EN 13623:2010

(Main)Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems - Test method and requirements (phase 2, step 1)

Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems - Test method and requirements (phase 2, step 1)

This European Standard specifies a test method and the minimum requirements for bactericidal activity of chemical disinfectant products intended to be used for treatment in aqueous systems against Legionella pneumophila that form a homogeneous, physically stable preparation when diluted with buffered ferrous hard water or hard water. Whenever Legionella pneumophila poses a risk to human health, this method is suitable for water used in cooling towers and water for general purposes, like spas, pools, showers and other uses. The method is not suitable for electro-chemical disinfection.

The European Standard applies to products used to treat water in order to kill Legionella pneumophila.

NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used.

NOTE 2 This method corresponds to a phase 2 step 1 test .

NOTE 3 This method does not take into account the fact that Legionella pneumophila is often found in cells of amoebae and/or biofilms and that thereby a product’s activity against the bacteria may be reduced.

EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendation".

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der bakteriziden Wirkung gegen Legionella von chemischen Desinfektionsmitteln für wasserführende Systeme - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)

Diese Europäische Norm legt ein Prüfverfahren und die Mindestanforderungen an die bakterizide Wirkung von chemischen Desinfektionsmitteln zur Verwendung bei der Aufbereitung in wasserführenden Systemen gegen Legionella pneumophila fest, die bei Verdünnung mit gepuffertem eisenhaltigem Wasser standardisierter Härte oder Wasser standardisierter Härte als homogenes, physikalisch stabiles Präparat vorliegen. Immer wenn Legionella pneumophila ein Risiko für die menschliche Gesundheit darstellt, ist dieses Verfahren für in Kühltürmen genutztes Wasser und Wasser für allgemeine Zwecke, wie z. B. Bäder, Schwimm- und Bade-becken, Duschen und andere Zwecke, geeignet. Das Verfahren ist nicht für die elektrochemische Desinfektion geeignet. Diese Europäische Norm gilt für Produkte, die zur Wasseraufbereitung verwendet werden, um Legionella pneumophila abzutöten. ANMERKUNG 1 Das beschriebene Verfahren dient zur Bestimmung der Wirksamkeit von handelsüblichen Zube-reitungen oder Wirkstoffen unter den Bedingungen, unter denen sie angewendet werden. ANMERKUNG 2 Das Verfahren entspricht einer Prüfung der Phase 2, Stufe 1. ANMERKUNG 3 Das vorliegende Verfahren berücksichtigt nicht die Tatsache, dass Legionella pneumophila oft in Zellen von Amöben und/oder Biofilmen zu finden ist und das dadurch die Wirksamkeit des Produkts gegen die Bakterien möglicherweise verringert ist. EN 14885 legt im Einzelnen die Beziehungen der verschiedenen Prüfungen untereinander und zu den „Anwendungsempfehlungen“ fest.

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité bactéricide vis-à-vis des légionelles des désinfectants chimiques pour les systèmes aqueux - Méthode d'essai et prescriptions (phase 2, étape 1)

La présente Norme européenne décrit une méthode d'essai et les prescriptions minimales relatives à l'activité bactéricide des produits désinfectants chimiques destinés au traitement des systèmes aqueux vis-à-vis de Legionella pneumophila et donnant une préparation homogène, physiquement stable quand ils sont dilués dans de l'eau dure ferreuse tamponnée ou dans de l'eau dure. Lorsque Legionella pneumophila présente un risque pour la santé humaine, la présente méthode est applicable pour l’eau utilisée dans les tours de refroidissement et l’eau à usage général telle que l’eau utilisée dans les jacuzzis, les piscines, les douches et autres. La méthode n’est pas adaptée à la désinfection électrochimique.

La Norme européenne s’applique aux produits de traitement de l’eau destinés à tuer Legionella pneumophila.

NOTE 1 La méthode décrite vise à déterminer l’activité des formulations commerciales ou des substances actives dans les conditions dans lesquelles elles sont utilisées.

NOTE 2 La présente méthode correspond à un essai de phase 2, étape 1.

NOTE 3 Cette méthode ne tient pas compte du fait que Legionella pneumophila se trouve souvent dans des cellules amibiennes et/ou dans des biofilms, ce qui peut réduire l’activité du produit vis-à-vis des bactéries.

L’EN 14885 spécifie de manière détaillée la relation entre les différents essais et les « recommandations d’emploi ».

