EN 1004-1:2020

(Main)Mobile access and working towers made of prefabricated elements - Part 1: Materials, dimensions, design loads, safety and performance requirements

Mobile access and working towers made of prefabricated elements - Part 1: Materials, dimensions, design loads, safety and performance requirements

This document applies to the design of mobile access and working towers made of prefabricated elements with dimensions which are fixed by the design and with a height up to 12 m (indoors) and up to 8 m (outdoors). This document applies to mobile access and working towers used as temporary work equipment.

This document:

- gives guidelines for the choice of the main dimensions and stabilizing methods,

- gives safety and performance requirements, and

- gives information on complete towers.

This product standard does not apply to scaffolds according to EN 12810-1 and EN 12811-1.

Fahrbare Arbeitsbühnen aus vorgefertigten Bauteilen - Teil 1: Werkstoffe, Maße, Lastannahmen und sicherheitstechnische Anforderungen

Dieses Dokument gilt für die Konstruktion und Bemessung von fahrbaren Arbeitsbühnen aus vorgefertigten Bauteilen, mit Abmessungen die durch Konstruktion und Bemessung festgelegt sind und mit einer Höhe bis zu 12 m (innerhalb von Gebäuden) und bis zu 8 m (außerhalb von Gebäuden). Dieses Dokument gilt für fahrbare Arbeitsbühnen, die als temporäre Arbeitsmittel eingesetzt werden.

Dieses Dokument

- gibt Empfehlungen für die Auswahl der Hauptmaße und Stabilisierungsverfahren,

- stellt Sicherheits- und Leistungsanforderungen und

- enthält Angaben über die Gesamtkonstruktion der Arbeitsbühnen.

Diese Produktnorm gilt nicht für Gerüste nach EN 12810 1 und EN 12811 1.

Échafaudages roulants en éléments préfabriqués - Partie 1 : Matériaux, dimensions, calculs de charge, exigences de performance et de sécurité

Le présent document s’applique à la conception des échafaudages roulants constitués d'éléments préfabriqués dont les dimensions sont fixées par la conception et, d’une hauteur allant jusqu’à 12,0 m (à l'intérieur) et jusqu’à 8,0 m (à l'extérieur). Le présent document s'applique aux échafaudages roulants utilisés comme équipement de travail temporaire.

Ce document :

- donne des directives pour le choix des dimensions principales et des méthodes de stabilisation ;

- donne les exigences de sécurité et de performance, et

- donne des informations concernant les échafaudages roulants complets.

Cette norme produit ne s'applique pas aux échafaudages conformes aux EN 12810-1 et EN 12811-1.

Pomični delovni odri na kolesih iz predizdelanih tipskih elementov - 1. del: Materiali, mere, obtežbe in varnostne zahteve

General Information

- Status

- Published

- Publication Date

- 17-Nov-2020

- Withdrawal Date

- 29-Nov-2021

- Technical Committee

- CEN/TC 53 - Temporary works equipment

- Drafting Committee

- CEN/TC 53/WG 4 - Mobile access towers

- Current Stage

- 9020 - Submission to 2 Year Review Enquiry - Review Enquiry

- Start Date

- 15-Jan-2026

- Completion Date

- 15-Jan-2026

Relations

- Effective Date

- 25-Nov-2020

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 1991-1-4:2005 - Eurocode 1: Actions on structures - Part 1-4: General actions - Wind actions - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview - EN 1004-1:2020 (CEN)

EN 1004-1:2020 is the CEN product standard for mobile access and working towers made of prefabricated elements. It covers towers with fixed component dimensions and a working height up to 12 m (indoors) and 8 m (outdoors) used as temporary work equipment. The standard provides guidance on choice of main dimensions and stabilizing methods, sets materials, dimensions, design loads, safety and performance requirements, and gives information on complete towers (testing, marking and documentation).

Key keywords: EN 1004-1:2020, mobile access and working towers, prefabricated elements, design loads, safety requirements, temporary work equipment.

Key topics and technical requirements

- Scope & classification

- Applies to prefabricated, free‑standing towers with castors and options for outriggers, stabilizers and ballast.

- Establishes load classes, access classes and height classes for tower design.

- Materials & components

- References applicable material standards and corrosion protection rules for components and coatings.

- Dimensions & platform design

- Defines platform geometry (length, width, clear platform heights) and allowable openings.

- Design loads & wind considerations

- Specifies uniformly distributed loads, characteristic actions on the whole structure and its parts, and provisions for wind (document notes a wind load requirement).

- Stability & stabilizing methods

- Requirements for outriggers, stabilizers, wall struts, ballast and positional stability checks.

- Castors, access and side protection

- Rules for castor wheels, access types (ladders, stairways), side protection and guardrails to prevent falls and retain materials.

- Structural design & verification

- Design principles, structural analysis, deflection limits and verification procedures aligned with referenced Eurocodes.

- Testing, marking & documentation

- Test methods (including stiffness tests), mandatory instruction manual content (EN 1298 referenced), component marking and manufacturer’s label requirements.

