prEN 15045

(Main)Transportable gas cylinders - Specification for the design and construction of refillable seamless aluminium or aluminium alloy gas cylinders for portable carbon dioxide fire extinguishers of water capacities from 0,5 litre up to 150 litres

Transportable gas cylinders - Specification for the design and construction of refillable seamless aluminium or aluminium alloy gas cylinders for portable carbon dioxide fire extinguishers of water capacities from 0,5 litre up to 150 litres

This standard specifies minimum requirements for the material, design, construction and workmanship, manufacturing processes and tests at manufacture of refillable seamless aluminium or aluminium alloy gas cylinders that are fitted with bursting disc devices for portable CO2 fire extinguishers of water capacities from 0,5 l up to 15 l.

Ortsbewegliche Gasflaschen - Gestaltung und Konstruktion von wiederbefüllbaren ortsbeweglichen nahtlosen Gasflaschen aus Aluminium und Aluminiumlegierung für Tragbare Feuerlösche Kohlenstoffdioxid mit einem Fassungsraum von 0,5 Liter bis einschließlich 150 Liter

Bouteilles à gaz transportables - Spécifications pour la conception et la fabrication de bouteilles à gaz rechargeables et transportables en aluminium ou alliage d'aluminium sans soudure d'extincteurs d'incedie portatif de dioxide de carbone de capacité de l'eau comprise entre 0,5 litre et 150 litres inclus

Premične plinske jeklenke – Specifikacija za zasnovo in konstrukcijo ponovno polnljivih nevarjenih plinskih valjev iz aluminija ali aluminijeve zlitine za prenosne gasilne naprave z ogljikovim dioksidom z vodno prostornino od 0,5 litra do 150 litrov

General Information

- Status

- Not Published

- Publication Date

- 08-Apr-2007

- Technical Committee

- CEN/TC 23 - Transportable gas cylinders

- Drafting Committee

- CEN/TC 23/SC 1/WG 3 - Aluminium cylinders

- Current Stage

- 4598 - Decision to abandon - Finalization for Vote

- Start Date

- 01-Feb-2007

- Completion Date

- 01-Feb-2007

- Directive

- 97/23/EC - Pressure equipment

Overview

prEN 15045 (CEN draft) specifies minimum requirements for the design, material, manufacture and testing of refillable seamless aluminium or aluminium‑alloy gas cylinders used in portable CO2 (carbon dioxide) fire extinguishers. The standard applies to portable extinguishers with water capacities from 0.5 litre up to and including 15 litres and requires cylinders to be fitted with bursting‑disc devices. prEN 15045 supports regulatory conformity (PED) and is intended for CEN member adoption.

Key topics and technical requirements

- Materials and certification: Permitted aluminium and aluminium‑alloy grades are referenced (see EN 573‑3). Cylinders may be made from high‑purity unalloyed aluminium or specified alloys; material conformity must be documented (EN 10204).

- Heat treatment and forming: Requirements for solution heat treatment, artificial ageing, quenching, stabilizing treatments and manufacturer‑specified process controls (temperature and time tolerances).

- Design and wall‑thickness calculation: Wall thickness is calculated from the material yield stress and the hydraulic test pressure; design limits on stress factors and minimum thicknesses are defined to ensure elastic behaviour.

- Pressure testing: Hydraulic test pressures are linked to CO2 filling ratios and must at least match the developed pressure at 65 °C (examples in the draft show minimum test pressures in the order of ~137–174 bar and maximum allowable pressures of 200–250 bar, depending on filling ratio).

- Manufacturing controls and tests: Includes new‑design (type) approval tests, production testing, corrosion testing (Annex A), sustained‑load‑cracking resistance (Annex B) and visual inspection criteria (Annex C). Annex F gives specific rules for AA2001 alloy.

- Construction, workmanship and marking: Requirements for forming, joining, valve threads and permanent marking/stamp (EN ISO 13769).

Applications and who uses this standard

- Cylinder manufacturers and suppliers specifying refillable seamless aluminium CO2 cylinders

- Fire‑extinguisher OEMs designing portable CO2 extinguishers

- Test houses, notified bodies and quality inspectors performing type approval and production testing

- Safety engineers, procurement teams and regulators ensuring compliance with PED and safe pressure containment

- Service and refill stations verifying cylinder fitness, markings and test certificates

Related standards

- EN 573‑3 (aluminium chemical composition)

- EN 629‑1 / EN 629‑2 (valve thread 25E)

- EN ISO 13769 (stamp marking)

- EN ISO 15245 (parallel threads)

- EN 10002‑1, EN 10003‑1 (mechanical testing methods)

prEN 15045 is essential reading where safe, compliant design and production of small refillable aluminium CO2 cylinders is required. It links material selection, heat treatment, structural design and mandated tests to practical safety and regulatory conformity.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

prEN 15045 is a draft published by the European Committee for Standardization (CEN). Its full title is "Transportable gas cylinders - Specification for the design and construction of refillable seamless aluminium or aluminium alloy gas cylinders for portable carbon dioxide fire extinguishers of water capacities from 0,5 litre up to 150 litres". This standard covers: This standard specifies minimum requirements for the material, design, construction and workmanship, manufacturing processes and tests at manufacture of refillable seamless aluminium or aluminium alloy gas cylinders that are fitted with bursting disc devices for portable CO2 fire extinguishers of water capacities from 0,5 l up to 15 l.

