EN 13185:2001

(Main)Non-destructive testing - Leak testing - Tracer gas method

Non-destructive testing - Leak testing - Tracer gas method

This standard describes the techniques to be applied for the detection of a leak, using a tracer gas and a tracer gas specific leak detector.

Zerstörungsfreie Prüfung - Dichtheitsprüfung - Prüfgasverfahren

1 Anwendungsbereich

Diese Europäische Norm legt die Verfahren des Lecknachweises bei Benutzung eines Prüfgases und eines

prüfgasspezifischen Leckdetektors fest.

Essais non destructifs - Contrôle d'étanchéité - Méthode par gaz traceur

La présente norme européenne décrit les techniques à appliquer pour la détection d'une fuite à l'aide d'un gaz traceur et d'un détecteur de fuite spécifique au gaz traceur utilisé.

Neporušitveno preskušanje - Preskušanje tesnosti - Metoda slednega plina

General Information

- Status

- Withdrawn

- Publication Date

- 20-Mar-2001

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 138 - Non-destructive testing

- Drafting Committee

- CEN/TC 138/WG 6 - Leak testing

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Feb-2018

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Replaced By

EN ISO 20485:2018 - Non-destructive testing - Leak testing - Tracer gas method (ISO 20485:2017) - Effective Date

- 14-Feb-2018

- Refers

EN 1779:1999 - Non-destructive testing - Leak testing - Criteria for method and technique selection - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13192:2001 - Non destructive testing - Leak testing - Calibration of reference leaks for gases - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 10-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

EN 13185:2001 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing - Leak testing - Tracer gas method". This standard covers: This standard describes the techniques to be applied for the detection of a leak, using a tracer gas and a tracer gas specific leak detector.

This standard describes the techniques to be applied for the detection of a leak, using a tracer gas and a tracer gas specific leak detector.

EN 13185:2001 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13185:2001 has the following relationships with other standards: It is inter standard links to EN ISO 20485:2018, EN 1779:1999, EN ISO 20484:2017, EN 13192:2001, EN 13625:2001, EN ISO 9712:2022, EN 45502-2-3:2010, EN 16084:2011, EN 12799:2000, EN 13184:2001, EN ISO 14903:2017, EN ISO 15848-1:2015, EN 13185:2001/A1:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13185:2001 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13185:2001 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Neporušitveno preskušanje - Preskušanje tesnosti - Metoda slednega plinaZerstörungsfreie Prüfung - Dichtheitsprüfung - PrüfgasverfahrenEssais non destructifs - Contrôle d'étanchéité - Méthode par gaz traceurNon-destructive testing - Leak testing - Tracer gas method19.100Neporušitveno preskušanjeNon-destructive testingICS:Ta slovenski standard je istoveten z:EN 13185:2001SIST EN 13185:2002en01-junij-2002SIST EN 13185:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13185March 2001ICS 19.100English versionNon-destructive testing - Leak testing - Tracer gas methodEssais non destructifs - Contrôle d'étanchéité - Méthodepar gaz traceurZerstörungsfreie Prüfung - Dichtheitsprüfung -PrüfgasverfahrenThis European Standard was approved by CEN on 18 January 2001.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2001 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13185:2001 ESIST EN 13185:2002

