EN 17414-1:2020

(Main)District cooling pipes - Factory made flexible pipe systems - Part 1: Classification, general requirements and test methods

District cooling pipes - Factory made flexible pipe systems - Part 1: Classification, general requirements and test methods

This document specifies requirements and test methods for factory made thermally insulated flexible pipe-in-pipe assemblies for directly buried district cooling distribution systems, comprising a service pipe and a casing of polyethylene. The pipe assembly can also include the following additional elements: measuring wires, spacers and diffusion barriers.

This document is intended to be used in conjunction with EN 17414‑2 or EN 17414‑3.

This document applies only to insulated pipe assemblies, for continuous operation with water at various temperatures (1 to 30) °C and a maximum operation pressure of 25 bar dependent on material specified.

The design is based on an expected service life with continuous operation of a minimum 50 years. For pipe systems with plastic service pipes, the respective temperature profiles are defined in EN 17414‑2 and EN 17414‑3.

NOTE For the transport of other liquids, for example potable water, additional requirements could be applicable.

Fernkälterohre - Werkmäßig gefertigte flexible Rohrsysteme - Teil 1: Klassifikation, allgemeine Anforderungen und Prüfung

Dieses Dokument legt Anforderungen und Prüfverfahren für werkmäßig gefertigte, wärmegedämmte flexible Rohr-in-Rohr-Systeme für direkt erdverlegte Fernkältenetzwerke, bestehend aus einem Mediumrohr und einem Polyethylenmantel, fest. Das Rohrsystem kann darüber hinaus die folgenden zusätzlichen Bauteile umfassen: Messdrähte, Abstandshalter und Diffusionsbarrieren.

Dieses Dokument ist für die Verwendung im Zusammenhang mit EN 17414 2 oder EN 17414 3 vorgesehen.

Dieses Dokument ist nur anzuwenden für gedämmte Rohrsysteme, für den Dauerbetrieb mit Wasser bei verschiedenen Temperaturen 1 °C bis 30 °C und je nach Werkstoff einem Betriebsdruck von höchstens 25 bar.

Die Auslegung basiert auf einer erwarteten Lebensdauer von mindestens 50 Jahren bei Dauerbetrieb. Für Rohrsysteme mit Kunststoff-Mediumrohren sind die jeweiligen Temperaturprofile in EN 17414 2 und EN 17414 3 festgelegt.

ANMERKUNG Für den Transport anderer Flüssigkeiten, z. B. Trinkwasser, könnten zusätzliche Anforderungen gelten.

Réseaux d’eau glacée - Systèmes de tuyaux flexibles manufacturés - Partie 1 : Classification, prescriptions générales et méthodes d'essai

Le présent document spécifie les exigences et méthodes d’essai pour les tuyaux à double enveloppe flexibles isolés thermiquement manufacturés pour réseaux de distribution d’eau glacée enterrés directement, comprenant un tube de service et un tube de protection en polyéthylène. Le tuyau préisolé peut également comprendre les éléments supplémentaires suivants : les câbles de mesure, les entretoises et les barrières anti diffusion.

Le présent document est destiné à être utilisé conjointement avec l’EN 17414-2 ou l’EN 17414-3.

Le présent document s’applique uniquement aux tuyaux préisolés conçus pour un fonctionnement continu avec de l’eau à diverses températures (allant de 1 °C à 30 °C) et à une pression de service maximale de 25 bar dépendant du matériau spécifié.

La conception est basée sur une durée utile prévue en fonctionnement continu d’au moins 50 ans. Pour les systèmes de tuyaux avec des tubes de service en plastique, les profils de température respectifs sont définis dans l’EN 17414-2 et l’EN 17414-3.

NOTE Pour le transport d’autres liquides, par exemple de l’eau potable, des prescriptions supplémentaires peuvent s’appliquer.

Cevi za daljinsko hlajenje - Tovarniško izdelani gibki cevni sistemi - 1. del: Razvrstitev, splošne zahteve in preskusne metode

General Information

- Status

- Published

- Publication Date

- 28-Jul-2020

- Withdrawal Date

- 30-Jan-2021

- Technical Committee

- CEN/TC 107 - Pre-fabricated district heating pipe systems

- Current Stage

- 9020 - Submission to 2 Year Review Enquiry - Review Enquiry

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 845:2009 - Cellular plastics and rubbers - Determination of apparent density (ISO 845:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 17414-1:2020 (CEN) specifies the classification, general requirements and test methods for factory made, thermally insulated flexible pipe-in-pipe assemblies used in directly buried district cooling distribution systems. The standard covers assemblies comprised of a service pipe and a polyethylene casing and may include measuring wires, spacers and diffusion barriers. It applies to insulated pipe assemblies for continuous operation with water at temperatures from 1 °C to 30 °C and a maximum operating pressure of 25 bar, with a design life of minimum 50 years. EN 17414-1:2020 is intended to be used together with EN 17414‑2 or EN 17414‑3.