Practical applications and users

Who uses EN 1004-1:

- Manufacturers of mobile towers and prefabricated tower components for design, production and CE marking.

- Design engineers and structural consultants checking tower stability and load verification.

- Rental companies, site managers and safety officers ensuring correct selection, erection, stabilization and safe use.

- Inspection bodies and certifiers performing tests, assessments and conformity checks.

Practical uses:

- Designing towers for indoor/outdoor temporary works, specifying outriggers/ballast, selecting appropriate load and access classes, preparing user instruction manuals and ensuring compliance with on-site wind and safety rules.

Related standards

- EN 12810-1 / EN 12811-1 (scaffolds) - excluded from scope

- EN 131-2 (ladders), EN 1298 (instruction manuals)

- Eurocodes referenced for structural actions and materials (EN 1991‑1‑4, EN 1993‑1‑1, EN 1995‑1‑1, EN 1999‑1‑1)

- EN 12811 series for temporary works equipment and testing

EN 1004-1:2020 is essential for safe design, manufacture and use of mobile access and working towers across construction, maintenance and industrial sectors.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1004-1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Mobile access and working towers made of prefabricated elements - Part 1: Materials, dimensions, design loads, safety and performance requirements". This standard covers: This document applies to the design of mobile access and working towers made of prefabricated elements with dimensions which are fixed by the design and with a height up to 12 m (indoors) and up to 8 m (outdoors). This document applies to mobile access and working towers used as temporary work equipment. This document: - gives guidelines for the choice of the main dimensions and stabilizing methods, - gives safety and performance requirements, and - gives information on complete towers. This product standard does not apply to scaffolds according to EN 12810-1 and EN 12811-1.

This document applies to the design of mobile access and working towers made of prefabricated elements with dimensions which are fixed by the design and with a height up to 12 m (indoors) and up to 8 m (outdoors). This document applies to mobile access and working towers used as temporary work equipment. This document: - gives guidelines for the choice of the main dimensions and stabilizing methods, - gives safety and performance requirements, and - gives information on complete towers. This product standard does not apply to scaffolds according to EN 12810-1 and EN 12811-1.

EN 1004-1:2020 is classified under the following ICS (International Classification for Standards) categories: 91.220 - Construction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1004-1:2020 has the following relationships with other standards: It is inter standard links to EN 1004:2004, EN ISO 2081:2025, EN 131-2:2010+A3:2025, EN 12811-1:2003, EN 1991-1-4:2005/A1:2010, EN 12811-3:2002, EN 1999-1-1:2023, EN 1991-1-4:2005, EN 1999-1-1:2007/A2:2013, EN 1995-1-1:2025, EN 1993-1-1:2022, EN 1999-1-1:2007/A1:2009, EN 12811-2:2004, EN 12810-2:2003, EN 17293:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1004-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2021

Nadomešča:

SIST EN 1004:2005

Pomični delovni odri na kolesih iz predizdelanih tipskih elementov - 1. del:

Materiali, mere, obtežbe in varnostne zahteve

Mobile access and working towers made of prefabricated elements - Part 1: Materials,

dimensions, design loads, safety and performance requirements

Fahrbare Arbeitsbühnen aus vorgefertigten Bauteilen - Werkstoffe, Maße,

Lastannahmen und sicherheitstechnische Anforderungen

Tours d'accès et de travail roulantes en éléments préfabriqués - Matériaux, dimensions,

charges de calcul et exigences de sécurité

Ta slovenski standard je istoveten z: EN 1004-1:2020

ICS:

91.220 Gradbena oprema Construction equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 1004-1

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2020

EUROPÄISCHE NORM

ICS 91.220 Supersedes EN 1004:2004

English Version

Mobile access and working towers made of prefabricated

elements - Part 1: Materials, dimensions, design loads,

safety and performance requirements

Échafaudages roulants en éléments préfabriqués - Fahrbare Arbeitsbühnen aus vorgefertigten Bauteilen -

Partie 1 : Matériaux, dimensions, calculs de charge, Werkstoffe, Maße, Lastannahmen und

exigences de performance et de sécurité sicherheitstechnische Anforderungen

This European Standard was approved by CEN on 14 March 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 1004-1:2020 E

worldwide for CEN national Members.

