prEN 12797

(Main)Brazing - Destructive tests of brazed joints

Brazing - Destructive tests of brazed joints

This European Standard describes destructive test procedures and test piece types necessary to perform the tests on brazed joints.

Brazed joints are used in a wide variety of assemblies and the design requirements placed upon these joints will also vary widely; there will usually be some level of strength required but this may not be explicitly stated and is frequently of minor importance compared to some other criterion, e.g. hermeticity. It follows that a test which measures strength may be totally irrelevant in assessing a joint for a particular application where strength is a minor consideration. This situation is made more complicated because brazed joints are almost invariably designed to be loaded in shear and the dimensions of the joint affect the shear strength to a much greater extent than they do the tensile strength. The tests described in this standard have been used successfully to give information on specific properties and where such information is needed, it is recommended that one of them be specified.

It is vital to recognise that for many fabrications none of these tests will be suitable and specific tests will have to be devised, which do yield the requisite information (which may be qualitative rather than quantitative). The destructive test methods described are as follows:

a) shear tests (see Clause 4);

b) tensile tests (see Clause 5);

c) metallographic examination (see Clause 6);

d) hardness tests (see Clause 7);

e) peel test (see Clause 8);

f) bend tests (see Clause 9).

Details of burst tests are not included as these are not commonly used on brazed joints.

The type of test piece described for each test can be quoted or incorporated in engineering applications standards that deal with brazed assemblies.

The results of the tests are used:

g) to determine basic data regarding filler metal performance;

h) to arrive at optimum brazing designs (including gaps) and brazing procedures;

i) to relate production results to results achieved in development.

This European Standard does not recommend the number of samples to be tested or the repeat tests allowed. Neither does it specify methods of sampling brazed joints, except to give guidance regarding the precautions necessary, nor does it comment on the acceptance criteria applicable to any of the tests.

No attempt is made to define which test or tests, if any, should be applied in any situation. This is a matter to be established before any particular method of test is selected.

Hartlöten - Zerstörende Prüfung von Hartlötverbindungen

Diese Europäische Norm beschreibt zerstörende Prüfverfahren und Arten von Prüfstücken, die zur Durchführung von Prüfungen an Hartlötverbindungen notwendig sind.

Hartlötverbindungen werden in einer Vielzahl von Baugruppen genutzt und die konstruktiven Anforderungen, die an diese Verbindungen gestellt werden, sind ebenfalls sehr unterschiedlich; normalerweise wird eine bestimmte Festigkeit gefordert; das wird jedoch möglicherweise nicht ausdrücklich angegeben und ist häufig im Vergleich zu anderen Kriterien, z. B. Luftdichtheit, von geringerer Bedeutung. Daraus folgt, dass eine Festigkeitsprüfung für die Beurteilung einer Verbindung für eine besondere Anwendung vollständig belanglos sein kann, wenn die Festigkeit von geringerer Bedeutung ist. Diese Situation wird dadurch erschwert, dass Hartlötverbindungen nahezu ausnahmslos dafür ausgelegt sind, auf Scherung beansprucht zu werden, und die Abmessungen der Verbindung die Scherfestigkeit in viel größerem Umfang beeinflussen als die Zugfestigkeit. Die in dieser Norm beschriebenen Prüfverfahren sind erfolgreich angewendet worden, um Informationen über spezifische Eigenschaften zu erhalten; es wird empfohlen, eines von ihnen festzulegen, wenn derartige Informationen benötigt werden.

Wesentlich ist die Erkenntnis, dass für viele Fertigungen keine dieser Prüfungen geeignet ist und daher spezifische Prüfungen zu entwickeln sind, um die notwendigen Informationen zu erhalten (die eher qualitativ als quantitativ sein können). Die folgenden zerstörenden Prüfverfahren werden beschrieben:

a) Scherzugprüfungen (siehe Abschnitt 4);

b) Zugprüfungen (siehe Abschnitt 5);

c) Metallographische Untersuchung (siehe Abschnitt 6);

d) Härteprüfungen (siehe Abschnitt 7);

e) Schälprüfung (siehe Abschnitt 8);

f) Biegeprüfungen (siehe Abschnitt 9).