Key topics and technical requirements

- Classification of factory made flexible pipe systems (single, twin, bonded/non-bonded in accompanying parts).

- Thermal insulation properties: test procedures for thermal conductivity and radial thermal resistance (annexed test method).

- Mechanical behaviour: bending properties, bending radius requirements and flexibility testing.

- Resistance to external load: compressive creep, ring stiffness and resistance against soil and installation loads.

- Casing requirements: polyethylene casing characteristics and dimensional tolerances.

- Surveillance systems: provisions for monitoring (e.g., measuring wires) and requirements for marking and manufacturer’s information.

- Test methods: detailed tests including bending tests, compressive creep, thermal conductivity measurements and heat-flow calculations (normative and informative annexes).

- Marking & documentation: minimum marking information and manufacturer’s technical data to support installation and specification.

Applications and practical value

- Standardizes design, testing and quality assurance for buried district cooling pipes, enabling consistent thermal performance and structural reliability.

- Helps manufacturers validate product performance against recognized test methods, supporting product certification and market comparability.

- Supports system designers and consulting engineers in selecting insulated pipe assemblies that meet long-term thermal and mechanical performance criteria.

- Aids procurement teams and infrastructure owners in specifying compliant pipe systems for urban cooling networks, campus cooling, data center chilled-water loops and other large-scale chilled-water distribution projects.

Who should use this standard

- Pipe and insulation manufacturers

- District cooling system designers and civil/mechanical engineers

- Testing laboratories and product certifiers

- Project specifiers, procurement managers and utility owners

- Contractors installing directly buried cooling pipe systems

Related standards

- EN 17414-2 / EN 17414-3 (system-specific requirements for bonded/non-bonded plastic service pipes)

- EN 17248 (terms and definitions)

- Other CEN/TC 107 documents on district heating/cooling pipe systems and surveillance methods

Keywords: EN 17414-1:2020, district cooling pipes, factory made flexible pipe systems, thermal insulation, pipe-in-pipe, test methods, buried district cooling, design life.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 17414-1:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "District cooling pipes - Factory made flexible pipe systems - Part 1: Classification, general requirements and test methods". This standard covers: This document specifies requirements and test methods for factory made thermally insulated flexible pipe-in-pipe assemblies for directly buried district cooling distribution systems, comprising a service pipe and a casing of polyethylene. The pipe assembly can also include the following additional elements: measuring wires, spacers and diffusion barriers. This document is intended to be used in conjunction with EN 17414‑2 or EN 17414‑3. This document applies only to insulated pipe assemblies, for continuous operation with water at various temperatures (1 to 30) °C and a maximum operation pressure of 25 bar dependent on material specified. The design is based on an expected service life with continuous operation of a minimum 50 years. For pipe systems with plastic service pipes, the respective temperature profiles are defined in EN 17414‑2 and EN 17414‑3. NOTE For the transport of other liquids, for example potable water, additional requirements could be applicable.

This document specifies requirements and test methods for factory made thermally insulated flexible pipe-in-pipe assemblies for directly buried district cooling distribution systems, comprising a service pipe and a casing of polyethylene. The pipe assembly can also include the following additional elements: measuring wires, spacers and diffusion barriers. This document is intended to be used in conjunction with EN 17414‑2 or EN 17414‑3. This document applies only to insulated pipe assemblies, for continuous operation with water at various temperatures (1 to 30) °C and a maximum operation pressure of 25 bar dependent on material specified. The design is based on an expected service life with continuous operation of a minimum 50 years. For pipe systems with plastic service pipes, the respective temperature profiles are defined in EN 17414‑2 and EN 17414‑3. NOTE For the transport of other liquids, for example potable water, additional requirements could be applicable.

