EN 301:2023

(Main)Adhesives, phenolic and aminoplastic, for load-bearing timber structures - Classification and performance requirements

Adhesives, phenolic and aminoplastic, for load-bearing timber structures - Classification and performance requirements

This document establishes a classification for phenolic and aminoplastic polycondensation adhesives according to their suitability for use for load-bearing timber products in defined climatic exposure conditions, and specifies performance requirements for such adhesives for the factory manufacture or factory-like manufacturing conditions of load-bearing timber products only.

This document only specifies the performance of an adhesive for use in an environment corresponding to the defined conditions.

The performance requirements of this document are applicable to the adhesive only, not to the manufacturing timber products. This document does not cover the performance of adhesives for on-site gluing (except for factory-like conditions) or the production of wood-based panels, except solid wood panels, or modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g. acetylated wood, heat treated wood and polymer impregnated wood.

This document is primarily intended for use by adhesive manufacturers and for use in timber products bonded with adhesives, to assess or control the quality of adhesives. The requirements are applicable to the type testing of the adhesives. Production control activities are outside the scope of this document.

Adhesives meeting the requirements of this document are adequate for use in load-bearing timber products, provided that the bonding process has been carried out according to an appropriate product standard.

Klebstoffe, Phenoplaste und Aminoplaste, für tragende Holzbauteile - Klassifizierung und Leistungsanforderungen

Dieses Dokument stellt eine Klassifizierung für Polykondensationsklebstoffe auf Phenoplast- und Aminoplastbasis entsprechend ihrer Eignung zur Verwendung für tragende Holzprodukte unter bestimmten Klimabedingungen auf und legt die Leistungsanforderungen an derartige Klebstoffe ausschließlich zur werksmäßigen Herstellung oder Herstellung unter werksähnlichen Bedingungen von tragenden Holzprodukten fest.

Dieses Dokument legt nur das Leistungsverhalten eines Klebstoffs für den Einsatz in einer Umgebung fest, die den festgelegten Bedingungen entspricht.

Die Leistungsanforderungen in diesem Dokument sind lediglich für den Klebstoff anwendbar, nicht für die Herstellung von Holzprodukten. Dieses Dokument behandelt weder das Leistungsverhalten von Klebstoffen für die Vor-Ort-Verklebung (ausgenommen bei werksähnlichen Bedingungen) noch die Produktion von Holzwerkstoffen, ausgenommen Massivholzplatten. Es ist nicht für modifiziertes und vergütetes Holz mit beträchtlich verringerten Quellungs- und Schwindungseigenschaften anwendbar, wie z. B. acetyliertes Holz, wärmebehandeltes Holz und mit Kunstharz imprägniertes Holz.

Dieses Dokument ist in erster Linie für den Gebrauch durch die Hersteller der Klebstoffe und der verklebten Holzprodukte bestimmt, um die Qualität von Klebstoffen zu beurteilen oder zu überprüfen. Die Anforderungen sind für die Typprüfung von Klebstoffen anwendbar. Aktivitäten im Rahmen der Produktionskontrolle gehören nicht zum Anwendungsbereich dieses Dokuments.

Klebstoffe, die die Anforderungen dieses Dokuments erfüllen, sind für den Einsatz in tragenden Holzprodukten geeignet, vorausgesetzt, dass der Verklebungsvorgang nach einer entsprechenden Produktnorm vorgenommen wurde.

Adhésifs de nature phénolique et aminoplaste, pour structures portantes en bois - Classification et exigences de performance

Le présent document établit une classification des adhésifs de polycondensation de type phénolique ou aminoplaste en fonction de leur aptitude à l’emploi dans les structures portantes en bois dans des conditions d’exposition climatique définies, et spécifie les exigences de performance applicables à ces adhésifs uniquement lorsqu’ils sont utilisés pour la fabrication en usine de produits porteurs en bois, ou dans des conditions semblables à la fabrication en usine.