This standard specifies minimum requirements for the material, design, construction and workmanship, manufacturing processes and tests at manufacture of refillable seamless aluminium or aluminium alloy gas cylinders that are fitted with bursting disc devices for portable CO2 fire extinguishers of water capacities from 0,5 l up to 15 l.

prEN 15045 is classified under the following ICS (International Classification for Standards) categories: 23.020.35 - Gas cylinders. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 15045 is associated with the following European legislation: EU Directives/Regulations: 94/55/EC, 96/49/EC, 96/86/EC, 96/87/EC, 97/23/EC; Standardization Mandates: M/071, M/086. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 15045 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI OSIST prEN 15045:2004

PREDSTANDARD

december 2004

Premične plinske jeklenke – Specifikacija za zasnovo in konstrukcijo

ponovno polnljivih nevarjenih plinskih valjev iz aluminija ali aluminijeve zlitine

za prenosne gasilne naprave z ogljikovim dioksidom z vodno prostornino od

0,5 litra do 150 litrov

Transportable gas cylinders - Specification for the design and construction of

refillable seamless aluminium or aluminium alloy gas cylinders for portable carbon

dioxide fire extinguishers of water capacities from 0,5 litre up to 150 litres

ICS 23.020.30 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2004

ICS

English version

Transportable gas cylinders - Specification for the design and

construction of refillable seamless aluminium or aluminium alloy

gas cylinders for portable carbon dioxide fire extinguishers of

water capacities from 0,5 litre up to 150 litres

Bouteilles à gaz transportables - Spécifications pour la Ortsbewegliche Gasflaschen - Gestaltung und Konstruktion

conception et la fabrication de bouteilles à gaz von wiederbefüllbaren ortsbeweglichen nahtlosen

rechargeables et transportables en aluminium ou alliage Gasflaschen aus Aluminium und Aluminiumlegierung für

d'aluminium sans soudure d'extincteurs d'incedie portatif de Tragbare Feuerlösche Kohlenstoffdioxid mit einem

dioxide de carbone de capacité de l'eau comprise entre 0,5 Fassungsraum von 0,5 Liter bis einschließlich 150 Liter

litre et 150 litres inclus

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 23.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15045:2004: E

worldwide for CEN national Members.

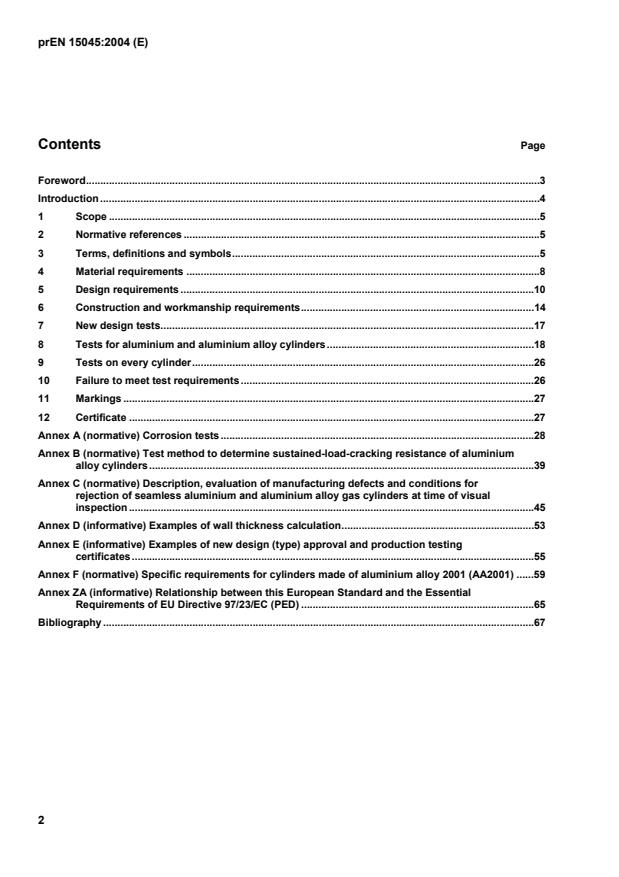

Contents Page

Foreword.3

Introduction .4

1 Scope .5

2 Normative references .5

3 Terms, definitions and symbols.5

4 Material requirements .8

5 Design requirements .10

6 Construction and workmanship requirements.14

7 New design tests.17

8 Tests for aluminium and aluminium alloy cylinders.18

9 Tests on every cylinder.26

10 Failure to meet test requirements.26

11 Markings .27

12 Certificate .27

Annex A (normative) Corrosion tests.28

Annex B (normative) Test method to determine sustained-load-cracking resistance of aluminium

alloy cylinders.39

Annex C (normative) Description, evaluation of manufacturing defects and conditions for

rejection of seamless aluminium and aluminium alloy gas cylinders at time of visual

inspection .45

Annex D (informative) Examples of wall thickness calculation.53

Annex E (informative) Examples of new design (type) approval and production testing

certificates .55

Annex F (normative) Specific requirements for cylinders made of aluminium alloy 2001 (AA2001) .59

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 97/23/EC (PED) .65

Bibliography .67

Foreword

This document (prEN 15045:2004) has been prepared by Technical Committee CEN/TC 23 “Transportable

gas cylinders”, the secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

This European Standard has been prepared to address the essential requirements of the PED for portable,

refillable seamless aluminium CO fire extinguishers of water capacities from 0,5 litre up to and including 15

litres.