EN 17414-1:2020 is classified under the following ICS (International Classification for Standards) categories: 23.040.99 - Other pipeline components. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17414-1:2020 has the following relationships with other standards: It is inter standard links to EN 60811-406:2012, ISO 16770:2019, EN ISO 16534:2020, EN ISO 3127:2017, EN ISO 29768:2022, EN 17415-1:2020, EN ISO 11357-6:2025, EN 17248:2019, EN ISO 845:2009, EN 1605:2013, EN 13941-1:2019+A1:2021, EN ISO 9969:2016, EN 15534-1:2014/prA1, EN 14419:2019, EN ISO 16871:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17414-1:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2020

Cevi za daljinsko hlajenje - Tovarniško izdelani gibki cevni sistemi - 1. del:

Razvrstitev, splošne zahteve in preskusne metode

District cooling pipes - Factory made flexible pipe systems - Part 1: Classification,

general requirements and test methods

Fernkühlungsrohre - Werkmäßig gedämmte flexible Rohrsysteme - Teil 1: Klassifikation,

allgemeine Anforderungen und Prüfung

Réseaux d’eau glacée - Systèmes de tuyaux flexibles manufacturés - Partie 1 :

Classification, exigences générales et méthodes d’essai

Ta slovenski standard je istoveten z: EN 17414-1:2020

ICS:

23.040.99 Drugi sestavni deli za Other pipeline components

cevovode

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17414-1

EUROPEAN STANDARD

NORME EUROPÉENNE

July 2020

EUROPÄISCHE NORM

ICS 23.040.99

English Version

District cooling pipes - Factory made flexible pipe systems

- Part 1: Classification, general requirements and test

methods

Réseaux d'eau glacée - Systèmes de tuyaux flexibles Fernkälterohre - Werkmäßig gefertigte flexible

manufacturés - Partie 1 : Classification, prescriptions Rohrsysteme - Teil 1: Klassifikation, allgemeine

générales et méthodes d'essai Anforderungen und Prüfung

This European Standard was approved by CEN on 22 June 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17414-1:2020 E

worldwide for CEN national Members.

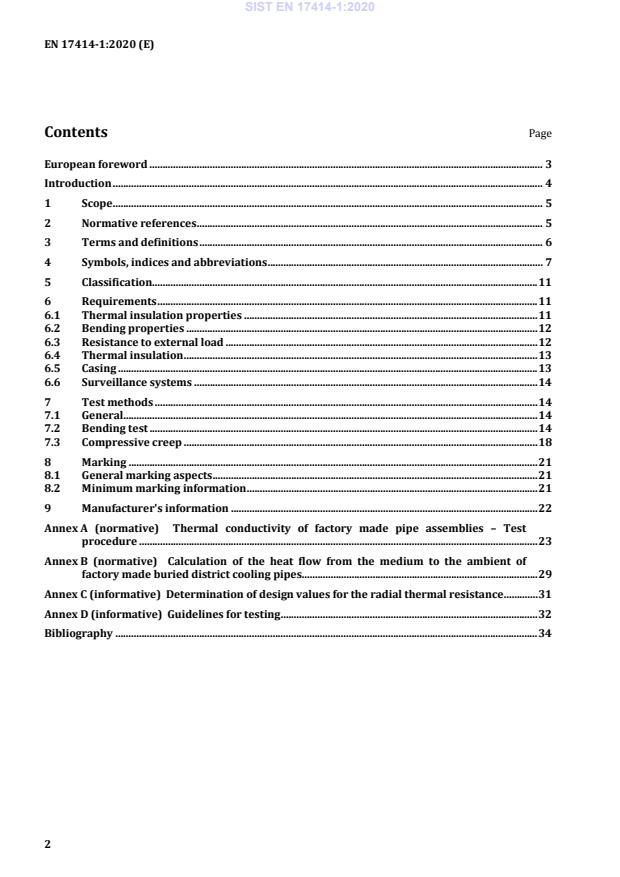

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Symbols, indices and abbreviations . 7

5 Classification. 11

6 Requirements . 11

6.1 Thermal insulation properties . 11

6.2 Bending properties . 12

6.3 Resistance to external load . 12

6.4 Thermal insulation . 13

6.5 Casing . 13

6.6 Surveillance systems . 14

7 Test methods . 14

7.1 General. 14

7.2 Bending test . 14

7.3 Compressive creep . 18

8 Marking . 21

8.1 General marking aspects . 21

8.2 Minimum marking information . 21

9 Manufacturer's information . 22

Annex A (normative) Thermal conductivity of factory made pipe assemblies – Test

procedure . 23

Annex B (normative) Calculation of the heat flow from the medium to the ambient of

factory made buried district cooling pipes. 29

Annex C (informative) Determination of design values for the radial thermal resistance . 31