Kemična razkužila in antiseptiki - Kvantitativni suspenzijski preskus za vrednotenje baktericidnega delovanja kemičnih razkužil za razkuževanje vode na bakterijo Legionella - Preskusna metoda in zahteve (faza 2, stopnja 1)

Ta evropski standard določa preskusno metodo in minimalne zahteve za baktericidno delovanje kemičnih izdelkov za razkuževanje, namenjenih obdelavi vodnih sistemov proti bakteriji Legionella pneumophila, ki tvorijo homogen, fizično stabilni pripravek, kadar so razredčeni s puferirano železno trdo vodo ali trdo vodo. Kadar koli bakterija Legionella pneumophila predstavlja tveganje za zdravje ljudi, je ta metoda primerna za vodo, ki se uporablja v hladilnih stolpih, ter za vodo za splošne namene, kot v zdraviliščih, bazenih, tuših in za druge uporabe. Ta metoda ni primerna za elektro-kemično razkuževanje. Ta evropski standard velja za proizvode, ki se uporabljajo za obdelavo vode z namenom uničiti bakterijo Legionella pneumophila. EN 14885 podrobno določa razmerje različnih preskusov drugega z drugim in za »priporočilo za uporabo«.

General Information

- Status

- Withdrawn

- Publication Date

- 31-Aug-2010

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 216 - Chemical disinfectants and antiseptics

- Drafting Committee

- CEN/TC 216/WG 1 - Human medicine

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Oct-2020

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 25-May-2016

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

EN 13623:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems - Test method and requirements (phase 2, step 1)". This standard covers: This European Standard specifies a test method and the minimum requirements for bactericidal activity of chemical disinfectant products intended to be used for treatment in aqueous systems against Legionella pneumophila that form a homogeneous, physically stable preparation when diluted with buffered ferrous hard water or hard water. Whenever Legionella pneumophila poses a risk to human health, this method is suitable for water used in cooling towers and water for general purposes, like spas, pools, showers and other uses. The method is not suitable for electro-chemical disinfection. The European Standard applies to products used to treat water in order to kill Legionella pneumophila. NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. NOTE 2 This method corresponds to a phase 2 step 1 test . NOTE 3 This method does not take into account the fact that Legionella pneumophila is often found in cells of amoebae and/or biofilms and that thereby a product’s activity against the bacteria may be reduced. EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendation".

This European Standard specifies a test method and the minimum requirements for bactericidal activity of chemical disinfectant products intended to be used for treatment in aqueous systems against Legionella pneumophila that form a homogeneous, physically stable preparation when diluted with buffered ferrous hard water or hard water. Whenever Legionella pneumophila poses a risk to human health, this method is suitable for water used in cooling towers and water for general purposes, like spas, pools, showers and other uses. The method is not suitable for electro-chemical disinfection. The European Standard applies to products used to treat water in order to kill Legionella pneumophila. NOTE 1 The method described is intended to determine the activity of commercial formulations or active substances under the conditions in which they are used. NOTE 2 This method corresponds to a phase 2 step 1 test . NOTE 3 This method does not take into account the fact that Legionella pneumophila is often found in cells of amoebae and/or biofilms and that thereby a product’s activity against the bacteria may be reduced. EN 14885 specifies in detail the relationship of the various tests to one another and to "use recommendation".

EN 13623:2010 is classified under the following ICS (International Classification for Standards) categories: 71.100.35 - Chemicals for industrial and domestic disinfection purposes. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13623:2010 has the following relationships with other standards: It is inter standard links to EN 13623:2020, EN 14885:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13623:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der bakteriziden Wirkung gegen Legionella von chemischen Desinfektionsmitteln für wasserführende Systeme - Prüfverfahren und Anforderungen (Phase 2, Stufe 1)Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité bactéricide contre des légionelles des désinfectants chimiques pour les systèmes aqueux - Méthode d'essai et prescriptions (phase 2, étape 1)Chemical disinfectants and antiseptics - Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems - Test method and requirements (phase 2, step 1)71.100.35Kemikalije za dezinfekcijo v industriji in domaChemicals for industrial and domestic disinfection purposesICS:Ta slovenski standard je istoveten z:EN 13623:2010SIST EN 13623:2010en,de01-november-2010SIST EN 13623:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13623

September 2010 ICS 71.100.35 English Version

Chemical disinfectants and antiseptics -Quantitative suspension test for the evaluation of bactericidal activity against Legionella of chemical disinfectants for aqueous systems - Test method and requirements (phase 2, step 1)

