EN 16753:2016

(Main)Gas cylinders - Periodic inspection and testing, in situ (without dismantling) of refillable seamless steel tubes of water capacity between 150 l and 3 000 l, used for compressed gases

Gas cylinders - Periodic inspection and testing, in situ (without dismantling) of refillable seamless steel tubes of water capacity between 150 l and 3 000 l, used for compressed gases

This European Standard specifies requirements for using a combination of appropriate in situ (without dismantling), non-destructive examination (NDE) techniques, for example visual examination, acoustic emission testing [AT] and ultrasonic testing [UT] when periodically inspecting and testing seamless steel pressure vessels (tubes) with a water capacity between 150 l and 3 000 l, used for compressed and liquefied gases for a further period of service.

This European Standard is applicable only to pressure vessels (tubes) installed in locations where attempting any removal from their containing superstructure would be hazardous, or where the downtime required to remove them would hinder a continuous operation of a plant or service.

This European Standard does not apply to pressure receptacles used for the transport of gases as described under the TPED.

This European Standard only applies to pressure vessel (tube) assemblies where the designs permit all necessary inspections stipulated.

Gasflaschen - Wiederkehrende Inspektion und Prüfung, im Einbauzustand (ohne Demontage), von wiederbefüllbaren nahtlosen Großflaschen aus Stahl mit einem Fassungsraum zwischen 150 l und 3 000 l für verdichtete Gase

Diese Europäische Norm legt Anforderungen an die Anwendung einer Kombination geeigneter Verfahren der zerstörungsfreien Prüfung (ZfP) im Einbauzustand (ohne Demontage) fest, z. B. Sichtprüfung, Schallemissionsprüfung [AT] und Ultraschallprüfung [UT] für die wiederkehrende Inspektion und Prüfung von nahtlosen Druckbehältern (Großflaschen) aus Stahl mit einem Fassungsraum zwischen 150 l und 3 000 l fest, die für einen weiteren Betriebszeitraum mit verdichteten und verflüssigten Gasen verwendet werden.

Diese Europäische Norm gilt ausschließlich für Druckbehälter (Großflaschen) in Einbaulagen, bei denen der Versuch, sie aus der Rahmenkonstruktion zu entfernen, gefährlich wäre oder bei denen die für das Entfernen der Großflasche erforderliche Ausfallzeit den kontinuierlichen Betrieb eines Werks oder Dienstes behindern würde.

Diese Europäische Norm gilt nicht für Druckgefäße, die für den Transport von Gasen verwendet werden, wie unter TPED (Richtlinie über ortsbewegliche Druckgeräte) beschrieben.

Diese Europäische Norm gilt ausschließlich für Druckbehälterbaugruppen (Großflaschen), deren Auslegung alle festgelegten erforderlichen Prüfungen zulässt.

Bouteilles à gaz - Contrôles et essais périodiques sur site (sans démontage) des tubes en acier sans soudure rechargeables d'une contenance en eau de 150 l à 3 000 l, utilisés pour les gaz comprimés

La présente Norme européenne spécifie les exigences relatives à l'utilisation d'une combinaison de techniques appropriées d'examens non destructifs (END) sur site (sans démontage), par exemple, examen visuel, essais d'émission acoustique et essais aux ultrasons, dans le cadre des contrôles et des essais périodiques pratiqués sur des appareils à pression (tubes) en acier sans soudure destinés au stockage des gaz comprimés et liquéfiés, d'une contenance en eau comprise entre 150 l et 3 000 l, en vue d'une nouvelle période d'utilisation.

La présente Norme européenne ne s’applique qu’aux appareils à pression (tubes) placés en des endroits où toute tentative de retrait de la superstructure les abritant s’avèrerait dangereuse ou dans les cas où leur enlèvement nécessiterait un temps d’arrêt entravant la continuité du fonctionnement d’une usine ou d'un service.

La présente Norme européenne ne s’applique pas aux réceptacles sous pression utilisés pour le transport de gaz tels que décrits dans l’ESPT.