Annex D (informative) Guidelines for testing . 32

Bibliography . 34

European foreword

This document (EN 17414-1:2020) has been prepared by Technical Committee CEN/TC 107

“Prefabricated district heating and district cooling pipe system”, the secretariat of which is held by DS.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by January 2021, and conflicting national standards shall

be withdrawn at the latest by January 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

Factory made flexible pipe systems for directly buried district cooling networks are of common

technical usage. In order to ensure quality including product-related service life, to ensure safety in use,

economical energy usage and to facilitate comparability in the market, CEN/TC 107 decided to set up

standards for these products.

This document is one of a series of standards which form several parts of EN 17414, District cooling

pipes – Factory made flexible pipe systems:

— Part 1: Classification, general requirements and test methods (this document);

— Part 2: Bonded system with plastic service pipes - Requirements and test methods;

— Part 3: Non bonded system with plastic service pipes - Requirements and test methods.

The other standards from CEN/TC 107 covering this subject are:

— EN 17415-1, District cooling pipes - Bonded single pipe systems for directly buried cold water

networks - Part 1: Factory made pipe assembly of steel or plastic service pipe, polyurethane thermal

insulation and a casing of polyethylene;

— EN 17415-2, District cooling pipes – Bonded single pipe systems for directly buried cold water

networks Part 2: Factory made fitting assemblies of steel or plastic service pipe, polyurethane thermal

insulation and a casing of polyethylene ;

— EN 17415-3, District cooling pipes – Bonded single pipe systems for directly buried cold water

networks Part 3: Factory made steel valve assembly for steel or plastic service pipe, polyurethane

thermal insulation and a casing of polyethylene ;

— EN ZZZZZ-1, District cooling pipes – Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried cold water networks – Part 1: Design ;

— EN ZZZZZ-2, District cooling pipes – Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried cold water networks – Part 2: Installation ;

— EN 489-1, District heating pipes - Bonded single and twin pipe systems for buried hot water networks

- Part 1: Joint casing assemblies and thermal insulation for hot water networks in accordance with

EN 13941-1;

— EN 14419, District heating pipes - Bonded single and twin pipe systems for buried hot water networks

- Surveillance systems;

Under preparation.

1 Scope

This document specifies requirements and test methods for factory made thermally insulated flexible

pipe-in-pipe assemblies for directly buried district cooling distribution systems, comprising a service

pipe and a casing of polyethylene. The pipe assembly can also include the following additional elements:

measuring wires, spacers and diffusion barriers.

This document is intended to be used in conjunction with EN 17414-2 or EN 17414-3.

This document applies only to insulated pipe assemblies, for continuous operation with water at

various temperatures (1 to 30) °C and a maximum operation pressure of 25 bar dependent on material

specified.

The design is based on an expected service life with continuous operation of a minimum 50 years. For

pipe systems with plastic service pipes, the respective temperature profiles are defined in EN 17414-2

and EN 17414-3.

NOTE For the transport of other liquids, for example potable water, additional requirements could be

applicable.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1605, Thermal insulating products for building applications - Determination of deformation under

specified compressive load and temperature conditions

EN 1606, Thermal insulating products for building applications - Determination of compressive creep

EN 12085, Thermal insulating products for building applications - Determination of linear dimensions of

test specimens

EN 13941-1, District heating pipes - Design and installation of thermal insulated bonded single and twin

pipe systems for directly buried hot water networks - Part 1: Design

EN 14419, District heating pipes - Bonded single and twin pipe systems for buried hot water networks -

Surveillance systems

EN 17248, District heating and district cooling pipe systems - Terms and definitions

EN 60811-406:2012, Electric and optical fibre cables - Test methods for non-metallic materials - Part 406:

Miscellaneous tests - Resistance to stress cracking of polyethylene and polypropylene compounds

EN 17415-1:2020, District cooling pipes - Bonded single pipe systems for directly buried cold water

networks - Part 1: Factory made pipe assembly of steel or plastic service pipe, polyurethane thermal

insulation and a casing of polyethylene

EN ISO 845, Cellular plastics and rubbers - Determination of apparent density (ISO 845)