Annexes A, B, C and F are normative. Annexes D, E and ZA are informative.

Introduction

The purpose of this standard is to provide a specification for the design, manufacture, inspection and approval

of refillable seamless aluminium or aluminium alloy gas cylinders for use in portable CO fire extinguishers.

The specification given is based upon knowledge of, and experience with, materials, design requirements,

manufacturing processes and control during manufacture, of cylinders in common use in the countries of the

CEN members.

This standard draws upon established practice as outlined in the ADR (European Agreement Concerning the

International Carriage of Dangerous Goods by Road) for determining the test pressure of CO cylinders (ADR

P200 4.1.4.1)

1 Scope

This standard specifies minimum requirements for the material, design, construction and workmanship,

manufacturing processes and tests at manufacture of refillable seamless aluminium or aluminium alloy gas

cylinders that are fitted with bursting disc devices for portable CO fire extinguishers of water capacities from

0,5 l up to 15 l.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 573-3, Aluminium and aluminium alloys — Chemical composition and form of wrought products — Part 3:

Chemical composition

EN 629-1, Transportable gas cylinders — 25E taper thread for connection of valves to gas cylinders — Part 1:

Specification

EN 629-2, Transportable gas cylinders — 25E taper thread for connection of valves to gas cylinders — Part 2:

Gauge inspection

EN 10002-1, Metallic materials — Tensile testing — Part 1: Method of test at ambient temperature

EN 10003-1, Metallic materials — Brinell hardness test — Part 1: Test method

EN 10204, Metallic Products — Types of inspection documents

EN ISO 7539-6, Corrosion of metals and alloys — Stress corrosion testing — Part 6: Preparation and use of

pre-cracked specimens for tests under constant load or constant displacement (ISO 7539-6:1989)

EN ISO 13341, Transportable gas cylinders — Fitting of valves to gas cylinders

EURONORM 6-55, Bend test for steel

prEN ISO 13769: 2004, Gas cylinders — Stamp marking (ISO 13769:2002)

EN ISO 15245-1, Gas cylinders — Parallel threads for connection of valves to gas cylinders — Part 1:

Specification

EN ISO 15245-2, Gas cylinders — Parallel threads for connection of valves to gas cylinders — Part 2: Gauge

Inspection

3 Terms, definitions and symbols

For the purpose of this document, the terms, definitions and symbols given in EN ISO 7539-6:1995 and the

following apply.

3.1 Terms and definitions

3.1.1

artificial ageing

heat treatment process in which the solute phase is precipitated to give an increased yield stress and tensile

strength

3.1.2

batch

quantity of up to 500 cylinders, plus cylinders for destructive testing, of the nominal diameter, thickness, length

and design made successively from the same cast and (if applicable) the same artificial ageing furnace load

3.1.3

crack mouth opening displacement (CMOD)

V

mode 1 (also called opening-mode) component of crack displacement due to elastic and plastic deformation,

measured at the location on a crack surface that has the greatest elastic displacement per unit load

3.1.4

design stress factor (variable)

F

ratio of equivalent wall stress at test pressure (P ) to guaranteed minimum yield stress (R )

h e

3.1.5

mass

weight of a cylinder, expressed in kilograms, comprising the combined weight of cylinder and permanently

attached parts (eg foot ring, neck ring) but without valve

3.1.6

quenching

controlled rapid cooling in a suitable medium to retain the solute phase in solid solution

3.1.7

solution heat treatment

thermal treatment which consists of heating the products to a suitable temperature, holding at that

temperature long enough to allow constituents to enter into solid solution and cooling rapidly enough to hold

the constituents in solution

3.1.8

stabilizing heat treatment

heat treatment applied to some 5000 series aluminium alloys in order to prevent changes in mechanical

properties and structure under service conditions

3.1.9

yield stress

value corresponding to 0,2 % proof stress (non-proportional elongation), R for aluminium alloys, or 1%

p0,2

proof stress for unalloyed aluminium in the unhardened state

3.2 Symbols

a Calculated minimum thickness, in millimetres, of the cylindrical shell

a' Guaranteed minimum thickness, in millimetres, of the cylindrical shell

A Percentage elongation, determined by the tensile test 8.2.2.2

b Guaranteed minimum thickness, in millimetres, at the centre of a convex base (see Figure 1)

d Diameter of former, in millimetres (see Figure 4)

D Nominal outside diameter of the cylinder, in millimetres (see Figure 1)

E Modulus of elasticity, in megapascals (MPa)

F Design stress factor (variable) (see 3.1.4)

H Outside height of domed part (convex head or base end), in millimetres (see Figure 1)

½

K Applied elastic stress intensity, in MPa×m

IAPP

n The ratio of the diameter of the bend test former to actual thickness of test piece (t)

1)

P Measured burst pressure, in bar above atmospheric pressure

b

1)

P Lower cyclic pressure, in bar above atmospheric pressure

lc

1)

P Hydraulic test pressure, in bar above atmospheric pressure

h

P Maximum allowable pressure in bar for which the cylinder is designed, as specified in 5.2