Le présent document spécifie la performance d’un adhésif uniquement dans l’environnement correspondant aux conditions définies.

Les exigences relatives à la performance définies dans le présent document ne s’appliquent qu’aux adhésifs et non aux produits manufacturés en bois. Le présent document ne couvre pas la performance des adhésifs utilisés pour le collage sur site (à l’exception des conditions semblables à la fabrication en usine) ou pour la fabrication de panneaux à base de bois, à l’exception des panneaux en bois massif, ou pour le bois modifié et stabilisé ayant une propension considérablement réduite au gonflement et au retrait, par exemple le bois acétylé, le bois traité à la chaleur et le bois imprégné de polymère.

Le présent document s’adresse avant tout aux fabricants d’adhésifs pour leur permettre, dans le domaine des produits en bois collés, d’évaluer ou de contrôler la qualité des adhésifs. Les exigences s’appliquent aux essais de type des adhésifs. Les activités de contrôle de la production ne relèvent pas du domaine d’application du présent document.

Les adhésifs répondant aux exigences du présent document conviennent pour une utilisation dans des produits porteurs en bois, à condition que le processus de collage ait été réalisé conformément à une norme de produit appropriée.

Lepila na osnovi fenolov in aminoplastov za nosilne lesene konstrukcije - Razvrstitev in zahteve za delovanje

Ta dokument določa razvrstitev za fenolna in aminoplastična lepila v skladu z njihovo primernostjo za uporabo pri nosilnih lesenih konstrukcijah pri določenih pogojih izpostavljenosti podnebnim razmeram ter določa zahtevane lastnosti za taka lepila za tovarniško proizvodnjo ali tovarni podobne proizvodne pogoje za izključno nosilne lesene konstrukcije.

Ta dokument določa lastnosti lepila izključno za uporabo v okolju, ki ustreza podanim pogojem.

Zahteve glede učinkovitosti v tem dokumentu se uporabljajo samo za lepila, ne za lesene konstrukcije. Ta dokument ne zajema lastnosti lepil za lepljenje na mestu uporabe (razen v pogojih, podobnih tovarniškim) niti proizvodnje lesnih plošč, razen polnih lesnih plošč, ali obdelanega in stabiliziranega lesa, ki bistveno manj nabreka in se krči, kot so acetiliran les, toplotno obdelan les in polimerno impregniran les.

Ta dokument je namenjen predvsem za proizvajalce lepil in za uporabo pri lesenih konstrukcijah, vezanih z lepili, za ocenjevanje ali nadzor kakovosti lepil. Zahteve se uporabljajo za tipsko preskušanje lepil. Dejavnosti kontrole proizvodnje ne spadajo na področje uporabe tega dokumenta.

Lepila, ki izpolnjujejo zahteve tega dokumenta, so primerna za uporabo pri nosilnih lesenih konstrukcijah pod pogojem, da je bil postopek vezave izveden v skladu z ustreznim standardom za proizvod.

General Information

- Status

- Published

- Publication Date

- 14-Feb-2023

- Technical Committee

- CEN/TC 193 - Adhesives

- Drafting Committee

- CEN/TC 193/SC 1/WG 8 - Revision of EN 301 and EN 302

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 15-Feb-2023

- Due Date

- 25-Oct-2023

- Completion Date

- 15-Feb-2023

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 1995-1-2:2025 - Eurocode 5 - Design of timber structures - Part 1-2: Structural fire design - Effective Date

- 28-Jan-2026

Overview

EN 301:2023 - "Adhesives, phenolic and aminoplastic, for load‑bearing timber structures - Classification and performance requirements" is a CEN standard that classifies phenolic and aminoplastic polycondensation adhesives for use in factory or factory‑like manufacture of load‑bearing timber products. It specifies performance requirements and test methods for the adhesive itself (type testing), not for finished timber products or on‑site gluing (except factory‑like conditions). The standard supports product standards for timber structures and is intended to align adhesive performance with Eurocode 5 requirements.

