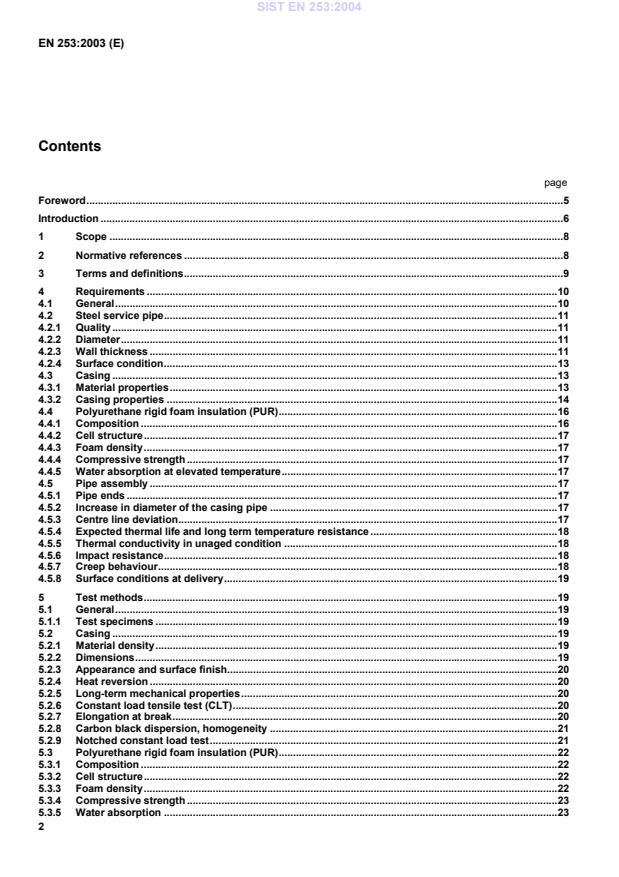

EN 253:2003

(Main)District heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks - Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene

District heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks - Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene

This European Standard specifies requirements and test methods for straight lengths of prefabricated thermally insulated pipe-in-pipe assemblies for directly buried hot water networks, comprising a steel service pipe from DN 20 to DN 1200, rigid polyurethane foam insulation and an outer casing of polyethylene.

This standard applies only to insulated pipe assemblies, for continuous operation with hot water at various temperatures up to 120 °C and occasionally with a peak temperature up to 140 °C.

The estimation of expected thermal life with continuous operation at various temperatures is outlined in annex B.

Fernwärmerohre - Werkmäßig gedämmte Verbundmantelrohrsysteme für direkt erdverlegte Fernwärmenetze - Verbund-Rohrsystem bestehend aus Stahl-Mediumrohr, Polyurethan-Wärmedämmung und Außenmantel aus Polyethylen

Tuyaux de chauffage urbain - Systèmes bloqués de tuyaux pré-isolés pour les réseaux d'eau chaude enterrés directement - Tube de service en acier, isolation thermique en polyuréthane et tube de protection en polyéthylène

La présente norme européenne définit les spécifications et les méthodes d'essais applicables aux longueurs droites de systèmes préfabriqués de tubes isolés thermiquement pour réseaux d'eau chaude enterrés directement comprenant un tube de service en acier de DN 20 à DN 1200, une isolation en mousse rigide de polyuréthane et un tube de protection en polyéthylène.

La présente norme s'applique uniquement aux systèmes isolés par mousse de polyuréthane utilisés pour l'eau chaude à différentes températures pouvant aller en service continu jusqu'à 120 °C et, parfois, à une température de pointe pouvant atteindre 140 °C.

L'estimation de la durée de vie thermique escomptée de systèmes opérant à différentes températures en service continu est donnée à l'annexe B.