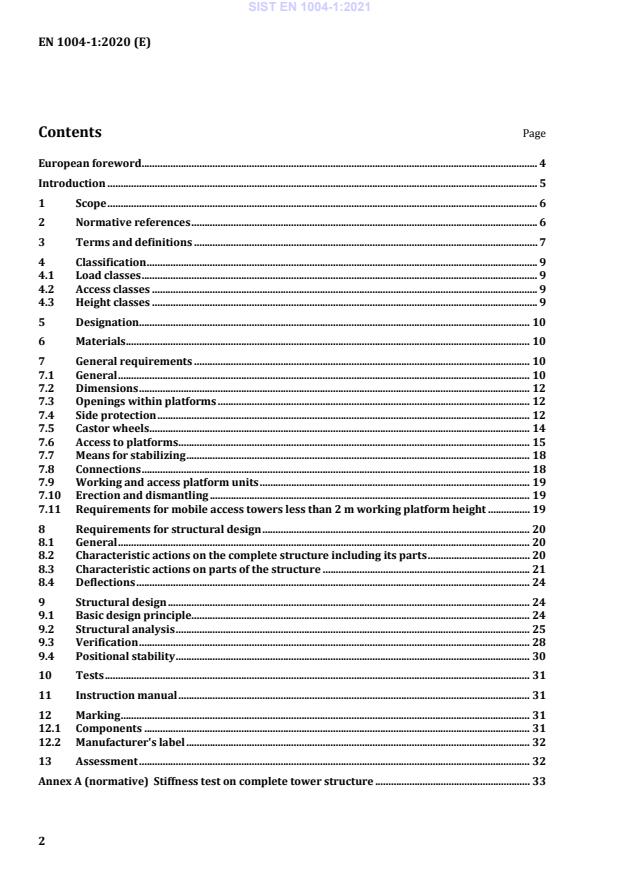

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Classification . 9

4.1 Load classes . 9

4.2 Access classes . 9

4.3 Height classes . 9

5 Designation. 10

6 Materials . 10

7 General requirements . 10

7.1 General . 10

7.2 Dimensions . 12

7.3 Openings within platforms . 12

7.4 Side protection . 12

7.5 Castor wheels . 14

7.6 Access to platforms . 15

7.7 Means for stabilizing . 18

7.8 Connections . 18

7.9 Working and access platform units . 19

7.10 Erection and dismantling . 19

7.11 Requirements for mobile access towers less than 2 m working platform height . 19

8 Requirements for structural design . 20

8.1 General . 20

8.2 Characteristic actions on the complete structure including its parts . 20

8.3 Characteristic actions on parts of the structure . 21

8.4 Deflections . 24

9 Structural design . 24

9.1 Basic design principle . 24

9.2 Structural analysis . 25

9.3 Verification . 28

9.4 Positional stability . 30

10 Tests . 31

11 Instruction manual . 31

12 Marking . 31

12.1 Components . 31

12.2 Manufacturer's label . 32

13 Assessment . 32

Annex A (normative) Stiffness test on complete tower structure . 33

Annex B (informative) A-deviations . 36

Annex C (informative) Reduction of the wind load to equal members being upwind . 37

Bibliography . 40

European foreword

This document (EN 1004-1:2020) has been prepared by WG4 “Mobile access towers” under the

direction of Technical Committee CEN/TC 53 “Temporary works equipment”, the secretariat of which is

held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2021, and conflicting national standards shall be

withdrawn at the latest by November 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 1004:2004.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

The development of mobile access and working towers systems is from the following two roots:

— scaffold manufacturers placed prefabricated unanchored scaffolds on four legs and castors;

— ladder manufacturers began to construct mobile access towers with light-weight ladders using

aluminium frames and castors.

Taking this into account, CEN/TC53 decided in 1980 to standardize the manufacture of mobile access

and working towers in parallel with the European standardization of prefabricated service and working

scaffolds EN 12810-2 and EN 12811-3.

For materials, this document refers only to valid documents. However, a large stock of equipment made

of materials conforming to documents no longer valid is in use. This document does not cover this

equipment.

Attention is drawn to the requirements of the European Council Directive 2009/104/EC (provisions

concerning the use of work equipment provided for temporary work at a height).

The average height of people continues to increase and that consideration will have to be given in later

revisions to altering vertical dimensions.

The wind load requirements of this standard (0,1 kN/m ).

Consider the fact that mobile access towers are generally intended for shorter duration tasks and may

be re-located or quickly dismantled. Attention is drawn to 3.1, Note 2 and to the requirements of

EN 1298 regarding information relating to wind conditions.

Mobile access and working towers are not anchor points for personal fall arrest equipment unless they

are specifically designed in accordance with relevant European standards by the manufacturer for that

purpose.

1 Scope

This document applies to the design of mobile access and working towers made of prefabricated

elements with dimensions which are fixed by the design and with a height up to 12 m (indoors) and up

to 8 m (outdoors). This document applies to mobile access and working towers used as temporary work

equipment.

This document:

— gives guidelines for the choice of the main dimensions and stabilizing methods,

— gives safety and performance requirements, and

— gives information on complete towers.

This product standard does not apply to scaffolds according to EN 12810-1 and EN 12811-1.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 131-2, Ladders — Part 2: Requirements, testing, marking

EN 1298, Mobile access and working towers — Rules and guidelines for the preparation of an instruction

manual

1)

EN 1991-1-4:2005, Eurocode 1: Actions on structures — Part 1-4: General actions - Wind actions

EN 1993-1-1, Eurocode 3: Design of steel structures — Part 1-1: General rules and rules for buildings

EN 1995-1-1, Eurocode 5: Design of timber structures — Part 1-1: General — Common rules and rules for

buildings

2)

EN 1999-1-1 , Eurocode 9: Design of aluminium structures — Part 1-1: General structural rules

EN 12810-2:2003, Façade scaffolds made of prefabricated components — Part 2: Particular methods of

structural design

EN 12811-1, Temporary works equipment — Part 1: Scaffolds — Performance requirements and general

design

EN 12811-2, Temporary works equipment — Part 2: Information on materials

EN 12811-3, Temporary works equipment — Part 3: Load testing

EN ISO 2081, Metallic and other inorganic coatings — Electroplated coatings of zinc with supplementary

treatments on iron or steel (ISO 2081)

1) This document is impacted by the amendment EN 1991-1-4:2005/A1:2010.

