EN 15746-3:2020

(Main)Railway applications - Track - Road-rail machines and associated equipment - Part 3: Technical requirements for running

Railway applications - Track - Road-rail machines and associated equipment - Part 3: Technical requirements for running

1.1 General

This document deals with the technical requirements to minimize the specific railway hazards of self-propelled road-rail machines, as defined in EN 15746 1:2020, 3.1, henceforward referred to as machines, when designed and intended for running on European railways within the scope of European Directive 2007/58/EC.

The running mode is an option designed by the manufacturer which permits the use of the machine on a specified railway infrastructure without the need for special operational rules.

NOTE 1 The use of special track safety equipment (i.e. part of automatic train protection systems) does not necessarily mean that the machine has a running mode; some Infrastructure Managers use such equipment as means of protection for machines in travelling and/or working modes.

NOTE 2 This document is written for 1 435 mm nominal track gauge; special requirements can apply for running on infrastructures with narrow gauge or broad gauge lines.

Urban rail and railways utilizing other than adhesion between the rail and wheels are not included in this document.

This document does not apply to the following:

- the specific requirements established by the machine operator for the use of machines, which will be the subject of negotiation between the manufacturer and the Infrastructure Manager;

- travelling and working both on and off rails;

- running on urban rail.

For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a particular clause this specific aspect is not dealt with in this European Standard.

1.2 Validity of this document

This document applies to all machines which are within the scope of the Commission Regulation (EU) No 1302/2014 for locomotives and passenger rolling stock.

Bahnanwendungen - Oberbau - Zweiwege-Maschinen und zugehörige Ausrüstungen - Teil 3: Technische Anforderungen an das Fahren

1.1 Allgemeines

Dieses Dokument behandelt die technischen Anforderungen zur Minimierung eisenbahnspezifischer Gefährdungen von selbstangetriebenen Zweiwege-Maschinen – im Folgenden als Maschinen bezeichnet – wie in EN 15746 1:2020, 3.1, beschrieben, die innerhalb des Anwendungsbereiches der Europäischen Richtlinie 2007/58/EG für den Betrieb im europäischen Schienennetz konstruiert und vorgesehen sind.

Der Fahrmodus ist eine vom Hersteller geschaffene Option, die es erlaubt, die Maschine auf einer bestimmten Eisenbahninfrastruktur ohne spezielle Betriebsregeln einzusetzen.

ANMERKUNG 1 Der Einsatz von speziellen Sicherheitseinrichtungen für die Strecken (d. h. Teil von automatischen Zugsicherungssystemen) lässt nicht zwangsläufig darauf schließen, dass die Maschine über einen Fahrmodus verfügt, da einige Infrastrukturbetreiber solche Einrichtungen als Schutzmaßnahme für ihre Maschinen im Versetzfahr- und/oder Arbeitsmodus verwenden.

ANMERKUNG 2 Dieses Dokument wurde für 1 435 mm Nennspurweite geschrieben; spezielle Anforderungen können für das Fahren auf Infrastrukturen mit Schmalspur- oder Breitspurstrecken gelten.

Schienennahverkehrs- und Eisenbahnsysteme, die etwas anderes als die Haftung (Adhäsion) zwischen Schiene und Rädern nutzen, werden in diesem Dokument nicht behandelt.

Dieses Dokument ist nicht anzuwenden für Folgendes:

- spezielle Anforderungen für die Nutzung der Maschinen, festgelegt von dem Maschinenbetreiber, die der Absprache zwischen Hersteller und Infrastrukturbetreiber unterliegen;

- Versetzbewegung und Arbeiten gleichzeitig im eingegleisten und ausgegleisten Zustand;

- Fahren in Schienennahverkehrssystemen.

Für die Umrüstung in eine Zweiwege-Maschine wird davon ausgegangen, dass ein EU Straßen-zugelassenes Basisfahrzeug ein akzeptiertes Sicherheitsniveau für seine vorgesehenen Grundfunktionen bietet. Sofern es nicht in einem bestimmten Abschnitt anders festgelegt ist, wird dieser spezielle Aspekt in dieser Euro¬päischen Norm nicht behandelt.

1.2 Gültigkeit dieses Dokuments

Dieses Dokument bezieht sich auf alle Maschinen, die im Anwendungsbereich der europäischen Ver-ordnung (EU) Nr. 1302/2014 für Lokomotiven und Personenwagen erfasst werden.

Applications ferroviaires - Voie - Machines rail-route et équipements associés - Partie 3 : Exigences techniques pour la circulation

1.1 Généralités

Le présent document traite des prescriptions techniques visant à réduire le plus possible les dangers ferroviaires spécifiques aux machines rail-route automotrices, définies dans l’EN 15746-1:2020, 3.1 (désignées ci-après les « machines »), lorsqu'elles sont conçues et destinées à circuler sur les réseaux ferroviaires européens relevant du domaine d'application de la Directive 2007/58/CE.

Le mode circulation est une option prévue par le fabricant pour permettre l'utilisation de la machine sur une infrastructure ferroviaire spécifiée sans avoir à répondre à des règles d'exploitation spéciales.

