EN 12516-1:2005

(Main)Industrial valves - Shell design strength - Part 1: Tabulation method for steel valve shells

Industrial valves - Shell design strength - Part 1: Tabulation method for steel valve shells

This document specifies the tabulation method for determining the wall thickness of valve bodies with essentially circular cross-section made in forged, cast or fabricated steel.

For valve shells with oval, rectangular or non-circular shapes, see 8.6.

The range of B or Class designations for which thicknesses are tabulated is:

B 2,5, B 6, B 10, B 16, B 20, B 25, B 40, Class 300, B 63, B 100, Class 600, Class 900, Class 1500, Class 2500, Class 4500.

Standard and special pressure temperature ratings are specified for each material group for the above B and Class designations.

The non-destructive examination procedures and acceptance levels that shall be applied to the valve shell components in order for the valve to be used at Special pressure temperature ratings are defined. Details are also given for the alternative rules for small bore valves of DN 65 and smaller.

This document does not apply to threaded end valves:

¾ DN 80 or larger;

¾ or which have pressure ratings greater than Class 2500;

¾ or which operate at temperatures greater than 540 °C.

Socket welding end valves DN 80 or larger are outside the scope of this document.

Industriearmaturen - Gehäusefestigkeit - Teil 1: Tabellenverfahren für drucktragende Gehäuse von Armaturen aus Stahl

Dieses Dokument legt das Tabellenverfahren zur Bestimmung der Wanddicke von Armaturengehäusen mit im Wesentlichen kreisrundem Querschnitt aus Schmiedestahl, Stahlguss oder Rohstahl fest.

Drucktragende Armaturengehäuse mit ovalen, rechteckigen oder nicht runden Profilen, siehe 8.6.

Dickenwerte sind in folgendem Bereich der B- oder Class-Bezeichnungen tabellarisch festgehalten:

B 2,5, B 6, B 10, B 16, B 20, B 25, B 40, Class 300, B 63, B 100, Class 600, Class 900, Class 1 500, Class 2 500, Class 4 500

Für jede Werkstoffgruppe werden die Druck-/Temperatur-Zuordnungen mit Standard- und Spezialbezeichnung für die vorgenannten B- oder Class-Bezeichnungen festgelegt.

Es werden die für die drucktragenden Gehäusebauteile geltenden zerstörungsfreien Prüfungen und Abnahmekriterien festgelegt, die für einen Einsatz der Armatur bei Druck-/Temperatur-Zuordnungen mit der Bezeichnung "Special" erforderlich sind. Einzelheiten über die alternativen Regelungen für Armaturen mit kleiner Bohrung von höchstens DN 65 sind ebenfalls enthalten.

Die vorliegende Norm gilt nicht für Armaturen mit Gewindeanschlüssen:

- DN 80 oder größer;

- bzw. mit Druckstufen > Class 2 500;

- bzw. für den Betrieb bei Temperaturen > 540 °C.

Armaturen mit Schweißmuffenenden DN 80 oder größer fallen nicht in den Anwendungsbereich dieser Norm.

Robinetterie industrielle - Résistance mécanique des enveloppes - Partie 1: Méthode tabulaire relative aux enveloppes d'appareils de robinetterie en acier

Le présent document spécifie la méthode tabulaire qui permet de déterminer l'épaisseur de paroi des corps, chapeaux et couvercles d'appareils de robinetterie à section transversale essentiellement circulaire, fabriqués en acier forgé, moulé ou mécanosoudé.

Pour les enveloppes d'appareils de robinetterie à forme ovale, rectangulaire ou non circulaire, voir 8.6.

La gamme des désignations B ou Class pour lesquelles les épaisseurs sont mises en Tableau est la suivante :

B 2,5, B 6, B 10, B 16, B 20, B 25, B 40, Class 300, B 63, B 100, Class 600, Class 900, Class 1500, Class 2500, Class 4500.

Les relations pression/température standard et Spécial sont spécifiées pour chaque groupe de matériaux en ce qui concerne les désignations B et Class ci-dessus.

Les modes opératoires des contrôles non destructifs et les critères d'acceptation qui doivent être appliqués aux composants de l'enveloppe de l'appareil de robinetterie afin de pouvoir utiliser ce dernier pour des relations pression/température Spécial, sont définis. Des détails sont également fournis sur les autres règles relatives aux appareils de robinetterie à passage réduit de DN 65 et inférieur.

