EN 12407:2007

(Main)Natural stone test methods - Petrographic examination

Natural stone test methods - Petrographic examination

This European Standard specifies methods for making technical petrographic descriptions of natural stone, except for roofing slates. Although chemical and physical methods of analysis are required for petrographic classification of some stone types, these methods will not be described in this standard For this product, the method for the petrographic examination is defined in EN 12326-2.

Prüfverfahren für Naturstein - Petrographische Prüfung

Méthodes d'essai pour pierres naturelles - Examen pétrographique

La présente norme européenne spécifie des méthodes permettant d’obtenir des descriptions pétrographiques techniques des pierres naturelles, à l’exception des ardoises pour toitures. La méthode d’examen pétrographique de ce dernier produit est définie dans l’EN 12326-2. Bien que la classification pétrographique de certains types de pierres se fasse par des méthodes d’analyse chimique et physique, ces méthodes ne sont pas décrites dans la présente norme.

Preskušanje naravnega kamna - Petrografska preiskava

General Information

- Status

- Withdrawn

- Publication Date

- 13-Mar-2007

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 246 - Natural stones

- Drafting Committee

- CEN/TC 246/WG 2 - Test methods

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 05-Jun-2019

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12407:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Natural stone test methods - Petrographic examination". This standard covers: This European Standard specifies methods for making technical petrographic descriptions of natural stone, except for roofing slates. Although chemical and physical methods of analysis are required for petrographic classification of some stone types, these methods will not be described in this standard For this product, the method for the petrographic examination is defined in EN 12326-2.

This European Standard specifies methods for making technical petrographic descriptions of natural stone, except for roofing slates. Although chemical and physical methods of analysis are required for petrographic classification of some stone types, these methods will not be described in this standard For this product, the method for the petrographic examination is defined in EN 12326-2.

EN 12407:2007 is classified under the following ICS (International Classification for Standards) categories: 73.020 - Mining and quarrying; 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12407:2007 has the following relationships with other standards: It is inter standard links to EN 12407:2000, EN 12407:2019, EN 12670:2019, EN 12440:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12407:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Natural stone test methods - Petrographic examinationPreskušanje naravnega kamna - Petrografska preiskavaMéthodes d'essai pour pierres naturelles - Examen pétrographiquePrüfverfahren für Naturstein - Petrographische PrüfungTa slovenski standard je istoveten z:EN 12407:2007SIST EN 12407:2007en;fr;de91.100.15Mineralni materiali in izdelkiMineral materials and products73.020Rudarstvo in kamnolomsko izkopavanjeMining and quarryingICS:SIST EN 12407:20021DGRPHãþDSLOVENSKI

STANDARDSIST EN 12407:200701-junij-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12407March 2007ICS 73.020; 91.100.15Supersedes EN 12407:2000

English VersionNatural stone test methods - Petrographic examinationMéthodes d'essai de pierres naturelles - ExamenpétrographiquePrüfverfahren für Naturstein - Petrographische PrüfungThis European Standard was approved by CEN on 21 January 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12407:2007: E

