EN 1088:1995+A2:2008

(Main)Safety of machinery - Interlocking devices associated with guards - Principles for design and selection

Safety of machinery - Interlocking devices associated with guards - Principles for design and selection

This standard specifies principles for the design and selection - independent of the nature of the energy source - of interlocking devices associated with guards (as defined in 3.23.1 'interlocking device [interlock]', 3.22.4 'interlocking guard' and 3.22.5 'interlocking guard with guard locking' of EN 292-1). It also provides requirements specifically intended for electrical interlocking devices (see clause 6). This standard covers the parts of guards which actuate interlocking devices. Requirements for guards are given in prEN 953. The processing of the signal from the interlocking device to stop and immobilize the machine is dealt with in prEN 954-1.

Sicherheit von Maschinen - Verriegelungseinrichtungen in Verbindung mit trennenden Schutzeinrichtungen - Leitsätze für Gestaltung und Auswahl

Diese Norm legt Prinzipien für Gestaltung und Auswahl von Verriegelungseinrichtungen in Verbindung mit trennenden Schutzeinrichtungen fest — unabhängig von der Energieart — (wie in EN 292-1:1991, 3.23.1 "Verriegelungseinrichtung [Verriegelung]"; EN 292-1:1991, 3.22.4 "verriegelte trennende Schutzeinrichtung" und EN 292-1:1991, 3.22.5 "verriegelte trennende Schutzeinrichtung mit Zuhaltung" festgelegt).

Weiterhin enthält sie Anforderungen speziell für elektrische Verriegelungseinrichtungen (siehe Abschnitt 6).

Diese Norm umfasst die Teile einer trennenden Schutzeinrichtung, die Verriegelungseinrichtungen betätigen. Anforderungen für trennende Schutzeinrichtungen sind in prEN 953 aufgeführt. Die Verarbeitung des von der Verriegelungseinrichtung ausgehenden Signals zum Anhalten und Stillsetzen der Maschine wird in prEN 954-1 behandelt.

Sécurité des machines - Dispositifs de verrouillage associés à des protecteurs - Principes de conception et de choix

La présente norme spécifie des principes de conception et de choix — indépendamment de la nature de la source d’énergie — des dispositifs de verrouillage associés à des protecteurs (tels que définis en 3.23.1 «dispositif de verrouillage», 3.22.4 «protecteur avec dispositif de verrouillage» et 3.22.5 «protecteur avec dispositif d’interverrouillage» de l’EN 292-1:1991).

Elle fournit également des prescriptions technologiques spécifiquement destinées aux dispositifs de verrouillage électrique (voir l’Article 6).

Cette norme couvre les parties des protecteurs qui actionnent les dispositifs de verrouillage. Les prescriptions relatives aux protecteurs sont données dans le prEN 953. Le traitement du signal issu du dispositif de verrouillage et entraînant l’arrêt et l’immobilisation de la machine est pris en considération dans le prEN 954 1.

Varnost strojev - Zaporne naprave, povezane z varovali - Načela za načrtovanje in izbiro

General Information

- Status

- Withdrawn

- Publication Date

- 08-Jul-2008

- Withdrawal Date

- 01-Oct-2013

- Technical Committee

- CEN/TC 114 - Safety of machinery

- Drafting Committee

- CEN/TC 114/WG 10 - Interlocking devices with and without guard locking

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Oct-2013

- Completion Date

- 02-Oct-2013

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 22, C 22, C 22, C 22, C 22, C 22, C 22, C 22, C, OJ Date: 28-Jan-2009

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Oct-2013

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1088:1995+A2:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Interlocking devices associated with guards - Principles for design and selection". This standard covers: This standard specifies principles for the design and selection - independent of the nature of the energy source - of interlocking devices associated with guards (as defined in 3.23.1 'interlocking device [interlock]', 3.22.4 'interlocking guard' and 3.22.5 'interlocking guard with guard locking' of EN 292-1). It also provides requirements specifically intended for electrical interlocking devices (see clause 6). This standard covers the parts of guards which actuate interlocking devices. Requirements for guards are given in prEN 953. The processing of the signal from the interlocking device to stop and immobilize the machine is dealt with in prEN 954-1.