NOTE 1 L'utilisation d'équipements de sécurité spéciaux (c'est-à-dire faisant partie des systèmes de protection automatique des trains) ne signifie pas nécessairement que la machine à un mode circulation. Certains gestionnaires d'infrastructure utilisent de tels équipements comme des moyens de protection pour les machines en modes déplacement et/ou travail.

NOTE 2 Le présent document est établi pour un écartement de voie nominal de 1 435 mm ; des prescriptions supplémentaires peuvent s'appliquer pour le déplacement sur les infrastructures ferroviaires à voies larges ou étroites.

Le présent document ne couvre pas les réseaux ferroviaires et les réseaux ferroviaires urbains n'utilisant pas l'adhérence rail/roue.

Le présent document ne s'applique pas :

— aux exigences spécifiques établies par l'opérateur de la machine en ce qui concerne l'emploi des machines et qui font l'objet de négociations entre le fabricant et le gestionnaire d'infrastructure ;

— au déplacement et au travail en voie et hors voie ;

— à la circulation sur un réseau ferroviaire urbain.

Pour une machine rail-route, il est supposé qu'un véhicule-hôte autorisé à circuler sur le réseau routier au sein de l'Union européenne offrira un niveau de sécurité acceptable pour ses fonctions de base avant conversion. Sauf spécification contraire explicite dans un article particulier, cet aspect spécifique n'est pas traité dans la présente Norme européenne.

1.2 Validité du présent document

Le présent document s'applique à toutes les machines qui relèvent du domaine d'application du Règlement (UE) n° 1302/2014 de la Commission relatif aux locomotives et au matériel roulant destiné au transport de passagers.

Železniške naprave - Zgornji ustroj proge - Dvopotna železniška vozila in oprema - 3. del: Tehnične zahteve za obratovanje

General Information

- Status

- Published

- Publication Date

- 22-Dec-2020

- Withdrawal Date

- 29-Jun-2021

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 5 - Track construction and maintenance machines

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 23-Dec-2020

- Due Date

- 03-Feb-2020

- Completion Date

- 23-Dec-2020

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15746-3:2020 - Railway applications - Track - Road-rail machines and associated equipment - Part 3: Technical requirements for running (CEN) sets out the railway-specific technical requirements to minimise hazards when self‑propelled road‑rail machines operate in a running mode on European mainline infrastructure. The standard addresses machines defined in EN 15746‑1:2020 and is written primarily for the 1 435 mm (standard) track gauge, and for running on networks covered by Directive 2007/58/EC. Urban rail, non‑adhesion traction systems and travelling/working modes are excluded.

Key topics and technical requirements

EN 15746‑3:2020 covers a broad set of requirements focused on safe running on the railway, including:

- Machine categorization and type‑qualification for running on track (categories and conditions for being in a train)

- Running safety equipment (indicator devices, data recorders and signalling interaction)

- Rolling stock gauge: running gauge and limits for machine envelope when in running mode

- Derailment prevention and dynamic testing for first type‑approved machines

- Stability and overturning prevention, frame design, lifting/jacking points and recovery considerations

- Running gear and wheel arrangements, wheel profiles, axle load distribution and suspension requirements

- Braking systems suitable for safe running mode operation

- Cabs, visibility and audibility (marker lights, headlights, horns) for safe interface with rail traffic

- Interaction with track equipment: operation of track circuits, axle counters, treadles and detectors

- Fire protection, environmental and labelling requirements, plus user information and marking

- Procedures for conformity verification, certificates and national special conditions (annexes)

Notes in the standard clarify that the presence of special track safety equipment (e.g., ATP elements) does not automatically constitute a running mode, and that many operator‑specific requirements are outside the standard’s remit.

Practical applications

This standard is used to:

- Define design requirements for manufacturers converting road vehicles into road‑rail machines intended to run on mainline networks

- Inform Infrastructure Managers when assessing type approvals and safe operation on their networks

- Guide conformity assessment and certification bodies applying Commission Regulation (EU) No 1302/2014 scope

- Support designers, system integrators and safety assessors in ensuring compatibility with signalling, braking and gauge constraints

Who should use this standard

- Road‑rail machine manufacturers and OEMs

- Infrastructure Managers and railway operators

- Certification and testing laboratories

- Design engineers, safety assessors and procurement teams

Related standards and regulations

- EN 15746 series (Part 1: travelling/working; Part 2: general safety; Part 4: urban rail)

- EU Directive 2007/58/EC and (informative) links to EU Regulation 1302/2014 and Directive (EU) 2016/797