Antiseptiques et désinfectants chimiques - Essai quantitatif de suspension pour l'évaluation de l'activité bactéricide contre des légionelles des désinfectants chimiques pour les systèmes aqueux - Méthode d'essai et prescriptions (phase 2, étape 1)

Chemische Desinfektionsmittel und Antiseptika - Quantitativer Suspensionsversuch zur Bestimmung der bakteriziden Wirkung gegen Legionella von chemischen Desinfektionsmitteln für wasserführende Systeme - Prüfverfahren und Anforderungen (Phase 2, Stufe 1) This European Standard was approved by CEN on 15 April 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13623:2010: ESIST EN 13623:2010

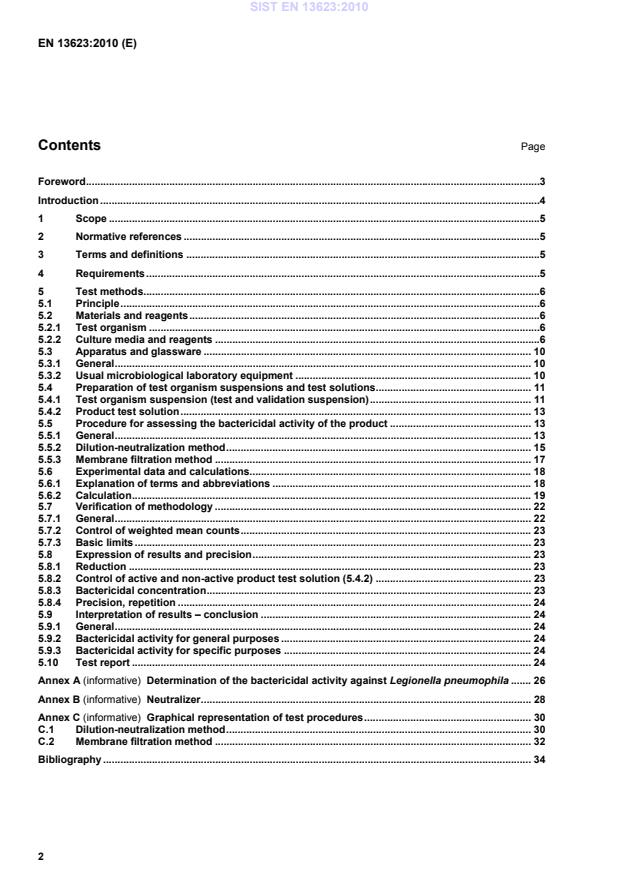

Determination of the bactericidal activity against Legionella pneumophila . 26Annex B (informative)

Neutralizer . 28Annex C (informative)

Graphical representation of test procedures . 30C.1 Dilution-neutralization method . 30C.2 Membrane filtration method . 32Bibliography . 34 SIST EN 13623:2010

Application of European Standards for chemical disinfectants and antiseptics 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 14885 and the following apply. 3.1 cooling water water used to remove heat from a process or environment 3.2 water for general purposes water used in premises other than water used as cooling water 4 Requirements The product shall demonstrate al least a four decimal log (lg) reduction, when diluted with buffered ferrous hard water (5.2.2.10) or hard water (5.2.2.7), and tested in accordance with Clause 5 under the obligatory test conditions (one selected test organism, at either 20 °C or 30 °C) within 60 min for rapid acting products or 15 h for slower acting products.

The bactericidal activity shall be evaluated using the following test organism: Legionella pneumophila.

Where indicated, additional specific bactericidal activity shall be determined applying other contact times and test organisms (in accordance with 5.2.1 and 5.5.1.1) in order to take into account intended specific use conditions.

5 Test methods 5.1 Principle

5.1.1

A sample of the product diluted with hard water (5.2.2.7 or 5.2.2.10) is added to a test suspension of bacteria in a solution of an interfering substance. The mixture is maintained at either (20 ± 1) °C or (30 ± 1) °C for 60 min ± 10 s or (15 ± 1) h (obligatory test conditions). At the end of the chosen contact time, an aliquot is taken, and the bactericidal and/or the bacteriostatic activity in this portion is immediately neutralized or suppressed by a validated method. The method of choice is dilution-neutralization. If a suitable neutralizer cannot be found membrane filtration is used. The numbers of surviving bacteria in each sample are determined and the reduction is calculated. 5.1.2 The test is performed using Legionella pneumophila as test organism (obligatory test conditions). 5.1.3 Additional and optional contact times are specified. Additional test organisms may be used. 5.2 Materials and reagents