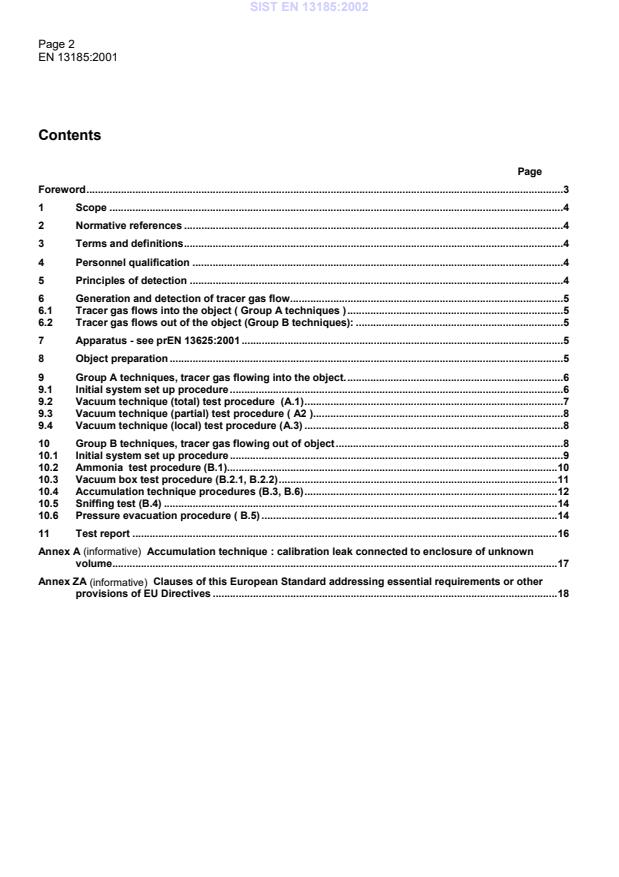

Page 2EN 13185:2001ContentsPageForeword.31Scope.42Normative references.43Terms and definitions.44Personnel qualification.45Principles of detection.46Generation and detection of tracer gas flow.56.1Tracer gas flows into the object ( Group A techniques ).56.2Tracer gas flows out of the object (Group B techniques):.57Apparatus - see prEN 13625:2001.58Object preparation.59Group A techniques, tracer gas flowing into the object.69.1Initial system set up procedure.69.2Vacuum technique (total) test procedure

(A.1).79.3Vacuum technique (partial) test procedure ( A2 ).89.4Vacuum technique (local) test procedure (A.3).810Group B techniques, tracer gas flowing out of object.810.1Initial system set up procedure.910.2Ammonia

test procedure (B.1).1010.3Vacuum box test procedure (B.2.1, B.2.2).1110.4Accumulation technique procedures (B.3, B.6).1210.5Sniffing test (B.4).1410.6Pressure evacuation procedure ( B.5).1411Test report.16Annex A (informative)

Accumulation technique : calibration leak connected to enclosure of unknownvolume.17Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or otherprovisions of EU Directives.18SIST EN 13185:2002

Page 3EN 13185:2001ForewordThis European Standard has been prepared by Technical Committee CEN/TC 138 "Non-destructive testing", thesecretariat of which is held by AFNOR.This European Standard shall be given the status of a national standard, either by publication of an identical text orby endorsement, at the latest by September 2001, and conflicting national standards shall be withdrawn at thelatest by September 2001.This European Standard has been prepared under a mandate given to CEN by the European Commission and theEuropean Free Trade Association, and supports essential requirements of EU Directive(s).For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this standard.Annex A is informative.According to the CEN/CENELEC Internal Regulations, the national standards organizations of the followingcountries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden,Switzerland and the United Kingdom.SIST EN 13185:2002

Page 4EN 13185:20011 ScopeThis standard describes the techniques to be applied for the detection of a leak, using a tracer gas and a tracergas specific leak detector.2 Normative referencesThis European Standard incorporates by dated or undated reference, provisions from other publications. Thesenormative references are cited at the appropriate places in the text and the publications are listed hereafter. Fordated references, subsequent amendments to or revisions of any of these publications apply to this EuropeanStandard only when incorporated in it by amendment or revision. For undated references the latest edition of thepublication referred to applies (including amendments).EN 473

Qualification and certification of NDT personnel - General principlesEN 1330 - 8

Non destructive testing – Terminology -Part 8 : Terms used in leak tightness testingEN 1779

Non destructive testing -Leak Testing – Criteria for method and technique selectionprEN 13192:2001 Non destructive testing -Leak test – Calibration of gaseous reference leaksprEN 13625:2001 Non destructive testing -Leak test - Guide to the selection of instrumentation for themeasurement of gas leakage.3 Terms and definitionsFor the purposes of this European Standard, the terms and definitions given in EN 1330-8 apply.4 Personnel qualificationIt is assumed that leak testing is performed by qualified and capable personnel. In order to provide thisqualification, it is recommended to certify the personnel in accordance with EN 473 or equivalent.NOTEFor pressure equipment see directive 97/23/EC (Annex I, paragraph 3.1.3) : "For pressure equipment in categoriesIII and IV, the personnel must be approved by a third party organization recognized by a Member State"5 Principles of detectionA partial pressure difference of tracer gas is created across the boundary of the object to be tested. The tracergas, having passed through the leak, is revealed by its physical or chemical properties.