Keywords: EN 15746‑3:2020, road‑rail machines, railway applications, technical requirements for running, CEN, running mode, track gauge, conformity.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 15746-3:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Road-rail machines and associated equipment - Part 3: Technical requirements for running". This standard covers: 1.1 General This document deals with the technical requirements to minimize the specific railway hazards of self-propelled road-rail machines, as defined in EN 15746 1:2020, 3.1, henceforward referred to as machines, when designed and intended for running on European railways within the scope of European Directive 2007/58/EC. The running mode is an option designed by the manufacturer which permits the use of the machine on a specified railway infrastructure without the need for special operational rules. NOTE 1 The use of special track safety equipment (i.e. part of automatic train protection systems) does not necessarily mean that the machine has a running mode; some Infrastructure Managers use such equipment as means of protection for machines in travelling and/or working modes. NOTE 2 This document is written for 1 435 mm nominal track gauge; special requirements can apply for running on infrastructures with narrow gauge or broad gauge lines. Urban rail and railways utilizing other than adhesion between the rail and wheels are not included in this document. This document does not apply to the following: - the specific requirements established by the machine operator for the use of machines, which will be the subject of negotiation between the manufacturer and the Infrastructure Manager; - travelling and working both on and off rails; - running on urban rail. For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a particular clause this specific aspect is not dealt with in this European Standard. 1.2 Validity of this document This document applies to all machines which are within the scope of the Commission Regulation (EU) No 1302/2014 for locomotives and passenger rolling stock.

1.1 General This document deals with the technical requirements to minimize the specific railway hazards of self-propelled road-rail machines, as defined in EN 15746 1:2020, 3.1, henceforward referred to as machines, when designed and intended for running on European railways within the scope of European Directive 2007/58/EC. The running mode is an option designed by the manufacturer which permits the use of the machine on a specified railway infrastructure without the need for special operational rules. NOTE 1 The use of special track safety equipment (i.e. part of automatic train protection systems) does not necessarily mean that the machine has a running mode; some Infrastructure Managers use such equipment as means of protection for machines in travelling and/or working modes. NOTE 2 This document is written for 1 435 mm nominal track gauge; special requirements can apply for running on infrastructures with narrow gauge or broad gauge lines. Urban rail and railways utilizing other than adhesion between the rail and wheels are not included in this document. This document does not apply to the following: - the specific requirements established by the machine operator for the use of machines, which will be the subject of negotiation between the manufacturer and the Infrastructure Manager; - travelling and working both on and off rails; - running on urban rail. For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a particular clause this specific aspect is not dealt with in this European Standard. 1.2 Validity of this document This document applies to all machines which are within the scope of the Commission Regulation (EU) No 1302/2014 for locomotives and passenger rolling stock.

EN 15746-3:2020 is classified under the following ICS (International Classification for Standards) categories: 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15746-3:2020 has the following relationships with other standards: It is inter standard links to EN 50617-2:2015, EN 62625-1:2013, EN 12663-2:2010, EN 15437-1:2009, EN 12663-1:2010+A1:2014, EN 15528:2015, EN 14033-1:2017, EN 15153-1:2020, EN 14033-2:2017, EN 14363:2016+A1:2018, EN ISO 12100:2010, EN 15273-2:2013+A1:2016, EN 15437-2:2012, CEN/TR 17498:2020, EN 15746-2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15746-3:2020 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/483, M/486, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15746-3:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2021

Železniške naprave - Zgornji ustroj proge - Dvopotna železniška vozila in oprema -

3. del: Tehnične zahteve za obratovanje

Railway applications - Track - Road-rail machines and associated equipment - Part 3:

Technical requirements for running

Bahnanwendungen - Oberbau - Zweiwege-Maschinen und zugehörige Ausrüstungen -

Teil 3: Technische Anforderungen an das Fahren

Applications ferroviaires - Voie - Machines rail-route et équipements associés - Partie 3 :

Exigences techniques pour la circulation

Ta slovenski standard je istoveten z: EN 15746-3:2020

ICS:

45.060.01 Železniška vozila na splošno Railway rolling stock in

general

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15746-3

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2020

EUROPÄISCHE NORM

ICS 93.100

English Version

Railway applications - Track - Road-rail machines and

associated equipment - Part 3: Technical requirements for

running

Applications ferroviaires - Voie - Machines rail-route et Bahnanwendungen - Oberbau - Zweiwege-Maschinen

équipements associés - Partie 3 : Prescriptions pou la und zugehörige Ausrüstungen - Teil 3: Technische

circulation Anforderungen an das Fahren

This European Standard was approved by CEN on 5 May 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15746-3:2020 E

worldwide for CEN national Members.