EN ISO 3127, Thermoplastics pipes - Determination of resistance to external blows - Round-the-clock

method (ISO 3127)

EN ISO 9967, Thermoplastics pipes - Determination of creep ratio (ISO 9967)

EN ISO 9969, Thermoplastics pipes - Determination of ring stiffness (ISO 9969)

EN ISO 11357-6, Plastics - Differential scanning calorimetry (DSC) - Part 6: Determination of oxidation

induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) (ISO 11357-6)

EN ISO 16871, Plastics piping and ducting systems - Plastics pipes and fittings - Method for exposure to

direct (natural) weathering (ISO 16871)

ISO 6964, Polyolefin pipes and fittings — Determination of carbon black content by calcination and

pyrolysis — Test method

ISO 16770, Plastics — Determination of environmental stress cracking (ESC) of polyethylene — Full-notch

creep test (FNCT)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 17248 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

compressive creep

slow progressive strain under the influence of stresses caused by compressive forces

3.2

flexibility

ability to withstand the flexibility test

3.3

insulation layer

layer which provides the designated thermal characteristics of the pipe assembly

3.4

insulation material

material which reduces the heat loss

3.5

operating pressure

pressure at which the cold water network is designed to operate continuously

3.6

pipe assembly

assembled product, consisting of at least one service pipe, insulating material and casing

3.7

single pipe system

SPS

pipe system with two single service pipes (one supply pipe and one return pipe)

3.8

standard dimension ratio

SDR

numerical designation of a pipe series, which is a convenient round number, approximately equal to the

dimension ratio of the nominal outside diameter and the minimum wall thickness

3.9

twin pipe system

TPS

pipe assembly with two service pipes in one casing

4 Symbols, indices and abbreviations

For the purposes of this document, symbols, indices and abbreviations given in Tables 1, 2 and 3 apply.

Table 1 — Symbols, definitions and dimensions

Symbol Description Unit

A projected area of the service pipe (length × width) mm

d inner diameter of the service pipe mm

D actual diameter of casing, measured with circumference tape mm

D deviation of service pipe %

e

D minimum casing diameter, measured with calliper mm

min

D maximum casing diameter, measured with calliper mm

max

d inner diameter of the service pipe at the peak of a corrugation mm

1,p

d inner diameter of the service pipe at the trough of a corrugation mm

1,t

d outer diameter of the service pipe mm

d outer diameter of the service pipe at the peak of a corrugation mm

2,p

d outer diameter of the service pipe at the trough of a corrugation mm

2,t

d inner diameter of the casing mm

d inner diameter of the casing at the peak of a corrugation mm

3,p

d inner diameter of the casing at the trough of a corrugation mm

3,t

d outer diameter of the casing mm

d4,p outer diameter of the casing at the peak of a corrugation mm

d outer diameter of the casing at the trough of a corrugation mm

4,t

F force N

f ageing factor /

a

Symbol Description Unit

f correction factor for differences between calculated and measured thermal /

cor

conductivities

or

correction factor for existing open splits, thermal bridges or change of the factor

for shape caused by influence of laying in the ground and the relevant factors set

up by EN ISO 23993

Fexp force resulting from heat expansion N

f moisture factor /

m

F force resulting from weight in N N

weight

g acceleration due to gravity m/s

H soil cover above pipe m

L length of the test specimen m

M mass of the service pipe including the water inside kg

O ovality %

P area related load on the insulation resulting from heat expansion of the service MPa

exp

pipe

Ptest area related test load MPa

P area related load on the cross section of the test specimen of the insulation MPa

weight

material

q heat flow rate W/m

q radial heat flow rate for buried single pipe system in the supply pipe W/m

f

q radial heat flow rate for buried single pipe system in the supply and return pipe W/m

f+r

q radial heat flow rate for buried single pipe system in the return pipe W/m

r

Q heat flow W

r bending radius in the axis of the pipe mm

R radial thermal resistance m·K/W

R thermal resistance from earth surface to ambient air m ·K/W

R design value for the radial resistance m·K/W

design

R radial thermal resistance of the supply pipe m·K/W

f

R radial thermal resistance of the return pipe m·K/W

r

R radial thermal resistance of the soil m·K/W

soil

s thickness mm

s thickness of insulation, mean value of 4 measurements at 3,6,9 and 12 o’clock mm

i

position at test piece end

s maximum thickness of the insulation mm

iB

s thickness of test piece after load testing and temperature testing mm

STB

𝜏𝜏 axial shear stress MPa

𝑎𝑎x

Symbol Description Unit

t thickness of the casing mm

U coefficient of heat flow W/(m·K)