Le présent document ne s'applique pas aux appareils de robinetterie à extrémités filetées :

- de DN 80 ou supérieur ;

- qui ont des relations de pression supérieures à Class 2500 ;

- ou qui fonctionnent à des températures supérieures à 540 °C.

Les appareils de robinetterie à extrémités à emboîter et à souder de DN 80 ou supérieur n'entrent pas dans le domaine d'application de ce document.

Industrijski ventili - Trdnost ohišja - 1. del: Tabelarična metoda za jeklena ohišja

General Information

- Status

- Withdrawn

- Publication Date

- 19-Apr-2005

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 69 - Industrial valves

- Drafting Committee

- CEN/TC 69/WG 1 - Basic standards

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Oct-2014

- Completion Date

- 09-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10228-1:2016 - Non-destructive testing of steel forgings - Part 1: Magnetic particle inspection - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 12516-1:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Industrial valves - Shell design strength - Part 1: Tabulation method for steel valve shells". This standard covers: This document specifies the tabulation method for determining the wall thickness of valve bodies with essentially circular cross-section made in forged, cast or fabricated steel. For valve shells with oval, rectangular or non-circular shapes, see 8.6. The range of B or Class designations for which thicknesses are tabulated is: B 2,5, B 6, B 10, B 16, B 20, B 25, B 40, Class 300, B 63, B 100, Class 600, Class 900, Class 1500, Class 2500, Class 4500. Standard and special pressure temperature ratings are specified for each material group for the above B and Class designations. The non-destructive examination procedures and acceptance levels that shall be applied to the valve shell components in order for the valve to be used at Special pressure temperature ratings are defined. Details are also given for the alternative rules for small bore valves of DN 65 and smaller. This document does not apply to threaded end valves: ¾ DN 80 or larger; ¾ or which have pressure ratings greater than Class 2500; ¾ or which operate at temperatures greater than 540 °C. Socket welding end valves DN 80 or larger are outside the scope of this document.

This document specifies the tabulation method for determining the wall thickness of valve bodies with essentially circular cross-section made in forged, cast or fabricated steel. For valve shells with oval, rectangular or non-circular shapes, see 8.6. The range of B or Class designations for which thicknesses are tabulated is: B 2,5, B 6, B 10, B 16, B 20, B 25, B 40, Class 300, B 63, B 100, Class 600, Class 900, Class 1500, Class 2500, Class 4500. Standard and special pressure temperature ratings are specified for each material group for the above B and Class designations. The non-destructive examination procedures and acceptance levels that shall be applied to the valve shell components in order for the valve to be used at Special pressure temperature ratings are defined. Details are also given for the alternative rules for small bore valves of DN 65 and smaller. This document does not apply to threaded end valves: ¾ DN 80 or larger; ¾ or which have pressure ratings greater than Class 2500; ¾ or which operate at temperatures greater than 540 °C. Socket welding end valves DN 80 or larger are outside the scope of this document.

EN 12516-1:2005 is classified under the following ICS (International Classification for Standards) categories: 23.060.01 - Valves in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12516-1:2005 has the following relationships with other standards: It is inter standard links to EN 12516-1:2014, EN 12627:2017, EN 736-1:1995, EN 10222-3:2017, EN ISO 3452-6:2008, EN ISO 9606-1:2017, EN ISO 3452-4:1998, EN 10222-4:2017+A1:2021, EN 10228-3:1998, EN 10028-4:2017, EN 19:2023, EN ISO 19232-4:2013, EN 10228-1:2016, EN 10222-2:2017+A1:2021, EN ISO 19232-1:2013. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12516-1:2005 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12516-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Industrial valves - Shell design strength - Part 1: Tabulation method for steel valve shellsRobinetterie industrielle - Résistance mécanique des enveloppes - Partie 1: Méthode tabulaire relative aux enveloppes d'appareils de robinetterie en acierIndustriearmaturen - Gehäusefestigkeit - Teil 1: Tabellenverfahren für drucktragende Gehäuse von Armaturen aus StahlTa slovenski standard je istoveten z:EN 12516-1:2005SIST EN 12516-1:2005en23.060.01ICS:SLOVENSKI