2) This document is impacted by the amendments EN 1999-1-1:2007/A1:2009 and EN 1999-1-1:2007/A1:2013.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1

mobile access and working towers

temporary free-standing structures consisting of prefabricated elements, having dimensions fixed by

the design and four legs with castors, providing one or more platforms

Note 1 to entry: Mobile access and working towers can have outriggers or stabilizers. They can be stabilized by

supports on the ground or wall struts against a stable structures or ballast.

Note 2 to entry: Mobile access and working towers have castor wheels. Mobile access and working towers can

be removed immediately, in case of arising wind greater than equivalent dynamic pressure 0,1 kN/m or at the

end of the work shift.

3.2

height (h)

distance from the ground to the upper surface of the uppermost platform

3.3

castor wheel

swivelling wheel secured to the base of a mobile access and working tower to enable the tower to be

moved

3.4

adjustable leg

component incorporated into the structure of a mobile access and working tower at its base used for

the purpose of levelling the structure when situated on uneven or sloping ground

3.5

platform unit

prefabricated unit which forms the platform or part of the platform, that supports a load on its own and

might form a structural part of the mobile access and working tower

3.6

bracing member

means used to stiffen the structure

3.7

outrigger

component that increases the effective base dimensions of a tower, with provision for the attachment of

a castor

3.8

stabilizer

component that increases the effective base dimensions of a tower, without provisions for the

attachment of a castor

3.9

ballast

weights placed at the base of the tower to increase its resistance to overturning

3.10

wall strut

means for providing compressive restraint to prevent a tower overturning

Note 1 to entry: It is normally a horizontal tubular member, one end of which is connected to the tower, while

the other end rests against a wall or other structure.

3.11

stairway

means of access intended for persons carrying tools or materials

3.12

stairladder

means of access intended for person's not carrying tools or materials

3.13

inclined ladder

means of access intended for persons not carrying tools or materials with an inclination from 60° to 75°

3.14

vertical ladder

means of access intended for persons not carrying tools or materials with an inclination of 90°

3.15

platform

one or more platform units placed side by side at the same level

3.16

platform length (l)

greater of the two plane dimensions at the platform level

Note 1 to entry: See Figure 1.

3.17

platform width (w)

lesser of the two plane dimensions at the platform level

Note 1 to entry: See Figure 1.

Figure 1 — Width and length of a platform

3.18

indoors

place where the tower will not be exposed to wind loads

3.19

outdoors

place where the tower might be exposed to wind loads

3.20

side protection

components forming a barrier to protect people from the risk of falling and to retain materials

3.21

working platform

platform in a mobile access and working tower from where the work will be carried out

3.22

intermediate platform

platform in a mobile access and working tower that is not a working platform

3.23

positive locking device

mechanical locking device not relying on friction which prevents unintentional disconnection

EXAMPLE A pin, bolt or protrusion.

4 Classification

4.1 Load classes

The classes of uniformly distributed load are given in Table 1.

Table 1 — Classes of uniformly distributed load

Uniformly distributed load q

Load class

kN/m

2 1,50

3 2,00

4.2 Access classes

Four options for access to the platform are described in 7.6.

4.3 Height classes

Two options for minimum clear height between platforms are described in 7.2.

5 Designation

The following data are required for the designation of all prefabricated mobile access and working

towers:

a) class of uniformly distributed load (see 4.1);

b) maximum height outdoors/indoors;

c) access classes (see 4.2);

d) clear height classes (see 4.3).

Example

6 Materials

Materials shall fulfil the requirements given in European standards, where design data are provided. If

European standards do not exist, ISO standards can be applied.

Materials shall be sufficiently robust and durable to withstand normal working conditions.

Additional requirements for some materials are given in EN 12811-2.

When materials are used, whose properties in relation to the intended application (e.g. temperature,

ageing, UV-degradation) are not given in any available standard an adequate assessment is required.

Steel shall be protected by one of the methods given in EN 12811-2, or zinc plated to the level required

for the design service environment stated in EN ISO 2081.

7 General requirements

7.1 General

A mobile access and working tower shall only consist of a single-bay structure.

The mobile access and working tower shall be designed such that it can be assembled, altered and

dismantled without the need for personal fall protection equipment.

Only one platform shall be a working platform at one time.

The mobile access and working tower shall be designed in such a way that the uppermost platform is a

working platform and lower platforms are intermediate platforms.

