EN 12697-24:2004+A1:2007

(Main)Bituminous mixtures - Test methods for hot mix asphalt - Part 24: Resistance to fatigue

Bituminous mixtures - Test methods for hot mix asphalt - Part 24: Resistance to fatigue

This document specifies the methods for characterising the fatigue of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports.

The procedure is used to rank bituminous mixtures on the basis of resistance to fatigue, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures.

Because this document does not impose a particular type of testing device, the precise choice of the test conditions depends on the possibilities and the working range of the used device. For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures shall be respected. The applicability of this document is described in the product standards for bituminous mixtures. Results obtained from different test methods are not assured to be comparable.

Asphalt - Prüfverfahren für Heißasphalt - Teil 24: Beständigkeit gegen Ermüdung

Dieses Dokument legt die Verfahren fest zur Charakterisierung der Ermüdung von Asphalt durch verschiedene Prüfungen, einschließlich Biegeprüfungen und Prüfungen der direkten sowie der indirekten Zug¬festigkeit. Die Prüfungen werden an verdichtetem Asphalt unter sinusförmiger oder einer anderen kontrollier¬ten Belastung unter Verwendung verschiedener Probekörpertypen und Auflagerungen vorgenommen.

Das Verfahren dient zur Einstufung von Asphalt nach seiner Beständigkeit gegen Ermüdung, als Hinweis auf sein relatives Leistungsvermögen in der Fahrbahnbefestigung, um Daten zur Abschätzung des Tragverhal¬tens in der Straße zu erhalten und die Prüfdaten nach den für Asphalt geltenden Festlegungen zu beurteilen.

Da dieses Dokument keinen bestimmten Prüfgerätetyp vorschreibt, hängt die genaue Auswahl der Prüfbedingungen von den Möglichkeiten und dem Arbeitsbereich des im betreffenden Fall verwendeten Prüf¬geräts ab. Bei der Auswahl der jeweiligen Prüfbedingungen müssen die Anforderungen der Produktnormen für Asphalt berücksichtigt werden. Die Anwendbarkeit dieses Dokumentes ist in den Produktnormen für Asphalt beschrieben. Die mit verschiedenen Prüfverfahren erhaltenen Prüfergebnisse sind nicht notwendiger¬weise miteinander vergleichbar.

Mélanges bitumineux - Méthodes d'essai pour mélange hydrocarboné à chaud - Partie 24: Résistance à la fatigue

Le présent document spécifie les méthodes qui sont utilisées pour caractériser la fatigue des mélanges bitumineux par différents types d’essais, dont des essais de flexion et des essais de traction directe et indirecte. Les essais sont réalisés sur des matériaux bitumineux compactés, au moyen d’une charge sinusoïdale ou d’une autre charge contrôlée, en utilisant différents types d’éprouvettes et de supports.

La procédure est utilisée pour classer les mélanges bitumineux selon leur résistance à la fatigue, prise comme guide comparatif des performances dans les structures de chaussée, de manière à obtenir des données permettant d’estimer le comportement structurel du matériau dans la chaussée et de pouvoir juger les résultats d’essais en fonction des spécifications des mélanges bitumineux.

Comme le présent document n’impose pas un type de dispositif d’essai particulier, le choix précis des conditions d’essai dépend des possibilités et de la plage de fonctionnement du dispositif utilisé. Pour le choix des conditions d’essai spécifiques, il sera nécessaire de respecter les critères des normes produit des mélanges bitumineux. Le domaine d’application du présent document est décrit dans les normes produit des mélanges bitumineux. Il n’est pas certain que les résultats obtenus selon les différentes méthodes d’essai soient comparables.

Bitumenske zmesi - Preskusne metode za vroče asfaltne zmesi - 24. del: Odpornost proti utrujanju

General Information

- Status

- Withdrawn

- Publication Date

- 03-Jul-2007

- Withdrawal Date

- 22-May-2012

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-May-2012

- Completion Date

- 23-May-2012

Not Harmonized89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 30-May-2012

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12697-24:2004+A1:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Test methods for hot mix asphalt - Part 24: Resistance to fatigue". This standard covers: This document specifies the methods for characterising the fatigue of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports. The procedure is used to rank bituminous mixtures on the basis of resistance to fatigue, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures. Because this document does not impose a particular type of testing device, the precise choice of the test conditions depends on the possibilities and the working range of the used device. For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures shall be respected. The applicability of this document is described in the product standards for bituminous mixtures. Results obtained from different test methods are not assured to be comparable.