STANDARDSIST EN 12516-1:200501-julij-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12516-1April 2005ICS 23.060.01English versionIndustrial valves - Shell design strength - Part 1: Tabulationmethod for steel valve shellsRobinetterie industrielle - Résistance mécanique desenveloppes - Partie 1: Méthode tabulaire relative auxenveloppes d'appareils de robinetterie en acierIndustriearmaturen - Gehäusefestigkeit - Teil 1:Tabellenverfahren für drucktragende Gehäuse vonArmaturen aus StahlThis European Standard was approved by CEN on 15 March 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12516-1:2005: E

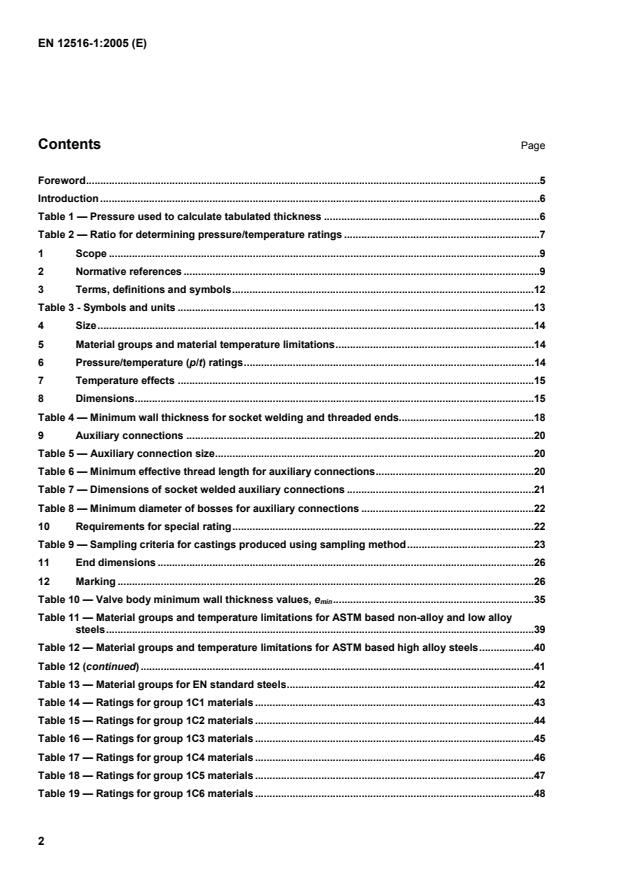

Relationship between DN, NPS , pipe inside diameter Dni and pipe outside diameter.93 Table A.1 — Pipe inside and outside diameters Dni and OD.93 Annex B (normative)

Radiography procedure and acceptance standards.94 Table B.1 — Radiographic acceptance criteria.95 Annex C (normative)

Magnetic particle examination procedure and acceptance standards.96 Annex D (normative)

Liquid penetrant examination procedure and acceptance standards.98 Annex E (normative)

Ultrasonic examination procedure and acceptance standards.100 Annex F (informative)

Methods used for establishing pressure-temperature ratings.101 Table F.1 — Pressure used to calculate tabulated thickness.101 Table F.2 — Constant, c, used to calculate tabulated minimal thickness.101 Table F.3 — Ratio for determining pressure/temperature ratings.102 Table F.4 — Standard and special Class 4500 ceiling pressures.103 Annex G (normative)

Requirement for Limited Class valves in sizes DN 65 and smaller.105 Table G.1 — Pressure rating index.106 Table G.2 — Temperature coefficient.106 Annex H (informative)

Material groups.108 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directives 97/23/EC.110 Table ZA.1 — Correspondence between this European Standard and Directive 97/23/EC.110 Bibliography.111

The equation for calculating the thickness is ()()constant2,111825,1cmin+−×=cipDpe (1) For the Class designations, except Class 150, the rules for determining the pressure/temperature ratings are the same for both valve shells and flanges. Hence, only one designation is required. The rules for determining Class 150 flange pressure/temperature ratings are different to those for the valve shell and therefore B 20 is used for the designation of the valve shell.

