EN 131-2:2010+A1:2012

(Main)Ladders - Part 2: Requirements, testing, marking

Ladders - Part 2: Requirements, testing, marking

This European Standard specifies the general design features, requirements and test methods for portable ladders.

It does not apply to step stools or ladders for specific professional use such as firebrigade ladders, roof ladders and mobile ladders.

It does not apply to ladders used for work on or near live electrical systems or installations. For this purpose EN 61478 applies.

This European Standard is intended to be used in conjunction with EN 131 1.

For single or multiple hinge joint ladders EN 131 4 applies.

Leitern - Teil 2: Anforderungen, Prüfung, Kennzeichnung

Diese Europäische Norm legt die allgemeinen Konstruktionsmerkmale, Anforderungen und Prüfverfahren für

tragbare Leitern fest.

Sie gilt nicht für Tritte oder Leitern für den besonderen beruflichen Gebrauch, wie Feuerwehrleitern,

Dachleitern und fahrbare Leitern.

Sie gilt nicht für Leitern, die für Arbeiten an oder in der Nähe von elektrischen Systemen verwendet werden.

Hierfür gilt EN 61478.

ANMERKUNG Für isolierende Leitern für Arbeiten an oder in der Nähe elektrischer Anlagen im Niederspannungsbereich

unter 1 000 V Wechselspannung oder 1 500 V Gleichspannung ist EN 50528 in Vorbereitung.

Diese Europäische Norm ist in Zusammenhang mit EN 131-1 anzuwenden.

Für Ein- oder Mehrgelenkleitern gilt EN 131-4.

Échelles - Partie 2: Exigences, essais, marquage

La présente Norme européenne spécifie les caractéristiques générales de conception, les exigences et les méthodes

d’essai applicables aux échelles portables.

Elle ne s’applique pas aux marchepieds ou aux échelles à usage professionnel spécifique tels que les échelles

à incendie, les échelles de toit et les échelles escamotables.

Elle ne s’applique pas aux échelles utilisées pour effectuer des travaux sur des installations électriques ou à proximité

de circuits électriques sous tension. À cet effet, l’EN 61478 s’applique.

NOTE Pour les échelles à caractères isolants (une tension inférieure à 1 000 V c.a. ou à 1 500 V c.c.), l’EN 50528

est en préparation.

La présente norme doit être utilisée conjointement avec l’EN 131-1.

Pour les échelles articulées à articulations simple et multiple, l’EN 131-4 s’applique.

Lestve - 2. del: Zahteve, preskušanje, označevanje

Ta evropski standard določa splošne konstrukcijske značilnosti, zahteve in preskusne metode za prenosne lestve. Ne uporablja se za pručke ali lestve za posebno poklicno uporabo, kot so gasilske lestve, strešne lestve in mobilne lestve. Ne uporablja se za lestve, ki so namenjene za delo na električnih sistemih ali napravah pod napetostjo ali v njihovi bližini. V ta namen se uporablja standard EN 61478.

General Information

- Status

- Withdrawn

- Publication Date

- 22-May-2012

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 93 - Ladders

- Drafting Committee

- CEN/TC 93/WG 10 - Revision of EN 131-2

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Jan-2017

- Completion Date

- 11-Feb-2026

- Directive

- Not Harmonized2001/95/EC - General product safety

Not Harmonized92/59/EEC - General product safety

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 14080:2013 - Timber structures - Glued laminated timber and glued solid timber - Requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Frequently Asked Questions

EN 131-2:2010+A1:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ladders - Part 2: Requirements, testing, marking". This standard covers: This European Standard specifies the general design features, requirements and test methods for portable ladders. It does not apply to step stools or ladders for specific professional use such as firebrigade ladders, roof ladders and mobile ladders. It does not apply to ladders used for work on or near live electrical systems or installations. For this purpose EN 61478 applies. This European Standard is intended to be used in conjunction with EN 131 1. For single or multiple hinge joint ladders EN 131 4 applies.

This European Standard specifies the general design features, requirements and test methods for portable ladders. It does not apply to step stools or ladders for specific professional use such as firebrigade ladders, roof ladders and mobile ladders. It does not apply to ladders used for work on or near live electrical systems or installations. For this purpose EN 61478 applies. This European Standard is intended to be used in conjunction with EN 131 1. For single or multiple hinge joint ladders EN 131 4 applies.