5.2.1 Test organism The bactericidal activity shall be evaluated using the following strain as test organism1): Legionella pneumophila: serogroup 1, Philadelphia (NCTC 11192; ATCC 33152). If required for specific applications, additional test organisms may be used, e.g. Legionella pneumophila serogroup 1 Benidorm (NCTC 12006, ATCC 43108). The required incubation temperature for this test organism is (36 ± 1) °C or (37 ± 1) °C (5.3.2.3). The same temperature (either 36 °C or 37 °C) shall be used for all incubations performed during a test and its control and validation. If additional test organisms are used, they shall be incubated under optimum growth conditions (temperature, time, atmosphere, media) noted in the test report. If the additional test organisms selected do not correspond to the specified strains, their suitability for supplying the required inocula shall be verified. If these additional test organisms are not classified at a reference centre, their identification characteristics shall be stated. In addition, they shall be held by the testing laboratory or national culture collection under a reference for five years. 5.2.2 Culture media and reagents 5.2.2.1 General Unless specifically stated, all weights of chemical substances given in this standard refer to the anhydrous salts. Hydrated forms may be used as an alternative, but the weights required shall be adjusted to allow for consequent molecular weight differences. The reagents shall be of analytical grade and/or appropriate for microbiological purposes. They shall be free from substances that are toxic or inhibitory to the test organisms.

1) The NCTC and ATCC numbers are the collection numbers of strains supplied by the National Type Culture Collection (NCTC) and American Type Culture Collection (ATCC). This information is given for the convenience of users of this standard and does not constitute an endorsement by CEN of the product named. SIST EN 13623:2010

NOTE 2 For each culture medium and reagent, a limitation for use should be fixed.

5.2.2.2 Water The water shall be freshly glass-distilled water and not demineralized water. If distilled water of adequate quality is not available, water for injections (bibliographic reference [1]) can be used. Sterilize in the autoclave (5.3.2.1, a)). Sterilization is not necessary if the water is used e.g. for preparation of culture media and subsequently sterilized. NOTE See 5.2.2.10 for the procedure to prepare buffered ferrous hard water. 5.2.2.3 Buffered Charcoal Yeast Extract (BCYE) Agar BCYE agar, consisting of

yeast extract (bacteriological grade)

10,0 g;

agar

12,0 g;

activated charcoal

2,0 g;

alpha-ketoglutarate, monopotassium salt

1,0 g;

ACES buffer (N-2-acetamido-2-aminoethanesulfonic acid)

10,0 g;

potassium hydroxide (KOH) (pellets)

2,8 g;

L-cysteine hydrochloride monohydrate

0,4 g;

iron(III) pyrophosphate [Fe4(P207)3]

0,25 g;

distilled water

to 1 000,0 ml. Preparation a) Cysteine and iron solutions Prepare fresh solutions of L-cysteine hydrochloride and iron(III) pyrophosphate by adding 0,4 g and 0,25 g respectively to 10-ml-volumes of water (5.2.2.2). Sterilize each solution by membrane filtration (5.3.2.7).

Store in clean sterile containers at (20

± 3) °C for not more than three months. b) ACES buffer Add the ACES granules to 500 ml of water (5.2.2.2) and dissolve by standing in a water bath at 45 °C to 50 °C.

To a separate 480 ml of water (5.2.2.2), add all the potassium hydroxide pellets and dissolve with gentle shaking.

To prepare the ACES buffer, mix the two solutions. NOTE 1 ACES buffer can cause denaturation of the yeast extract if the following sequence is not followed. SIST EN 13623:2010