(2) The Standard Class pressure temperature rating for Class 4500 is calculated using the equation: allowable pressure at temperature 00075004×=1,25temp.atstressstandardselectedtt (3) NOTE In ASME B16.34, 7 000 times 1,25 is shown as 8750. This appears to show that allowable pressures for standard rating valves are always 80 % of the equivalent special rating values. However, the rules for determining the selected stress for standard and special ratings are different. Therefore at low temperatures, the difference in allowable pressures is nil or very small and it is only at high temperatures where the full 80 % difference can be seen. The selected stresses are applicable for a group of materials and are determined from the material properties of ASME Section IID (see [3]) The reason for the down rating of standard rating values relative to Special rating is that the standard rating body is not subject to the specified non-destructive examination procedures and acceptance levels. The thicknesses for all designations are approximately proportional to the Class 4500 thickness in the ratio of the pressures in Table 1. Similarly, the pressure/temperature ratings are proportional to the Class 4500 rating. For B designated ratings the ratio are based on 760 bar being the metric value needed to get equivalence to the value of Class 4500. See Table 2. Table 2 — Ratio for determining pressure/temperature ratings Class Designation B 2,5 B 6 B 10 B 16 B 20 B 25 B 40 300 Ratio

2,5 760 6 760 10 760 16 760 20 760 25 760 40 760 300 4500 Class Class Class Class Class Designation B 63 B 100 600 900 1500 2500 4500 — Ratio

63 760 100 760 600 4500 900 4500 1500 4500 2500 4500 4500 4500 —

For each material group, this results in a series of pressure temperature lines. For flanges a series of pressure temperature lines is also calculated and designated PN 2,5, PN 6, PN 10, PN 16, Class 150, PN 25, PN 40, PN 63 and PN 100. The rules for calculating these flange lines differ from those for the valve shell. Hence, there are points where these two families of lines, i.e. flanges and B designated valve shells, intersect. The main reasons for the differences are due to the treatment of ceiling values. In PN flanges, a constant ceiling stress of 225 N/mm2 at room temperature is applied. In B and Class designations, the ASME B16.34 ceiling criteria apply, which are temperature dependent. In the case where the valve body designed with this part of EN 12516 has PN, designated flanged ends the designer should consider the requirements laid down in 6.6 to ensure that the valve body is not weaker than the flange.

General The rating Tables 14 to 63 specify the allowable pressures at different temperatures for bodies, bonnets and covers with B and Class designations made from the appropriate material group (see Annex F). The temperature of the valve is generally the temperature of the contained fluid. NOTE B has been used for the designation letter instead of PN and Class 150 to differentiate from the ratings specified in EN 1092-1and EN 1759-1. 6.2

Standard rating In conformance with the present document, standard rating applies to flanged (see 6.6) and butt welding end valves in all sizes and to valves with threaded and socket welding ends up to DN 65 (NPS 2 1/2). When a valve body or bonnet is manufactured by welding parts together, it shall be classified as suitable for standard rating provided that 10 % of the welds are subject to random non destructive testing in such a manner that it results in a joint efficiency of 0,85. 6.3

Special rating The bodies, bonnets and covers that have been subjected to the levels of NDE specified in Clause 10 can be used for a higher pressure/temperature rating than standard. When a valve body or bonnet is manufactured by welding parts together, it shall only be classified as suitable for special rating if it meets the requirements of 10.6. 6.4

Limited Class Welding and threaded end valves in sizes DN 65 (NPS 2 ½) and smaller, which are in accordance with Annex G, may be designated as Limited Class. Ratings shall not exceed the values calculated in accordance with Annex G. 6.5

Intermediate ratings Any pressure/temperature ratings in either standard or special ratings, between those listed in the tables, may be assigned to welding or threaded end valves providing all the requirement of this document are met.

Flanged ratings For valves with flanged ends, the designer shall ensure that at all points on the p/t curve the p/t rating of the valve body and bonnet or cover within the temperature limits marked on the valve, is at least equal to the p/t rating of the flange. When the table of p/t ratings gives a working pressure lower than that of the flanges, the designer shall increase the wall thickness and make an interpolation. The p/t rating of the valve with flanged ends shall be identical to the p/t rating of the flange as given in EN 1092-1 for PN flanges and EN 1759-1 for Class flanges for the appropriate material group. 7 Temperature effects 7.1