S

r Inside knuckle radius, in millimetres (see Figure 1)

r Inside crown radius, in millimetres (see Figure 1)

i

R Minimum guaranteed value of yield stress (see 3.1.9) in megapascals, for the finished cylinder

e

R Actual value of yield stress, in megapascals, determined by the tensile test in 8.1.2

ea

R Average of measured yield stress of two specimens from the test cylinder representing the SLC test

eSLC

specimens location at room temperature, in megapascals (for location of the specimens, see B.4.3)

R Minimum guaranteed value of tensile strength, in megapascals, for the finished cylinder

g

R Actual value of tensile strength, in megapascals, determined by the tensile test in 8.1.2

m

S Original cross sectional area of tensile test piece, in square millimetres, according to EN 10002-1

o

SLC Sustained-load-cracking

T Titre

T Maximum allowable temperature, in degree Celsius (°C)

s

t Actual thickness of test specimen, in millimetres

V Crack mouth opening displacement (CMOD), in millimetres

1)

1bar = 10 Pa = 0.1MPa.

4 Material requirements

4.1 General provisions

4.1.1 Cylinders for portable CO fire extinguishers may be manufactured from unalloyed aluminium of at least

99,5% purity.

1)

4.1.2 Aluminium alloy(s) that conform to EN 573-3 (or Aluminum Association documents) as listed in Table 1

may be used to produce portable CO fire extinguisher cylinders, provided that they satisfy the requirements

of the corrosion resistance tests defined in annex A, and meet all other requirements of this standard including

annex B. For specific requirements relating to Aluminium Alloy 2001, refer to annex F.

4.1.3 The cylinder manufacturer shall permanently mark the cylinders with the particular cast of the alloy from

which they are made, and shall obtain documentation prepared by the material manufacturer that affirms

conformity to the specified material. This documentation shall take the form of a certificate of specific product

control (EN 10204).

4.2 Heat treatment

4.2.1 Heat-treatable alloys

The manufacturer shall specify on the new design (type) approval documentation the solution heat treatment

and artificial ageing temperatures and the times for which the cylinders have been held at those temperatures.

The medium used for quenching after solution heat treatment shall be identified.

4.2.2 Non-heat-treatable alloys

The manufacturer shall specify on the new design (type) approval documentation the type of metal forming

operation carried out (extrusion, drawing, ironing, head forming, etc).

Unless the alloy is subjected to a temperature in excess of 400°C during the forming process, a stabilizing

heat treatment shall be carried out and the temperature and time at temperature shall be specified by the

manufacturer.

4.2.3 Control of specified heat treatment

During the heat treatment, the manufacturer shall comply with the specified temperatures and durations,

within the following tolerances.

a) Temperatures:

— solution temperature ± 10 °C;

— artificial ageing temperature ± 5 °C;

— stabilizing temperature ± 10 °C.

b) Durations:

— stabilizing treatment ± 10%.

th

2)

AA is the Aluminum Association Inc., 900 19 Street N.W.,Washington D.C., 20006-2168, USA.

Table 1 — Chemical composition of aluminium alloys

a

Type of alloy Marking Chemical composition weight

code

%

reference

Si Fe Cu Mn Mg Cr Ni Zn Ti Zr Pb Others Aluminium

Each Total

min - - - 0,50 4,5 - - - - - - - - Remainder

EN AW-5283A 5283

max 0,30 0,30 0,03 1,0 5,1 0,05 0,03 0,10 0,03 0,05 0,0030 0,05 0,15

min 0,40 - 0,15 - 0,8 0,04 - - - - - - - Remainder

EN AW-6061A 6061

max 0,8 0,7 0,40 0,15 1,2 0,35 - 0,25 0,15 - 0,0030 0,05 0,15

min - - 5,2 0,15 0,2 - - - - - - - - Remainder

EN AW-2001 2001

max 0,20 0,20 6,0 0,5 0,45 0,10 0,05 0,10 0,20 0,05 0,0030 0,05 0,15

min - - 1,8 - 1,3 0,15 - 6,1 - - - - - Remainder

EN AW-7060 7060

max 0,15 0,20 2,6 0,20 2,1 0,25 - 7,5 0,05 0,05 0,0030 0,05 0,15

min - - 1,8 - 1,7 0,15 - 5,6 - - - - - Remainder

b

AA-7032 7032

max 0,1 0,12 2,4 0,05 2,5 0,25 - 6,6 0,1 0,05 0,0030 0,05 0,15

2)

Where a melt contains scrap or other re-used material the bismuth content shall not exceed 0,0030 %.

a

Alloy designation according to EN 573-3.

th

b

AA is the Aluminum Association Inc., 900 19 Street N.W., Washington D.C., 20006-2168, USA. AA 7032 is awaiting inclusion in EN 573-3.

5 Design requirements

5.1 General provisions for heat-treatable alloys

5.1.1 The calculation of the wall thickness of the pressure-containing parts shall be related to the yield stress

(R ) of the material to ensure elastic behaviour.

e

5.1.2 For calculation purposes the value of the yield stress (R ) is limited to a maximum of 0,90 R for

e g

aluminium alloys.

5.1.3 The internal pressure upon which the calculation of wall thickness is based shall be the hydraulic test

pressure (p ).

h

5.2 Calculation of cylindrical wall thickness for heat-treatable alloys

The guaranteed minimum thickness of the cylindrical shell (a') shall not be less than the thickness calculated

using the equation:

10FR − 3.p

D

e h

a = 1−

2 10FR

e

where the value of F shall not exceed 0,875.