Cevi za daljinsko ogrevanje – Izolirani vezani cevni sistemi za podzemeljska toplovodna omrežja – Cevni sestav iz jeklene cevi, poliuretanske toplotne izolacije in zunanjega polietilenskega plašča

General Information

- Status

- Withdrawn

- Publication Date

- 11-Feb-2003

- Withdrawal Date

- 20-Jan-2009

- Technical Committee

- CEN/TC 107 - Pre-fabricated district heating pipe systems

- Drafting Committee

- CEN/TC 107/WG 2 - Basic consideration

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 21-Jan-2009

- Completion Date

- 21-Jan-2009

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 28-Jan-2009

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 253:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "District heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks - Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene". This standard covers: This European Standard specifies requirements and test methods for straight lengths of prefabricated thermally insulated pipe-in-pipe assemblies for directly buried hot water networks, comprising a steel service pipe from DN 20 to DN 1200, rigid polyurethane foam insulation and an outer casing of polyethylene. This standard applies only to insulated pipe assemblies, for continuous operation with hot water at various temperatures up to 120 °C and occasionally with a peak temperature up to 140 °C. The estimation of expected thermal life with continuous operation at various temperatures is outlined in annex B.

This European Standard specifies requirements and test methods for straight lengths of prefabricated thermally insulated pipe-in-pipe assemblies for directly buried hot water networks, comprising a steel service pipe from DN 20 to DN 1200, rigid polyurethane foam insulation and an outer casing of polyethylene. This standard applies only to insulated pipe assemblies, for continuous operation with hot water at various temperatures up to 120 °C and occasionally with a peak temperature up to 140 °C. The estimation of expected thermal life with continuous operation at various temperatures is outlined in annex B.

EN 253:2003 is classified under the following ICS (International Classification for Standards) categories: 23.040.07 - Pipeline and its parts for district heat; 23.040.10 - Iron and steel pipes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 253:2003 has the following relationships with other standards: It is inter standard links to EN 253:1994, EN 253:2009, EN 253:2003/A2:2006, EN 253:2003/A1:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 253:2003 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 253:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.RG]HPHOMVNDFernwärmerohre - Werkmäßig gedämmte Verbundmantelrohrsysteme für direkt erdverlegte Fernwärmenetze - Verbund-Rohrsystem bestehend aus Stahl-Mediumrohr, Polyurethan-Wärmedämmung und Außenmantel aus PolyethylenTuyaux de chauffage urbain - Systemes bloqués de tuyaux pré-isolés pour les réseaux d'eau chaude enterrés directement - Tube de service en acier, isolation thermique en polyuréthane et tube de protection en polyéthyleneDistrict heating pipes - Preinsulated bonded pipe systems for directly buried hot water networks - Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene91.140.65Oprema za ogrevanje vodeWater heating equipment23.040.10Železne in jeklene ceviIron and steel pipes23.040.07Cevovodi za daljinsko ogrevanje in njihovi deliPipeline and its parts for district heatICS:Ta slovenski standard je istoveten z:EN 253:2003SIST EN 253:2004en01-oktober-2004SIST EN 253:2004SLOVENSKI

STANDARDSIST EN 253:20001DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 253February 2003ICS 23.040.99Supersedes EN 253:2003English versionDistrict heating pipes - Preinsulated bonded pipe systems fordirectly buried hot water networks - Pipe assembly of steelservice pipe, polyurethane thermal insulation and outer casing ofpolyethyleneTuyaux de chauffage urbain - Systèmes bloqués de tuyauxpré-isolés pour les réseaux d'eau chaude enterrésdirectement - Tube de service en acier, isolation thermiqueen polyuréthane et tube de protection en polyéthylèneFernwärmerohre - Werkmäßig gedämmteVerbundmantelrohrsysteme für direkt erdverlegteFernwärmenetze - Verbund-Rohrsystem bestehend ausStahl-Mediumrohr, Polyurethan-Wärmedämmung undAußenmantel aus PolyethylenThis European Standard was approved by CEN on 28 November 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovak Republic, Spain, Sweden, Switzerland andUnited Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 253:2003 ESIST EN 253:2004

Relation between actual continuous operating conditions and acceleratedageing test conditions.31Annex B (informative)

Calculation of the minimum expected thermal life with operation at varioustemperatures with respect to PUR foam performance.33Annex C (normative)