EN 131-2:2010+A1:2012 is classified under the following ICS (International Classification for Standards) categories: 97.145 - Ladders. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 131-2:2010+A1:2012 has the following relationships with other standards: It is inter standard links to EN 131-2:2010+A2:2017, EN 131-2:2010, EN 61478:2001, EN 1309-3:2018, EN ISO 3834-1:2021, EN 14080:2013, EN ISO 3834-3:2021, EN ISO 6892-1:2019, EN 204:2016, EN 131-3:2018+A1:2025, EN 59:2016, EN 844-9:1997, EN ISO 14731:2019, EN ISO 527-1:2019, EN 408:2010+A1:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 131-2:2010+A1:2012 is associated with the following European legislation: EU Directives/Regulations: 2001/95/EC, 92/59/EEC; Standardization Mandates: M/285. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 131-2:2010+A1:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Leitern - Teil 2: Anforderungen, Prüfung, KennzeichnungÉchelles - Partie 2: Exigences, essais, marquageLadders - Part 2: Requirements, testing, marking97.145LestveLaddersICS:Ta slovenski standard je istoveten z:EN 131-2:2010+A1:2012SIST EN 131-2:2010+A1:2012en,fr,de01-julij-2012SIST EN 131-2:2010+A1:2012SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 131-2:2010+A1

May 2012 ICS 97.145 Supersedes EN 131-2:2010English Version

Ladders - Part 2: Requirements, testing, marking

Échelles - Partie 2: Exigences, essais, marquage

Leitern - Teil 2: Anforderungen, Prüfung, Kennzeichnung This European Standard was approved by CEN on 20 May 2010 and includes Amendment 1 approved by CEN on 16 April 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 131-2:2010+A1:2012: ESIST EN 131-2:2010+A1:2012

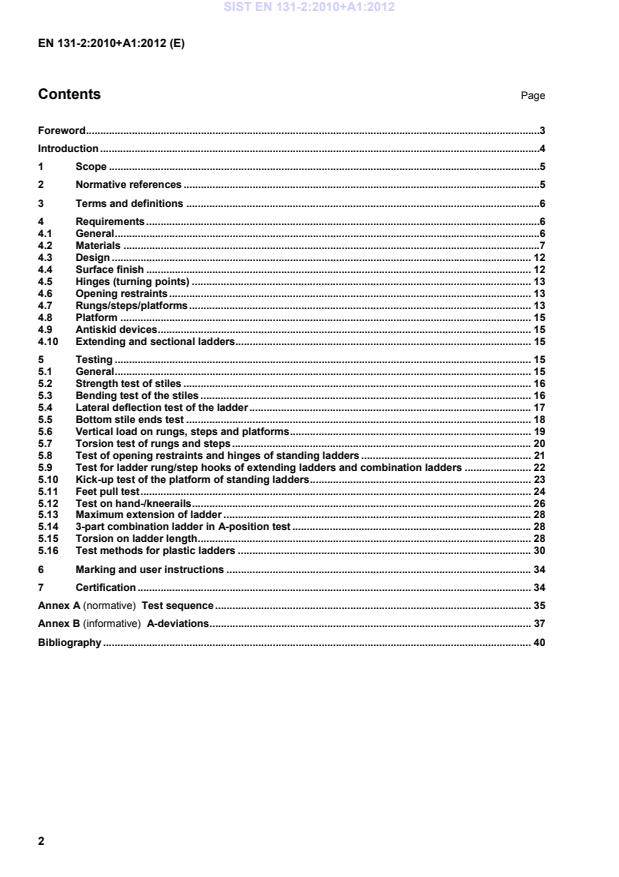

Test sequence . 35Annex B (informative)

A-deviations . 37Bibliography . 40 SIST EN 131-2:2010+A1:2012

It does not apply to ladders used for work on or near live electrical systems or installations. For this purpose EN 61478 applies. NOTE For insulating ladders for use on or near low voltage electrical installations in the range below 1000 V a.c or

1 500 V d.c. EN 50528 is under preparation. This European Standard is intended to be used in conjunction with EN 131-1. For single or multiple hinge joint ladders EN 131-4 applies. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 59, Glass reinforced plastics — Measurement of hardness by means of a Barcol impressor EN 131-1:2007, Ladders — Part 1: Terms, types, functional sizes EN 131-3, Ladders — Part 3: User Instructions EN 204, Classification of thermoplastic wood adhesives for non-structural applications EN 301, Adhesives, phenolic and aminoplastic, for load-bearing timber structures — Classification and performance requirements EN 385, Finger jointed structural timber — Performance requirements and minimum production requirements EN 386:2001, Glued laminated timber — Performance requirements and minimum production requirements EN 391:2001, Glued laminated timber — Delamination test of glue lines EN 392, Glued laminated timber — Shear test of glue lines EN 408, Timber structures — Structural timber and glued laminated timber — Determination of some physical and mechanical properties EN 844-9:1997, Round and sawn timber — Terminology — Part 9: Terms relating to features of sawn timber EN 1310, Round and sawn timber — Method of measurement of features EN 61478, Live working — Ladders of insulating material (IEC 61478:2001) EN ISO 179-1, Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact test (ISO 179-1:2000) EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1:1993 including Corr 1:1994) SIST EN 131-2:2010+A1:2012

