EN 15092:2008

(Main)Building valves - Inline hot water supply tempering valves - Tests and requirements

Building valves - Inline hot water supply tempering valves - Tests and requirements

This European Standard specifies dimensions, materials and performance requirements (including methods of test) for in line hot water supply tempering valves for sanitary hot water systems, of nominal sizes from DN 15 to DN 50. Tempering valves reduce the temperature of sanitary hot water for distribution throughout the hot water system. The conditions of use are specified in Table 1.

The valves are intended to be used with storage water heaters to provide tempered hot water to the terminal fitting. They are not intended to control the temperature at the point of use.

Tempering valves control the distribution temperature from a water heater to a preset value or an adjustable range, both between 45 °C and 65 °C.

Table 1 - Conditions of use

Gebäudearmaturen - Thermostatische Mischer für Warmwasserbereiter - Prüfungen und Anforderungen

Diese Europäische Norm legt die Anforderungen an die Maße, Werkstoffe und Funktionsfähigkeit (einschließlich der Prüfverfahren) von thermostatischen Mischern für das Warmwasserverteilsystem für Sanitär-Warmwasserversorgungsanlagen der Nennweiten von DN 15 bis DN 50 fest. Thermostatische Mischer reduzieren die Temperatur von Warmwasser für den Sanitärgebrauch für die Verteilung im gesamten Warmwassersystem. Die Einsatzbedingungen sind in Tabelle 1 festgelegt.

Die Mischer sind für die Verwendung in Kombination mit Speicherwassererwärmern bestimmt, um den Endan¬schluss mit temperiertem Warmwasser zu versorgen. Sie sind nicht zur Regelung der Auslauftemperatur an der Entnahmestelle bestimmt.

Die thermostatischen Mischer regeln die Verteilungstemperatur ab dem Wassererwärmer auf einen voreingestellten Wert oder einen einstellbaren Bereich, jeweils zwischen 45 °C und 65 °C.

Robinetterie des bâtiments - Vannes mélangeuses en ligne d'alimentation en eau chaude - Essais et exigences

La présente Norme européenne spécifie les dimensions, les matériaux et les exigences de performance (y compris les méthodes d’essai) pour les vannes mélangeuses en ligne d’alimentation en eau chaude, pour systèmes d’eau chaude sanitaire, de dimensions nominales allant de DN 15 à DN 50. Les vannes mélangeuses réduisent la température de l’eau chaude sanitaire avant sa distribution dans le système d’eau chaude. Les conditions d’utilisation sont spécifiées dans le Tableau 1.

Les vannes sont destinées à une utilisation avec des chauffe-eau à accumulation, afin de fournir de l’eau chaude tempérée au branchement terminal. Elles ne sont pas destinées à contrôler la température au point d’utilisation.

Les vannes mélangeuses contrôlent la température de distribution à partir d’un chauffe-eau à une valeur prédéfinie ou dans une plage réglable, cette valeur ou cette plage étant situées entre 45 °C et 65 °C.

Ventili v stavbah - Mešalni termostatski ventili za oskrbo z vročo vodo - Preskusi in zahteve

General Information

- Status

- Published

- Publication Date

- 24-Jun-2008

- Technical Committee

- CEN/TC 164 - Water supply

- Current Stage

- 9020 - Submission to 2 Year Review Enquiry - Review Enquiry

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13959:2004 - Anti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D - Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15092:2008 - published by CEN - defines tests and requirements for inline hot water supply tempering valves used in sanitary hot water systems. It covers valves of nominal sizes DN 15 to DN 50 designed to reduce and control distribution temperature from storage water heaters (not intended for point-of-use temperature control). Tempering valves covered by this standard provide fixed or adjustable distribution temperatures in the range 45 °C to 65 °C, and may include a temporary temperature override for thermal disinfection.

Key topics and technical requirements

- Scope and application: Inline tempering valves between storage heaters and distribution system; nominal sizes DN 15–DN 50.

- Conditions of use (summary of Table 1):

- Dynamic pressure: minimum 0.02 MPa; recommended operation 0.1–0.5 MPa (1–5 bar).

- Static pressure: max 1 MPa (10 bar).

- Hot inlet temperature: up to 90 °C (recommended 60–80 °C).

- Cold inlet temperature: ≤ 25 °C.

- Outlet (distribution) temperature: 45–65 °C.

- Materials and corrosion: Requirements on material selection and surface finishes; copper alloys listed as examples. Where dezincification is a risk, products must meet EN ISO 6509 limits (dezincification depth < 200 µm where applicable).

- Design and connections: Dimensional requirements and permissible end-connections (per EN 1254 series and ISO thread standards). No direct heat joints (capillary) on valve body.