U coefficient of heat flow for buried single pipe system in the supply pipe W/(m·K)

f

U coefficient of heat flow for buried single pipe system in the return pipe W/(m·K)

r

Z depth of burial (measured to centreline of pipe assembly) m

Z corrected value of depth Z mm

c

λ thermal conductivity at 15 °C W/(m·K)

λ thermal conductivity of the casing W/(m·K)

C

λ calculation value of the thermal conductivity of the insulation material W/(m·K)

design

λ thermal conductivity of the insulation W/(m·K)

I

λ thermal conductivity of the soil W/(m·K)

soil

λ thermal conductivity of the service pipe W/(m·K)

S

ϑ temperature at the inner diameter of the service pipe K

ϑ temperature at the inner diameter of the service supply pipe K

1,f

ϑ temperature at the inner diameter of the service return pipe K

1,r

ϑ temperature at the outer diameter of the service pipe K

ϑ temperature at the inner diameter of the casing K

ϑ temperature at the outer diameter of the casing K

ϑ ambient temperature K

amb

ϑ supply temperature K

f

ϑ mean temperature of the insulation K

i, mean

ϑ return temperature K

r

Σ compression of the thermal insulation %

Table 2 — Indices

Symbol Definition

0 thermal transmittance (from earth surface to ambient air)

1 position at the inner diameter of the service pipe

2 position at the outer diameter of the service pipe

3 position at the inner diameter of the casing

4 position at the outer diameter of the casing

15 at 15 °C

a ageing

amb ambient

C casing

cor corrective

design design

exp expansion

f flow (supply)

I insulation

m moisture

mean mean

min minutes

p peak of corrugation

r return

s service pipe

soil soil

STB stability

t trough of a corrugation

test test

weight weight

x placeholder for 1, 2, 3 or 4

Table 3 — Abbreviations

Abbreviation Name

PB-1 polybutene

PE 100 polyethylene classified to MRS 10

PE 80 polyethylene classified to MRS 8

PE-HD high density polyethylene

PE-MD medium density polyethylene

PE-LD low density polyethylene

PE-LLD linear low density polyethylene

PE-RT polyethylene of raised temperature resistance

PE-X cross linked polyethylene

PP-B block copolymer polypropylene

PP-H homopolymer polypropylene

PP-R random copolymer polypropylene

polypropylene random copolymer with modified

PP-RCT

crystallinity and temperature resistance

5 Classification

Table 4 defines the field of application for the different designs of pipe assembly.

Table 4 — Classification system

Part of Service pipe Pipe assembly Field of application

EN 17414 material design

Operating Design

pressure temperature

bar °C

2 plastics bonded 6, 10, 16, 20 1 to 30

and 25

3 plastics non bonded 6, 10, 16, 20 1 to 30

and 25

For operating pressures as well as temperature and time profiles, see part 2 or 3, as applicable.

6 Requirements

6.1 Thermal insulation properties

The manufacturer shall submit values for the heat flow of buried pipe assemblies for all pipe

dimensions rounded to 0,1 W/m. For single pipe assemblies the values shall be calculated in accordance

with Annex B. For twin pipe assemblies the values shall be calculated in accordance with EN 13941-1.

NOTE 1 Annex A specifies how to determine thermal conductivity.

NOTE 2 A heat flow from a district cooling service pipe to the surrounding soil is not seen as a heat loss but can

be seen as an advantage for the district cooling system. On the other hand, a heat flow into a district cooling

service pipe (normally into the supply pipe) from the surrounding soil has a negative impact on the district

cooling system.

NOTE 3 When making heat flow calculations for twin pipe systems in accordance with EN 13941-1, it is

important to specify the corrected depth Zc in millimetres to get dimensionless numbers of Zc/Di, C/Zc, etc.

6.2 Bending properties

6.2.1 Flexibility

The flexibility of the pipe assembly is verified by testing at the minimum bending radius. The

manufacturer of the pipe assembly shall declare the minimum installation bending radii for all

dimensions produced, related to the central axis of the pipe assembly.

The minimum declared installation bending radius of the pipe assembly according to this document

shall not exceed thirty times the outer diameter of the casing.