Da Berstprüfungen bei Hartlötverbindungen nicht allgemein gebräuchlich sind, sind Einzelheiten darüber nicht enthalten.

Die Art des Prüfstücks, das für jede Prüfung beschrieben wird, kann angeführt oder in die technischen Anwendungsnormen, die hartgelötete Baugruppen behandeln, aufgenommen werden.

Die Ergebnisse der Prüfungen werden genutzt, um:

g) Basisdaten bezüglich des Verhaltens des Lots zu ermitteln;

h) optimale Hartlötkonstruktionen (einschließlich Hartlötspalten) und Hartlötverfahren zu erstellen;

i) die Fertigungsergebnisse mit den Ergebnissen, die bei der Entwicklung erzielt wurden, in Beziehung zu setzen.

Diese Europäische Norm empfiehlt nicht die Anzahl der zu untersuchenden Proben oder der zulässigen Wiederholungsprüfungen. Sie legt bis auf einen aufgeführten Leitfaden bezüglich der notwendigen Vorsichtsmaßnahmen weder die Verfahren der Probenahme aus den Hartlötverbindungen fest, noch erläutert sie die Bewertungsmerkmale, die für jede der Prüfungen gelten.

Es wurde nicht versucht festzulegen, welche Prüfung bzw. Prüfungen in welcher Situation angewendet werden sollte(n). Dies ist zu vereinbaren, bevor ein spezielles Prüfverfahren ausgewählt wird.

Brasage fort - Essais destructifs des assemblages réalisés par brasage fort

La présente norme européenne décrit des procédures d'essais destructifs et des types de pièce d'essai nécessaires pour effectuer les essais sur assemblages réalisés par brasage fort (assemblages brasés).

Les assemblages brasés sont utilisés pour une grande variété d'assemblages et les exigences de conception dont font l'objet ces assemblages brasés sont très diverses ; en général, un certain niveau de résistance est exigé, mais celui-ci peut ne pas être mentionné explicitement et il revêt souvent une moindre importance en comparaison avec d'autres critères tels que l'étanchéité. Il s'ensuit qu'un essai consistant à mesurer la résistance peut être complètement inadéquat pour évaluer un assemblage brasé pour une application particulière où la résistance a une moindre importance. La situation est rendue plus complexe car les assemblages brasés sont presque systématiquement conçus pour des charges de cisaillement et les dimensions de l'assemblage brasé affectent la résistance au cisaillement dans une bien plus grande mesure qu'ils n'affectent la résistance à la traction. Les essais décrits dans la présente norme européenne ont permis d'obtenir des informations sur des propriétés spécifiques, et lorsque de telles informations sont nécessaires, il est recommandé que l'un de ces essais soit spécifié.

Il faut admettre que pour de nombreuses fabrications brasées, aucun de ces essais ne convient et des essais spécifiques appropriés, permettant d'obtenir les informations recherchées, doivent être conçus (ils peuvent être qualitatifs plutôt que quantitatifs). Les méthodes d'essai destructif décrites sont les suivantes :

a) essai de cisaillement (voir article 4) ;

b) essai de traction (voir article 5) ;

c) examen métallographique (voir article 6) ;

d) essai de dureté (voir article 7) ;

e) essai de pelage (voir article 8) ;

f) essai de pliage (voir article 9).

Les essais d'éclatement ne font pas partie des méthodes décrites en détail, étant donné qu'ils ne sont pas couramment utilisés pour les assemblages brasés.

Le type de pièce d'essai décrit pour chaque essai peut être cité ou incorporé dans les normes d'applications techniques qui portent sur les assemblages brasés.