- Temperature settings: Defines Type 1 (pre-set) and Type 2 (adjustable) valves, lockable or tool-secured adjustments, and rules for override functions.

- Mechanical tests: Body strength (pressure test e.g., 2.5 MPa), bending moment and torque tests for stops and controls.

- Performance tests: Verification of set temperatures, minimum flow rate determination, temperature stability under changing flow rate, inlet pressure and temperature variations, thermal shutoff on cold water failure, and thermostat endurance.

- Acoustics and durability: Noise tests per EN ISO 3822 series and endurance testing procedures.

- Marking, classification and instructions: Required labeling of temperature, flow, identification and user instructions.

Applications and practical use

- Ensures safe, consistent hot water tempering for multi-point sanitary distribution in residential, commercial and institutional buildings.

- Supports compliance for manufacturers designing tempering valves and for test laboratories certifying performance.

- Useful to building services engineers, specifiers, product managers and procurement teams seeking compliant tempering valves for hot water safety and legionella control strategies (via periodic thermal disinfection).

Who should use this standard

- Valve manufacturers and product designers

- Test laboratories and conformity assessment bodies

- Building services engineers, plumbing specifiers and consultants

- Regulators and authorities setting installation requirements for sanitary hot water systems

Related standards

- EN 1254 series (copper plumbing fittings), EN 1092-3 (flanges), EN 13959 (check valves), EN ISO 3822-1/3 (acoustic testing), EN ISO 6509 (dezincification), ISO 7-1 / EN ISO 228-1 (thread standards).

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15092:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building valves - Inline hot water supply tempering valves - Tests and requirements". This standard covers: This European Standard specifies dimensions, materials and performance requirements (including methods of test) for in line hot water supply tempering valves for sanitary hot water systems, of nominal sizes from DN 15 to DN 50. Tempering valves reduce the temperature of sanitary hot water for distribution throughout the hot water system. The conditions of use are specified in Table 1. The valves are intended to be used with storage water heaters to provide tempered hot water to the terminal fitting. They are not intended to control the temperature at the point of use. Tempering valves control the distribution temperature from a water heater to a preset value or an adjustable range, both between 45 °C and 65 °C. Table 1 - Conditions of use

This European Standard specifies dimensions, materials and performance requirements (including methods of test) for in line hot water supply tempering valves for sanitary hot water systems, of nominal sizes from DN 15 to DN 50. Tempering valves reduce the temperature of sanitary hot water for distribution throughout the hot water system. The conditions of use are specified in Table 1. The valves are intended to be used with storage water heaters to provide tempered hot water to the terminal fitting. They are not intended to control the temperature at the point of use. Tempering valves control the distribution temperature from a water heater to a preset value or an adjustable range, both between 45 °C and 65 °C. Table 1 - Conditions of use

EN 15092:2008 is classified under the following ICS (International Classification for Standards) categories: 91.140.60 - Water supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15092:2008 has the following relationships with other standards: It is inter standard links to EN ISO 228-1:2003, EN 1254-3:2021+A1:2025, EN ISO 3822-3:2018, EN 1254-4:2021, EN ISO 6509-1:2014, EN ISO 3822-1:1999, EN 12165:2024, EN 13959:2004, prEN 15116, EN 1092-3:2003, EN 1982:2024, EN 1254-1:2021, EN 1254-5:2021, EN 12164:2024, EN 1254-2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15092:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gebäudearmaturen - Thermostatische Mischer für Warmwasserbereiter - Anforderungen und PrüfungenRobinetterie des bâtiments - Vannes mélangeuses en ligne d'alimentation en eau chaude - Essais et exigencesBuilding valves - Inline hot water supply tempering valves - Tests and requirements91.140.60Sistemi za oskrbo z vodoWater supply systems23.060.01Ventili na splošnoValves in generalICS:Ta slovenski standard je istoveten z:EN 15092:2008SIST EN 15092:2009en,fr,de01-januar-2009SIST EN 15092:2009SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15092June 2008ICS 91.140.60 English VersionBuilding valves - Inline hot water supply tempering valves - Testsand requirementsRobinetterie des bâtiments - Vannes mélangeuses en ligned'alimentation en eau chaude - Essais et exigencesGebäudearmaturen - Thermostatische Mischer fürWarmwasserbereiter - Prüfungen und AnforderungenThis European Standard was approved by CEN on 29 May 2008.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15092:2008: ESIST EN 15092:2009