Calculated continuous operating temperature (CCOT).34C.1General.34C.2Symbols.34C.3Ageing and shear strength determinations.34C.4Calculations.35C.4.1Determination of the thermal life at different ageing temperatures.35C.4.2Adoption to the Arrhenius relation.35C.4.3Calculated continuous operating temperature, CCOT.35Annex D (informative)

Guidelines for inspection and testing.37D.1Manufacturer's type test.37D.2Manufacturer’s quality surveillance.37D.3External inspection.37D.4Manufacturer's responsibility.37Annex E (informative)

Change of blowing agent and influence on thermochemical andthermomechanical properties of polyurethane rigid foam (PUR).40Annex F (normative)

Radial creep behaviour of the polyurethane foam (PUR).41Annex G (normative)

Thermal conductivity of pre-insulated pipes - Test procedure.43G.1Scope.43G.2Requirements (EN ISO 8497:1994, Clause 5).43G.2.1Test specimen (EN ISO 8497:1994, 5.1).43G.2.2Operating temperature (EN ISO 8497:1994, 5.2).43G.2.3Types of apparatus (EN ISO 8497:1994, 5.5).43G.3Apparatus (EN ISO 8497:1994, Clause 7).43G.3.1Guarded end apparatus.43G.3.2Calibrated end apparatus.44G.3.3Dimensions (EN ISO 8497:1994, 7.2).44G.3.4Heater pipe surface temperature.44G.4Test specimens (EN ISO 8497:1994, Clause 8).44G.4.1Conditioning (EN ISO 8497:1994, 8.4).44G.4.2Dimension measurement (EN ISO 8497:1994, 8.5).44G.4.3Surface temperature measurement.44G.5Procedure (EN ISO 8497:1994, Clause 9).44G.5.1Test length (EN ISO 8497:1994, 9.1.1).44G.5.2Diameter (EN ISO 8497:1994, 8.5).45G.5.3Thickness of casing.45G.5.4Ambient requirements (EN ISO 8497:1994, 9.2).45G.5.5Test pipe temperature (EN ISO 8497:1994, 9.3).45G.5.6Power supply (EN ISO 8497:1994, 7.9).45G.5.7Axial heat loss (EN ISO 8497:1994, 5.7).45SIST EN 253:2004

(informative)

National A-deviations.48H.1 Swedish national legislative deviations on steel service pipes.48Bibliography.50SIST EN 253:2004

To avoid stresses due to temperature differences and misalignment, the tolerances given in Table 3 are more stringentthan the tolerances for T given in EN 10216-2, EN 10217-2 or EN 10217-5.

1) Other steel qualities or standards can be used by agreement.2) Other steel qualities or standards can be used by agreement.3) Other steel qualities or standards can be used by agreement.4) Other steel qualities or standards can be used by agreement.SIST EN 253:2004

5) The wall thickness at any point, ei, is the measured wall thickness at that point, rounded to the next higher 0,05 mm.SIST EN 253:2004

6) Surface treatment to improve the shear strength between the PUR foam and casing pipe is permissible provided that thetreated pipe still complies with the specification.SIST EN 253:2004

-04.5.3 Centre line deviationThe distance between the centre lines of the service pipe and the casing at any point shall not exceed the limitsgiven in Table 7.SIST EN 253:2004

75 to 160180 to 400450

to 630710 to 800900 to 14003,05,08,010,014,04.5.4 Expected thermal life and long term temperature resistance4.5.4.1 General remarksFor normal applications, the pipe assembly should have a life of at least 30 years at a continuous operatingtemperature of 120 °C, at least 50 years at a continuous operating temperature of 115 °C and over 50 years at acontinuous operating temperature below 115 °C.Higher continuous operating temperatures can be stated. If so, the calculated continuous operating temperature(CCOT) shall be established in accordance with annex C.4.5.4.2 Shear strengthThe shear strength shall be tested in either the axial or tangential direction.The shear strength shall fulfil the minimum requirements of Table 8 in both unaged and aged condition inaccordance with 5.4.4.Table 8 — Shear strengthTest temperature°CTest clausettaxMPaTest clausetttanMPa23 ± 25.4.2.10,125.4.30,20140 ± 25.4.2.20,08——4.5.5 Thermal conductivity in unaged conditionWhen tested in acco

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...