Allow excess moisture on the plates to dry and store at (4 ± 2) °C in airtight containers in the dark for up to four weeks. Prolonged heating during sterilisation or heating at too high a temperature shall be avoided, as it can affect the nutritional qualities of BCYE medium. Batch-to-batch variation of the ingredients of the medium (particularly α-ketoglurarate) can also affect its performance. Therefore it is essential to check the quality of each newly prepared batch of media for its ability to support the growth of the test organism within three days of incubation using the validation suspension NV (5.4.1.5). NOTE 2 The ability of the media to support the growth of Legionella should be assessed quantitatively using either known quantities of the obligatory Legionella strain or by direct comparison to previous batches. Commercially supplied media may be used without testing if it has been performance tested in a laboratory accredited to EN ISO/IEC 17025:2005 for that purpose. 5.2.2.4 BCYE Broth Prepared by the same method as BCYE agar (5.2.2.3), but omitting the addition of the agar. 5.2.2.5 Neutralizer The neutralizer shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and 5.5.2. It shall be sterile. NOTE Information on neutralizers that have been found to be suitable for some categories of products is given in Annex B. 5.2.2.6 Rinsing liquid (for membrane filtration) The rinsing liquid shall be validated for the product being tested in accordance with 5.5.1.2, 5.5.1.3 and 5.5.3. It shall be sterile, compatible with the filter membrane and capable of filtration through the filter membrane under the test conditions described in 5.5.3. NOTE Information on rinsing liquids that have been found to be suitable for some categories of products is given in Annex B. 5.2.2.7 Hard water for general purposes (HWGP) For the preparation of 1 l of hard water, the procedure is as follows: a) prepare solution A: dissolve 19,84 g magnesium chloride (MgCl2) and 46,24 g calcium chloride (CaCl2) in water (5.2.2.2) and dilute to 1 000 ml. Sterilize by membrane filtration (5.3.2.7) or in the autoclave (5.3.2.1, a)). Autoclaving – if used – may cause a loss of liquid. In this case make up to 1 000 ml with water (5.2.2.2) under aseptic conditions. Store the solution in the refrigerator (5.3.2.8) for no longer than one month; SIST EN 13623:2010

The hard water shall be freshly prepared under aseptic conditions and used within 12 h. NOTE 1 When preparing the product test solutions (5.4.2), the addition of the product to the hard water produces a different final water hardness in each test tube. In any case the final hardness is lower than 300 mg/l of calcium carbonate (CaCO3) in the test tube. NOTE 2 This hard water represents typical conditions of non cooling water. 5.2.2.8 Interfering substance (yeast extract) yeast extract

0,5 g; water

to 1 000,0 ml. Sterilize in the autoclave (5.3.2.1, a)). Final concentration of the yeast extract in the test is 0,000 5 %. 5.2.2.9 Page’s Saline Saline solution, consisting of: sodium chloride (NaCl)

0,120 g; magnesium sulphate (MgSO4 x 7H20)

0,004 g; calcium chloride (CaCl2 x 2H20)

0,004 g; disodium hydrogen phosphate (Na2HPO4) 0,142 g; potassium dihydrogenphosphate (KH2PO4) 0,136 g; water (5.2.2.2)

to 1 000,0 ml. Sterilize in the autoclave (5.3.2.1, a)). NOTE To aid accurate preparation, it is recommended that a 10 l volume of Page’s Saline is prepared and dispensed in smaller volumes as required for autoclaving. Alternatively the salt solutions may be made up individually in concentrated form for dilution when the product is required. 5.2.2.10 Buffered ferrous hard water for treatment of cooling water (BFHW) For the preparation of 1 l of BFHW, the procedure is as follows: a) prepare solution A: dissolve 19,84 g magnesium chloride (MgCl2) and 46,24 g calcium chloride (CaCl2) in water (5.2.2.2) and dilute to 1 000 ml. Sterilize by membrane filtration (5.3.2.7) or in the autoclave (5.3.2.1, a)). Autoclaving – if used – may cause a loss of liquid. In this case make up to 1 000 ml with SIST EN 13623:2010

0,2 M boric acid (13,6 g of Boric acid made up to 1 000 ml with distilled water), 30 ml of 0,05 M borax (19,07 g of Borax made up to 1 000 ml with distilled water) and 6,0 ml (5.3.2.9) of solution A, then 8,0 ml of solution B. Finally add 1,0 ml ferric sulphate solution (3,0 x 10-3 mol/l). Mix and dilute to 1 000 ml with water (5.2.2.2). The pH of the hard water shall be 8,0 ± 0,2, when measured at (20 ± 1) °C (5.3.2.4). If necessary, adjust the pH by using a solution of approximately 40 g/l (about 1 mol/l) of sodium hydroxide (NaOH) or approximately 36,5 g/l (about 1 mol/l) of hydrochloric acid (HCl). Sterilize by membrane filtration (5.3.2.7). The hard water shall be freshly prepared under aseptic conditions and used within 12 h. NOTE 1 When preparing the product test solutions (5.4.2), the addition of the product to the hard water produces a different final water hardness in each test tube. In any case the final hardness is lower than 300 mg/l of calcium carbonate (CaCO3) in the test tube. NOTE 2 This buffered ferrous hard water represents typical conditions of cooling water. 5.3 Apparatus and glassware 5.3.1 General Sterilize all glassware and parts of the apparatus that will come into contact with the culture media and reagents or the sample, except those that are supplied sterile, by one of the following methods: a) By moist heat, in the autoclave (5.3.2.1, a)); b) By dry heat, in the hot air oven (5.3.2.1, b)). 5.3.2 Usual microbiological laboratory equipment2)