La présente Norme européenne ne s'applique qu'aux assemblages d’appareils à pression (tubes) dont la conception permet d'effectuer tous les contrôles nécessaires stipulés.

Plinske jeklenke - Periodični pregledi in preskusi ponovno polnjivih velikih jeklenk iz celega iz jekla za stisnjene pline s prostornino od 150 do 3000 l na mestu obratovanja (brez demontaže)

Ta evropski standard določa zahteve za uporabo kombinacije ustreznih (brez demontaže) neporušitvenih preiskovalnih tehnik (NDE) [npr. vizualna preiskava, preskušanje akustičnih emisij (AT) in ultrazvočno preskušanje (UT)] pri periodičnem pregledovanju in preskušanju nevarjenih jeklenih cevi z vodno prostornino 150–3000 l, ki se uporabljajo za stisnjene pline za nadaljnjo uporabo.

Ta evropski standard se uporablja le za cevi, ki so vgrajene na mestih, kjer bi bil kakršen koli poskus njihove odstranitve iz celotne strukture nevaren ali težak (npr. podmornice, plavajoči objekti) ali kjer bi čas izpada zaradi odstranitve cevi oviral varno delovanje obrata ali storitve (npr. proizvajanje energije, bolnišnice, napredne raziskovalne aplikacije in pomorski objekti, kot so sistemi za kompenzacijo potiska na polpotopnih naftnih ploščadih).

Baterijska vozila, npr. zasnovana v skladu s standardom EN 13807, je mogoče preskušati v skladu s standardom EN ISO 16148.

Ta standard se uporablja samo za sestave cevi, katerih zasnove omogočajo vse potrebne preglede, ki so predpisani tukaj.

General Information

- Status

- Published

- Publication Date

- 21-Jun-2016

- Technical Committee

- CEN/TC 23 - Transportable gas cylinders

- Drafting Committee

- CEN/TC 23/SC 3/WG 2 - Inspection and periodic testing

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Dec-2021

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16753:2016 - Gas cylinders: Periodic inspection and testing, in situ - defines requirements for the periodic, on‑site (without dismantling) inspection and testing of refillable seamless steel tubes with a water capacity between 150 l and 3 000 l, used for compressed and liquefied gases. The standard specifies a combination of non‑destructive examination (NDE) techniques (for example visual examination, acoustic emission (AE) testing and ultrasonic testing (UT)) to determine whether vessels can continue in service. It applies only where removal of the vessel would be hazardous or would cause unacceptable plant downtime, and excludes pressure receptacles used for transport (TPED).

Key Topics

- Scope and applicability: In‑situ inspection of seamless steel pressure vessels 150–3 000 l; only where design allows all required inspections and removal is impractical or unsafe.

- NDE techniques: Use of combined methods - visual inspection, AE testing, ultrasonic thickness and flaw detection, hydraulic testing, magnetic particle, radiography, eddy current, hardness and supplementary dye‑penetrant methods as needed.

- Operational principles:

- Mandatory pre‑inspection site visit and questionnaire to assess installation, gas type, pressure ratings, accessibility, and risk.

- On‑site inspection sequence and decision logic for follow‑up tests if anomalies are found.

- Safety and environmental considerations (noise, vibrational background for AE).

- Personnel and reporting: Qualification of NDE personnel per referenced certification standards; marking, certification and formal test reports required.

- Rejection and remediation: Annex A provides defect descriptions and rejection criteria for visual findings; provisions for rendering tubes unserviceable if required.

- Annexes:

- Annex A - defect evaluation and rejection criteria

- Annex B - AE examination procedure and real‑time evaluation

- Annex C - recommended time intervals when no national regulation exists

- Annex D - pre‑inspection site survey/checklist and risk analysis

Applications

EN 16753:2016 is intended for use by:

- Plant owners and asset managers with fixed high‑capacity gas vessels (offshore/onshore storage, diving systems, emergency evacuation vessels, research and medical installations).

- Inspection bodies and certified NDE technicians performing periodic on‑site assessments.