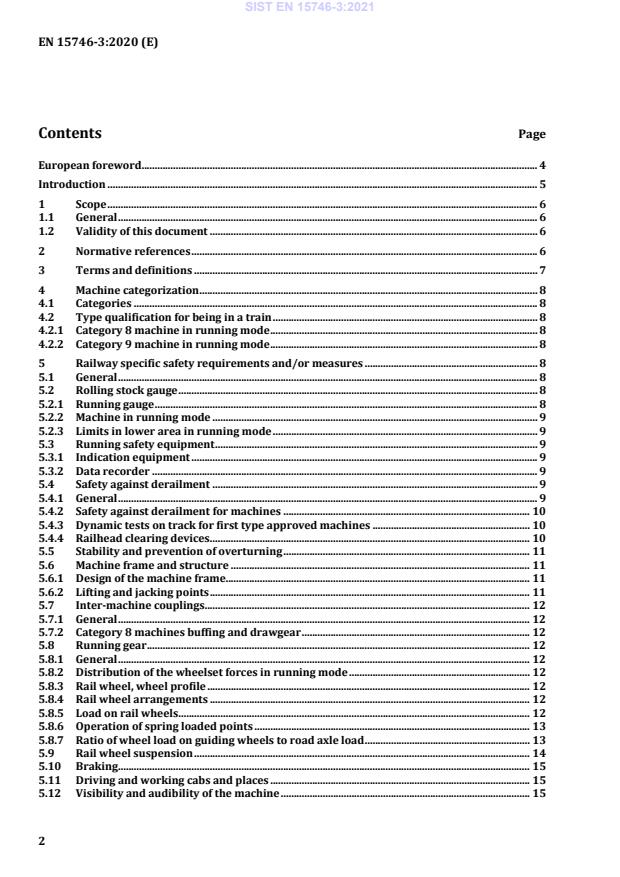

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

1.1 General . 6

1.2 Validity of this document . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Machine categorization . 8

4.1 Categories . 8

4.2 Type qualification for being in a train . 8

4.2.1 Category 8 machine in running mode . 8

4.2.2 Category 9 machine in running mode . 8

5 Railway specific safety requirements and/or measures . 8

5.1 General . 8

5.2 Rolling stock gauge . 8

5.2.1 Running gauge . 8

5.2.2 Machine in running mode . 9

5.2.3 Limits in lower area in running mode . 9

5.3 Running safety equipment . 9

.................................................................................................................................... 9

5.3.1 Indication equipment

5.3.2 Data recorder . 9

5.4 Safety against derailment . 9

5.4.1 General . 9

5.4.2 Safety against derailment for machines . 10

5.4.3 Dynamic tests on track for first type approved machines . 10

5.4.4 Railhead clearing devices . 10

5.5 Stability and prevention of overturning . 11

5.6 Machine frame and structure . 11

5.6.1 Design of the machine frame. 11

5.6.2 Lifting and jacking points . 11

5.7 Inter-machine couplings. 12

5.7.1 General . 12

5.7.2 Category 8 machines buffing and drawgear . 12

5.8 Running gear . 12

5.8.1 General . 12

5.8.2 Distribution of the wheelset forces in running mode . 12

5.8.3 Rail wheel, wheel profile . 12

5.8.4 Rail wheel arrangements . 12

5.8.5 Load on rail wheels . 12

5.8.6 Operation of spring loaded points . 13

5.8.7 Ratio of wheel load on guiding wheels to road axle load . 13

5.9 Rail wheel suspension . 14

5.10 Braking . 15

5.11 Driving and working cabs and places . 15

5.12 Visibility and audibility of the machine . 15

5.12.1 General . 15

5.12.2 Marker lights in running mode . 15

5.12.3 Head lights. 16

5.12.4 Warning horns . 16

5.13 Operation of track equipment . 16

5.13.1 Operation of track circuits . 16

5.13.2 Operation of axle-counters and treadles . 17

5.13.3 Operation of treadles associated with level crossings . 17

5.13.4 Operation of hot axlebox and unreleased brake detectors . 17

5.13.5 Operation of other signalling equipment . 17

5.14 Fire protection . 17

5.14.1 Material requirements . 17

5.14.2 Specific measures for flammable liquids . 17

5.14.3 Portable fire extinguishers . 17

5.14.4 Fire detection systems . 17

5.14.5 Driver’s cab emergency exit . 17

5.15 Recovery . 17

5.16 Space between machines during coupling . 18

5.17 Doors . 18

5.18 Side windows. 18

5.19 Load conditions . 18

5.20 Minimum curve radius . 18

5.21 Lifeguards . 18

5.22 Environmental . 18

5.23 Equipotential bonding . 18

5.24 Driver's vigilance . 18

5.25 Driver's indication . 18

5.26 Labelling in cab . 18

5.27 Remote controls . 18

5.28 Noise . 19

6 Marking and numbering of the machines . 19

7 User information . 19

8 Verification of the conformity to the requirements and/or particular safety

measures . 20

Annex A (normative) Special national conditions . 21

Annex B (normative) Check list for conformity . 22

Annex C (informative) Certificates . 26

C.1 Certificate of type approval to EN 15746-3:2020. 26

C.2 Conformance control document for the technical requirements of EN 15746-3:2020. 27

C.2.1 Machine identification . 27

C.2.2 General characteristics . 27

Annex D (informative) Structure of European Standards for track construction and

maintenance machines . 29

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive (EU) 2016/797 aimed to be covered . 31

Bibliography . 35

European foreword

This document (EN 15746-3:2020) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2021, and conflicting national standards shall be

withdrawn at the latest by June 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

EN 15746, Railway applications — Track — Road-rail machines and associated equipment, is currently

composed with the following parts:

— Part 1: Technical requirements for travelling and working;

— Part 2: General safety requirements;

— Part 3: Technical requirements for running;

— Part 4: Technical requirements for running, travelling and working on urban rail.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

This European Standard was prepared to meet the essential requirements of EU Directives to facilitate

an open market for goods and services.

This document is the third of a series of four parts of the European Standard, Railway applications —

Track — Road-rail machines and associated equipment, dealing with railway specific risks of the road-

rail machines when running, travelling and working on railway infrastructures:

— Part 1 covers the technical requirements for the machines in travelling and working modes, and is

applicable for all machines.