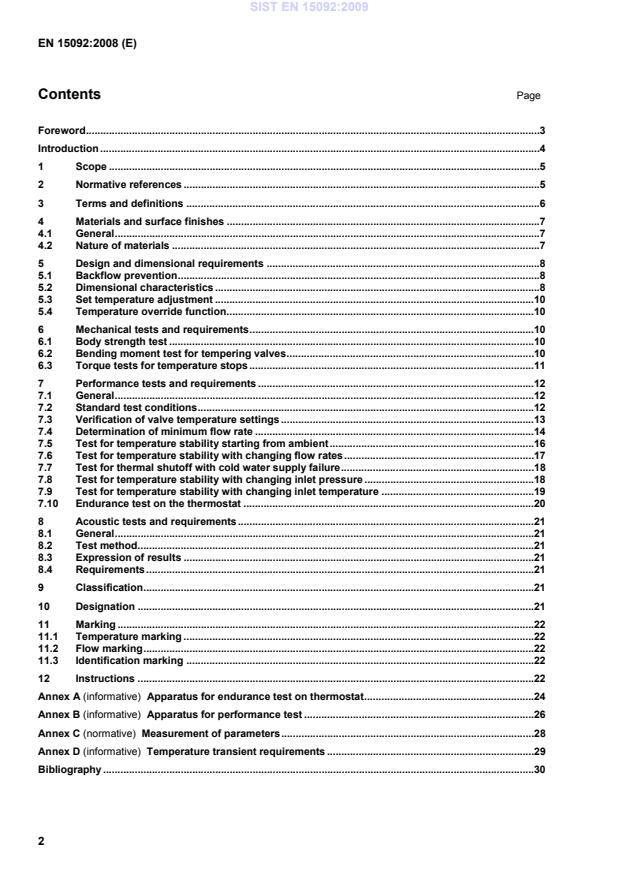

Apparatus for endurance test on thermostat.24 Annex B (informative)

Apparatus for performance test.26 Annex C (normative)

Measurement of parameters.28 Annex D (informative)

Temperature transient requirements.29 Bibliography.30

Limits of use Recommended limits for operation Dynamic pressure 0,02 MPa (0,2 bar) min. 0,1 MPa ≤ P ≤ 0,5 MPa (1 bar ≤ P ≤ 5,0 bar) Static pressure 1 MPa (10 bar) max. — Hot water inlet temperature T ≤ 90 °C 60 °C ≤ T ≤ 80 °C Cold water inlet temperatures T ≤ 25 °C T ≤ 25 °C Distribution (outlet) temperature 45 °C ≤ T ≤ 65 °C

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1092-3, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN desig-nated — Part 3: Copper alloy flanges EN 1254-1, Copper and copper alloys — Plumbing fittings — Part 1: Fittings with ends for capillary soldering or capillary brazing to copper tubes EN 1254-2, Copper and copper alloys — Plumbing fittings — Part 2: Fittings with compression ends for use with copper tubes EN 1254-3, Copper and copper alloys — Plumbing fittings — Part 3: Fittings with compression ends for use with plastics pipes EN 1254-4, Copper and copper alloys — Plumbing fittings — Part 4: Fittings combining other end connections with capillary or compression ends EN 1254-5, Copper and copper alloys — Plumbing fittings — Part 5: Fittings with short ends for capillary braz-ing to copper tubes EN 1982, Copper and copper alloys — Ingots and castings EN 12164, Copper and copper alloys — Rod for free machining purposes EN 12165, Copper and copper alloys — Wrought and unwrought forging stock EN 13959, Anti-pollution check valves DN 6 to DN 250 inclusive family E, Types A, B, C and D SIST EN 15092:2009

CuSn10-C

CC480K

EN 1982

CuSn5Pb5Zn5-C

CC491K

EN 1982

CuSn3Zn8Pb5-C

CC490K

EN 1982

CuZn39Pb3

CW614N EN 12164/EN 12165

CuZn40Pb2

CW617N EN 12164/EN 12165

CuZn36Pb2As

CW602N EN 12164/EN 12165

Copper-zinc alloys containing more than 10 % zinc are subject to dezincification when submitted to water capable of dezincification. In the countries where the use of products made of dezincification resistant materials is required, the products have to guarantee a dezincification depth of less than 200 µm in any direction; they have to be tested in accordance with EN ISO 6509 and have to be marked in compliance with the indications specified in Clause 11, Marking. 5 Design and dimensional requirements 5.1 Backflow prevention Integral backflow prevention devices shall comply with the appropriate standard in their own right. When fitted check valves, they shall comply with the requirements of EN 13959. 5.2 Dimensional characteristics 5.2.1 General Tempering valves shall be classified by the nominal size (DN) of outlet end connection. 5.2.2 End connections Examples of end connections are given in Table 3. All end connections shall comply with EN 1254. Connec-tions requiring the use of heat to make or break the joint (e.g. capillary) are not permitted directly on the valve body. 5.2.3 Other connections (e.g. unions) Connections, other than those specified in 5.2.1, shall comply with the functional aspects of the equivalent part of EN 1254. SIST EN 15092:2009