In particular, the following: 5.3.2.1 Apparatus for sterilization a) for moist heat sterilization, an autoclave capable of being maintained at (12130+) °C for a minimum

holding time of 15 min;

b) for dry heat sterilization, a hot air oven capable of being maintained at (18050+) °C for a minimum holding time of 30 min, at (170 50+) °C for a minimum holding time of 1 h or at (16050+) °C for a minimum holding time of 2 h.

2) Disposable equipment is an acceptable alternative to reusable glassware. SIST EN 13623:2010

5.3.2.3 Incubator, capable of being controlled at (36 ± 1) °C or (37 ± 1) °C. Plates will need to be incubated in sealed bags or containers to prevent drying out of the agar. 5.3.2.4 pH-meter, having an inaccuracy of calibration of no more than ± 0,1 pH units at (20 ± 1) °C. NOTE A puncture electrode or a flat membrane electrode should be used for measuring the pH of the agar media (5.2.2.3). 5.3.2.5 Stopwatch 5.3.2.6 Electromechanical Agitator (e.g. Vortex® mixer)3)

5.3.2.7 Membrane filtration apparatus, constructed of a material compatible with the substances to be filtered. The apparatus shall have a filter holder of at least 50 ml volume. It shall be suitable for use with filters of diameter 47 mm to 50 mm and 0,45 µm pore size for sterilization of solutions and suspensions and if the membrane filtration is used (5.5.3).

The vacuum source used shall give an even filtration flow rate. In order to obtain a uniform distribution of the micro-organisms over the membrane and to prevent overlong filtration, the device shall be set so as to obtain the filtration of 100 ml of rinsing liquid in 20 s to 40 s. 5.3.2.8 Refrigerator, capable of being controlled at 2 °C to 8 °C. 5.3.2.9 Graduated pipettes, of nominal capacities 10 ml, 1 ml and 0,1 ml, or calibrated automatic pipettes.

5.3.2.10 Petri dishes (plates), of size 90 mm to 100 mm.

5.3.2.11 Centrifuge (2 000 gN).

5.3.2.12 Volumetric flasks. 5.4 Preparation of test organism suspensions and test solutions 5.4.1 Test organism suspension (test and validation suspension) 5.4.1.1 General Two different suspensions shall be prepared: the "test suspension" to perform the test and the "validation suspension" to perform the controls and method validation. 5.4.1.2 Preservation and stock cultures of test organism The test organisms and their stock cultures shall be kept and reconstituted in accordance with the supplier's instructions.

3) Vortex® is an example of a suitable product available commercially. This information is given for the convenience of users of this standard and does not constitute an endorsement by CEN of this product. SIST EN 13623:2010

b) Adjust the number of cells in the suspension to 1,5 x 108 cfu/ml4) to 5 x 108 cfu/ml using Page’s saline, (5.2.2.9), estimating the number of cfu by any suitable means. Maintain this test suspension in the water bath at either 20 °C for products intended for non cooling water

applications or 30 °C for cooling water products

(5.5.1.1, a)) and use within 2 h. NOTE

The use of spectrophotometer for adjusting the number of cells is highly recommended (about 620 nm wavelength - cuvette 10 mm path length). Each laboratory should therefore produce calibration data for each test organism knowing that suitable values of optical density are found between 0,150 and 0,400. A colorimeter is a suitable alternative. c) For counting, prepare 10-6 and 10-7 dilutions of the test suspension using Page’s saline (5.2.2.9). Mix (5.3.2.6). Take a sample of 1,0 ml of each dilution in duplicate and inoculate using the spread plate technique. Spread each 1,0 ml sample – divided into portions of approximately equal size (max. 0,2 ml) – on an appropriate number of plates containing BCYE (5.2.2.3). For incubation and counting see 5.4.1.6. 5.4.1.5 Validation suspension ("NV") a) To prepare the validation suspension, dilute the test suspension (5.4.1.4) with Page’s saline (5.2.2.9) to obtain 3,0 x 10² cfu/ml to 1,6 x 10³ cfu/ml (about one fourth (1+3) of the 10-5 dilution). b) For counting prepare a 10-1 dilution with Page’s saline (5.2.2.9). Mix (5.3.2.6). Take a sample of 1,0 ml in duplicate and inoculate using the spread plate technique (5.4.1.4, c)). For incubation and counting see 5.4.1.6. 5.4.1.6 Incubation and counting of the test and validation suspensions a) Incubate (5.3.2.3) the plates for seven days. Discard any plates that are not countable for any reason. Count the plates and determine the number of cfu.