Les résultats des essais sont utilisés :

g) afin de déterminer les résultats essentiels concernant les performances du métal d'apport de brasage fort ;

h) afin de parvenir à une conception optimale des assemblages brasés (y compris des jeux) et à des modes opératoires de brasage optimums ;

i) afin de mettre en relation les résultats obtenus en production avec ceux obtenus en développement.

La présente norme européenne ne donne pas de recommandations concernant le nombre d'échantillons à sou- mettre aux essais ou concernant les contre-essais autorisés. Elle ne spécifie pas de méthodes d'échantillonnage des assemblages brasés, bien qu'elle donne des précisions sur les précautions à prendre à ce sujet, et ne formule pas de commentaires sur les critères d'acceptation applicables aux essais.

Cette norme n'a pas pour objet de définir les essais qu'il convient d'effectuer en fonction des situations particulières. Ce point doit être établi avant la sélection d’une méthode d’essai particulière.

Trdo spajkanje - Porušitveno preskušanje trdo spajkanih spojev

General Information

- Status

- Not Published

- Publication Date

- 28-Feb-2019

- Withdrawal Date

- 01-Sep-2019

- Technical Committee

- CEN/TC 121 - Welding

- Drafting Committee

- CEN/TC 121/WG 20 - Brazing

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 19-Dec-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Jan-2023

Overview

prEN 12797 (CEN draft) defines the destructive test procedures and test-piece types for assessing brazed joints. The standard addresses commonly used methods to obtain information on mechanical and metallurgical properties of brazed assemblies. It clarifies the scope and limitations of these destructive tests and highlights that test selection must be driven by the design requirements of the brazed assembly (for example, strength vs. hermeticity).

Key considerations in the standard include the prevalence of shear loading in brazed joints, the influence of joint dimensions on shear strength, and the fact that some applications require bespoke or qualitative tests rather than the standard destructive methods.

Key Topics

- Destructive test methods covered:

- Shear tests (Clause 4)

- Tensile tests (Clause 5)

- Metallographic examination (Clause 6)

- Hardness tests (Clause 7)

- Peel tests (Clause 8)

- Bend tests (Clause 9)

- Tests not included: burst tests are not covered as they are not commonly used on brazed joints.

- Purpose of tests:

- Determine basic data on filler metal performance

- Support optimisation of brazing designs (including joint gaps) and brazing procedures

- Relate production results to development findings

- Limitations noted in the standard:

- Does not specify sample counts, repeat-test rules, or acceptance criteria

- Does not prescribe sampling methods beyond general precautions

- Does not mandate which test(s) must be applied for a given situation

Applications

prEN 12797 is intended for engineers, metallurgists and QA professionals involved in the design, development and production of brazed assemblies. Typical applications include:

- Generating comparative data on filler metal behaviour under destructive loading

- Validating joint designs (gap control, joint geometry) for intended load conditions

- Investigating metallurgical structure and hardness changes after brazing or post-braze heat treatment

- Supporting production-quality assessment by comparing manufacturing results to development test pieces

The standard emphasises that many brazed fabrications may require specific, bespoke test methods when the standard tests are not representative of service conditions.

Related Standards

Normative references and related documents cited in prEN 12797 include (non-exhaustive):

- EN 12799:2000 - Non-destructive examination of brazed joints

- EN ISO 4545-1 (Knoop hardness)

- EN ISO 6892-1 (Tensile testing at room temperature)

- EN ISO 6506-1 / 6507-1 / 6508-1 (Brinell, Vickers, Rockwell hardness)

- EN ISO 5173 / EN ISO 7438 (Bend tests)

- ISO 5187 (Mechanical test methods for assemblies with brazing filler metals)

For practical use, select the most appropriate destructive method(s) in combination with non-destructive examination and project-specific acceptance criteria. The test-piece types described in the standard can be referenced or incorporated into engineering application standards dealing with brazed assemblies.