The calculated minimum thickness shall also satisfy the equation:

D

a≥+1

where the value of a shall be at least 1,5 mm.

Cylinders for CO fire extinguishers shall be designed using hydraulic test pressures related to selected filling

ratios. The test pressure shall not be less than the developed pressure at 65°C (see Table 2).

Table 2 — Test pressure versus filling ratio

Filling ratio Maximum

Minimum test pressure P

h

allowable

kg/l

pressure P

S bar

bar

0,667 136,8 200

0,675 138,4 200

0,750 173,5 250

When choosing the minimum guaranteed value of the thickness of the cylindrical shell (a'), the manufacturer

shall take into account all requirements for type and production testing, particularly the burst test requirements

of 8.2.

H

NOTE For examples of wall thickness calculations, see annex D.

5.3 Design of ends (heads and bases)

The thickness and shape of the base and head of the cylinders shall be such as to meet the requirements of

the tests laid down in 8.3 and 8.4

In order to achieve satisfactory stress distribution, the cylinder wall thickness shall increase progressively in

the transition zone between the cylindrical shell and the ends, particularly the base end. For example, typical

shapes of convex heads and base ends are shown in Figure 1. The thickness at any part of the base shall not

be less than the guaranteed minimum thickness of the cylindrical part.

The internal knuckle radius (r) shall not be less than 10 % of the internal diameter of the shell.

For convex ends, the inside crown radius (r ) shall not be greater than 1,2 times the internal diameter of the

i

shell.

a'

D

a) b)

Figure 1 — Examples of convex ends

r

i

a'

r

D

c) d)

e) f)

r

i

a'

r

g) h)

Figure 1 — Examples of heads and convex ends (cont.)

b

b

H

H

i) j)

k)

Figure 1 — Examples of heads and convex ends (cont.)

5.4 Neck design

5.4.1 The external diameter and thickness of the formed neck end of the cylinder shall be adequate for the

torque applied in fitting the valve to the cylinder. The torque may vary according to the diameter of thread, the

form, and the sealant used in the fitting of the valve. The torques specified in EN ISO 13341 shall not be

exceeded, since this could result in permanent damage to the cylinder. Where the cylinder manufacturer

specifies a lower torque this also shall not be exceeded. The manufacturer shall notify any such requirements

to the purchaser of aluminium or aluminium alloy cylinders for portable CO fire extinguishers.

5.4.2 The thickness of the wall in the cylinder neck shall be sufficient to prevent permanent expansion of the

neck during initial and subsequent fitting of the valve into the cylinder. Where the cylinder is specifically

designed to be fitted with neck reinforcement, such as a neck ring or shrunk-on collar this may be taken into

account (see EN ISO 13341).

5.4.3 Cylinders for portable CO fire extinguishers may be designed with one or two opening(s) along the

central cylinder axis only.

5.5 Foot-rings

When a foot-ring is provided, it shall be sufficiently strong to support the cylinder in a vertical orientation and

made of material compatible with that of the cylinder. The shape should be cylindrical and shall give the

cylinder sufficient stability. The foot-ring shall be secured to the cylinder by a method other than welding,

brazing or soldering. Any gaps that may form water traps shall be sealed to prevent ingress of water, by a

method other than welding, brazing or soldering.

5.6 Neck-rings

When a neck-ring is provided, it shall be made of a material that is compatible with that of the cylinder, and

shall be securely attached by a method other than welding, brazing or soldering.

The manufacturer shall ensure that the axial load required to remove the neck ring is greater than 10 times the

weight of the empty cylinder and not less than 1 000 N, and shall also ensure that the minimum torque

required to turn the neck ring is greater than 100 N.m.

5.7 Design drawing

A design drawing that is fully annotated with all dimensions, including the specification of the material and that

makes reference to this standard, shall be prepared.

6 Construction and workmanship requirements

6.1 General

The cylinder shall be produced by:

— cold or hot extrusion from cast or extruded or rolled billet;

— cold or hot extrusion, followed by cold drawing, from cast or extruded or rolled billet;

— cupping, flow forming, spinning and cold drawing sheet or plate;

— formed from tube by spinning of the ends – specific for double ended cylinders only.

Once the manufacturing route has been established and new design approval obtained, no other significant

changes to the process shall be permitted unless the product is submitted for re-approval.

6.2 Welding

Welding of seamless aluminium and aluminium alloy gas cylinders shall not be permitted under any

circumstances.

6.3 Wall thickness

Each cylinder shall be examined for thickness and for external and internal surface defects. The wall thickness

at any point shall not be less than the minimum design thickness.

6.4 End forming

The crown end shall be homogeneously formed by an appropriate method, e.g. forging, swaging or spinning.

Prior to and/or after the closing-in operation, significant remnants of the as-cast structure of the open-end of

the shell shall be removed.

Where heat has to be applied in order to form the cylinder neck/shoulder, uniform heat distribution shall be

achieved prior to the forming operation (e.g. by means of induction heating). This heat distribution shall be

achieved independently of the process employed for the manufacture of the shell.

For 6000 series alloys special precautions shall be taken to achieve a fine grain structure in the neck of the

finished cylinder.