(ISO 6892-1:2009) EN ISO 14125, Fibre-reinforced plastic composites — Determination of flexural properties (ISO 14125:1998) EN ISO 14731, Welding coordination — Tasks and responsibilities (ISO 14731:2006) 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 131-1:2007 and the following apply. 3.1 thermoset plastic plastic that has been cured by heat or by other means such as radiation, catalysts, etc., into a substantially infusible and insoluble state [EN ISO 472:2001] 3.2 composite material crosslinkable resin-based material with a continuous reinforcement fibre as filler (e.g. fibreglass) 3.3 thermoplastic material plastic material other than thermoset plastic or composite with or without filler and with or without rein-forcement 3.4 maximal total load maximum weight that the ladder is designed to support when set up in accordance with the manufacturer's instruction 4 Requirements 4.1 General The requirements are based upon a maximum total load of 150 kg. SIST EN 131-2:2010+A1:2012

EN ISO 6892-1 of minimum 5 %. All load bearing parts made of aluminium alloy shall have a thickness of at least 1,2 mm. 4.2.2 Steel If cold rolled steel or a special alloy-steel is used the ratio between 0,2 % yield-stress and ultimate strength (Rp 0,2/Rm) shall be lower than 0,92. All load bearing parts made of steel shall have a thickness of at least 1,0 mm. 4.2.3 Plastics Glass-fibre reinforced plastics shall be protected against penetration of water and dirt. The surface shall be smooth. The fibres shall be embedded. The Barcol hardness according to EN 59 shall be at least 35. The test methods and acceptance criteria for defining the characteristics of the composite and reinforced thermoplastic materials are given in 5.16. They apply to the load-bearing elements (stiles, climbing supports, platforms) of the structure of ladders at time of use. Thermoplastic materials without reinforcements shall not be used for load bearing-elements.

The minimum thickness for load-bearing elements made of thermoset plastics and composite material is 2 mm. When using plastics materials, ageing and temperature resistance shall be taken into account. 4.2.4 Timber 4.2.4.1 Different kind of timber For stiles, stanchions, braces, rungs and steps the types of timber to be used shall have a bulk density greater than or equal to 450 kg/m3 for softwoods and 690 kg/m3 for hardwoods. The bulk density shall be measured with a moisture content of 15 %. Examples of suitable species of wood are: Softwood: Fir (Abies alba) Larch (Larix decidua) Spruce (Picea abies) Pine (Pinus sylvestris) Oregon pine (Pseudotsuga menziesii) Hemlock (Tsuga heterophylla) Hardwood: Beech (Fagus sylvatica) Ash (Fraxisnus excelsior) SIST EN 131-2:2010+A1:2012

Table 1 — General requirements Hard-wood Soft-wood Criteria Requirements X X 1. Wane Only permitted for stiles on one edge for a max. depth of 10 mm with a max. length of 500 mm. It is not permitted for rungs (see Figure 1). X

X X 2. Width of annual rings< 4 mm Pitch pine: < 6 mm at a bulk density of 550 kg/m3. For ring porous hardwoods < 1 mm not permitted e.g. oak (Quercus sp.), ash (Fraxinus sp.) robinia (Robinia sp.). X X 3. Slope of annual ringsA deviation of the slope of annual rings from the longitudinal edges of the wood of 100 mm per 1 000 mm maximum is admissible (see Figure 2). Local deviation e. g at knot positions, are neglected. X X 4. Shakes

— splitsa

not permitted

— checksa < 100 mm length

Lightning/frost shakes, Ring shake not permitted

5. Colour

X Blue stain Permitted

X Red streakes permitted up to 25 % of the surface

X Red rot, brown rot not permitted X

Red heart of beech, brown heart of ash Permitted X

Doty wood not permitted X X 6. Reaction wood admissible until 1/5 of the cross section or of the surface X X 7. Pithnot permitted X

8. Defects caused by insectsnot permitted X X 9. Mistletoe traces not permitted

X 10. Resin pockets

not continuous permitted until 4 mm width and 1,5 × width of the stiles (see Figure 3)

Continuous not permitted X X 11. Spiral grain A deviation of the grain direction from the longi-tudinal edges of the wood of not more than 50 mm per 1 000 mm, measured either with the help of shrinkage shakes or the scratching method is admissible (see Figure 4). The measurement is to be carried out in two faces perpendicular to each other. The largest deviation is decisive. In the case of rungs and steps, the grain ends, with the exception of knots, shall be at the rung or step ends. a Definitions see EN 844-9:1997

Figure 1 — Admissible wane Dimensions in millimetres

Figure 2 — Admissible deviation of the slope of annual rings to the longitudinal edges Dimensions in millimetres