This document specifies the methods for characterising the fatigue of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports. The procedure is used to rank bituminous mixtures on the basis of resistance to fatigue, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures. Because this document does not impose a particular type of testing device, the precise choice of the test conditions depends on the possibilities and the working range of the used device. For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures shall be respected. The applicability of this document is described in the product standards for bituminous mixtures. Results obtained from different test methods are not assured to be comparable.

EN 12697-24:2004+A1:2007 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12697-24:2004+A1:2007 has the following relationships with other standards: It is inter standard links to EN 12697-24:2004, EN 12697-24:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12697-24:2004+A1:2007 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/124. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12697-24:2004+A1:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bituminous mixtures - Test methods for hot mix asphalt - Part 24: Resistance to fatigueMélanges bitumineux - Méthodes d'essai pour mélange hydrocarboné a chaud - Partie 24: Résistance a la fatigueAsphalt - Prüfverfahren für Heißasphalt - Teil 24: Beständigkeit gegen ErmüdungTa slovenski standard je istoveten z:EN 12697-24:2004+A1:2007SIST EN 12697-24:2004+A1:2007en,fr,de93.080.20Materiali za gradnjo cestRoad construction materialsICS:SLOVENSKI

STANDARDSIST EN 12697-24:2004+A1:200701-november-2007

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12697-24:2004+A1

July 2007 ICS 93.080.20 Supersedes EN 12697-24:2004English Version

Bituminous mixtures - Test methods for hot mix asphalt - Part 24: Resistance to fatigue

Mélanges bitumineux - Méthodes d'essai pour mélange hydrocarboné à chaud - Partie 24: Résistance à la fatigue Asphalt - Prüfverfahren für Heißasphalt - Teil 24: Beständigkeit gegen Ermüdung This European Standard was approved by CEN on 2 March 2004 and includes Amendment 1 approved by CEN on 16 May 2007.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2007 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12697-24:2004+A1:2007: E

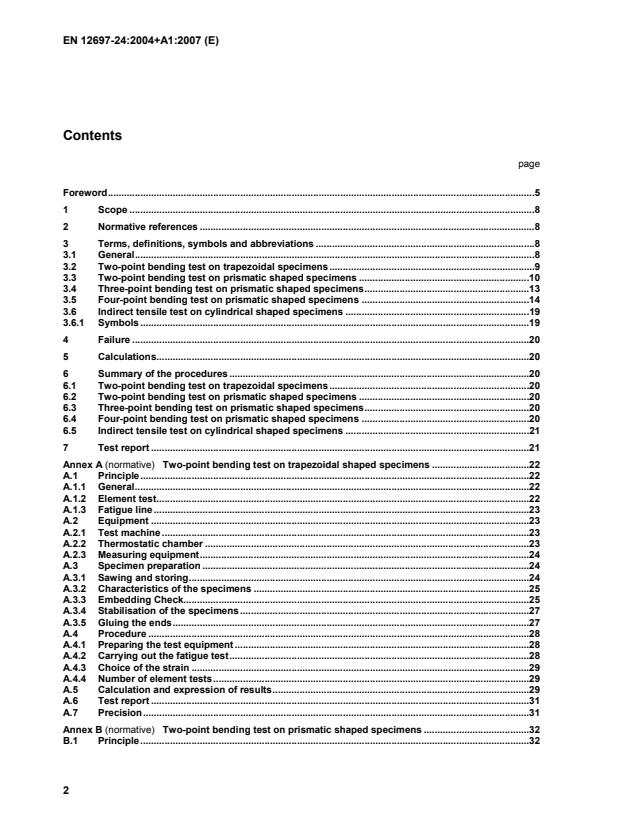

Two-point bending test on trapezoidal shaped specimens.22 A.1 Principle.22 A.1.1 General.22 A.1.2 Element test.22 A.1.3 Fatigue line.23 A.2 Equipment.23 A.2.1 Test machine.23 A.2.2 Thermostatic chamber.23 A.2.3 Measuring equipment.24 A.3 Specimen preparation.24 A.3.1 Sawing and storing.24 A.3.2 Characteristics of the specimens.25 A.3.3 Embedding Check.25 A.3.4 Stabilisation of the specimens.27 A.3.5 Gluing the ends.27 A.4 Procedure.28 A.4.1 Preparing the test equipment.28 A.4.2 Carrying out the fatigue test.28 A.4.3 Choice of the strain.29 A.4.4 Number of element tests.29 A.5 Calculation and expression of results.29 A.6 Test report.31 A.7 Precision.31 Annex B (normative)