4) cfu/ml:

colony forming unit(s) per millilitre. SIST EN 13623:2010

c) Calculate the numbers of cfu/ml in the test suspension N and in the validation suspension NV using the methods given in 5.6.2.3 and 5.6.2.5. Verify according to 5.7. 5.4.2 Product test solution The concentration of a product test solution shall be ten times the desired test concentration because it is diluted to 10 % during the test and the method validation (5.5.2 or 5.5.3). Product test solutions shall be prepared in hard water at minimum three different concentrations to include one concentration in the active range and one concentration in the non-active range (5.8.2). The type of hard water is selected according to the intended use: BFHW (5.2.2.10) for products intended to be used for treatment of cooling water and HWGP (5.2.2.7) for products intended to be used for treatment of water for general purposes. The product as received may be used as one of the product test solutions, in this case the highest tested concentration is 10 %. For solid products, dissolve the product as received by weighing at least 1,0 g ± 10 mg of the product in a volumetric flask and filling up with hard water (5.2.2.7 or 5.2.2.10). Subsequent dilutions (lower concentrations) shall be prepared in volumetric flasks (5.3.2.12) on a volume/volume basis in hard water (5.2.2.7 or 5.2.2.10). For liquid products, dilutions of the product shall be prepared with hard water on a volume/volume basis using volumetric flasks (5.3.2.12). The product test solutions shall be prepared freshly and used in the test within 2 h. They shall give a physically homogeneous preparation that is stable during the whole procedure. If during the procedure a visible inhomogeneity appears due to the formation of a precipitate or flocculant (for example, through the addition of the interfering substance), it shall be recorded in the test report. NOTE Counting micro-organisms embedded in a precipitate or flocculant is difficult and unreliable. The concentration of the product stated in the test report shall be the desired test concentration. Record the test concentration in terms of mass per volume or volume per volume and details of the product sample as received. 5.5 Procedure for assessing the bactericidal activity of the product 5.5.1 General

5.5.1.1 Experimental conditions (obligatory and additional) Besides the obligatory, contact time and test organisms, additional experimental conditions (including test organisms) may be selected according to the practical use considered for the product (Clause 4), as follows: a) temperature θ

(in degrees Celsius (°C)): 1) the obligatory temperature to be tested for Cooling Water (3.1) is θ = 30 °C;

2) the obligatory temperature to be tested for Water for General Purposes (3.2) is θ = 20 °C;

3) the allowed deviation for the chosen temperature is ± 1 °C; NOTE No additional temperatures are considered relevant to this test. b) contact time t (in minutes (min)): SIST EN 13623:2010

t = 60 min; 2) for slow acting products the obligatory contact time is 15 h; 3) the additional contact times may be chosen from 2 h, 6 h, 15 h, 40 h, 48 h; 4) the allowed deviation for the chosen contact time of 60 min or less is ± 10 s, for contact times of 6 h or less it is ± 5 min and ± 1 h for all other contact times;

c) interfering substance: the obligatory interfering substance to be tested is 0,05 % yeast extract solution; d) test organism: 1) the obligatory test organism is Legionella pneumophila (5.2.1); 2) additional test organisms (other strains of Legionella pneumophila or species of Legionella) may be used. 5.5.1.2

Choice of test method The method of choice is the dilution-neutralization method. To determine a suitable neutralizer carry out the validation of the dilution neutralization method (5.5.2.3, 5.5.2.4 and 5.5.2.5 in connection with 5.5.2.6) using a neutralizer, chosen according to laboratory experience and published data. If this neutralizer is not valid, repeat the validation test using an alternative neutralizer taking into account the information given in Annex B. If both neutralizers are found to be invalid, the membrane filtration method (5.5.3) may be used. 5.5.1.3 General instructions for validation and control procedures The neutralization and/or removal of the bactericidal or bacteriostatic activity of the product shall be controlled and validated – only for the highest product test concentration – for each of the used test organisms and for each experimental condition (contact time). These procedures (experimental condition control, neutralizer or filtration control and method validation) shall be performed at the same time with the test and with the same neutralizer – or rinsing liquid – used in the test. The same hard water (5.2.2.7 or 5.2.2.10) used in the test (5.5.2.2) shall be used in the validation and controls. The same agar (5.2.2.3) used in the test (5.5.2.2) shall be used in the validation and controls. 5.5.1.4 Equilibration of temperature Prior to testing, equilibrate all reagents (product test solutions (5.4.2), test suspension (5.4.1.4), validation suspension (5.4.1.5) hard water (5.2.2.7 or 5.2.2.10) and interfering substance (5.2.2.8) to the test temperature of either 20 °C for products intended for non cooling water