Chemical detection isgenerally based on reactions that cause a local colour change (the object surface shall therefore be visible).Detection based on physical properties usually involves a sensor, for example: a mass spectrometer, tuned for the specific tracer gas used

(generally helium-4 ); an alkali ion diode, for halogen gas, and electron-capture equipment (i.e. for SF6 ); a Pirani gauge, for

tracer gas with thermal conductivity different from that of the ambient atmosphere; a photometer, with band-pass filter in the frequency range of the tracer gas absorption or emission.These types of detection generally give an electrical signal which varies with the tracer gas partial pressure.SIST EN 13185:2002

Page 5EN 13185:20016 Generation and detection of tracer gas flowTwo basic techniques are used - see EN 17796.1 Tracer gas flows into the object ( Group A techniques )A pressure difference across the wall is obtained either by evacuation of the object, e.g. through a connectionor by placing it in a pressurized chamber. Usually the test object is evacuated.

Tracer gas is then applied tothe external surface using a probe jet or by enclosing the object (totally or partially ) in a hood or chamber filledwith the tracer gas. Tracer gas leakage into the test object is detected by a sensor within or connected to theinternal volume.6.2 Tracer gas flows out of the object (Group B techniques):The object is filled with a tracer gas. A pressure difference across the wall is obtained either by pressurizationof the object, e.g. through a connection or by placing it in a vacuum chamber. The tracer gas is collected onthe outside surface by a sampling probe or by

accumulation into a hood or chamber. Tracer gas can also bedetected by chemical reactions.A special technique (bombing ) may also be used. This involves pressurization of a sealed object to forcetracer gas into its internal cavities, if a leak exists. The object is then placed in a vacuum chamber andescaping tracer gas is detected (usually this procedure is used only with helium- 4).This method is applicable to specimens with small free internal volumes (in the order of a few cubiccentimetres).7 Apparatus - see prEN 13625:2001The test apparatus can include part or all of the following:7.1Leak detector or chemical reagents able to detect the selected tracer

gas7.2Calibration leaks, calibrated for discharge into vacuum and/or against atmospheric pressure ; refer toprEN 13192:2001.7.3Pressure and

temperature gauges7.4Tracer gas or certified gas mixture.7.5Auxiliary vacuum systems7.6Hood, vacuum or pressurizing chamber, jet or sampling probe7.7Purging dry gas, liquid nitrogen (for cold trap), if necessary.7.8Equipment for tracer gas treatment-recovery7.9Equipment for test area ventilation7.10Data recording equipment8 Object preparationThe object to be tested shall be adequately cleaned, degreased and dried. Openings and apertures which arenot involved in the test must be closed with test seals, e.g. plugs, welding, suitable material

and gaskets.Whenever possible, testing should be carried before plating, painting or the application of ultrasonic couplant.SIST EN 13185:2002

Page 6EN 13185:2001If the object has to be evacuated, the presence of porous or plastic materials should be avoided. This helps toavoid spurious indications