Two-point bending test on prismatic shaped specimens.32 B.1 Principle.32

Three-point bending test on prismatic shaped specimens.38 C.1 Principle.38 C.1.1 General.38 C.1.2 Element test.38 C.1.3 Fatigue line.38 C.2 Equipment.38 C.2.1 Test machine.38 C.2.2 Load cell.38 C.2.3 Extensometer and displacement sensor.38 C.2.4 Clamping device.39 C.2.5 Data acquisition equipment.39 C.2.6 Thermostatic chamber.39 C.2.7 Other general equipment.39 C.2.8 Check on the operation of the complete equipment and the mounting of the specimen.39 C.3 Specimen preparation.39 C.3.1 Manufacturing and sawing.39 C.3.2 Bulk density.39 C.3.3 Storing.40 C.3.4 Clamping devices preparation.40 C.4 Procedure.40 C.4.1 Preparing the test equipment.40 C.4.2 Carrying out the fatigue test.40 C.4.3 Load function, extensometer signal function, and displacement function recording.40 C.4.4 End of test.41 C.5 Calculation and expression of results.41 C.5.1 Calculation of the stress function and the strain function at a cycle.41 C.5.2 Calculation of the dynamic modulus, phase difference angle, and density of dissipated energy at one cycle.42 C.5.3 Determination of the fatigue law and energy law.43 C.6 Test report.44 C.7 Precision.44 Annex D (normative)

Four-point bending test on prismatic shaped specimens.45 D.1 Principle.45 D.1.1 General.45 D.1.2 Element test.45 D.1.3 Fatigue line.46 D.2 Equipment.47 D.2.1 Test machine.47 D.2.2 Clamping device.47 D.2.3 Thermostatic chamber.47 D.2.4 Electronic data registration equipment.47 D.2.5 Check on the operation of the complete equipment and the mounting of the specimen.48

Indirect tensile test on cylindrical shaped specimens.53 E.1 Principle.53 E.2 Equipment.53 E.2.1 Test machine.53 E.2.2 Loading.53 E.2.3 Displacement.53 E.2.4 Thermostatic chamber.53 E.2.5 Recording and measuring system.53 E.2.6 Loading frame.54 E.2.7 Positioning rig.55 E.2.8 Glue.55 E.3 Specimen preparation.56 E.3.1 Test specimen.56 E.3.2 Specimen dimensions.56 E.3.3 Position of the deformation and loading strips.56 E.3.4 Conditioning.57 E.4 Procedure.57 E.5 Calculation and reporting of results.57 E.6 Test report.60 E.7 Precision.60 Bibliography.61

1 Scope This document specifies the methods for characterising the fatigue of bituminous mixtures by alternative tests, including bending tests and direct and indirect tensile tests. The tests are performed on compacted bituminous material under a sinusoidal loading or other controlled loading, using different types of specimens and supports. The procedure is used to rank bituminous mixtures on the basis of resistance to fatigue, as a guide to relative performance in the pavement, to obtain data for estimating the structural behaviour in the road and to judge test data according to specifications for bituminous mixtures. Because this document does not impose a particular type of testing device, the precise choice of the test conditions depends on the possibilities and the working range of the used device. For the choice of specific test conditions, the requirements of the product standards for bituminous mixtures shall be respected. The applicability of this document is described in the product standards for bituminous mixtures. Results obtained from different test methods are not assured to be comparable. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. !EN 12697-6:2003+A1", Bituminous mixtures — Test methods for hot mix asphalt — Part 6: Determination of bulk density of bituminous specimen. EN 12697-26, Bituminous mixtures — Test methods for hot mix asphalt — Part 26: Stiffness. EN 12697-27, Bituminous mixtures — Test methods for hot mix asphalt — Part 27: Sampling. EN 12697-29, Bituminous mixtures — Test methods for hot mix asphalt — Part 29: Determination of the dimensions of bituminous specimen. EN 12697-31, Bituminous mixtures — Test methods for hot mix asphalt — Part 31: Specimen preparation, gyratory compactor. !EN 12697-33:2003+A1, Bituminous mixtures — Test methods for hot mix asphalt — Part 33: Specimen prepared by roller compactor." 3 Terms, definitions, symbols and abbreviations For the purposes of this document, the following terms and definitions, symbols and abbreviations apply. 3.1 General 3.1.1 fatigue reduction of strength of a material under repeated loading when compared to the strength under a single load 3.1.2 conventional criteria of failure (constant displacement) number of load applications, Nf/50, when the complex stiffness modulus has decreased to half its initial value