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

prEN 12797 is a draft published by the European Committee for Standardization (CEN). Its full title is "Brazing - Destructive tests of brazed joints". This standard covers: This European Standard describes destructive test procedures and test piece types necessary to perform the tests on brazed joints. Brazed joints are used in a wide variety of assemblies and the design requirements placed upon these joints will also vary widely; there will usually be some level of strength required but this may not be explicitly stated and is frequently of minor importance compared to some other criterion, e.g. hermeticity. It follows that a test which measures strength may be totally irrelevant in assessing a joint for a particular application where strength is a minor consideration. This situation is made more complicated because brazed joints are almost invariably designed to be loaded in shear and the dimensions of the joint affect the shear strength to a much greater extent than they do the tensile strength. The tests described in this standard have been used successfully to give information on specific properties and where such information is needed, it is recommended that one of them be specified. It is vital to recognise that for many fabrications none of these tests will be suitable and specific tests will have to be devised, which do yield the requisite information (which may be qualitative rather than quantitative). The destructive test methods described are as follows: a) shear tests (see Clause 4); b) tensile tests (see Clause 5); c) metallographic examination (see Clause 6); d) hardness tests (see Clause 7); e) peel test (see Clause 8); f) bend tests (see Clause 9). Details of burst tests are not included as these are not commonly used on brazed joints. The type of test piece described for each test can be quoted or incorporated in engineering applications standards that deal with brazed assemblies. The results of the tests are used: g) to determine basic data regarding filler metal performance; h) to arrive at optimum brazing designs (including gaps) and brazing procedures; i) to relate production results to results achieved in development. This European Standard does not recommend the number of samples to be tested or the repeat tests allowed. Neither does it specify methods of sampling brazed joints, except to give guidance regarding the precautions necessary, nor does it comment on the acceptance criteria applicable to any of the tests. No attempt is made to define which test or tests, if any, should be applied in any situation. This is a matter to be established before any particular method of test is selected.

This European Standard describes destructive test procedures and test piece types necessary to perform the tests on brazed joints. Brazed joints are used in a wide variety of assemblies and the design requirements placed upon these joints will also vary widely; there will usually be some level of strength required but this may not be explicitly stated and is frequently of minor importance compared to some other criterion, e.g. hermeticity. It follows that a test which measures strength may be totally irrelevant in assessing a joint for a particular application where strength is a minor consideration. This situation is made more complicated because brazed joints are almost invariably designed to be loaded in shear and the dimensions of the joint affect the shear strength to a much greater extent than they do the tensile strength. The tests described in this standard have been used successfully to give information on specific properties and where such information is needed, it is recommended that one of them be specified. It is vital to recognise that for many fabrications none of these tests will be suitable and specific tests will have to be devised, which do yield the requisite information (which may be qualitative rather than quantitative). The destructive test methods described are as follows: a) shear tests (see Clause 4); b) tensile tests (see Clause 5); c) metallographic examination (see Clause 6); d) hardness tests (see Clause 7); e) peel test (see Clause 8); f) bend tests (see Clause 9). Details of burst tests are not included as these are not commonly used on brazed joints. The type of test piece described for each test can be quoted or incorporated in engineering applications standards that deal with brazed assemblies. The results of the tests are used: g) to determine basic data regarding filler metal performance; h) to arrive at optimum brazing designs (including gaps) and brazing procedures; i) to relate production results to results achieved in development. This European Standard does not recommend the number of samples to be tested or the repeat tests allowed. Neither does it specify methods of sampling brazed joints, except to give guidance regarding the precautions necessary, nor does it comment on the acceptance criteria applicable to any of the tests. No attempt is made to define which test or tests, if any, should be applied in any situation. This is a matter to be established before any particular method of test is selected.

prEN 12797 is classified under the following ICS (International Classification for Standards) categories: 25.160.50 - Brazing and soldering. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 12797 has the following relationships with other standards: It is inter standard links to EN 12797:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 12797 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2017