NOTE An intermediate platform can be changed to be the working platform if it is equipped with side

protection, including toe boards.

The vertical distance between platforms shall be no greater than 2,25 m.

The vertical distance between the ground and the first platform shall be no greater than 3,40 m.

However, if a platform is placed ≤ 0,6 m from the ground, it is allowed to have a vertical distance no

greater than 3,40 m between that platform and the next platform. See Figure 2.

If the mobile access and working tower cannot be entered from the inside of the structure, the

requirements of 7.11 shall apply.

Key

x ≤ 0,6 m

y ≤ 3,40 m

z ≤ 2,25 m

1 first platform

2 second platform

NOTE Stabilizers are omitted from this figure for clarity.

Figure 2 — Maximum distance between platforms

7.2 Dimensions

The minimum width, w, of the platform shall be 0,60 m and the minimum length, l, shall be 1,00 m. See

Figure 1.

The minimum clear width between the toe boards shall be 0,5 m.

The minimum clear height between platforms H shall be in accordance with Table 2.

Table 2 — Clear height classes

Clear height class Minimum clear height H in m

H1 1,85

H2 1,90

7.3 Openings within platforms

7.3.1 Access openings

Access openings in platforms through which the user will climb shall have a minimum clear opening of

0,40 m wide × 0,60 m long.

Access openings in platforms shall be provided with a means to prevent falling through. The trapdoor

shall be fastenable in the closed position.

7.3.2 Apertures

Apertures in platforms or between platform units shall not exceed 25 mm in width. This does not apply

to apertures like hand holes in hatches.

7.4 Side protection

7.4.1 General

Dimensions for side protection shall be in accordance with Figure 3.

Dimensions in millimetres

Key

h distance between uppermost surface of the platform and uppermost surface of the principal guardrail

GR

r corner radius of side protection consisting of a frame to be constant (see 7.4.3)

const

Figure 3 — Dimensions for side protection

Side protection is composed of a principal guardrail, intermediate side protection and a toe board. The

principal guardrail, intermediate side protection, and toe-board may be combined.

Side protection components shall be incapable of removal except by direct intentional action.

It shall be possible to erect protection at platform edges comprising:

a) both a principal guardrail and intermediate side protection;

b) toe-board.

3)

Toe boards may be omitted on intermediate platforms.

7.4.2 Principal guardrail

The principal guardrail shall be fixed so that its uppermost surface is a minimum of 1 000 mm above the

uppermost surface of the platform it is protecting, measured vertically (dimension h in Figure 3). A

GR

minus tolerance of 50 mm is acceptable.

7.4.3 Intermediate side protection

Intermediate side protection shall be fixed between the principal guardrail and the toe-board.

Intermediate side protection may consist of:

— one or more intermediate guardrails, or

— a frame, or

3) See A-deviations in Annex B.

— a frame of which the principal guardrail forms the top edge, or a fencing structure.

Openings in the side protection shall be so dimensioned so that a sphere with a diameter of more than

470 mm will not pass through them.

7.4.4 Toe-board

It shall be possible to fix a solid toe-board such that its top edge is at least 150 mm above the adjacent

platform level. Apertures in toe boards shall not exceed 25 mm in width. This does not apply to

apertures like hand holes.

7.5 Castor wheels

7.5.1 General

Castor wheels shall be fixed to the tower in such a way that they cannot be unintentionally detached.

The castor wheel shall not detach from the frame due to the action of its self-weight.

7.5.2 Brakes

All castors shall have wheel brakes. They shall have swivel brakes if the wheels are eccentric when

locked.

The brake mechanism shall be designed in such a way that it can only be unlocked by a deliberate

action. The brake mechanism shall effectively prevent any rotation of the wheel when a horizontal force

of 0,30 kN is applied through the vertical swivel axis of the castor as close as possible above the castor

housing and in the rolling direction of the castor. The full value of the specified service load per castor

wheel is to be applied when testing the castor brakes. A minimum of five control tests shall be carried

out.

7.5.3 Test loads

The test shall be carried out on the complete castor wheel.

The vertical service load per wheel given by the manufacturer of the mobile access and working tower

shall be verified by a minimum of five tests.

The test load shall be three times the service load per castor wheel derived from the most unfavourable

load combination from Table 3.

When the brakes are locked, an initial vertical load of 0,50 kN shall be applied. The plate of the fork shall

be taken as the origin for measurements of vertical displacement, d , and the residual deformation, d .

c r

The load shall be increased to the maximum test load, maintained for one minute and the vertical

deformation, d , shall be measured. The load shall be returned to 0,50 kN. After 30 min, the residual

c

deformation, d , shall be measured.

r

The test shall meet both of the following requirements:

— residual deformation, d , after 30 min shall not be more than 3,00 mm;

r

— total deformation, d , shall not be more than 15 mm.

c

The service load is verified if all five tests meet the test requirements.

7.5.4 Wheels

Wheels shall be of puncture less type.