- Maintenance engineers, safety managers and regulators who need a documented scheme of examination for in‑situ pressure vessels. Practical benefits include reduced downtime, safer inspections where removal is hazardous, and a standardized approach to combining AE/UT/visual methods to assess structural integrity.

Related Standards

- EN ISO 16148 (AE and UT procedures for refillable seamless steel tubes)

- EN ISO 9712 (NDT personnel qualification and certification)

- EN ISO 11120 (design/certification of gas cylinders) - referenced for context

- EN ISO 25760, ISO 6406 and TPED (transport exclusions)

Keywords: EN 16753:2016, gas cylinders, in situ inspection, non‑destructive examination, acoustic emission testing, ultrasonic testing, seamless steel tubes, periodic inspection.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 16753:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas cylinders - Periodic inspection and testing, in situ (without dismantling) of refillable seamless steel tubes of water capacity between 150 l and 3 000 l, used for compressed gases". This standard covers: This European Standard specifies requirements for using a combination of appropriate in situ (without dismantling), non-destructive examination (NDE) techniques, for example visual examination, acoustic emission testing [AT] and ultrasonic testing [UT] when periodically inspecting and testing seamless steel pressure vessels (tubes) with a water capacity between 150 l and 3 000 l, used for compressed and liquefied gases for a further period of service. This European Standard is applicable only to pressure vessels (tubes) installed in locations where attempting any removal from their containing superstructure would be hazardous, or where the downtime required to remove them would hinder a continuous operation of a plant or service. This European Standard does not apply to pressure receptacles used for the transport of gases as described under the TPED. This European Standard only applies to pressure vessel (tube) assemblies where the designs permit all necessary inspections stipulated.

This European Standard specifies requirements for using a combination of appropriate in situ (without dismantling), non-destructive examination (NDE) techniques, for example visual examination, acoustic emission testing [AT] and ultrasonic testing [UT] when periodically inspecting and testing seamless steel pressure vessels (tubes) with a water capacity between 150 l and 3 000 l, used for compressed and liquefied gases for a further period of service. This European Standard is applicable only to pressure vessels (tubes) installed in locations where attempting any removal from their containing superstructure would be hazardous, or where the downtime required to remove them would hinder a continuous operation of a plant or service. This European Standard does not apply to pressure receptacles used for the transport of gases as described under the TPED. This European Standard only applies to pressure vessel (tube) assemblies where the designs permit all necessary inspections stipulated.

EN 16753:2016 is classified under the following ICS (International Classification for Standards) categories: 23.020.30 - Pressure vessels, gas cylinders; 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16753:2016 has the following relationships with other standards: It is inter standard links to EN 1968:2002, EN ISO 16148:2016, EN ISO 25760:2015, EN ISO 13769:2018, EN ISO 9712:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16753:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gasflaschen - Wiederkehrende Inspektion und Prüfung, im Einbauzustand (ohne Demontage), von wiederbefüllbaren nahtlosen Großflaschen aus Stahl mit einem Fassungsraum zwischen 150 l und 3 000 l für verdichtete GaseBouteilles à gaz - Contrôles et essais périodiques sur site (sans démontage) des tubes en acier sans soudure rechargeables d'une contenance en eau de 150 l à 3 000 l, utilisés pour les gaz comprimésGas cylinders - Periodic inspection and testing, in situ (without dismantling) of refillable seamless steel tubes of water capacity between 150 l and 3 000 l, used for compressed gases23.020.35Plinske jeklenkeGas cylindersICS:Ta slovenski standard je istoveten z:EN 16753:2016SIST EN 16753:2016en,fr,de01-november-2016SIST EN 16753:2016SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16753

June

t r s x ICS

t uä r t rä u r English Version

Gas cylinders æ Periodic inspection and testingá in situ water capacity between

s w r l and

u

r r r lá used for compressed gases Bouteilles à gaz æ Contrôles et essais pßriodiques sur rechargeables d 5une contenance en eau de

s w r l à

u

r r r lá utilisßs pour les gaz comprimßs

Gasflaschen æ Wiederkehrende Inspektion und Prüfungá wiederbefüllbaren nahtlosen Großflaschen aus Stahl mit einem Fassungsraum zwischen

s w r l und

u

r r r l für verdichtete Gase This European Standard was approved by CEN on

s w April

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x y w uã t r s x ESIST EN 16753:2016