Regardless of the method used for the closing-in operation, the tools used for the head forming process shall

facilitate metal flow and result in smooth surfaces of the cylinder, especially in the neck/shoulder areas. There

shall be no crimping effect, sudden contour changes or significant folds (see 6.7) that can act as stress raisers

during the cylinder's eventual service conditions.

6.5 Surface defects

The internal and external surfaces of the finished cylinder shall be free from defects that would adversely

affect the safe working of the cylinder. Such defects shall be removed by local dressing. The wall thickness of

any dressed area shall not be less than the minimum thickness specified.

6.6 Neck threads

The internal neck threads shall conform to a recognized standard (e.g. EN 629-1 or EN ISO 15245-1) to

permit the use of a corresponding valve, thus minimizing neck stresses following the valve torquing operation.

Internal neck threads may be checked using gauges, e.g. gauges that conform to EN 629-2 or EN ISO 15245-

2. Particular care shall be taken to ensure that neck threads are accurately cut, are of full form and free from

any sharp profiles, edge burrs or severe tap marks.

6.7 Examination for surface imperfections and neck folds

Each cylinder shall be examined for neck folds by e.g. introscope, borescope, dental mirror, tactile, ultrasonics.

Folds that are visible as a line running into the threaded portion (as shown on the left hand side of Figure 2)

shall be removed by a machining operation until the lines are no longer visible. After the machining operation,

the thickness of the machined area and the thread characteristics shall be at least that required to pass all

necessary testing. The whole internal shoulder area shall be re-inspected to verify that folding or its lines have

been removed.

Key

1 Folds

2 Machine away

Figure 2 — Example of cylinder neck folds before and after machining

6.8 Out-of-roundness

The out-of-roundness of the cylindrical shell, i.e. the difference between the maximum and minimum outside

diameters at the same cross-section, shall not exceed 2 % of the mean of these diameters.

6.9 Straightness

The maximum deviation of the cylindrical part of the shell from a straight line shall not exceed 3 mm per metre

length.

6.10 Stability

For a cylinder designed to stand on its base incorporating foot-ring or foot protrusions, the cylinder shall stand

on a flat surface firmly and vertical. The maximum deviation of the cylindrical part of the shell from a vertical

line shall not exceed 1 % of its height.

6.11 Mean diameter

The mean external diameter shall not deviate more than ± 1 % from the nominal design diameter.

6.12 Checking of water capacity

The minimum water capacity shall be measured and recorded. Care shall be taken to prevent water remaining

in cylinders after the water capacity checks. In the event that water does remain in the cylinders after the

water capacity checks, an internal drying stage shall be introduced prior to hydraulic pressure testing.

6.13 Mass measurement

The mass of each cylinder expressed in kilograms shall be marked on the cylinder, rounded down to two

decimal places. This mass shall be the combined mass of the cylinder and permanently attached parts (e.g.

foot-ring, neck-ring) but without the valve or dip tube.

The tare of each cylinder expressed in kilograms shall also be permanently marked to two decimal places

rounded down. The tare shall be the mass of the cylinder plus the mass of the valve and dip tube. The mass

of the horn (spray nozzle) shall not be included.

7 New design tests

7.1 General requirements

7.1.1 Testing shall be carried out for each new design of cylinder. A previously approved cylinder design

shall be considered to be of a new design when any of the following conditions apply:

— it is manufactured by a different plant;

— it is manufactured by a different process (this includes the case when major process changes are made

during the production period);

— it is manufactured from an alloy of different specified composition limits from that used in the original type

test;

— it is given a different heat treatment that is outside the tolerance specified in 4.2.3;

— the base profile has changed, e.g. concave, convex, hemispherical, or there is a change in the base

thickness;

— the overall length of the cylinder has increased by more than 50 % (cylinders with a length/diameter ratio

less than 3 shall not be used as reference cylinders for any new designs for cylinders with a length/diameter

ratio greater than 3);

— the nominal outside diameter has changed;

— the guaranteed minimum thickness a' has been decreased;

— the hydraulic test pressure has been changed (where a cylinder is to be used for a lower pressure duty

than that for which design approval has been given, it shall not be deemed to be of a new design);

— the guaranteed minimum yield stress (R ) and/or the guaranteed minimum tensile strength (R ) have

e g

changed;

— the F factor used in the design has changed.

7.1.2 The applicant, e.g. a manufacturer, for new design approval shall, for each new design of cylinder,

submit the documentation necessary for the checks specified in 7.1.3. The applicant shall also make available

a batch of at least 50 cylinders from which the number of cylinders required for the tests will be taken together

with any additional information required.

However, if the total production is less than 50 cylinders, enough cylinders shall be made available to

complete the new design test required, in addition to the production quantity. In this case the approval validity

shall be limited to this particular production batch.

In particular, the applicant shall declare the type of heat treatment and mechanical treatment used, and the

temperature and the duration of treatment, as indicated in 4.2. The applicant shall also provide cast analysis

certificates for materials used in the manufacture of the cylinders.

7.1.3 In the course of the new design testing, it shall be verified that:

the calculation specified in 5.2 has been performed correctly;

the thickness of the walls and ends of two of the cylinders taken for tests meet the requirements of 5.2

and 5.3. The thickness measurements shall be taken on three transverse sections of the body of the

cylinder and over the whole of a longitudinal section of the base and the head;

the requirements of 4.1 (material) are met;

the geometrical requirements of 6.8 to 6.11 are met for all cylinders selected;

the internal and external surfaces of the cylinders are free of any defect which might make them unsafe to

use (see annex C);

the sustained-load-cracking test in annex B for the alloy of use has been successfully completed.