Trdo spajkanje - Porušitveno preskušanje trdo spajkanih spojev

Brazing - Destructive tests of brazed joints

Hartlöten - Zerstörende Prüfung von Hartlötverbindungen

Brasage fort - Essais destructifs des assemblages réalisés par brasage fort

Ta slovenski standard je istoveten z: prEN 12797

ICS:

25.160.50 Trdo in mehko lotanje Brazing and soldering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2017

ICS 25.160.50 Will supersede EN 12797:2000

English Version

Brazing - Destructive tests of brazed joints

Brasage fort - Essais destructifs des assemblages Hartlöten - Zerstörende Prüfung von

réalisés par brasage fort Hartlötverbindungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 121.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2017 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 12797:2017 E

worldwide for CEN national Members.

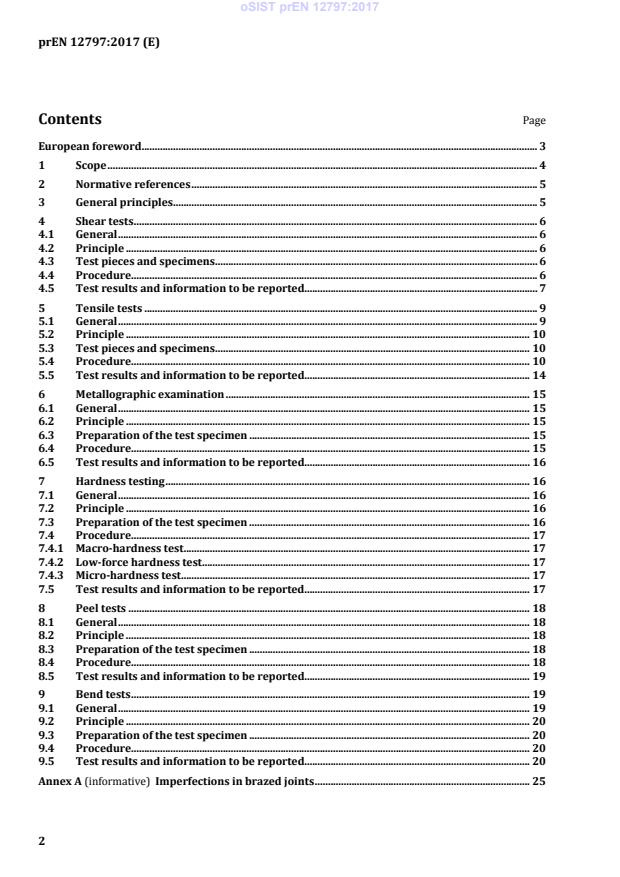

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 5

3 General principles . 5

4 Shear tests . 6

4.1 General . 6

4.2 Principle . 6

4.3 Test pieces and specimens . 6

4.4 Procedure. 6

4.5 Test results and information to be reported. 7

5 Tensile tests . 9

5.1 General . 9

5.2 Principle . 10

5.3 Test pieces and specimens . 10

5.4 Procedure. 10

5.5 Test results and information to be reported. 14

6 Metallographic examination . 15

6.1 General . 15

6.2 Principle . 15

6.3 Preparation of the test specimen . 15

6.4 Procedure. 15

6.5 Test results and information to be reported. 16

7 Hardness testing . 16

7.1 General . 16

7.2 Principle . 16

7.3 Preparation of the test specimen . 16

7.4 Procedure. 17

7.4.1 Macro-hardness test . 17

7.4.2 Low-force hardness test. 17

7.4.3 Micro-hardness test. 17

7.5 Test results and information to be reported. 17

8 Peel tests . 18

8.1 General . 18

8.2 Principle . 18

8.3 Preparation of the test specimen . 18

8.4 Procedure. 18

8.5 Test results and information to be reported. 19

9 Bend tests . 19

9.1 General . 19

9.2 Principle . 20

9.3 Preparation of the test specimen . 20

9.4 Procedure. 20

9.5 Test results and information to be reported. 20

Annex A (informative) Imperfections in brazed joints . 25

European foreword

This document (prEN 12797:2017) has been prepared by Technical Committee CEN/TC 121 “Welding

and allied processes”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 12797:2000.