This standard specifies principles for the design and selection - independent of the nature of the energy source - of interlocking devices associated with guards (as defined in 3.23.1 'interlocking device [interlock]', 3.22.4 'interlocking guard' and 3.22.5 'interlocking guard with guard locking' of EN 292-1). It also provides requirements specifically intended for electrical interlocking devices (see clause 6). This standard covers the parts of guards which actuate interlocking devices. Requirements for guards are given in prEN 953. The processing of the signal from the interlocking device to stop and immobilize the machine is dealt with in prEN 954-1.

EN 1088:1995+A2:2008 is classified under the following ICS (International Classification for Standards) categories: 13.110 - Safety of machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1088:1995+A2:2008 has the following relationships with other standards: It is inter standard links to EN 1088:1995/A1:2007, EN 1088:1995, EN ISO 14119:2013, EN 60204-1:1992, EN 60947-5-1:1991, EN ISO 14120:2015, EN ISO 12100:2010, EN 294:1992, EN ISO 14118:2018, EN 292-1:1991, EN 292-2:1991, EN ISO 13855:2024, EN ISO 13849-1:2023, EN 940:2009+A1:2012, EN 848-2:2007+A2:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1088:1995+A2:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1088:1995+A2:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.L]ELURSicherheit von Maschinen - Verriegelungseinrichtungen in Verbindung mit trennenden Schutzeinrichtungen - Leitsätze für Gestaltung und AuswahlSécurité des machines - Dispositifs de verrouillage associés à des protecteurs - Principes de conception et de choixSafety of machinery - Interlocking devices associated with guards - Principles for design and selection13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1088:1995+A2:2008SIST EN 1088:2000+A2:2008en,fr,de01-december-2008SIST EN 1088:2000+A2:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1088:1995+A2

July 2008 ICS 13.110 Supersedes EN 1088:1995 English Version

Safety of machinery - Interlocking devices associated with guards - Principles for design and selection

Sécurité des machines - Dispositifs de verrouillage associés à des protecteurs - Principes de conception et de choix

Sicherheit von Maschinen - Verriegelungseinrichtungen in Verbindung mit trennenden Schutzeinrichtungen -Leitsätze für Gestaltung und Auswahl This European Standard was approved by CEN on 13 November 1995 and includes Amendment 1 approved by CEN on 8 March 2007and Amendement 2 approved by CEN on 6 June 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1088:1995+A2:2008: ESIST EN 1088:2000+A2:2008

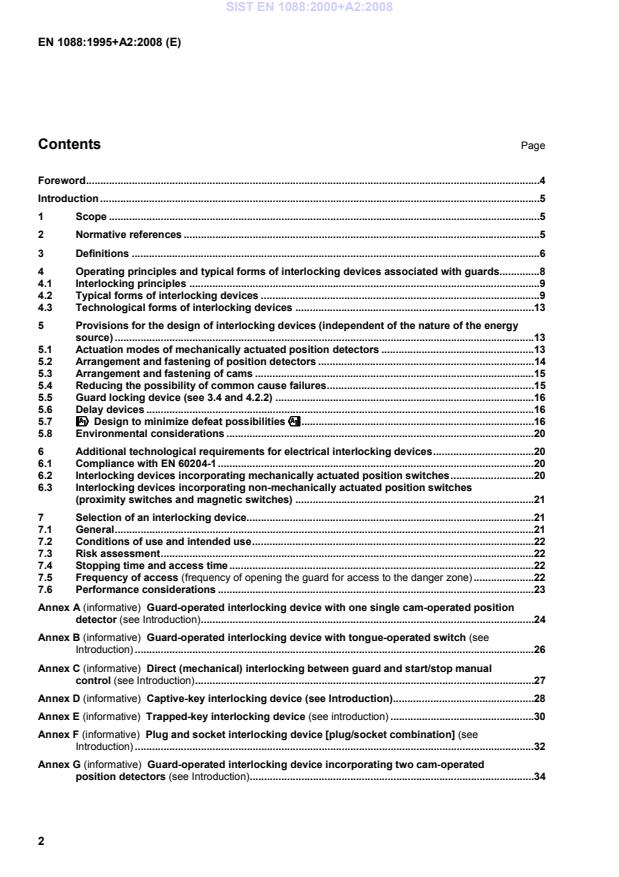

Guard-operated interlocking device with one single cam-operated position detector (see Introduction).24 Annex B (informative)

Guard-operated interlocking device with tongue-operated switch (see Introduction).26 Annex C (informative)