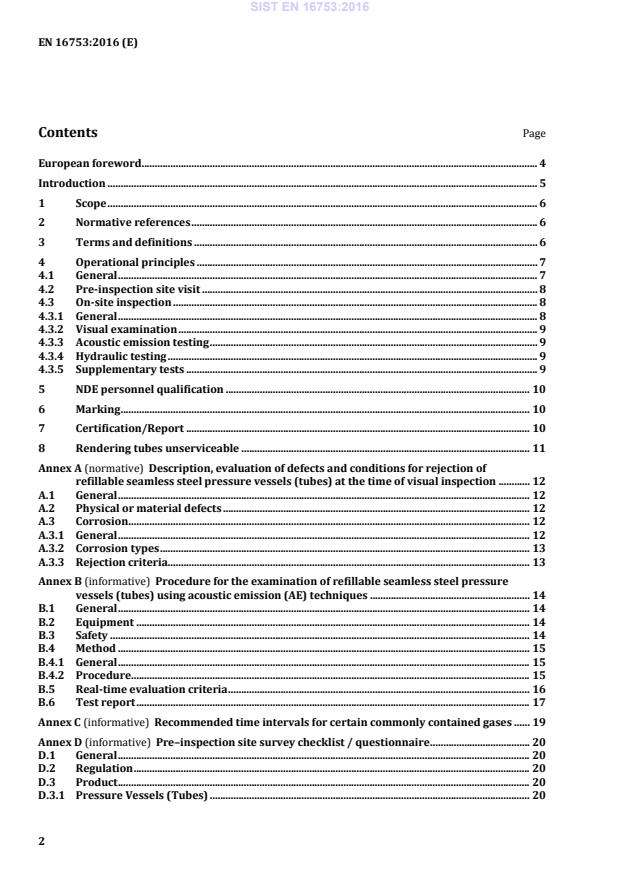

Description, evaluation of defects and conditions for rejection of refillable seamless steel pressure vessels (tubes) at the time of visual inspection . 12 A.1 General . 12 A.2 Physical or material defects . 12 A.3 Corrosion . 12 A.3.1 General . 12 A.3.2 Corrosion types . 13 A.3.3 Rejection criteria . 13 Annex B (informative)

Procedure for the examination of refillable seamless steel pressure vessels (tubes) using acoustic emission (AE) techniques . 14 B.1 General . 14 B.2 Equipment . 14 B.3 Safety . 14 B.4 Method . 15 B.4.1 General . 15 B.4.2 Procedure. 15 B.5 Real-time evaluation criteria . 16 B.6 Test report . 17 Annex C (informative)

Recommended time intervals for certain commonly contained gases . 19 Annex D (informative)

Pre–inspection site survey checklist / questionnaire . 20 D.1 General . 20 D.2 Regulation . 20 D.3 Product . 20 D.3.1 Pressure Vessels (Tubes) . 20 SIST EN 16753:2016

s { r y z. This standard is intended to be used under a variety of regulatory regimes. In case of conflict, the applicable regulation takes precedence. SIST EN 16753:2016

s { x z:2002, Transportable gas cylinders — Periodic inspection and testing of seamless steel gas cylinders EN ISO

{ y s t, Non-destructive testing — Qualification and certification of NDT personnel (ISO 9712) EN ISO

s u y x {, Gas cylinders — Stamp marking (ISO 13769) EN ISO 16148, Gas cylinders — Refillable seamless steel gas cylinders and tubes — Acoustic emission examination (AT) and follow-up ultrasonic examination (UT) for periodic inspection and testing (ISO 16148) EN ISO 25760, Gas cylinders — Operational procedures for the safe removal of valves from gas cylinders (ISO 25760) ISO 6406:2005, Gas cylinders — Seamless steel gas cylinders — Periodic inspection and testing 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 acoustic emission (AE) activity number of bursts (or events if the appropriate conditions are fulfilled) detected during a test or part test 3.2 flow noise acoustic emission events caused by the action of pressurizing the vessel and not by any structural flaws within it Note 1 to entry: This can be reduced by slowing the fill rate and/or filtering out such emissions electronically within the AE recording equipment. SIST EN 16753:2016