EN 12697-26); bi is the base, in millimetre (mm); hi is the height, in millimetre (mm); ei is the width, in millimetre (mm). 3.3.4 Symbols The symbols are as follows, with a strain of 1 microstrain (µstrain) being equal to 10–6 by convention: 3.3.4.1 Sample i hI is the height, in millimetres (mm) bI is (A) small base or (B) base, in millimetres (mm) eI is the thickness, in millimetres (mm) mI is the mass, in grams (g) vi% is the vacuum achieved by the geometric method as a proportion of atmospheric pressure, in per cent (%) Kσi is the constant for consideration of the geometry of specimen at constant strength, in inverse millimetres (mm–1) 3.3.4.2 Strength at head and greatest tension at specimen i at level of tension εj max Pij is the amplitude of the strength with which the head is applied, in Newtons (N) σj max is the greatest relative tension of the specimen, corresponding to the strength, with which the head is applied 3.3.4.3 Fatigue life of a specimen i at the level of tension σj max Nij is the fatigue life. 3.3.4.4 Fatigue life relative to sample i at the strain level εj Nij is the conventional fatigue life. 3.3.4.5 Fatigue line pσ

is the slope of fatigue line ln(σj max) = f (ln(Nij)) 6σˆ is the tension corresponding with 106 cycles, in megapascals (MPa) yxσs is the estimation of the residual standard deviation of the natural logarithms of fatigue lives 6σ∆ˆ is the confidence of 6σˆfor a probability of 95 %

is the phase angle of the approximate strain function, in radians (rad) Dc is the displacement at instant t, in microns (µm) 2D0 is the total amplitude of displacement function, in microns (µm) DDE is the density of dissipated energy, in megapascals (MPa) or megajoules per cubic metre (MJ/m3) DE(total) is the total density of dissipated energy throughout the whole test, in megajoules per cubic metre (MJ/m3) DDE (x)

is the density of dissipated energy at cycle x, in megajoules per cubic metre (MJ/m3) EXT is the instant extensometer signal, in millimetres (mm) L is the distance between supports, in millimetres (mm) MD is the dynamic modulus, in megapascals (MPa) N is the number of cycle at end of test P is the instant load, in megapascals (MPa) W is the total density of dissipated energy throughout the whole test, in megajoules per cubic metre (MJ/m3) b is the width of specimen, in millimetres (mm) e is the thickness of specimen, in millimetres (mm)

is the instant stress, in megapascals (MPa) σ a is the approximate stress function value, in megapascals (MPa) σ c is the cyclic amplitude of stress function, in megapascals (MPa) Φ is the phase difference angle, in degrees (°) 3.5 Four-point bending test on prismatic shaped specimens 3.5.1 (complex) stiffness modulus ratio S = Smix,n × eiφ of the calculated stress and strain during cycle n in the specimen NOTE The stiffness modulus defines the relationship between stress and strain for a linear viscoelastic material subjected to sinusoidal loading. 3.5.2 initial (complex) stiffness modulus values for the initial modulus Smix,0 in megapascals (MPa) of the complex modulus and for the initial phase lag φo in degrees of

the complex modulus taken at the 100th load application 3.5.3 fatigue life Ni,j,k number of cycles for specimen i, corresponding with the chosen failure criteria j (e.g. conventional failure j = f/50) at the set of test conditions k (temperature, frequency and loading mode; e.g. constant deflection level, or constant force level, and or any other constant loading condition) 3.5.4 test condition k set of conditions at which a specimen is tested. This set contains the applied frequency f0, the test temperature Θ and the loading mode (constant deflection, or constant force, and or constant dissipated energy per cycle) 3.5.5 average fatigue life of a series of specimens value defined according to a failure criteria j on a series of m specimens at a test condition k given by: mNeN∑==mi)kj,i,(lnk,J1 (7)

calculated phase lag in degrees during one cycle between the occurring stress and strain in the sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...