Direct (mechanical) interlocking between guard and start/stop manual control (see Introduction).27 Annex D (informative)

Captive-key interlocking device (see Introduction).28 Annex E (informative)

Trapped-key interlocking device (see introduction).30 Annex F (informative)

Plug and socket interlocking device [plug/socket combination] (see Introduction).32 Annex G (informative)

Guard-operated interlocking device incorporating two cam-operated position detectors (see Introduction).34 SIST EN 1088:2000+A2:2008

Mechanical interlocking between a guard and a movable element (see Introduction).36 Annex J (informative)

Electrical interlocking device incorporating magnetically actuated [magnetic] switches (see Introduction).37 Annex K (informative)

Electrical interlocking device incorporating two proximity detectors (see Introduction).38 Annex L (informative)

Pneumatic/hydraulic interlocking devices (see Introduction).39 Annex M (informative)

Interlocking device with spring applied/power released guard locking device (see Introduction).41 Annex N (informative)

Interlocking device with guard locking, with manually operated delay device (see Introduction).43 Annex ZA (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC$.44 Annex ZB (informative)

#Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC$.45 Bibliography.46

by the guard can operate, but the closure and locking of the guard do not by themselves initiate their operation. [3.22.5 of EN 292-1:1991] SIST EN 1088:2000+A2:2008

*) in accordance with prEN 1037 Figure 1 — Location of interlocking devices in machinery [based on Annex A of EN 292-1] SIST EN 1088:2000+A2:2008

4.1 Interlocking principles 4.1.1 Control interlocking The stop command from the interlocking device is introduced into the control system so that interruption of the energy supply to the machine actuators – or mechanical disconnection of moving parts from the machine actuators – is triggered by the control system (indirect interruption: levels A and B in figure 1). 4.1.2 Power interlocking The stop command from the interlocking device directly interrupts the energy supply to the machine actuators or disconnects moving parts from the machine actuators (level C in figure 1). "Directly" means that, unlike control interlocking (see 4.1.1), the control system does not play any intermediate role in the interlocking function. 4.2 Typical forms of interlocking devices 4.2.1 Interlocking device (without guard locking) (see table 1 and figure 3a)) It is always possible to open the guard. As soon as the guard is no longer closed, the interlocking device generates a stop command. As it is possible to start opening the guard during operation of the machine (or of the hazardous machine elements), the function is that of an interlocking device, as defined in 3.22.4 of EN 292-1:1991. Examples of interlocking devices without guard locking are shown in annexes A, B, F, G, J, K, L. 4.2.2 Interlocking device with guard locking (see table 1 and figure 3b)) The guard is held closed by a guard locking device (see 3.4). There are two types of devices: those where unlocking the guard can be initiated at any time by the operator (unconditional unlocking: see table 1 and figure 3b1)); those where unlocking the guard is possible only if a condition is fulfilled, thus ensuring that the hazard has disappeared (conditional unlocking: see table 1 and figure 3b2)). The guard locking device (see 3.4) can be an integral part of an interlocking device, or a separate unit. In a guard locking device, the part which is intended to lock/unlock the guard can be: manually applied, manually released (see figure N.1 in annex N); spring applied, power released (see figure 2a)); power applied, spring released (see figure 2b)); power applied, power released (see figure 2c)). SIST EN 1088:2000+A2:2008

a) spring applied… …power released

b) power applied… …spring released

c) power applied… …power released

Figure 2 — Operating modes of the guard locking device in power-actuated guard locking devices Examples of interlocking devices with guard locking are given in annexes C, D, E, H, M, N. SIST EN 1088:2000+A2:2008

a) interlocking device without guard locking ("two-state interlocking")

b1) Unconditional unlocking ("three-state interlocking") b2) Conditional unlocking ("four-state interlocking")

b) interlocking devices with guard locking Figure 3 — Functional diagrams of the different types of interlocking devices SIST EN 1088:2000+A2:2008

Interlocking devices with guard locking (see 4.2.2 and figure 3b))

Conditional unlocking (see figure 3b2)) Unlocking the guard is made possible only if (or is triggered when) one of the following conditions is fulfilled:

Unconditional unlocking (see figure 3b1)) Unlocking the guard can be started at any time by the operator, but the time necessary for the guard to be unlocked is longer than the time necessary for the hazard to disappear - a fixed time**) has elapsed after the stop command has been given; - disappearance of the hazzard has been detected (e.g. zero-speed detection).