— Part 2 covers the safety requirements for the machines in travelling and working modes; this is a

document harmonized with the European Machinery Directive 2006/42/EC.

— Part 3 covers the essential requirements for the machines that have a running mode and run on

tracks within the scope of the Railway Directive 2007/58/EC; this is a document harmonized with

the Railway Interoperability Directive 2008/57/EC and its associated Technical Specifications for

Interoperability (TSI).

— Part 4 covers the technical requirements for the machines intended to have running, travelling

and/or working mode on urban rail.

Part 1 defines requirements for approval of the machine for use on the railway. Depending on the

decision of the Infrastructure Manager or National rules the assessment of conformance could be by the

Infrastructure Manager concerned, by a third party assessor or declaration of conformity by the

manufacturer.

Part 2 defines requirements for the machine to be declared conformant by the manufacturer, except in

the case of machines classified under Annex 4 of the Machinery Directive, which require a conformity

check in conjunction with a notified body.

Part 3 defines requirements for running on the European railway network. Assessment of conformity is

by a notified body as prescribed in the Railway Interoperability Directive.

Part 4 defines requirements for approval of the machine for use on urban rail. Depending on the

decision of the controller of the network or National rules the assessment of conformance could be by

the Urban Rail Manager concerned, by a third party assessor or declaration of conformity by the

manufacturer.

The risks which exist in all mechanical, electrical, hydraulic, pneumatic and other components of

machines and which are dealt with in the relevant European Standards are not within the scope of this

European Standard. Where necessary, references are made to appropriate standards of this type.

1 Scope

1.1 General

This document deals with the technical requirements to minimize the specific railway hazards of self-

propelled road-rail machines, as defined in EN 15746-1:2020, 3.1, henceforward referred to as

machines, when designed and intended for running on European railways within the scope of European

Directive 2007/58/EC.

The running mode is an option designed by the manufacturer which permits the use of the machine on a

specified railway infrastructure without the need for special operational rules.

NOTE 1 The use of special track safety equipment (i.e. part of automatic train protection systems) does not

necessarily mean that the machine has a running mode; some Infrastructure Managers use such equipment as

means of protection for machines in travelling and/or working modes.

NOTE 2 This document is written for 1 435 mm nominal track gauge; special requirements can apply for

running on infrastructures with narrow gauge or broad gauge lines.

Urban rail and railways utilizing other than adhesion between the rail and wheels are not included in

this document.

This document does not apply to the following:

— the specific requirements established by the machine operator for the use of machines, which will

be the subject of negotiation between the manufacturer and the Infrastructure Manager;

— travelling and working both on and off rails;

— running on urban rail.

For a road-rail machine it is assumed that an EU road permissible host vehicle will offer an accepted

safety level for its designed basic functions before conversion. Unless explicitly stated otherwise in a

particular clause this specific aspect is not dealt with in this European Standard.

1.2 Validity of this document

This document applies to all machines which are within the scope of the Commission Regulation (EU)

No 1302/2014 for locomotives and passenger rolling stock.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12663-1:2010+A1:2014, Railway applications — Structural requirements of railway vehicle bodies —

Part 1: Locomotives and passenger rolling stock (and alternative method for freight wagons)

EN 12663-2:2010, Railway applications — Structural requirements of railway vehicle bodies — Part 2:

Freight wagons

EN 14033-1:2017, Railway applications — Track — Railbound construction and maintenance

machines — Part 1: Technical requirements for running

EN 14033-2:2017, Railway applications — Track — Railbound construction and maintenance

machines — Part 2: Technical requirements for travelling and working

EN 14363:2016+A1:2018, Railway applications — Testing and Simulation for the acceptance of running

characteristics of railway vehicles — Running Behaviour and stationary tests

EN 15153-1:2020, Railway applications — External visible and audible warning devices for trains —

Part 1: Head, marker and tail lamps

EN 15273-2:2013+A1:2016, Railway applications — Gauges — Part 2: Rolling stock gauge

EN 15437-1:2009, Railway applications — Axlebox condition monitoring — Interface and design

requirements — Part 1: Trackside equipment and rolling stock axlebox

EN 15437-2:2012, Railway applications — Axlebox condition monitoring — Interface and design

requirements— Part 2: Performance and design requirements of on-board systems for temperature

monitoring

EN 15528:2015, Railway applications — Line categories for managing the interface between load limits

of vehicles and infrastructure

EN 15746-1:2020, Railway applications — Track — Road-rail machines and associated equipment —

Part 1: Technical requirements for travelling and working

EN 15746-2:2020, Railway applications — Track — Road-rail machines and associated equipment —

Part 2: General safety requirements

EN 50617-2:2015, Railway applications — Technical parameters of train detection systems for the

interoperability of the trans-European railway system — Part 2: Axle counters

EN 62625-1:2013, Electronic railway equipment — On board driving data recording system — Part 1:

System specification (IEC 62625-1:2013)

EN ISO 12100:2010, Safety of machinery — General principles for design — Risk assessment and risk

reduction (ISO 12100:2010)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

EN 15746-1:2020 and EN 15746-2:2020 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

As impacted by EN 50617-2:2015/AC:2016.