applications or 30 °C for cooling water products (5.5.1.1, a)) using the water bath (5.3.2.2) controlled at (20 ± 1) °C or (30 ± 1) °C.

Check that the temperature of the reagents is stabilized at the chosen temperature. The neutralizer (5.2.2.5) or the rinsing liquid (5.2.2.6) and water (5.2.2.2) shall be equilibrated at a temperature of (20 ± 1) °C. 5.5.1.5 Precautions for manipulation of test organisms Do not touch the upper part of the test tube sides when adding the test or the validation suspensions (5.4.1). SIST EN 13623:2010

Dilution-neutralization method5) 5.5.2.1 General The test and the control and validation procedures (5.5.2.2 to 5.5.2.5) shall be carried out at the same time. 5.5.2.2 Test "Na" – determination of bactericidal concentrations The procedure for determining bactericidal concentrations is as follows: a) Pipette 0,1 ml of the interfering substance (5.2.2.8) and 7,9 ml BFHW (5.2.2.10) or HWGP (5.2.2.7) into a tube. Add 1,0 ml of the test suspension (5.4.1.4). Start the stopwatch (5.3.2.5) immediately, mix (5.3.2.6) and place the tube in a water bath controlled at either 20 °C for products intended for non cooling water

applications or 30 °C for cooling water products

(5.5.1.1, a)) for 2 min ± 10 s. At the end of this time, add 1,0 ml of one of the product test solutions (5.4.2). Restart the stopwatch at the beginning of the addition. Mix (5.3.2.6) and place the tube in a water bath controlled at either 20 °C for products intended for non cooling water

applications or 30 °C for cooling water products for the chosen contact time t (5.5.1.1, b)). Just before the end of t, mix (5.3.2.6) again. b) At the end of t, take a 1,0 ml sample of the test mixture Na and transfer into a tube containing 8,0 ml neutralizer (5.2.2.5) and 1,0 ml water (5.2.2.2). Mix (5.3.2.6) and place in a water bath controlled at (20 ±1) °C. After a neutralization time of 5 min ± 10 s, immediately take four samples of 1,0 ml neutralized test mixture Na (containing neutralizer, product test solution, interfering substance and test suspension). Inoculate two of the 1,0 ml samples using the spread plate technique divided into portions of approximately equal size (max. 0,2 ml) on an appropriate number of BCYE plates (5.2.2.3). Dilute the two remaining 1,0 ml samples with 9,0 ml of Page’s saline (5.2.2.9) and inoculate 1,0 ml from each onto an appropriate number of BCYE plates (5.2.2.3). For incubation and counting, see 5.5.2.6. c) Perform the procedures a) and b) using the other product test solutions at the same time. d) Perform the procedures a) to c) applying the other obligatory and – if appropriate – other additional experimental conditions (5.5.1.1). 5.5.2.3 Experimental conditions control A – validation of the selected experimental conditions and/or verification of the absence of any lethal effect in the test conditions To validate the selected experimental conditions and/or verify the absence of any lethal effect in the test conditions, the procedure is as follows: a) Pipette 0,1 ml of the interfering substance used in the test (5.5.2.2) into a tube. Add 1,0 ml of the validation suspension (5.4.1.5). Start the stopwatch immediately, mix (5.3.2.6) and place the tube in a water bath controlled at either 20 °C for products intended for non cooling water

applications or 30 °C for cooling water products.for 2 min ± 10 s. At the end of this time, add 8,9 ml of hard water (5.2.2.10 or 5.2.2.7). Restart the stopwatch at the beginning of the addition. Mix (5.3.2.6) and place the tube in a water bath controlled at either 20 °C for products intended for non cooling water applications or 30 °C for cooling water products.for t. Just before the end of t, mix (5.3.2.6) again. b) At the end of t, take a sample of 1,0 ml of this mixture A in duplicate and inoculate using the spread plate technique (5.5.2.2b)).

5) For a graphical representation of this method, see C.1. SIST EN 13623:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...