Figure 3 — Admissible resin pockets Dimensions in millimetres

Figure 4 — Admissible deviation of the grain direction related to the longitudinal edges

(spiral grain) SIST EN 131-2:2010+A1:2012

Figure 5 — Inadmissible knot Pin knots2) (including black pin knots) with a diameter of less than or equal to 5 mm are permitted. In the upper and lower third of the stile or supporting element, one sound, intergrown knot1), of diameter d, less than or equal to 0,2 × b (the width of the stile) is permitted per metre. The diameter of the knot is measured in accordance with EN 1310. The knot shall be a minimum of 10 mm from the edges of the stile or supporting element and a minimum of 50 mm from any rung holes, tenons and milled recesses for treads. (see Figure 6). Dimensions in millimetres

Figure 6 — Admissible knot For ladders made of laminated wood the above mentioned number, size and position of knots are allowed over the total length of the ladder. 4.2.4.3.2 Knots in rungs, steps, braces Intergrown pin knots up to a maximum diameter of 3 mm are admissible. 4.2.4.4 Moisture content (Related to the kiln-dry weight) at time of manufacture The moisture content shall be determined by means of hygrometer; in critical or referee cases in accordance with the oven-dry method. The moisture content of the wood is to be chosen according to the equilibrium moisture content resulting from open air drying, normally in Europe 12 % to 20 %. The moisture content of the rungs and steps shall be lower than that of the stiles at time of production.

1) Definitions see EN 844-9:1997 2) Pin knots are knots having approximately a circular cross section SIST EN 131-2:2010+A1:2012

EN ISO 3834-1 to EN ISO 3834-4 have to be observed. 4.4 Surface finish In order to avoid injuries, accessible edges, corners, and protruding parts shall be free of burrs, for example chamfered or rounded. Metal parts susceptible to corrosion shall be protected by means of a paint coating or other coating. Under normal conditions aluminium alloys are not susceptible to corrosion. Wooden parts shall be smoothed and coated on all sides. The coating shall be transparent and permeable to water vapour. SIST EN 131-2:2010+A1:2012

Key 1 stile 2 rung Figure 7 — Example of a concealed joint

Key 1 stile 2 rung Figure 8 — Example of an open joint

Key 1 stile 2 rung Figure 9 — Example of a concealed joint Round rungs shall have a diameter greater than or equal to 25 mm. The top surface of flat standing surfaces shall have an angle less than or equal to 25° to the horizontal. For leaning ladders the angle related to the stile shall be 65° to 90° for rungs and 60° to 70° for steps. SIST EN 131-2:2010+A1:2012

± 1 mm for longitudinal measurements;

± 5 mm for the measurement of the distance between the supports and the overhanging length;

± 1° for the measurement of angles;

± 1 % for static forces and torque. SIST EN 131-2:2010+A1:2012

Figure 10 — Strength test 5.3 Bending test of the stiles The test shall be carried out on the complete ladder. In the case of extending ladders and combination ladders the test shall be carried out on the complete extended ladder. Sectional ladders shall be tested at full length with all permitted pieces. The test shall be carried out without supporting legs if not permanently fixed to the ladder. Where the ascendable side cannot be determined by the construction of the product, or where it is a multiple part combination ladder the ladder shall be tested twice. For the second test the ladder shall be rotated 180° about the longitudinal axis. SIST EN 131-2:2010+A1:2012

for ladders of length less than or equal to 5 m; fmax = 0,043 × l − 90 mm for ladders of length more than 5 m and less than or equal to 12 m; fmax = 0,06 × l − 294 mm for ladders of length more than 12 m. Dimensions in millimetres

Figure 11 — Bending test 5.4 Lateral deflection test of the ladder This test shall be conducted on all one-piece ladders as well as on each ascendable part of multiple-piece ladders (standing ladders, sectional ladders, combination ladders, extending ladders) and on the supporting-legs of standing rung- or step-ladders. The ladder shall be placed horizontally on supports situated 200 mm from each end of the ladder. The supports shall be cylindrical with diameters between 25 mm and 100 mm and one shall be free to rotate the other shall be fixed. The ladder shall be placed in the lateral position. A pre-load of 100 N shall be applied for the duration of one minute. The position of the ladder after removal of the pre-load is the origin for measurement. A load F of 250 N (see Figure 12) shall be applied to the lower stile equidistant from the supports. The deflection is measured equidistant from the supports 1 minute after loading. SIST EN 131-2:2010+A1:2012

Figure 12 — Lateral deflection test 5.5 Bottom stile ends test Place the ladder laterally, with the longitudinal axis of the ladder in the horizontal position. The lower stile is to be fixed to the support so that the stile ends overhang the supporting surface (see Figure 13). If the rungs/steps are bolted, riveted, or similarly fixed to the stile the edge of the support shall be in line with the bottom lower edge of the assem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...