(virtual leaks), and shortens the clean up time.The connections between the object, the pumping system, the leak detector or (LD) and the calibration leaksused shall be suitable and checked for tightness.9 Group A techniques, tracer gas flowing into the object.These techniques are applicable to an object that can be evacuated or withstand an external test pressure.The tracer gas is applied on the outer surface of the object and the LD is connected to the internal volume. Ifthe LD is of Mass Spectrometer type (MLSD), the pumping system of the MSLD itself can be used to evacuatedirectly small items under test.Larger objects need an auxiliary pumping system. In this case, the loss of sensitivity shall be considered, asonly part of the tracer gas will enter the LD.Three techniques may be used - refer to EN 1779:- Vacuum technique (Total) – A.1The object, placed in an enclosure (a bag or a chamber), is evacuated and connected to the detector. Theenclosure is then filled with the tracer gas or a gas mixture containing the tracer gas. This technique allows theevaluation of the leakage rate but does not permit precise location of the leaks.When the purpose of the leak testing is the determination of the acceptability of the test object against aspecified leakage rate, only the integral technique shall be used. In this case, the tracer gas concentration,pressure and temperature shall be measured and the homogeneity of the gas mixture shall be ensured.Further the enclosure shall be gas-tight and, preferably, rigid.- Vacuum technique (Partial) – A.2The object to be tested is evacuated and connected to the detector. Suspect areas are then covered by asuitable gas-tight enclosure filled with tracer gas.- Vacuum technique (Local) – A.3The object to be tested is evacuated and connected to the detector. Suspect areas on the external surface ofthe object are sprayed with tracer gas. Leaks can be localised using this technique but it is not possible tomeasure the total leakage rate.9.1 Initial system set up procedure9.1.1The LD shall be adjusted in accordance with manufacturer's instructions, using a calibration leak (ifrequired the leak shall be "standard"). If a MSLD is used, a leak for discharge to vacuum has to be connecteddirectly to the inlet of the LD, or the built-in leak for the calibration is to be used.9.1.2The object is connected to the LD and then evacuated to a suitable pressure, either by LD pumping systemor by an auxiliary pumping system. This is determined by the maximum inlet pressure of the LD.9.1.3The initial background signal shall be measured.9.1.4The maximum signal for the specified calibration leak connected to the object shall be recorded to verifythe system sensitivity. The ratio of the pumping speed of the LD to the pumping speed of the auxiliary system shallnot be altered.9.1.5For large objects or complex systems, the "response time" of the system shall be measured by means of asuitable calibration leak the rate of leakage of which is as near as possible to the specified maximum allowableleakage. Unless otherwise specified, this leak shall be connected to the object under test, via an isolation valve, inthe most unfavourable position, to determine the response time.An auxiliary line should be provided, if possible, to evacuate the volume between the leak outlet and theisolation valve. In any case, care should be taken to avoid the inlet of the accumulated gas in the system. Theresponse time is the time from opening of the valve until the 90% of the maximum stable signal is reached.SIST EN 13185:2002

Page 7EN 13185:2001The signal amplitude and the response time shall be taken as reference for the test. The system layout orpumping speed shall not be changed.9.1.6The isolation valve to the leak, used for time response determination, is then closed and the clean up timeis measured.9.1.7To evaluate large leaks that saturate the LD signal, the sensitivity of test can be reduced. This reductioncan be achieved either by lowering the fraction of tracer gas in the mixture or increasing the pumping speed of theauxiliary system. The factors established in paragraphs 9.1.4 to 9.1.6 shall be determined for the new conditions.9.2 Vacuum technique (total) test procedure

(A.1)After the initial set-up has been performed the following step shall be taken:9.2.1The object is placed into the auxiliary enclosure (bag or chamber) and it is then evacuated. If the enclosureis a flexible bag (usually plastic), it shall be sufficiently large to enclose the perimeter of the object.9.2.2A preliminary evacuation of the enclosure may be useful. If the enclosure is a flexible bag, it should laydown well against the object walls (without tearing). After it has been evacuated the tracer gas is admitted. If theenclosure has not been evacuated, it should be adequately purged using dry tracer gas, or a gas mixturecontaining tracer gas, to ensure that the tracer gas concentration is homogeneous and as intended. The personperforming the test shall note the volume fraction of the tracer gas in the mixture, so that the correspondingcorrection in subsequent measurements can be made. If a flexible bag is used, it shall be filled with gas until it is nolonger touching the object walls.9.2.3If the enclosure is rigid, pressures shall be recorded before and after tracer gas introduction. It is possibleto calculate the volume fraction of the tracer gas, applying the Boyle-Mariotte law to the recorded pressures.9.2.4The duration of the tracer gas admission to the auxiliary enclosure shall be at least twice the response timeor 10 min, whichever is the greater. When the response time exceeds 20 min, different specifications for theadmission time may be given.9.2.5After the appearance of any signal, it is necessary to wait until either: the maximum signal level is obtained: the overall leakage

rate can then be calculated by comparison with thesignal generated by the known leak; or the signal, corresponding to the maximum allowable leakage rate, is obtained: in this case the test can beinterrupted for decisions.9.2.6The total leakage rate of the object, in molecular flow conditions, is calculated using the formula givenbelow:pcRSRSqq3251011CLCLLLCLG(1)whereqG is the total leakage rate, in pascals cubic metres per second;qCLis the leakage rate of the calibration leak in pascals

cubic metres per second ( pure tracer gas);SL is the leak signal;SCLis the signal generated by the calibration leakRL,