In comparison with the previous edition, the main changes are:

a) the normative references have been updated;

b) the document has been revised editorially.

1 Scope

This European Standard describes destructive test procedures and test piece types necessary to

perform the tests on brazed joints.

Brazed joints are used in a wide variety of assemblies and the design requirements placed upon these

joints will also vary widely; there will usually be some level of strength required but this may not be

explicitly stated and is frequently of minor importance compared to some other criterion, e.g.

hermeticity. It follows that a test which measures strength may be totally irrelevant in assessing a joint

for a particular application where strength is a minor consideration. This situation is made more

complicated because brazed joints are almost invariably designed to be loaded in shear and the

dimensions of the joint affect the shear strength to a much greater extent than they do the tensile

strength. The tests described in this standard have been used successfully to give information on

specific properties and where such information is needed, it is recommended that one of them be

specified.

It is vital to recognise that for many fabrications none of these tests will be suitable and specific tests

will have to be devised, which do yield the requisite information (which may be qualitative rather than

quantitative). The destructive test methods described are as follows:

a) shear tests (see Clause 4);

b) tensile tests (see Clause 5);

c) metallographic examination (see Clause 6);

d) hardness tests (see Clause 7);

e) peel test (see Clause 8);

f) bend tests (see Clause 9).

Details of burst tests are not included as these are not commonly used on brazed joints.

The type of test piece described for each test can be quoted or incorporated in engineering applications

standards that deal with brazed assemblies.

The results of the tests are used:

g) to determine basic data regarding filler metal performance;

h) to arrive at optimum brazing designs (including gaps) and brazing procedures;

i) to relate production results to results achieved in development.

This European Standard does not recommend the number of samples to be tested or the repeat tests

allowed. Neither does it specify methods of sampling brazed joints, except to give guidance regarding

the precautions necessary, nor does it comment on the acceptance criteria applicable to any of the

tests.

No attempt is made to define which test or tests, if any, should be applied in any situation. This is a

matter to be established before any particular method of test is selected.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 12799:2000, Brazing - Non-destructive examination of brazed joints

EN ISO 4545-1, Metallic materials - Knoop hardness test - Part 1: Test method (ISO 4545-1)

EN ISO 5173, Destructive tests on welds in metallic materials - Bend tests (ISO 5173)

EN ISO 6506-1, Metallic materials - Brinell hardness test - Part 1: Test method (ISO 6506-1)

EN ISO 6507-1, Metallic materials - Vickers hardness test - Part 1: Test method (ISO 6507-1)

EN ISO 6508-1, Metallic materials - Rockwell hardness test - Part 1: Test method (ISO 6508-1)

EN ISO 6892-1, Metallic materials - Tensile testing - Part 1: Method of test at room temperature

(ISO 6892-1)

EN ISO 7438, Metallic materials - Bend test (ISO 7438)

ISO 5187, Welding and allied processes - Assemblies made with soft solders and brazing filler metals -

Mechanical test methods

3 General principles

Imperfections may be observed when joints are examined by destructive tests. They may reduce the

quality and performance characteristics of the joint or the brazed assembly.

Destructive tests may be needed to determine the effects of the brazing process or any subsequent heat

treatment on the properties of the joint (e.g. parent materials, filler metals, internal stresses).

This European Standard does not give guidance regarding the cause of the imperfection or its effect

upon the joint quality or the effects of single or multiple defects upon the performance characteristics of

the brazed assembly. This will depend upon the life-limiting processes to which the joint is subjected

and the life requirements and performance specific to the brazed assembly.