Key topics and technical requirements

- Scope limits: Applies only to adhesives (not full timber product performance); excludes on‑site gluing (except factory‑like), wood‑based panels (except solid wood panels), and modified/stabilized woods (e.g., acetylated, heat‑treated, polymer‑impregnated).

- Classification:

- Two Types by climatic suitability: Type I (service classes 1, 2, 3) and Type II (service class 1 only).

- Three application areas: General Purpose (GP), Finger Jointing (FJ), Gap Filling (GF).

- Designation codes include type, application, maximum temperature, glue line thickness and application mode (mixed M or separate S).

- Service classes: Defined climatic conditions (Service class 1 = typical indoor; 2 = covered exterior; 3 = exterior/high moisture).

- Glue‑line definitions: Close contact (≤0.1 mm), thick glue line (0.3–2.0 mm), with maximum glue‑line limits specified per class.

- Required test methods (from EN 302 series and related standards):

- EN 302‑1 Tensile shear strength

- EN 302‑2 Delamination resistance

- EN 302‑3 Effect of acid damage / fibre damage

- EN 302‑4 Effects of wood shrinkage on shear strength

- EN 302‑8 Static load test (multiple bond lines)

- Annex A: delamination test for separate adhesive/hardener application

- Other topics: working properties (viscosity, pH), marking and labelling, and limits for test specimen materials (e.g., preservative-treated pine/fir).

Applications and who uses it

- Adhesive manufacturers: Type testing, product classification, technical data and labelling.

- Timber product manufacturers (glulam, laminated beams, finger‑jointed timber): Selecting adhesives suitable for intended service class and glue‑line.

- Test laboratories and certification bodies: Performing EN 302 series tests and issuing conformity evidence.

- Specifiers, structural engineers and regulators: Ensuring adhesive choice complies with product standards and Eurocode 5 requirements.

Related standards

- EN 302 series (Parts 1,2,3,4,5,6,7,8), EN 408, EN 923, EN 1245, EN 12092, EN 13183. These provide the detailed test methods and definitions referenced by EN 301:2023.

Keywords: EN 301:2023, phenolic adhesives, aminoplastic adhesives, load‑bearing timber, adhesive classification, test methods, service classes, finger joint, gap filling, glulam.

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 301:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Adhesives, phenolic and aminoplastic, for load-bearing timber structures - Classification and performance requirements". This standard covers: This document establishes a classification for phenolic and aminoplastic polycondensation adhesives according to their suitability for use for load-bearing timber products in defined climatic exposure conditions, and specifies performance requirements for such adhesives for the factory manufacture or factory-like manufacturing conditions of load-bearing timber products only. This document only specifies the performance of an adhesive for use in an environment corresponding to the defined conditions. The performance requirements of this document are applicable to the adhesive only, not to the manufacturing timber products. This document does not cover the performance of adhesives for on-site gluing (except for factory-like conditions) or the production of wood-based panels, except solid wood panels, or modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g. acetylated wood, heat treated wood and polymer impregnated wood. This document is primarily intended for use by adhesive manufacturers and for use in timber products bonded with adhesives, to assess or control the quality of adhesives. The requirements are applicable to the type testing of the adhesives. Production control activities are outside the scope of this document. Adhesives meeting the requirements of this document are adequate for use in load-bearing timber products, provided that the bonding process has been carried out according to an appropriate product standard.