7.1.4 Witness the following tests on the cylinders selected, or establish that the stress corrosion test in

annex A has been satisfactorily performed for the alloy of use.

— The tests for resistance to corrosion (intercrystalline corrosion and stress corrosion as described in

annex B) on one cylinder. Use two cylinders if the size of the type of cylinder being tested does not allow it.

It is not necessary to carry out repeat stress corrosion tests for every new design. Intergranular corrosion

th

tests shall be carried out on every new cast and design, but not when condition 7.1.1 (5 indent) only

applies and/or when the nominal outside diameter has changed by less than 20 %.

The tests specified in 8.1.2 (tensile and bend tests) on two cylinders. Where the length of the cylinder is

1 500 mm or more, the tensile tests in a longitudinal direction and the bend tests shall be carried out on

test pieces taken from the upper and lower regions of the shell.

The tests specified in 8.2 (hydraulic burst test) on two cylinders.

The tests specified in 8.3 (pressure cycling test) on two cylinders.

7.1.5 If the results of the checks are not satisfactory, proceed as described in clause 10. If the results of

the test are satisfactory, a new design approval certificate, see annex E, shall be issued.

7.1.6 The manufacturer shall retain design drawings calculations, new design approval certificates and all

other relevant manufacturing test and inspection documentation for a minimum of 10 years.

8 Tests for aluminium and aluminium alloy cylinders

8.1 Mechanical tests

8.1.1 General requirements

Except for the requirements set out in 8.1.2, the mechanical tests shall be carried out in accordance with

EN 10002-1, EN 10003-1 and EURONORM 6-55.

All mechanical tests for checking the quality of the metal used for gas cylinders shall be carried out on

material taken from cylinders on which all operations affecting mechanical properties have been completed.

The cylinders do not need to have been pressure tested.

On every test cylinder, the following tests shall be carried out.

— One tensile test in a longitudinal direction.

— Four bend tests in a circumferential direction.

For the location of test pieces, see Figure 3.

8.1.2 Tensile test

8.1.2.1 Procedure

Carry out the tensile test on a test piece that conforms to the provisions of EN 10002-1, and has a gauge

length of 5,65 √S . Maintain the two faces of the test piece that correspond to the internal and external walls

o

of the cylinder.The two faces of the test-piece corresponding to the internal and external walls of the cylinder

shall be maintained.

Z

Z

Key

1 Bend test pieces

2 Tensile test pieces

Figure 3 — Location of test pieces

8.1.2.2 Expression of results

For the heat-treatable alloys referred to in 4.2.1, elongation after fracture (A) shall not be less than 12 %,

except AA2001 cylinders where the average of the four measurements shall not be less than 9 % (see

annex F).

For the non-heat-treatable alloys referred to in 4.2.2, the elongation after fracture shall not be less than 12 %

where the tensile test is carried out on a single test piece taken from the cylinder wall.

The tensile test mayalso be carried out on four test pieces distributed uniformly throughout the cylinder wall.

The results of the test shall be as follows:

— no individual value shall be less than 11 %; and

— the average of the four measurements shall be at least 12 %.

In the case of unalloyed aluminium, the elongation after fracture shall not be less than 12 %.

The value obtained for tensile strength shall not be less than R . The yield stress (R ) to be determined

g ea

during the tensile test shall not be less than the value R used for the cylinder wall thickness calculation.

e

8.1.3 Bend test

8.1.3.1 Principle

Four test pieces are cut from a cylinder and bent around a former and two rollers, and the ratio (n) of the

diameter of the former and thickness of the test piece is recorded.

8.1.3.2 Procedure

8.1.3.2.1 In order to obtain four test pieces, cut either one or two rings of a cylinder of width 3a'(± 1 mm)

into four equal parts. Ensure that the widths of the test pieces are less than 25 mm, and that each test piece is

of sufficient length to permit the bend test to be carried out correctly.

NOTE Each ring may be machined on the edges only. These edges may be rounded to a radius of no more than

1/10 of the thickness of the test pieces or chamfered at an angle of 45° and a width of less than 1/10 of the thickness of

the test pieces.

8.1.3.2.2 Carry out the bend tests using a former of diameter d and two rollers separated by a distance of d

+ 3a'. During the test, ensure that the inside face of the ring remains in contact with the former.

NOTE Several test pieces can be tested at the same time on the same test machine (see Figure 4).

8.1.3.2.3 Bend the test piece(s) inwards around the former until the inside edges are not further apart than

the diameter of the former (see Figure 4).