Stop command given: - at the beginning of the guard opening stroke (the interlocking device is actuated by the guard itself); - simultaneously with the beginning of the actuation of the lock*) and as a consequence of it; - shortly after the beginning of the actuation of the guard locking device and as a consequence of it; - by the operator, or automatically by the control system, then memorized by the interlocking device.

(see annexes A, G)

(see annex D)

(see annex N)

(see annex M) Typical examples *) Strictly speaking, the guard is unlocked after the beginning of the stop command. Where the hazard disappears "as soon as the stop command is given" (in any case before the guard is unlocked), the function ensured is equivalent to that of an interlocking guard with guard locking. **) Longer than the time necessary for the hazard to disappear.

Technological forms Provisions in clauses Examples in annexes Interlocking devices with mechanically actuated detectors: - with cam-operated detectors; - with tongue-operated detectors. 5.1 to 5.4, 5.7.2, 6.2

5.7.2.1 5.7.2.2

A, G, L, M B Interlocking devices with non-mechanically actuated detectors: - with magnetically actuated switches; - with electronic proximity switches.

5.7.3 – 6.3 5.7.3 – 6.3

J K Systems incorporating keys: - captive-key systems; - trapped-key systems.

D E Plug and socket systems 5.7.4 F Mechanical interlocking between guard and movable parts

H

5 Provisions for the design of interlocking devices (independent of the nature of the energy source) 5.1 Actuation modes of mechanically actuated position detectors

When a single detector is used to generate a stop command, it shall be actuated in the positive mode (see table 3 and 3.6). Non-positive mode actuation is only allowed in conjunction with a detector with positive mode actuation, notably to avoid common cause failures (see 5.4.1). The design of the actuator should be as simple as possible, since this may reduce the probability of failure. SIST EN 1088:2000+A2:2008

Table 3 — Actuation of position detectors in the positive mode and in the non-positive mode Mode of actuation Guard closed Guard open Working mode POSITIVE MODE

The detector stem (actuator) is held depressed by a cam as long as the guard is open. When the guard is closed, the detector changes its state as the result of the action of a return spring. NON-POSITIVE MODE

The detector stem (actuator) is held depressed by a cam as long as the guard is closed. When the guard is opened, the detector changes its state as the result of the action of a return spring.

5.2 Arrangement and fastening of position detectors 5.2.1 Position detectors shall be arranged so that they are sufficiently protected against a change of their position. In order to meet this requirement: the fasteners of the position detectors shall be reliable and loosening them shall require a tool; the use of slots shall be limited to initial adjustment; provisions shall be made for positive location after adjustment (e.g. by means of pins or dowels). Replacement of the detectors shall be possible without any readjusting need. 5.2.2 In addition, the following requirements shall be met: self-loosening or easy defeat of the detector and of its actuator shall be prevented; the support for position detectors shall be sufficiently rigid to maintain correct operation of the position detector; the movement produced by mechanical actuation shall remain within the specified operating range of the position detector to ensure correct operation and/or prevent overtravel; SIST EN 1088:2000+A2:2008

Key 1 guard closed 2 guard open 3 positive actuation mode 4 non-positive actuation mode Figure 4 — Avoiding common cause failure of two mechanically actuated position detectors by using associated positive and non-positive mode actuation SIST EN 1088:2000+A2:2008

Key 1 sliding guard (open) 3 switch 2 cover (fixed part) 4 tongue

Figure 5 — Example of protection against defeating a tongue–operated switch SIST EN 1088:2000+A2:2008

a) Sliding guard b) Rotating guard

Key 1 guard (open) 1 guard (closed) 2 cover (fixed part) 2 cover (fixed part) 3 proximity switch 3 magnetic switch (contact open when guard detected) 4 actuator 4 non–detectable part

5 detectable part

NOTE Defeating the detector is made difficult by the cover (Figures 6 a) and b)), or by the presence of the guard in front of it (Figure 6 b)). Figure 6 — Examples of protection against defeat of a proximity switch or magnetic switch

5.7.4 Additional requirements for the design of plug and socket interlocking devices Protection against defeat shall be achieved by means of at least one of the following measures: SIST EN 1088:2000+A2:2008

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...