This document establishes a classification for phenolic and aminoplastic polycondensation adhesives according to their suitability for use for load-bearing timber products in defined climatic exposure conditions, and specifies performance requirements for such adhesives for the factory manufacture or factory-like manufacturing conditions of load-bearing timber products only. This document only specifies the performance of an adhesive for use in an environment corresponding to the defined conditions. The performance requirements of this document are applicable to the adhesive only, not to the manufacturing timber products. This document does not cover the performance of adhesives for on-site gluing (except for factory-like conditions) or the production of wood-based panels, except solid wood panels, or modified and stabilized wood with considerably reduced swelling and shrinkage properties, e.g. acetylated wood, heat treated wood and polymer impregnated wood. This document is primarily intended for use by adhesive manufacturers and for use in timber products bonded with adhesives, to assess or control the quality of adhesives. The requirements are applicable to the type testing of the adhesives. Production control activities are outside the scope of this document. Adhesives meeting the requirements of this document are adequate for use in load-bearing timber products, provided that the bonding process has been carried out according to an appropriate product standard.

EN 301:2023 is classified under the following ICS (International Classification for Standards) categories: 83.180 - Adhesives. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 301:2023 has the following relationships with other standards: It is inter standard links to EN 301:2017, EN 302-2:2023, EN 1245:2011, EN 12092:2001, EN 408:2010+A1:2012, EN 923:2015, EN 302-3:2023, EN 15416-3:2017, EN 13381-7:2019, EN 12811-2:2004, EN 302-8:2023, CEN/TS 13307-2:2009, EN 15416-3:2017+A1:2019, EN 302-5:2023, EN 1995-1-2:2025. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 301:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2023

Lepila na osnovi fenolov in aminoplastov za nosilne lesene konstrukcije -

Razvrstitev in zahteve za delovanje

Adhesives, phenolic and aminoplastic, for load-bearing timber structures - Classification

and performance requirements

Klebstoffe, Phenoplaste und Aminoplaste, für tragende Holzbauteile - Klassifizierung und

Leistungsanforderungen

Adhésifs de nature phénolique et aminoplaste, pour structures portantes en bois -

Classification et exigences de performance

Ta slovenski standard je istoveten z: EN 301:2023

ICS:

83.180 Lepila Adhesives

91.080.20 Lesene konstrukcije Timber structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 301

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2023

EUROPÄISCHE NORM

ICS 83.180 Supersedes EN 301:2017

English Version

Adhesives, phenolic and aminoplastic, for load-bearing

timber structures - Classification and performance

requirements

Adhésifs de nature phénolique et aminoplaste, pour Klebstoffe, Phenoplaste und Aminoplaste, für tragende

structures portantes en bois - Classification et Holzbauteile - Klassifizierung und

exigences de performance Leistungsanforderungen

This European Standard was approved by CEN on 18 December 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 301:2023 E

worldwide for CEN national Members.