7.6 Access to platforms

7.6.1 Access types

The access type is classified by a letter A, B, C or D as follows:

— Access type A: Stairway;

— Access type B: Stairladder;

— Access type C: Inclined ladder;

— Access type D: Vertical ladder.

Where a range of access types is provided, a combined classification is used.

EXAMPLES

Type AXCX means that stairways and inclined ladders can be provided.

Type ABCD means that all four types of access can be provided.

NOTE The X in the designation means that those types of access are not provided.

7.6.2 General requirements

Access to the platforms ≥ 2 m height in an assembled tower shall be within the main structural supports

using one of the access methods specified in 7.6.1 and shall:

— be secured against unintentional loosening;

— not rest on the ground;

— have a distance from the ground to the first step or rung of 400 mm maximum taking into account

adjustable legs. If the first step is a platform, 600 mm is allowable;

— have steps/rungs with constant spacing and a slip resistant surface.

7.6.3 Additional requirements

7.6.3.1 Stairway and stairladder

The outside of stair flights shall be provided with a handrail which runs approximately parallel to the

stairs. Where a flight of stairs is provided in a continuous dog-leg style, a handrail shall also be provided

on the inside. When flights of stairs are interrupted by platforms at ≤ 2,25 m intervals, the inside

handrail may be omitted.

Flights of stairs in a continuous dog-leg style shall have landings. Each of these stairs shall have a

minimum of one landing and this shall have a minimum length of 300 mm.

The minimum clear height for access measured between the steps and the supporting structure of the

stairway or stairladder above shall not be less than 1,75 m.

7.6.3.2 Access type A - stairway (see Figure 4)

Stairways shall conform with the following geometric requirements:

Inclination α 35° ≤ α ≤ 55°;

Vertical step rise t1 190 mm ≤ t1 ≤ 250 mm;

Minimum step depth d d = 125 mm;

Minimum clear width w w = 400 mm;

clear clear

Horizontal gap between steps g 0 ≤ g ≤ 50 mm.

Stairways shall be designed in accordance with 8.3.3.

Figure 4 — Dimensions of stairway

7.6.3.3 Access type B - stairladder (see Figure 5)

Stairladders shall conform with the following geometric requirements:

Inclination α 35° ≤ α ≤ 55°;

Vertical step rise t 150 mm ≤ t ≤ 250 mm;

1 1

Minimum step depth d d = 80 mm;

Minimum clear width w w = 280 mm;

clear clear

Horizontal gap between steps g 0 ≤ g ≤ 160 mm.

Stairladders shall be designed in accordance with 8.3.3.

Figure 5 — Dimensions of stairladder

7.6.3.4 Access type C - inclined ladder (see Figure 6)

Inclined ladders shall conform with the following geometric requirements:

Inclination α 60° ≤ α ≤ 75°;

Step spacing t2 230 mm ≤ t2 ≤ 300 mm;

Step depth d d > 80 mm;

Rung spacing t 230 mm ≤ t ≤ 300 mm;

2 2

Rung diameter d 20 mm ≤ d ≤ 80 mm;

Minimum clear width w w = 280 mm.

clear clear

Inclined ladders shall be designed in accordance with 8.3.4.

Figure 6 — Dimensions of inclined ladder

7.6.3.5 Access type D -vertical ladder (see Figure 7)

Vertical ladders shall conform with the following geometric requirements:

From the front edge of the step or from the centre of the rung to any obstacle behind the

stairway/ladder, there shall be a horizontal distance of s = 150 mm minimum (see Figure 7).

Rung spacing t 230 mm ≤ t ≤ 300 mm;

2 2

Rung depth or diameter d 20 mm ≤ d ≤ 51 mm;

Minimum clear width w w = 280 mm.

clear clear

Vertical ladders shall be designed in accordance with 8.3.5.

a) Separate ladder b) Integral ladder c) w

clear

Figure 7 — Dimensions of vertical ladder

7.7 Means for stabilizing

7.7.1 Stabilizers and outriggers

The stabilizers and outriggers of a tower shall be designed as components of the main structure and

shall provide means of adjustment to ensure contact with the ground.

The method of fixing the stabilizer or outrigger to the tower shall have adequate strength and shall be

such that the reaction loads in the stabilizer or outrigger are transferred to the tower without slip,

rotation, or other movement of the stabilizer or outrigger.

7.7.2 Ballast

If ballast is necessary, it shall be securely positioned to prevent unintentional movement or removal.

Ballast shall be made of rigid materials such as steel or concrete. Alternatively, liquids or granular

materials may be used if they are in containers supplied by the manufacturer.

The containers shall have the following characteristics:

— they shall be closable and lockable to prevent escape of the filling material;

— they shall be impact resistant to prevent loss of the filling material;

— their filling level shall be clearly visible;

— the filling material shall be specified by the manufacturer.

7.8 Connections

7.8.1 General

Each connection device shall be effective, easy to monitor and the components shall be easy to

assemble. The securing of components forming part of the structure of the mobile access tower and

working tower and side protection components shall make them incapable of removal except by direct

intentional action.