When bending to the minimum radius, the service pipe and the casing of the pipe assembly shall not

break.

6.2.2 Ovality

The ovality of the casing shall not exceed 30 % when tested according to 7.2.2.

6.2.3 Cracks

Cracks in the insulation layer shall not exceed a width of 5 mm when tested according 7.2.3.

NOTE 1 With a crack size below 5 mm, the number of cracks is not relevant for the integrity of the pipe system,

because the temperature on the casing will not be influenced.

NOTE 2 The lower the SDR of the service pipe the higher the stress in the insulation.

6.2.4 Centre line deviation of service pipe

The deviation of the service pipe to the centre line shall not exceed 20 % when tested in accordance

with 7.2.4.

6.3 Resistance to external load

6.3.1 Ring stiffness

The ring stiffness shall be tested according to EN ISO 9969 where the diameter of the test piece is the

inner diameter of the casing determined at the cross section of the pipe assembly. The ring stiffness of

the pipe assembly shall be at least 4 kN/m and the ring stiffness divided by the creep ratio according to

EN ISO 9967 shall be at least 0,8.

6.3.2 Impact resistance

The impact resistance shall be tested according to EN ISO 3127. The casing of pipe assemblies and joint

casings shall show no cracks when exposed to an impact of 4 J.

NOTE The deformation of buried pipes with and without traffic load can be calculated according to

EN 1295-1.

6.4 Thermal insulation

6.4.1 Compressive creep

The compressive creep shall be tested in accordance with 7.3. The thermal insulation shall not be

compressed by more than 10 %.

6.4.2 Water absorption at elevated temperatures

The water absorption shall not exceed the limit defined in Table 5 for the test option selected.

For test option A, the water absorption shall be tested in accordance with the test procedure in

EN 17415-1.

Table 5 — Test option for water absorption

Test option Test temperature Water absorption (by volume)

°C %

A 100 10

B 80 1

6.4.3 Density of thermal insulation

6.4.3.1 Bonded System

The manufacturer shall declare a reference density in kg/m for the pipe assemblies produced. The

reference density may differ between different dimensions. The production shall follow this declared

density with a tolerance of ± 15 %.

The measurement of the density shall be done in accordance with EN 17415-1.

6.4.3.2 Non bonded system

The manufacturer shall declare a reference density in kg/m for the pipe assemblies produced. The

reference density could differ between different dimensions. The production shall follow this declared

density with a tolerance of ± 15 %.

The measurement of the density shall be done in accordance with EN ISO 845.

6.5 Casing

6.5.1 UV stability

Casings shall be made of a material containing carbon black to the amount of (2,0 to 2,5) % by mass.

The carbon black content shall be determined in accordance with ISO 6964.

Alternatively, after an exposure of the pipe assembly to an energy of ≥ 3,5 GJ/m2 in accordance with

EN ISO 16871, the requirements of Clauses 6.2 and 6.3 shall be met.

NOTE The UV stability requirement is for storage purposes, only.

6.5.2 Thermal stability of the material

The oxidation induction time of the material to be used for the casing shall be at least 20 minutes at

210 °C when tested in accordance with EN ISO 11357-6.

6.5.3 Stress crack resistance of the material

The time for the stress crack resistance of PE-HD materials used for the casing shall be at least

100 hours when tested at 4 MPa and 80 °C in accordance to ISO 16770.

NOTE The test can be carried out on specimens prepared by compression moulding, injection moulding or

extrusion from the same raw material as being used for the production of the casing.

PE-LD and PE-LLD materials used for the casing shall not exceed a failure rate F20 when tested for

1 000 hours in accordance with EN 60811-406:2012, procedure B.

6.5.4 Use of rework material

If rework material is used, only clean, rework material generated from the manufacturer's own

production that does not include any PU insulation material, shall be used.

6.6 Surveillance systems

If measuring elements for surveillance systems are being installed in flexible pipe systems, all elements

installed and the total installation in pipe systems shall comply with the requirements of EN 14419.

7 Test methods

7.1 General

Guidelines for testing frequencies and responsibilities are given in Annex D.

7.2 Bending test

7.2.1 Flexibility

The test shall be performed on a straight length of pipe assembly, taken directly after the production.

The pipe assembly shall be conditioned for 24 h at room temperature.

After conditioning, the pipe assembly shall be fixed onto a bending rig according to Figure 1. In addition,

twin pipes shall be bent in a way that both service pipes will

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...