The majority of brazed joints are designed with the component parts in a lap configuration. Because of

the capillary nature of a brazed joint, most imperfections will be contained within the joint region, with

the principal axes parallel to the plane of the joint. Any other imperfections are likely to have been

caused by stresses in the brazing metal or the parent materials, or were already present before brazing.

Guidance is given regarding the types of imperfection that are observed when destructive tests are

applied; these are defined diagrammatically in Annex A.

The importance of tolerance to typical imperfections, the cause for rejection, the method of

imperfection interpretation and the method of presentation of observations have to be established

before a specific method of test is selected.

The use of any method should always be considered in relation to testing as a whole. The benefits of

using any particular method can only be obtained by consideration of results in conjunction with results

obtained by using other test methods. The most appropriate method or methods of testing should be

selected.

The methods of destructive examination are not associated with any particular type of test piece but lay

down the general principles of the types of testing described. It is emphasized that a satisfactory

examination method can only be developed and used after taking into account all the relevant factors

regarding the equipment to be used and the characteristics of the test pieces being examined.

The use of the methods of test described enables results from different organizations to have a greater

validity when compared, and their use provides designers with basic data on the performance of

brazing filler metals and brazed constructions. However, it is essential to appreciate that the results

achieved, as with all mechanical tests, are not fundamental, and that the values obtained depend upon

the conditions of the test, the condition of the brazing filler metal, the design of the joint and the quality

achieved by the brazing process. The brazing process produces joints that are not homogeneous as they

are made up of parent materials and a filler metal.

Many factors (such as the joint gap, brazing cycle, diffusion of the filler into the parent material, etc.)

will affect the mechanical properties of the joint. Therefore expert knowledge is required to assess

whether it is possible to repeat in production the mechanical properties achieved in test pieces.

4 Shear tests

4.1 General

Many designs of test specimen have been used to produce shear data for brazed joints. The great

majority of brazed joints are designed to be stressed in shear, and it is not possible to convert the

results obtained from butt brazed joints into shear strengths. Test pieces detached from brazed

assemblies may be difficult to manufacture into standard shear test specimens; multi-jointed

assemblies produce similar problems, where the presence of one defective joint may not reduce the

overall strength but can cause failure in service. The shear specimen should essentially be simple in

design and economic to manufacture and test.

In all cases, particularly if there is a wide scatter in the results, the effect of non-bonded areas and other

imperfections observed by non-destructive examination and the visual examination of the fracture

surfaces should be considered.

4.2 Principle

The principle of the test is to subject the test specimen to mechanical loading in shear to fracture and

assess its mechanical properties when subjected to these methods of loading.

4.3 Test pieces and specimens

The details of the test pieces and specimens to be used shall be established before any testing is

undertaken, and may be, for example, one of the following types:

a) Type I as shown in Figure 1;

b) Type II as shown in Figure 2.

The dimensions shown in Figures 1 and 2 are those typically used but it may be necessary to vary these

to reflect specific applications.

4.4 Procedure

The test shall be conducted generally in accordance with the principles of ISO 5187.

4.5 Test results and information to be reported

The test results and information to be reported shall include the following:

a) test piece and details including dimensions, tolerances and brazed joint gap and method of

preparation;

b) references, e.g. contract number, part number, location on brazed structure, as applicable;

c) date of test;

d) brazing filler metal;

e) parent materials;

f) brazing process details;

g) test specimen type;

h) number of test specimens;

i) type of test machine;

j) temperature of test;

k) numerical results;

l) position of fracture;

m) appearance of fracture surface (imperfections if failure is in the brazed joint);

n) name of laboratory and authorizing signature.

Dimensions in millimetres, surface roughness values in micrometres

For the classification of filler

metals a value of a = 4 is

recommended

a) Test piece details b) Test piece before brazing c) Test specimen after

machinin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...