As impacted by EN 62625-1:2013/A11:2017.

4 Machine categorization

4.1 Categories

The machines are divided into four categories as shown in EN 15746-1:2020, Clause 4.

4.2 Type qualification for being in a train

4.2.1 Category 8 machine in running mode

Machines of Category 8 may be part of a train, but only under the conditions prescribed by the railway

undertaking of such a train and/or by the Infrastructure Manager.

4.2.2 Category 9 machine in running mode

The machine cannot be incorporated within a train but shall be designed and intended to operate

signalling and control systems, and shall comply with this standard.

NOTE The acceptance procedures for access to the railway infrastructure are likely to differ between running

mode and travelling/working modes

A compatibility assessment will need to be undertaken to ensure the signalling command and control

system fitted on the machine is compatible with the line to be run upon.

5 Railway specific safety requirements and/or measures

5.1 General

Machines shall comply with the safety requirements and/or protective measures in accordance with

EN 15746-1:2020, Clauses 5 and 6, and this standard.

5.2 Rolling stock gauge

5.2.1 Running gauge

Except in the lower area, machines in running mode shall meet the dimensional requirements of

EN 15273-2. The critical points near the limits of the permissible kinematic gauge,

see EN 14033-1:2017, Annex C, shall be recorded in the technical documentation as shown in Clause 7,

b), 3), i).

In the lower area deviations could be permitted by the Infrastructure Manager for machines according

to Category 9 B and Category 9 C and equivalent machines belonging to Category 8 to accommodate

road wheels, as shown in EN 15746-1:2020, Figure 5. The requirement is that the machine does not

damage the infrastructure.

NOTE 1 The G1 Profile in EN 15273-2:2013+A1:2016, Figure A.4 meets the cross acceptance gauging

requirements for the majority of mainland European countries.

NOTE 2 National conditions may apply to this exceedance amount, see Annex A.

Machines intended to run on infrastructures with more restrictive gauges shall conform to the specific

rules of those infrastructures and the corresponding restrictions shall be indicated in the instruction

handbook.

No metallic part of the vehicle shall be permitted, under any circumstance of predictable use and wear,

to encroach into the area outside the lower vehicle gauge shown in EN 15273-2:2013+A1:2016,

Figure A.6.

5.2.2 Machine in running mode

5.2.2.1 Stowing of moveable machine parts in running mode

When the machine is in the running mode any movable equipment which has the capacity to go outside

the gauge shall be capable of being stowed in a manner which prevents accidental or unintended

movement out of the gauge. All such moveable parts and assemblies forming part of the machine that

are unpacked in order to allow the machine to work in rail and non-rail mode shall, in their stowed

state, be secured by devices capable of resisting the foreseeable forces encountered during running,

which shall not rely upon a power source to retain the locking function. Moveable parts shall be held by

either:

— efficient locks. The visible positive locking components in running mode shall be painted in red. If

the locking mechanism is powered, the control of locking should preferably be possible from inside

the machine gauge;

or

— check valves on hydraulic systems, which shall prevent movement and be fail safe.

It shall be obvious to anyone checking the machine that these parts of the machine are locked in their

stowed position. Furthermore, for locking devices operable from the cab, either a red warning light

shall illuminate on the driver's desk to indicate if any moveable part of the machine is not locked, or a

green light shall indicate on the driver's desk that all moveable parts of the machine are locked.

5.2.2.2 Operating controls in running mode

When in running mode, all operating controls not related to running, including locking devices, shall be

deactivated.

5.2.3 Limits in lower area in running mode

Machines, where permitted by the Infrastructure Manager to exceed the lower gauge area

(see EN 14033-2:2017, Annex D) as shown in EN 15746-1:2020, 5.2.1, shall have any operating

restrictions stated on the type approval certificate.

5.3 Running safety equipment

5.3.1 Indication equipment

Machines with a running mode shall be fitted with special equipment specific for running safety on

specific infrastructures, see EN 14033-1:2017, Annex J.

The controls for this equipment shall be located in each driving cab.

5.3.2 Data recorder

Machines with a running mode shall carry at least one data recorder compliant with

EN 62625-1:2013 , 4.2.1, 4.2.2, 4.2.3, 4.2.4, 4.3.1.3, 4.3.1.4 and 4.3.1.6, where required by the specific

national safety authority; see Annex A.

5.4 Safety against derailment

5.4.1 General

The aim of the following requirements is to provide the same level of confidence for safety against

derailment on the operating track as given by the acceptance procedures defined in

EN 14363:2016+A1:2018, 6.1 and Clause 7.

5.4.2 Safety against derailment for machines

First type approved machines shall follow the acceptance procedure according to

EN 14363:2016+A1:2018:

— Subclause 6.1: the most adversely loaded condition when moving along the track in running mode

shall be investigated;

— Clause 7 in running mode: when using EN 14363 the machine is described as a “special vehicle” due

to the low numbers of these machines, as defined in EN 14363:2016+A1:2018, 3.15. In some cases

EN 14363 does not have specific requirements for “special vehicles”, in such case the machines

shall be assigned to a vehicle type most applicable to their design.