Temperature limits Bolted flange joints operating in the creep range or those which experience substantial thermal gradients are subject to decreasing bolt loads as relaxation of flanges, bolts and gaskets take place. The designer shall take into account that decreasing bolt loads reduce the capacity of the bolted joint to remain leak tight. Material shall be used within their established limits. If no material properties are available, an individual material assessment is required. Some materials are suitable for temperatures below room temperature, RT but the pressure rating shall not be greater than that given for room temperature. 7.2

Fluid thermal expansion It is possible, in some valve designs, for sealed cavities within the valve body to be filled with liquid, for example during hydrostatic test. If this liquid is not released, by partially opening the valve or some other means, and it is subject to a temperature increase, excessive pressure sufficient to cause pressure boundary failure can be generated. Where such a condition is possible, the design, installation, or operating procedures shall assure that the pressure in the valve does not exceed that allowed in this document. 8 Dimensions 8.1

Minimum wall thickness The wall thickness of valve bodies, at the time of manufacture and excluding all linings or liners, shall be not less than emin as listed in Table 10 except as allowed in 8.3, 8.4 and 8.5. Intermediate values between those listed in Table 10 may be obtained by linear interpolation. The specified thickness only applies from internally wetted surfaces. The thickness tabulated in Table 10 includes a 1,0 mm allowance for erosion and linear corrosion. 8.2

Inside diameter For the purpose of determining the wall thickness, emin , of a full bore valve the inside diameter, Di, is taken as the minimum diameter of the flow passage but not less than 90 % of the body end port inside diameter at (Dni). For the purpose of determining the wall thickness, emin, of a reduced bore valve the inside diameter, Di, is taken as the diameter of the flow passage in the plane at a distance, emin, from the outside surface of the body neck as measured along the body run. See Figure 1.

Valve body necks Valve body necks shall maintain the minimum wall thickness, emin for a distance of mini1,1eD measured from the body run along the neck direction as illustrated in Figure 1. Minimum wall thicknesses are applicable to and measured from internally wetted surfaces. Beyond the mini1,1eDregion, mentioned above, straight circular sections of the body necks with inside diameter of Di' shall be provided with a wall thickness at least equal to e' where e' is taken from the appropriate (tabulated or intermediate) rating in Table 10 for an appropriate Di''. For B and Class designations ≤ Class 2500 32'i"iDD=

(4) For B and Class designations > Class 2500 +=500ndesignatioClass2748'i"iDD

(5) a) For the special case where Di' > 1,5 Di the wall thickness shall be ≥ e' for the entire body neck length having inside diameter Di', including the mini1,1eD region. b) For the special case where, 4'ii≥DD (valve body necks having small diameter compared with the body run diameter, (for example access for a butterfly stem) the minimum local wall thickness for a length L as indicated in Figure 20 shall be ≥ e' where e' is obtained from Table 10 using the appropriate Di' and B or Class designation. +=minmin1,11eDeLi (6) Beyond the length, L valve body necks shall have a minimum local wall thickness based on Di''. c) For the case of a body neck in which holes are drilled or tapped in the body neck wall parallel to the body neck axis, up to the point where the body-bonnet joint is affected, the sum of the ligaments at the inner and outer sides shall be equal to or greater than emin or e' as applicable. The inner ligament and the ligament at the bottom of the drilled hole shall be no less than 0,25 × emin or 0,25 × e' as applicable. This thickness shall exist from the end of the body neck for a distance along the body neck for a distance equal to 1,5 times the hole or bolt diameter.

Figure 1a — Section of valve body run

Figure 1b — Section of valve body neck Figure 1 — Valve body run and neck

Local areas Local areas having less than the minimum thickness emin are acceptable providing the following conditions are satisfied a) The area of sub-minimum thickness can be enclosed by a circle whose diameter is no greater than mini35,0eD. For body necks take Di = Di’ b) Measured thickness is not less than 0,75 emin. c) Enclosed circles are separated from each other by an edge to edge distance of no less than mini75,1eD. 8.5

Contours at body ends a) Butt welding ends The weld preparation shall not reduce the body wall thickness to less than emin within a region closer to the outside surface of the body neck than emin measured in the pipe run direction. See Figure 1. The transition to the weld preparation shall be gradual and the section shall be essentially circular through the length of the transition. Sharp discontinuities or abrupt changes of section shall be avoided, except test collars or bands, either welded or integral, are allowed. In no case shall the thickness b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...