Internal thread to ISO 7-1:1994 d Rp ½ Rp ¾ Rp 1 Rp 1 ¼ Rp 1 ½ Rp 2

External thread to ISO 7-1:1994 d R ½ R ¾ R 1 R 1 ¼ R 1 ½ R 2

External thread to EN ISO 228-1 d G ¾ B G 1 B G 1 ¼ BG 1 ½ B G 1 ½ BG 1 ¾ BG 2 B

External thread with shoulder to

EN ISO 228-1 d G ½ B G ¾ B G 1 B G 1 ¼ B G 1 ½ BG 1 ¾ BG 2 B G 2 ê B Capillary socket to EN 1254-1 A 15/18 22 28 35 42 54

Male capillary end to EN 1254-1 A 15/18 22 28 35 42 54

Compression end for copper pipe to

EN 1254-2 d 15/18 22 28 35 42 54

EN 1092-3 D d K 95 75 14 105

14 115

14 140 100

18 150 110

18 160 120

1, F corresponding to the bending moment shown in Table 4, with a pressure of 1,6 MPa (16 bar) applied in increments of 0,1 MPa (1 bar) per 5 s. Maintain the bending moment and the pressure for 10 min. Repeat for the other inlets. 6.2.3 Requirement There shall be no rupture, leakage, visible damage or permanent deformation of the tempering valves. Table 4 — Bending moments Nominal diameter (DN) 15

50 Bending moment, Nm (F × L) for com-pression fittings 50

85 125 160 200 300 Bending moment for other end con-nections, Nm (F × L) 80 150 300 400 500 600

Key 1 – Tempering valve F – Force L – Moment arm of force Figure 1 — Bending moment 6.3 Torque tests for temperature stops Principle: Is to determine the resistance of the temperature stops to the stresses of operation. The test consists of sub-jecting the temperature control to stress, by applying torque, in order to verify its strength. Procedure: The test is carried out using a torque wrench adapted to the tempering valve Type 2 adjustment control device, or a lever arm and instrument for measuring the applied force. SIST EN 15092:2009

(6,00+) Nm to both the minimum distribution temperature stop and maximum distribution temperature stop and the override temperature stop if applicable. Requirement: Visually inspect, without disassembling the valve under test, the minimum distribution temperature stop and maximum distribution temperature stop, and the override temperature stop if applicable, as well as test associated components of the valve for cracking, breaking, part separation or other failures. There shall be no visible damage or permanent deformation of the tempering valve. After visual inspection, this should be verified by carrying out the tests described in 6.1, 6.2 and Clause 7. 7 Performance tests and requirements 7.1 General All performance tests shall be carried out with a suitable backflow prevention device fitted to the cold and hot water inlet. Valves can be supplied for testing with or without check valves. If not submitted with check valves, then the test is performed with suitable check valves complying with EN 13959 and the DN of the check valves shall be the same as the inlet of the valve. Backflow devices will be fitted to both the hot and cold inlets. All performance tests shall be carried out in the order that they appear in Clause 7. 7.2 Standard test conditions 7.2.1 General Standard test conditions should be used for each test as stated in Table 5, unless otherwise specified. With both hot and cold supply pressures of (0,3 ± 0,02) MPa [(3 ± 0,2) bar] and the inlet control valves open, adjust the outlet flow rate to the normal testing flow rate given in Table 5. Adjust the temperature control device to give a blend water temperature at the outlet of (50 20+) °C. In the case of Type 1 valves the outlet temperature is preset so testing should be done at the preset outlet temperature. In all tests a minimum differential temperature of 15 °C between the hot inlet temperature and the mixed water outlet temperature shall be maintained unless specified otherwise within the test procedure. 7.2.2 Expression of results For each test, calculate the mean average of three test results, but each individual result shall not deviate by more than 10 % of the stated requirement. 7.2.3 Testing temperatures by adjustment types Type 1: Pre-set temperature, non-adjustable Valves shall be tested at the pre-set temperature. SIST EN 15092:2009

32 40

50 Normal testing flow rate (l/min)

40 80 100 Reduced testing flow rate (l/min)

20 40

50 Test 7.7 Mixed water flow volume (ml) 100 100 200 500 not applicablenot applicable Hot water Cold water Inlet pressures 0,3 MPa ± 0,02 MPa (3 bar ± 0,2 bar) Inlet temperatures (unless otherwise specified) 65 °C or to 80 °C as necessary to maintain a ≥ 15 °C, differential between the hot water and mixed water temperatures 15 °C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...