The running characteristics of a machine or a machine type are permitted to be determined by running

tests or by reference to a similar type approved machine.

A “similar type approved machine” is a machine with similar configuration and running under similar

conditions, which can be used as a reference for the test exemption of a new machine, according to the

requirements of EN 14363:2016+A1:2018, 5.3.1 and Table U.1.

When running tests are required, they should be carried out by an authorized body or by the

manufacturer of the machine, if the manufacturer is recognized as a testing body by the accreditation

body.

5.4.3 Dynamic tests on track for first type approved machines

After the tests shown in 5.4.2 have been successfully undertaken the first type approved machine shall

have actual dynamic tests on track undertaken in the most adversely loaded condition in the running

mode when moving along the track at its maximum speed. Where the maximum speed is limited for

specific track conditions this shall be recorded in the instruction handbook, see Clause 7, a), 3), iii) to x)

and detailed on the identification plate EN 14033-1:2017, Annex F. These tests shall be carried out on

track shown in a) to d):

a) the suspension is not detrimentally excited by a representative range of track conditions;

b) the machine is able to run over raised check rails and guard rails, the height of these being specified

by the Infrastructure Manager;

c) where the machine is stated to run in areas of retarders (track mounted braking system) the

machine is able to run over these devices without derailing

d) the machine does not derail while going through switches, crossings and curves.

NOTE One possible method to prove safety against derailment in switches and crossing for machines with

small wheels is given in EN 14363:2016+A1:2018, Annex E.

These tests should be carried out by an authorized body or by the manufacturer of the machine if the

manufacturer is recognized as a testing body by the authorized body.

When doing ∆Q/Q test the Q is the mean wheel load of the axle and the ∆Q is the maximum wheel

unloading due to the test conditions applied.

5.4.4 Railhead clearing devices

Machines shall be equipped with devices as described in EN 15746-2:2020, 5.10.2 and/or 5.10.3.

5.5 Stability and prevention of overturning

Requirements for prevention of overturning and stability are shown in EN 15746-2:2020, 5.11.

5.6 Machine frame and structure

5.6.1 Design of the machine frame

5.6.1.1 Requirements for Category 9 machines

The machine frame shall meet the requirements of EN 15746-1:2020, 5.7.1.

5.6.1.2 Requirements for Category 8 machines

The machine frame shall be able to withstand the following forces without any permanent deformation

when running in a train:

a) machines not permitted to be loose shunted or hump shunted shall be constructed to meet the

requirements of the load cases 6.1 to 6.5 of Category FII of EN 12663-1 or EN 12663-2 with the

following deviations:

1) item 4.5, c) vertical load during lifting of the machine frame with the bogie to 2 g;

2) EN 12663-1:2010+A1:2014, Table 13 or EN 12663-2:2010, Table 10 to read acceleration in the

x direction ± 3 g;

3) machines which are restricted to be positioned only at the front or rear of a train are permitted

to be constructed to withstand towing and impact forces of 0,8 MN.

All other Category 8 machines shall be constructed to meet the requirements of the load cases 4.1 to 4.5

of Category FI of EN 12663-1 or EN 12663-2 with the following deviations:

b) Item 4.5, c) vertical load during lifting of the machine frame with the bogie to 2 g;

and

c) EN 12663-1:2010+A1:2014, Table 13 to read acceleration in the x direction ± 3 g.

5.6.2 Lifting and jacking points

Lifting and jacking points shall be fitted capable of safely supporting the whole machine while being

lifted or jacked. It shall also be possible to lift or jack one end of the machine (including its running

gear) with the other end resting on the remaining running gear. The locations (and any restrictions of

use) of lifting and jacking points, where fitted, shall be detailed in the instruction handbook, see

Clause 7, b), 3), viii).

In addition for Category 8 machines the following requirements apply:

a) The load cases specified in EN 12663-2 shall apply for lifting and jacking under workshop and

servicing operations.

b) For lifting cases associated only with rescue following derailment or other abnormal incident,

where some permanent deformation of the structure is acceptable, it is permissible to reduce the

safety factor in Tables 9 and 10 from 1,1 to 1,0. If a factor of 1,0 is used for a validation test, the

measured strains shall be extrapolated to demonstrate the conformance to the higher factor.

c) The location of the lifting and jacking points shall be defined by the customer's operational

requirements.

5.7 Inter-machine couplings

5.7.1 General

Except as shown in 5.7.2 the couplings shall comply with EN 15746-1:2020.

5.7.2 Category 8 machines buffing and drawgear

5.7.2.1 Couplings

Requirements shall be according to EN 14033-1:2017, 10.2.1.

5.7.2.2 Buffers

Requirements shall be according to EN 14033-1:2017, 10.2.2.

5.7.2.3 Space to be kept free at the end of the machine

Requirements shall be according to EN 14033-1:2017, 10.5.

5.8 Running gear

5.8.1 General

The running gear structures shall be designed to ensure that no significant permanent deformation or

fatigue fracture occurs under all intended load cases.