RCLare the background signal associated with signal SL and SCL, respectively;cis the volume fraction of the tracer gas in the gas mixture;p is the total pressure in the

auxiliary enclosure, in pascals.SIST EN 13185:2002

Page 8EN 13185:2001When the test is carried out with a gas mixture, the volume fraction of tracer gas shall be known (certified ifrequired) using approved procedures for mixture preparation.If high accuracy is required, the system calibration shall be performed using a calibration leak with the test gasmixture.9.3 Vacuum technique (partial) test procedure ( A2 )When only a part of an object is to be tested (e.g. welds, thermocouple wells, personnel access covers,electrical-or mechanical feedthroughs), the auxiliary enclosure may be restricted to that area only. The durationof tracer gas admission shall be indicated in the specification, taking into account the position of the part undertest relative to the pumping system and the LD.After the initial set-up has been performed the following steps shall be taken:9.3.1Plastic bags or chambers are fitted to the areas to be tested using adhesive tape or suitable gaskets.These should prevent significant escape of tracer gas during the test.The object is then evacuated.9.3.2Proceed as in 9.2.2 to 9.2.5.9.4 Vacuum technique (local) test procedure (A.3)After the initial set-up has been performed the following steps shall be taken:9.4.1The effect on the result of the speed of probing the surface of the test object with the spray gun shall beestablished by placing a conductance leak in the position of the calibration leak used in 9.1.4. The gas flow fromthe spray gun is adjusted and its tip is moved past the leak at the speed and distance specified for the test. Thesignal amplitude is recorded. If the signal is too small the scan rate should be reduced.9.4.2Tracer gas spraying should start at the top of the test object if the tracer gas is lighter than air. Sprayingshould start at the bottom if the tracer gas density is greater than air.

Scanning of the areas shall be performed asstated in the test specifications.9.4.3When a leak is detected, it may be necessary to evaluate its influence. The leak may have to betemporarily sealed to continue the test.9.4.4After a leak has been found and sealed, it is necessary to wait until initial conditions are restored in the LD(clean up time). If leak location only is required, the procedure may state the signal level (% of the maximumsignal) at which is possible to continue the scan, in order to shorten the test time.9.4.5After all leaks have been found, it may be desirable to determine the total leakage of the object, using othersuitable techniques (integral). This step may be carried out initially, to save time if no leaks exist. However, if theobject contains material permeable to the tracer gas, the sorbed gas may lower the sensitivity of the subsequenttest.10 Group B techniques, tracer gas flowing out of objectThese techniques are generally applicable to objects which cannot be evacuated or to open objects. A (partial)pressure difference of tracer gas is created across the object wall. Tracer gas is admitted to the internalvolume of the object and it is collected and detected in its external side. If the object to be tested is open, thegas is sprayed or applied with a bag in one side and it is collected in the other side by a vacuum box.SIST EN 13185:2002

Page 9EN 13185:2001Seven techniques may be used. They are briefly described here:- Chemical detection with ammonia – B.1The object is filled with anhydrous ammonia or an ammonia-nitrogen mixture to the specified overpressure. Acolour-change developer (generally a mixture containing a pH indicator, e.g. bromophenol blue), applied to theoutside surface, will reveal and locate leakages.- Vacuum box, using internal tracer gas – B.2.1Large objects, containing a gas or a gas mixture suitable to be used as tracer gas, are tested by a vacuum boxevacuated and connected to a LD, applied in the outer side.- Vacuum box applying the tracer gas on opposite side – B.2.2Open objects can be tested using partial enclosures, capable of being evacuated, which are tightly applied tothe wall (vacuum box, suction cup). Tracer gas is supplied on the opposite surface of the wall by a spray gun(probe jet) or by cups, filled by the tracer gas.- Pressure technique by accumulation – B.3The object, pressurized with the tracer gas, is placed in an enclosure. After a specified time, the accumulatedtracer gas is measured using a LD connected to the enclosure.

The leakage size can then be estimated (ordetermined if the enclosure volume and pressure are known).- Sniffing test – B.4The object is pressurized with the tracer gas (or gas mixture). Leak searching is performed on the atmosphericside of the object wall, using a sampling probe connected to a LD. This technique detects leakage and locatesthe leaks (direct probing).- Pressurisation-evacuation test – B.5The sealed object is subjected to a high pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...