s { x z); b) acoustic emission testing (see EN ISO 16148); c) internal and external visual examination (see EN

s { x z); d) ultrasonic thickness survey (see EN

s { x z); e) ultrasonic flaw detection (see EN

s { x z); f) magnetic particle testing (see EN ISO

{ { u v-1); g) radiographic testing (see EN ISO

w w y {); h) eddy current testing (see EN ISO 15548 (all parts)); i) hardness testing (see EN ISO

{ z r {-1). At the discretion of the competent person employed for the task, other appropriate test techniques may be used, e.g. dye penetrant. Indication of any anomaly in the tube(s) under test that are revealed at the time of the in situ inspection shall be evaluated using a different technique to be able to quantify (location and frequency) and size any possible imperfection. SIST EN 16753:2016

the environmental conditions at the test site (e.g. noise and vibration levels); and 10) a location-based risk analysis (see Annex D). If the collected information does not allow the use of this European Standard, such tube(s) shall not be tested and the owner informed accordingly. 4.3 On-site inspection 4.3.1 General Having gathered and analysed the data from the pre-inspection site visit (see 4.2), the most suitable test method(s) for the particular tube installation under consideration shall be selected. The selected methods shall form the basis of a written scheme of examination for the installation being inspected. At all times the inspection work shall be carried out in accordance with the appropriate written procedures(s) for the test(s) to be performed. SIST EN 16753:2016

a visual examination (see 4.3.2) of all accessible external surfaces, internal surfaces and an acoustic emission test (see 4.3.3) coupled with any other tests deemed necessary; or b)

a visual examination (see 4.3.2) of all accessible external surfaces, internal surfaces and a hydraulic test (see 4.3.4) coupled with any other tests deemed necessary. If it is found that the tube surface coating is unsatisfactory for a further period of use, it shall be brought to the attention of the tube owner for further appropriate action to remedy the situation. Once the tube(s) has failed one of the above mentioned tests, none of the other test methods shall be applied to approve the tube(s). If at any stage of the inspection process the valve/plug/adaptor/pressure control device within the tube needs to be removed, this shall be done in accordance with the requirements of EN ISO 25760. 4.3.2 Visual examination All external visual examinations (see Annex A) shall be performed in accordance with the requirements of EN

s { x z:2002, Annex C (additional information can be found in ISO/TR 16115). All internal visual examinations shall be performed in accordance with the requirements of EN

s { x z:2002, Annex C (additional information can be found in ISO/TR 16115). All signs of corrosion and any form of mechanical damage shall be carefully investigated. Where necessary, additional equipment (e.g. a video camera or an endoscope) shall be used to help clarify and interpret the initial observations. 4.3.3 Acoustic emission testing AT shall be carried out in accordance with the requirements of EN ISO 16148 (an examination procedure using AT is described in Annex B). 4.3.4 Hydraulic testing Hydraulic testing shall be carried out in accordance with the requirements of EN

s { x z:2002, 10.2. 4.3.5 Supplementary tests Where there is doubt about the type and/or severity of any imperfection identified by the tests in 4.3.2 to 4.3.4, additional test(s) shall be conducted to supplement or clarify the results obtained (e.g. UT, magnetic particle testing, radiographic testing, eddy current testing, hardness testing). Where particular parts of the tube are inspected using UT, the relevant requirements of ISO 6406:2005, 11.4 shall be met. Corrosion mapping or flaw detection may be used to further evaluate imperfection distribution. NOTE Corrosion mapping is a pulse-echo ultrasonic technique that produces a colour graphic image of the area scanned. It involves scanning with one or more straight beam probes using a prescribed, dual axis scan pattern over the tube surface whilst taking thickness measurements. The measurements are converted

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...