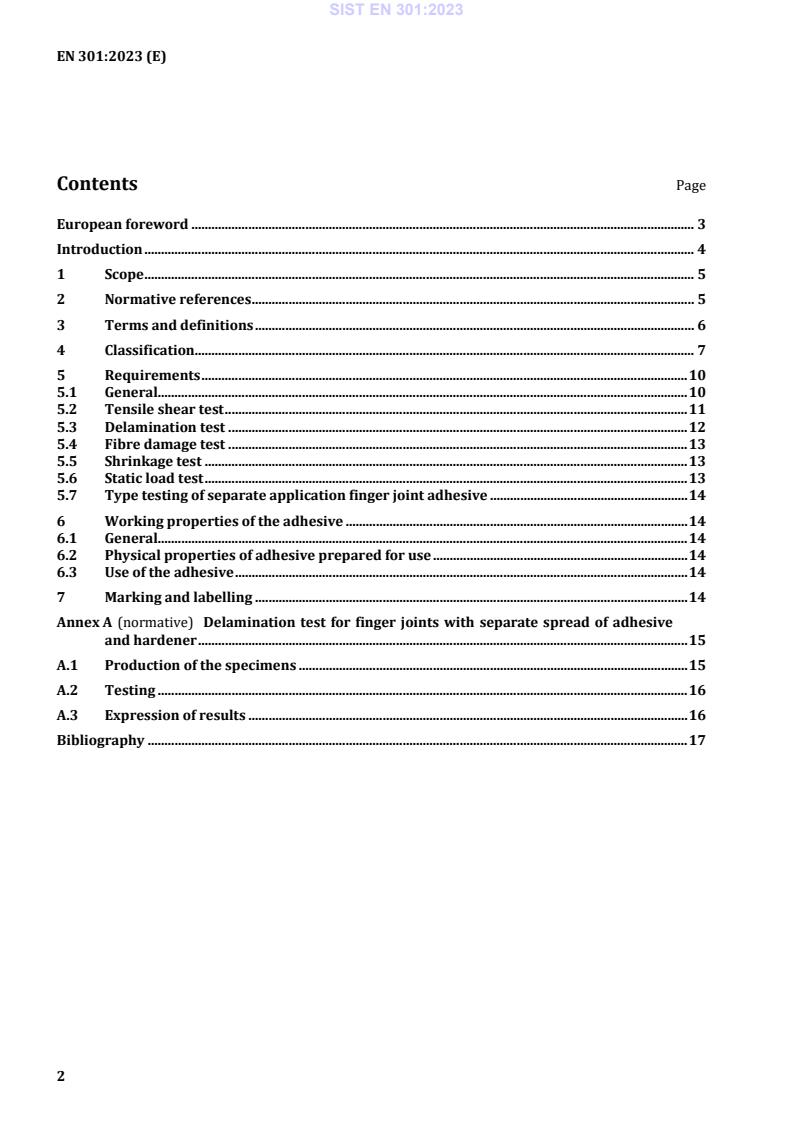

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Classification. 7

5 Requirements . 10

5.1 General. 10

5.2 Tensile shear test . 11

5.3 Delamination test . 12

5.4 Fibre damage test . 13

5.5 Shrinkage test . 13

5.6 Static load test . 13

5.7 Type testing of separate application finger joint adhesive . 14

6 Working properties of the adhesive . 14

6.1 General. 14

6.2 Physical properties of adhesive prepared for use . 14

6.3 Use of the adhesive . 14

7 Marking and labelling . 14

Annex A (normative) Delamination test for finger joints with separate spread of adhesive

and hardener . 15

A.1 Production of the specimens . 15

A.2 Testing . 16

A.3 Expression of results . 16

Bibliography . 17

European foreword

This document (EN 301:2023) has been prepared by Technical Committee CEN/TC 193 “Adhesives”,

the secretariat of which is held by UNE.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2023, and conflicting national standards shall

be withdrawn at the latest by August 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 301:2017.

a) Table 2 — 2 mm glue line – EN 302-3 Mandatory despite pH-value – beech used in the test;

b) Table 2 — Gap filling adhesives – EN 302-8 – tested with 1 mm glue line;

c) 5.1 b) test with representative samples of preservative treated Scots pine or Silver fir, which also

covers preservative treated Norway spruce, has been added.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the

United Kingdom.

Introduction

This document is one of a series of standards dealing with phenolic and aminoplastic adhesives for use

with timber structures, and is published in support of product standards for load-bearing timber

structures in connection with EN 1995-1-1, Eurocode 5: Design of timber structures — Part 1-1:

General — Common rules and rules for buildings.

The series consists of:

— one standard for classification and performance requirements (EN 301);

— six test methods (EN 302-1, EN 302-2, EN 302-3, EN 302-4, EN 302-8 and Annex A of this

document) used to assess the performance of adhesives after specified heat and humidity

treatments; and

— three test methods (EN 302-5, EN 302-6 and EN 302-7) to characterize the working properties of

the adhesive.

SAFETY STATEMENT

Persons using this document should be familiar with the normal laboratory practice, if applicable. This

document cannot address all of the safety problems, if any, associated with its use. It is the

responsibility of the user to establish appropriate safety and health practices and to ensure compliance

with any regulatory conditions.