The manufacturer shall either:

a) verify that the stress levels in each component of the running gear and their connection to the host

vehicle are within known limits for the material in use and that due account has been taken of the

dynamic stresses produced by running, travelling and working on the rails;

or

b) provide evidence of the stress levels in the running gear and their connection to the host vehicle

demonstrating, via the safety record of machines having a comparable design and loading, that the

stress levels in the running gear are within known limits for the material in use.

5.8.2 Distribution of the wheelset forces in running mode

In running mode the position of the rail wheelsets and their loads shall comply with the requirements of

EN 15528:2015. The “Line Category” of machines in running mode shall be shown on the identification

plate as described in Clause 6.

5.8.3 Rail wheel, wheel profile

Machines in running mode shall meet the requirements of EN 15746-1:2020, 5.9.4.

5.8.4 Rail wheel arrangements

The rail wheels shall be mounted in such a way as to give the machine safe rail guidance.

5.8.5 Load on rail wheels

The maximum static load per wheel in the working and non-working condition is given in Table 1.

Table 1 — Load on rail wheels

Wheel diameter Running mode load per rail

wheel

∅ Static

mm t

∅ ≥ 920 11,25

920 > ∅ ≥ 840 11,25

840 > ∅ ≥ 760 10,0

760 > ∅ ≥ 680 9,25

680 > ∅ ≥ 630 8,5

630 > ∅ ≥ 550 7,25

550 > ∅ ≥ 470 6,25

470 > ∅ ≥ 390 5,25

390 > ∅ ≥ 330 4,75

330 > ∅ Not permitted in running mode

∅ = worn rail wheel diameter limit (mm)

5.8.6 Operation of spring loaded points

Where the axle load is less than 5 t (wheel load of 2,5 t), the machine cannot be expected to operate

spring loaded points. These limitations shall be specified in the instruction handbook, see Clause 7, a),

1), ii).

5.8.7 Ratio of wheel load on guiding wheels to road axle load

For Category 9 C machines (where road wheels share the load with the guiding rail wheels), the rail

wheel load shall be set up to ensure that the machine complies with the braking, resistance to

derailment and stability requirements of this standard with all permitted load variations.

Where the ratio of wheel loads has the potential to vary, e.g. where controlled by hydraulic pressure,

there shall be a warning device given in EN 15746-2:2020, Table 4 to indicate an unsatisfactory

wheelset support force as an example see warning line indicated on Figure 1.

An example of the set up for a shared load is shown in the graph set out in Figure 1. This displays the

load on the road wheels compared against rail wheels. The “y” axis shows the load on the rail wheels,

and the “x” axis the road wheels. The figures set out are for an axle; hence the wheel loads on each axle

(or opposite each other on stub axles) should be added together. The comparison between road and rail

wheels should be made for adjacent wheels.

If it is decided to use the graph in Figure 1, then the road wheel weights should be taken with the

machine in road mode, then when in rail mode the rail wheel load adjusted to suit the figure in the

graph in Figure 1.

With Category 9 C machines it is vital that the wheel loads are shared appropriately between the road

and rail wheels to ensure the correct amount of guidance from rail wheels and brake/traction from

road wheels. On machines where the normal laden and tare weights do not vary significantly, e.g.

excavators, MEWPs, landrovers, etc., the initial setting could be considered sufficient to provide

adequate loading. Where the axle loads on the road wheels vary by a large proportion, e.g. between tare

and laden condition on lightweight machines, heavily laden machines such as water tankers, etc., the

load on the rail wheels could need to vary accordingly to ensure braking and resistance to derailment in

all load conditions. Consideration should also be given to the potential locations where the machine will

be used, for example where rails are sunken into concrete or tarmac (docks/depots/tramways, etc.)

there is the potential for the road wheel to relieve the load on rail wheel, hence a means of retaining the

rail wheel load will need to be fitted in this instance.

It is also good practice to warn the operator of too much rail wheel loading.

Key

1 wheelset support force of rail guide in relation to vehicle axle load

2 wheelset support force, in kN

3 axle load on road wheels, in kN

wheelset support force

min. wheelset support force

warning

Figure 1 — Ratio of wheelset load on guiding wheels to road axle load

5.9 Rail wheel suspension

The machine in running mode shall meet the requirements of EN 15746-1:2020, 5.10.

5.10 Braking

Requirements for the braking system are as given in EN 14033-1:2017, Clause 9.

NOTE The manufacturer is able to select whichever category set out in EN 14033-1:2017, Clause 9 best suits

the particular machine.

5.11 Driving and working cabs and places

Machines shall have a driving cab for the direction(s) of travel permitted in running mode meeting the

requirements of EN 14033-1:2017, 14.3.1, 14.3.2, 14.4, 14.5, 14.8 and 14.10.

Machines will be permitted for shunting operations in directions other than those permitted for

running mode with local operating rules specific to the country or area of operation.

Some Infrastructure Managers may permit machines in running mode with a maximum

speed < 20 km/h, for the driver to have visibility in the direction of movement provided by CCTV as set

out in EN 15746-2:2020, 5.4.6.3 and 5.4.6.4.

5.12 Visibility and audibility of the machine

5.12.1 General

All road lighting including flashing beacons, shall be isolated against use when t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...