7.8.2 Vertical spigot and socket connection

When assembled, the horizontal movement (slack or play) between upper and lower components shall

not exceed 4 mm or a movement away from the centre line of 2 mm.

In all cases, it shall not be possible to disconnect an upper component laterally until the upper

component has been lifted more than 80 mm.

When the spigot and socket connection acts over a distance less than 150 mm, the connection shall be

provided with a positive locking device, such as a cross pin, to prevent the upper component from being

lifted unintentionally and provide additional structural stiffness.

The positive locking device shall be designed in such a way that its positive action can be monitored

visually.

7.8.3 Other vertical connections

There shall be equivalent provisions related to 7.8.2 to limit the risk of accidental disconnections and

provide structural stiffness.

7.9 Working and access platform units

Components of platforms shall be durable and shall have a slip-resistant surface. Platform units shall be

secured at both ends so that turning or removal by wind is not possible.

7.10 Erection and dismantling

The tower shall remain stable and resist all loads imposed on the components during erection and

dismantling.

7.11 Requirements for mobile access towers less than 2 m working platform height

7.11.1 Requirements for access

Access to the platform in an assembled tower shall:

— be an integral component or components of the tower;

— be secured against unintentional loosening;

— have a distance from the ground to the first step or rung of 400 mm maximum taking into account

adjustable legs;

— have steps/rungs with constant spacing and a slip resistant surface;

— shall comply with the requirements of 7.6.

There is no requirement for access if the working platform height is ≤ 600 mm.

Access to working platforms in an assembled tower may be from the outside of the structure.

The structure may be provided with access openings in the side protection provided that:

— it shall be possible to close access openings in the side protection after access or egress;

— access openings in the side protection shall be provided with a means to prevent unintentional

opening;

— access openings in the side protection shall have a minimum clear width ≥ 400 mm:

— the access to the platform shall be aligned with access openings in the side protection;

— access openings in the side protection shall be designed in such a way that only one hand is

required to opening.

NOTE Attention is drawn to national regulation regarding work at height when considering side protection

for mobile access towers less than 2 m working platform height.

7.11.2 Requirements for positional stability when accessing from outside

7.11.2.1 General

This load case shall only be applied when a mobile access tower has an access provided from outside

the structural supports, in accordance with 7.11.1.

7.11.2.2 Safety factor

The safety factor against overturning shall be S ≥ 1,5.

7.11.2.3 Vertical loads

— Self-weight;

— a vertical load of either:

— for access types A, B and C; 0,75 kN applied to the first step or rung, or

— for access types D; 0,75 kN applied 0,5 m outside of the vertical plane of access.

8 Requirements for structural design

8.1 General

A tower structure shall be able to resist the combination of loads, taking from one line from each of the

five groups given in Table 3, in their worst combinations.

All loads are taken to be static loads.

Eccentricities of castor wheels, in their most unfavourable position, shall be taken into account.

Adjustable legs shall be extended to their maximum extension.

Platforms shall be assessed with respect to self-weight and the most unfavourable design load

according to Table 4.

8.2 Characteristic actions on the complete structure including its parts

8.2.1 Verticals loads

8.2.1.1 Tower nominal self-weight as given by the manufacturer

The self-weight of the tower including all parts and ballast (if applicable) shall be taken into account.

8.2.1.2 Uniformly distributed load on the topmost platform

— Load class 2: 1,5 kN/m ;

— Load class 3: 2,0 kN/m .

8.2.1.3 Load resulting from an inclination of 1 %

Vertical loads to be taken into consideration are:

— nominal self-weight as given (see 8.2.1.1);

— vertical service loads as given (see 8.2.1.2).

8.2.1.4 Minimum vertical service load on the structure, equally distributed on 4 legs

P = 5,0 kN;

NOTE P can be larger than 5,0 kN in accordance with the uniformly distributed loads as given in Table 3.

8.2.2 Horizontal loads

8.2.2.1 Horizontal service load on the topmost platform

On the level of the platforms with length l:

— l ≤ 4,0 m : 0,3 kN;

— l > 4,0 m : 2 × 0,3 kN.

NOTE 0,3 kN is taken from EN 12811-1.

8.2.2.2 Horizontal loads on all components to simulate wind

0,1 kN/m multiplied by the appropriate aerodynamic force coefficients c .

f

Aerodynamic force coefficients, c , appropriate for some cross sections of components of mobile access

f

towers, are given in EN 1991-1-4.

The value for the aerodynamic force coefficients c may be taken as 1,3 for all projected areas including

f

platforms and toe boards.

NOTE

0,1 kN/m relates to the peak velocity pressure, q , according to EN 1991-1-4:2005, 4.5.

p

0,1 kN/m refers to a wind velocity of vp = 45,5 km/h = 12,7 m/s.

The wind affected area shall include the required side protection components at the working level and

the intermediate levels.

Shelter effects for more than one component being upwind may be taken into consideration by the

application of EN 1991-1-4:2005, 7.9 and 7.11, as appropriate.

Alternatively, shelter effects may be taken into consideration, according to Annex C.