ENVIRONMENTAL STATEMENT

It is understood that some of the material permitted in this standard may have a negative

environmental impact. As technological advantages lead to acceptable alternatives for these materials,

they will be eliminated from this standard to the greatest extent possible.

At the end of the test, the user of the standard should take care to carry out an appropriate disposal of

the wastes, according to local regulations.

1 Scope

This document establishes a classification for phenolic and aminoplastic polycondensation adhesives

according to their suitability for use for load-bearing timber products in defined climatic exposure

conditions, and specifies performance requirements for such adhesives for the factory manufacture or

factory-like manufacturing conditions of load-bearing timber products only.

This document only specifies the performance of an adhesive for use in an environment corresponding

to the defined conditions.

The performance requirements of this document are applicable to the adhesive only, not to the

manufacturing timber products. This document does not cover the performance of adhesives for on-site

gluing (except for factory-like conditions) or the production of wood-based panels, except solid wood

panels, or modified and stabilized wood with considerably reduced swelling and shrinkage properties,

e.g. acetylated wood, heat treated wood and polymer impregnated wood.

This document is primarily intended for use by adhesive manufacturers and for use in timber products

bonded with adhesives, to assess or control the quality of adhesives. The requirements are applicable to

the type testing of the adhesives. Production control activities are outside the scope of this document.

Adhesives meeting the requirements of this document are adequate for use in load-bearing timber

products, provided that the bonding process has been carried out according to an appropriate product

standard.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 302-1, Adhesives for load-bearing timber structures — Test methods — Part 1: Determination of

longitudinal tensile shear strength

EN 302-2, Adhesives for load-bearing timber structures — Test methods — Part 2: Determination of

resistance to delamination

EN 302-3, Adhesives for load-bearing timber structures — Test methods — Part 3: Determination of the

effect of acid damage to wood fibres by temperature and humidity cycling on the transverse tensile

strength

EN 302-4, Adhesives for load-bearing timber structures — Test methods — Part 4: Determination of the

effects of wood shrinkage on the shear strength

EN 302-8, Adhesives for load-bearing timber structures — Test methods — Part 8: Static load test of

multiple bond line specimens in compression shear

EN 408, Timber structures — Structural timber and glued laminated timber — Determination of some

physical and mechanical properties

EN 923, Adhesives — Terms and definitions

EN 1245, Adhesives — Determination of pH

EN 12092, Adhesives — Determination of viscosity

EN 13183-2, Moisture content of a piece of sawn timber — Part 2: Estimation by electrical resistance

method

EN 13183-3, Moisture content of a piece of sawn timber — Part 3: Estimation by capacitance method

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 923 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

aminoplastic resin

thermosetting synthetic resin derived from a condensation reaction of the –NH groups or –NH groups

of amines or amides with aldehydes

3.2

phenolic resin

thermosetting synthetic resin derived from a condensation reaction of a phenol with an aldehyde

3.3

polycondensation adhesive

adhesive mixture made from a resin formed by a polymerization reaction involving the elimination of

water, usually with a hardener

Note 1 to entry: Such adhesives usually also contain extenders and/or fillers.

3.4

service class 1

climatic conditions characterized by a moisture content in the materials corresponding to a

temperature of 20 °C and the relative humidity of the surrounding air only exceeding 65 % for a few

weeks per year

Note 1 to entry: In service class 1, which comprises typical indoor conditions, the average moisture content in

most softwoods will not exceed 12 %.

[SOURCE: EN 1995-1-1:2004, 2.3.1.3, modified – Indoor conditions have been added in Note 1 to entry.]

3.5

service class 2

climatic conditions characterized by a moisture content in the materials corresponding to a

temperature of 20 °C and the relative humidity of the surrounding air only exceeding 85 % for a few

weeks per year

Note 1 to entry: In service class 2, to which most covered exterior conditions belong, the average moisture

content in most softwoods will not exceed 20 %.