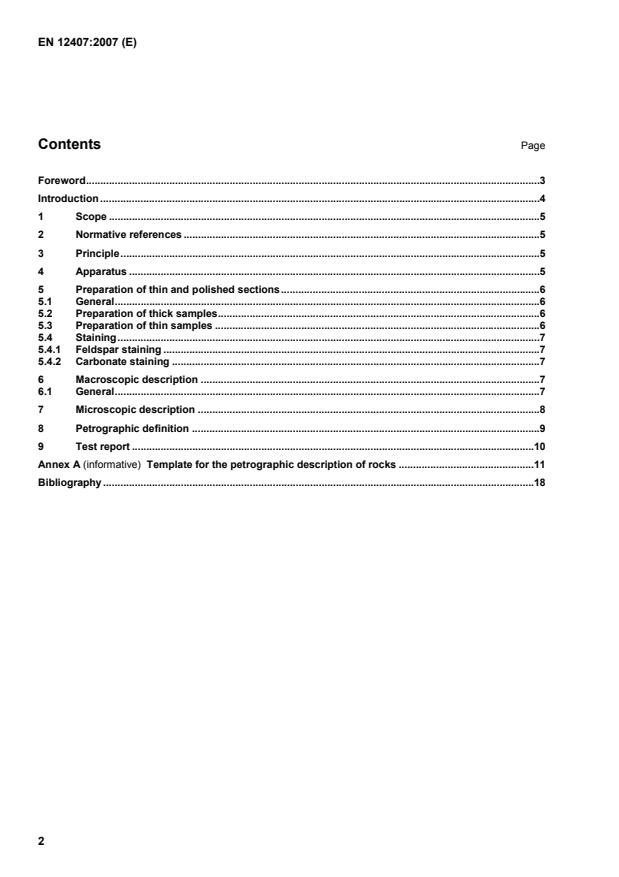

Template for the petrographic description of rocks.11 Bibliography.18

3 Foreword This document (EN 12407:2007) has been prepared by Technical Committee CEN/TC 246 “Natural stones”, the secretariat of which is held by UNI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by September 2007, and conflicting national standards shall be withdrawn at the latest by September 2007. This document supersedes EN 12407:2000. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

5 1 Scope This European Standard specifies methods for making technical petrographic descriptions of natural stone, except for roofing slates. For this product, the method for the petrographic examination is defined in EN 12326 –2. Although chemical and physical methods of analysis are required for petrographic classification of some stone types, these methods will not be described in this standard.

2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 12670, Natural stone – Terminology EN 12440, Natural stone – Denomination criteria 3 Principle First a macroscopic description of the sample is undertaken. The macroscopic description may involve a visual inspection aided by a hand lens or a stereoscopic microscope. Then one or more thin sections prepared from the sample are examined using a petrographic microscope in order to give a microscopic description of the sample; where appropriate an additional polished section shall be prepared.

4 Apparatus 4.1 Hand lens or stereoscopic microscope (if required) 4.2 Rock cutter with sliding guide, water cooled and with a vertical diamond disk 3 mm thick 4.3 Electrical heating plate 4.4 Glass plate 300 mm x 400 mm x 10 mm 4.5 Bristle brush 4.6 Multiple rectifier for thin slides for 16 slides, water cooled and semiautomatic stop. Thin sections can also be prepared by hand by a thin slides preparation expert 4.7 Electric solder 4.8 Multi Form mold 40 mm and plastic cup 4.9 Grinding and polishing machine 4.10 Petrographic microscope 4.11 Point counter or image analysis (if required)

A thin section is a portion of material mounted on a slide and mechanically reduced to a thin sheet measuring (0,030 ± 0,005) mm in thickness, and normally protected by a slide cover. For special purposes (observations with reflected light microscope for the determination of opaque minerals or microprobe analysis) polished sections or polished thin sections shall be prepared. Polished sections and polished thin sections have one side polished with alumina polishing paste (5 µm to 12 µm grade) and diamond paste (6 µm, 3 µm and 1 µm). The polished side remains uncovered. The section normally measures about 44 mm x 28 mm, but in the case of larger grain size stones, larger dimensions may be used (e.g. 75 mm x 50 mm) or several sections of normal dimensions can be prepared. If the rock is anisotropic it is necessary to prepare at least two sections with different orientation with respect to the anisotropy (e.g. parallel and perpendicular to bedding planes, cleavage planes). Preparation of thick samples The sample shall be sufficiently coherent so as not to disintegrate when cut. If the stone is brittle or fragile, it will be necessary to strengthen it by means of impregnation, preferably in a vacuum, with resins with an index of refraction approximately 1,54 (e.g. epoxy resins). Using the rock cutter several small blocks are cut of 44 mm x 32 mm and 3 to 4 mm thick. In case of porous samples pores are filled with Canada balsam, heated on the plate to approximately 100 °C and then cooled. Blocks are then successfully ground using diamond discs between 1 and 2 min depending on the type and hardness of the stone. Preparation of thin samples Blocks are cleaned placed on the plate and then treated with Canada balsam until caramel colour. After cooling and scratching the balsam off the surface, they are grinded dry in the glass plate with carborundum avoiding the appearance of pores. The blocks are then cleaned with the bristle brush to eliminate all carborundum particles. They are later heated in the plate with the adhesive mounting them on the supporting glass with thermoplastic adhesive. The samples are then mounted in the rectifying machine until sample thickness is 1 mm. Then they are subjected to another wet grinding process on the glass plates with the different carborundum sizes, checking the thickness every now and then controlling polarizing colours of one reference mineral existing in the sample, ending the process once the stipulated colours have been achieved (first order white and grey for quartz and feldspar for example). Thin slides are then washed with water and dried with a cloth. Samples are then cut by the edges with a cutter up until the measures of the cover glass (generally 24 mm x 32 mm). Then a volume of balsam of approximately 0,5 ml is poured over the samples and heated on the plate to 60 °C, exerting pressure on the cover plate to favour a thorough cover of the balsam over the samp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...