8.1.3.2.4 Record the ratio (n) of the diameter of the former and the thickness of the test piece.

8.1.3.3 Expression of results

The ratio (n) of the diameter of the former and the thickness of the test piece shall not exceed the values

given in Table 3:

Table 3 — Bend test requirements

Actual tensile

Value of n

strength R

m

MPa

R ≤ 220

m

220 < R ≤ 330

m

330 < R ≤ 440

m

R > 440

m

8.1.3.4 Test report

The test report shall include reference to the value of n, and a statement as whether it exceeds the relevant

value in Table 3.

d

d + 3a'

Figure 4 — Illustration of bend test

t

8.2 Hydraulic burst test

8.2.1 Procedure

8.2.1.1 Ensure that cylinders subjected to this test bear markings in accordance with EN ISO 13769.

8.2.1.2 The hydraulic burst test shall be carried out using a test rig that allows pressure to be increased

at a controlled rate until the cylinder bursts and the curve of pressure variation versus volumetric expansion or

time to be produced. Carry out the test at room temperature, and ensure that the temperature of the cylinder

o

throughout the test is less than 40 C (see Figure 5).

8.2.1.3 During the first stage of the test (the elastic deformation stage) increase the pressure at a

constant rate up to the level at which plastic deformation starts.

8.2.1.4 In the second stage of the test, maintain the pump discharge rate as constant as possible until the

cylinder bursts. Ensure that the duration of the test is no less than 2 min.

8.2.2 Expression of results

8.2.2.1 The interpretation of the burst test shall involve:

determination of the burst pressure (P ) during the test;

b

examination of the tear and of the shape of its edges;

in the case of cylinders with a concave base, verification that the base of the cylinder has not been

reversed.

8.2.2.2 The measured burst pressure (P ) shall be not less than 1,8 P :

b S

8.2.2.3 The burst test shall not cause fragmentation of the cylinder.

8.2.2.4 The main fracture (tear) shall not be of a brittle type, i.e. the edges of the fracture shall not be

radial but be sloping in relation to a diametral plane and shall display a reduction of area.

The fracture shall be deemed to be acceptable only if at least one of the following requirements is fulfilled.

The greater part of the fracture shall be unmistakably longitudinal except for cylinders where the ratio of

length of the cylinder to the outside diameter is less than 3 to 1.

At each end of the fracture, no more than two branches shall be allowed, provided that the shorter branch

at each end is less than 20 mm long.

o

The fracture shall not extend more than 90 around the circumference on either side of its main part.

The fracture shall not extend into those parts of the cylinder that have a thickness of more than 1,5 times

the maximum thickness measured halfway up the cylinder. For cylinders with convex bases, the fracture

shall not reach the centre of the cylinder base.

8.2.2.5 The tear shall not reveal any obvious defect in the metal.

8.3 Pressure cycling test

8.3.1 Principle

Gas cylinders are subjected to successive reversals with a non-corrosive liquid at an upper cyclic pressure

that is equal to the hydraulic test pressure (P ).

h

8.3.2 Procedure

The value of the lower cyclic pressure (P ) shall not exceed 10 % of the upper cyclic pressure, but shall have

lc

an absolute maximum of 25 bar.

Ensure that the frequency of reversals of pressure does not exceed 0,25 Hz (15 cycles/min), and check that

°

the temperature measured on the outside surface of the cylinder does not exceed 50 C. Check that the

cylinder actually experiences the maximum and minimum cyclic pressures

Ensure that the cylinders withstand 7 000 cycles without failure. Alternatively, reduce the upper cyclic

pressure to two-thirds of this test pressure. In this case, ensure that the cylinders withstand 60 000 cycles

without failure.

After the test, section the cylinder base and measure the thickness. The base thickness shall be no more than

15 % above the minimum base thickness prescribed in the design.

8.3.3 Expression of results

The gas cylinder shall be considered satisfactory if it attains the required number of cycles without developing

a leak.

8.4 Hydraulic test (proof test)

8.4.1 Procedure

8.4.2.1 Increase the water pressure in the cylinder at a controlled rate until the pressure P is reached.

h

Ensure that the water pressure does not exceed P by > 3 % of P or 10 bar, whichever is the lower.

h h

8.4.2.2 Establish that the water pressure P does not fall and that there are no leaks by maintaining the

h

water pressure in the cylinder at P for at least 30 s.

h

8.4.2.3 Inspect the cylinder for visible signs of permanent deformation.

8.4.2 Expression of results

The cylinder is deemed to have failed the test if there are visible signs of permanent deformation, and shall be

rejected.

Key

1 Test fluid reservoir

2 Tank for measurement of test fluid (The feed tank may be used as a measuring tank)

3 Pump

4 Pressure gauge

5 Pressure/volumetric expansion curve recorder

6 Vent or air release valve

7 Test well

Figure 5 — Typical hydraulic burst test installation

8.5 Check on the homogeneity of a batch

This test, which is carried out by the manufacturer on each cylinder, involves checking by means of a

hardness or electrical conductivity test that no error has been made in the choice of the original billets or in

carrying out the heat treatment.

9 Tests on every cylinder

9.1 Production testing

9.1.1 General

9.1.1.1 The manufacturer shall perform, or have performed in a testing laboratory, all the tests specified

in this standard. In addition, the manufacturer shall compile a report for every batch of cylinders produced that

states details or provides copies of:

— the new design approval certificate and design drawing;

— the cast ingot analysis certificates of the materials used for the manufacture of the cylinders;

— a means of identifying the cast of the material from which each cylinder was made;

— a statement of the processes utilized as specified in 4.2 and the relevant documentation relating to the

heat and mechanical treatment;

— the serial number of the cylinders;

— details of the thread checking method used and results thereof;

— a production document giving data concerning the batch of cylinders and stating that the requirements

covered by this standard have been met;

— details of the inspections ca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...