case of pmax or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...