8.3 Characteristic actions on parts of the structure

8.3.1 Loads on platform units

Platform units and the supporting structure shall be designed for concentrated loads and uniformly

distributed loads in accordance with Table 4.

The requirements for concentrated loads and uniformly distributed loads shall be fulfilled separately.

8.3.2 Load on side protection

8.3.2.1 Downward load

Any principal guardrail or intermediate guardrail, regardless of its method of support, shall be able to

resist a point load of 1,25 kN. This also applies to any other side protection component, such as a

fencing structure, which has a potential foothold of 50 mm wide or greater.

This load shall be considered as an accidental load and applied in the most unfavourable position in a

downward direction within a sector of ± 10° from the vertical.

8.3.2.2 Horizontal load

All components of the side protection, except toe-boards, shall be able to resist a horizontal load of

0,3 kN in each case in the most unfavourable position. This load may be distributed over an area of

300 mm × 300 mm, e.g. when applied to the grid of a fencing structure. For toe-boards, the horizontal

load is 0,15 kN.

Table 3 — Service loads on the whole structure

Group Line Kind of load Value of Subclause

load

1 Self-weight including ballast if as given 8.2.1.1

applicable

2 Vertical service load on the

topmost platform

2.1 Uniformly distributed load 8.2.1.2

2.1.1 for load class 2 2

1,5 kN/m

2.1.2 for load class 3 2

2,0 kN/m

2.2 minimum service load on the 5,0 kN/4

structure legs

3 Horizontal service load on the 8.2.2.1

topmost platform

a

3.1 l ≤ 4,0 m 0,3 kN

a

3.2 l > 4,0 m 2 × 0,3 kN

4 Horizontal loads to simulate 8.2.2.2

wind

5 Loads resulting from an 8.2.1.3

inclined position of 1 %

a

l = length of the platform

Table 4 — Service loads on parts of the structure

Line Element Type of load Value of Subclause

loads

1 platform

Uniformly distributed 8.2.1.2

1.1

on the whole area

Load class 2 2

1.1.1

1,5 kN/m

Load class 3 2

1.1.2

2,0 kN/m

Concentrated on an 1,5 kN 8.3.1

area of

500 mm × 500 mm in

the most unfavourable

position on the

1.2

platform

If the width of the

platform unit is less

than 500 mm, the load

shall not be reduced.

Concentrated on an 1,0 kN 8.3.1

area of

200 mm × 200 mm in

1.3

the most unfavourable

position on the

platform

2 guardrail

A downward point load 1,25 kN 8.3.2.1

on the guardrail in the

2.1

most unfavourable

position

A horizontal point load 0,3 kN 8.3.2.2

on the guardrail in the

2.2

most unfavourable

position

Toe board A horizontal point load 0,15 kN 8.3.2.2

on the toe board in the

most unfavourable

position

8.3.3 Load on stairways and stairladders

Each tread and landing shall be designed to support the more unfavourable of either:

a) a single load of 1,5 kN in the most unfavourable position, assumed to be uniformly distributed over

an area of 200 mm × 200 mm or over the actual width if it is less than 200 mm, or

b) a uniformly distributed load of 1,0 kN/m .

The structures of stairways and stair ladders shall be capable of supporting a uniformly distributed load

of 1,0 kN/m on all treads and landings.

8.3.4 Load on inclined ladders

Inclined ladders shall be designed in accordance with the test for torsion and vertical load on rungs in

EN 131-2.

8.3.5 Load on Vertical ladder

Vertical ladders shall be verified either by;

— structural analysis for the following characteristic vertical load, always acting in the most adverse

= 1,5 kN acting on 200 mm, or

position of F1,k

— in accordance with the test for torsion and vertical load on rungs in EN 131-2.

8.4 Deflections

8.4.1 Elastic deflection of platform components

When subjected to the concentrated loads specified in Table 4, line 1.2, the elastic deflection of any

platform component shall not exceed 0,01 of the span of that platform component.

In addition, in the case of platform components with spans of 2,5 m or greater, when the appropriate

concentrated load is applied, the maximum difference in levels between adjacent loaded and unloaded

platform components shall not exceed 25 mm.

8.4.2 Elastic deflection of side protection

When subjected to the load specified in Table 4, line 2.2, the maximum deflection of any principle or

intermediate guardrail, regardless of its span, shall not exceed 35 mm. When subjected to the load

specified in Table 4; line 3, the maximum deflection of any toe-board, regardless of its span shall not

exceed 35 mm. These are measured with reference to the supports at the points where they are

connected.

9 Structural design

9.1 Basic design principle

9.1.1 Introduction

Mobile access and working towers shall be designed for load bearing capacity, serviceability and

resistance to overturning. Unless otherwise stated in this clause, the Eurocodes for structural design

shall be applied.

The strength of joints and connections (e.g. welded joints, compressed connections, hollow type rivet

connections) shall be verified.

Concepts relate to the limit state method.

Full scale or detail testing may be undertaken in accordance with EN 12811-3 to suppl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...