[SOURCE: EN 1995-1-1:2004, 2.3.1.3 modified – Covered exterior conditions have been added in Note 1

to entry.]

3.6

service class 3

climatic conditions leading to higher moisture contents than in service class 2

Note 1 to entry: Exterior conditions typically belong to service class 3.

[SOURCE: EN 1995-1-1:2004, 2.3.1.3, modified – Note 1 to entry has been added.]

3.7

glue line

adhesive layer between the wood members

3.8

thick glue line

glue line of nominal thickness in the range of 0,3 mm to 2,0 mm at the time of bonding

Note 1 to entry: Thick glue lines are achieved by using spacers, grooves or similar devices when two plain

members are glued together.

3.9

close contact glue line

glue line of thickness maximum 0,1 mm

Note 1 to entry: Close contact glue line can be achieved by pressing together two plane wood members with a

clamping pressure of (0,8 ± 0,1) N/mm without additional grooves, spacers or similar devices.

4 Classification

Adhesives (General purpose, Finger jointing or Gap filling) for structural purposes shall produce joints

of such strength and durability that the integrity of the bond is maintained in the assigned service class

throughout the expected life of the structure.

Two types of adhesive, I and II, are classified according to their suitability for use in different climatic

conditions:

— Type Ι to be used in service classes 1, 2 and 3.

— Type ΙΙ to be used in service class 1 only.

These two types of adhesive are further divided into three application area according to the end use:

— General-purpose adhesive (GP) to be used for glue lines between laminations, for finger joints in

laminations and structural timber, and for large finger joints;

— Finger jointing adhesive (FJ) to be used for finger jointing of laminations and structural timber

only;

— Gap filling adhesive (GF) to be used for fibre parallel gluing, e.g. glue lines between glulam

components of block-glued glulam and for large finger joints. Gap filling adhesives are in addition

classified as application area GP and FJ in mixed application without further testing.

NOTE The definition of “General purpose” and “Type” can be different in other standards.

Table 1 specifies the thirteen adhesive classes for which this document is applicable to and their

designation codes. The designation code consist of:

— type: Ι or ΙΙ;

— application: GP, FJ or GF;

— maximum test temperature in degrees Celsius: 70 or 90 for type Ι, or maximum use temperature in

degrees Celsius: 50 for type ΙΙ;

— use: M for mixed application, and S for separate application of adhesive and hardener.

All application areas and use shall be part of the designation code.

EXAMPLE Designation code EN 301 I 70 GP 0,6M and designation code EN 301 I 70 FJ 0,1S, if classified as

general purpose adhesive for mixed application and classified as finger joint adhesive for separate application.

Table 1 — Adhesive classes

Adhesive class

Max. glue line

Max. test Service

thickness

Application area

c a

temp. classes

(Designation code)

Test Use

°C mm mm

Face lamination and

finger jointing for general

use

General purpose 70 1,0 0,6 1,2,3

EN 301 I 70 GP 0,6M

General purpose 70 1,0 0,3 1,2,3

EN 301 I 70 GP 0,3S

Special use

Gap filling 90 2,0 1,5 1, 2, 3

EN 301 I 90 GF 1,5M

General purpose 90 1,0 0,6 1, 2, 3

EN 301 I 90 GP 0,6M

General purpose 90 1,0 0,3 1, 2, 3

EN 301 I 90 GP 0,3S

Finger joint 90 0,3 0,1 1, 2, 3

EN 301 I 90 FJ 0,1M

Finger joint 90 0,3 0,1 1, 2, 3

EN 301 I 90 FJ 0,1S

Finger joint 70 0,3 0,1 1, 2, 3

EN 301 I 70 FJ 0,1M

Finger joint 70 0,3 0,1 1, 2, 3

EN 301 I 70 FJ 0,1S

b

General purpose 1,0 0,6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...