EN 13954:2005

(Main)Food processing machinery - Bread slicers - Safety and hygiene requirements

Food processing machinery - Bread slicers - Safety and hygiene requirements

1.1 This document specifies safety and hygiene requirements for the design and manufacture of bread slicing machines of type 1 and 2 as defined in Clause 3.

The intended use of these machines is to cut baked bread into slices.

This document deals with all significant hazards, hazardous situations and events relevant to bread slicers machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This document covers requirements for the safe operation of the machine including: loading, cutting, unloading, cleaning, crumb removal and maintenance.

These machines can be manually or automatically operated.

1.2 The following machines are excluded from the scope of this document:

- experimental and testing machines under development by the manufacturer;

- frame cutter machines with multiple blades moving horizontally;

- domestic appliances and machines intended for use by the general public;

- machines with horizontal circular cutting systems;

- rectangular cutting machines for cutting or sawing of panel size products into small pieces.

The significant hazards covered by this document are described in Clause 4.

1.4 In writing this document, it has been assumed that the bread slicers falling within the scope are operated only by trained personnel and that the machines are not intended to be cleaned with water jet.

1.5 This document applies to bread slicing machines which are manufactured before the date of publication by CEN of this document.

Nahrungsmittelmaschinen - Brotschneidemaschinen - Sicherheits- und Hygieneanforderungen

1.1 Diese Europäische Norm spezifiziert Sicherheits- und Hygieneanforderungen für die Konstruktion und Herstellung von Brotschneidemaschinen des Typ 1 und 2, wie sie in Abschnitt 3 definiert sind.

Diese Maschinen sind dazu bestimmt, gebackenes Brot in Scheiben zu schneiden.

Diese Europäische Norm erfasst signifikante Gefährdungen, Gefährdungssituationen und Ereignisse in Verbindung mit Brotschneidemaschinen, wenn diese so genutzt werden, wie vorgesehen und unter den vom Hersteller vorhersehbaren Missbrauch bzw. Fehlbedienungen (siehe Abschnitt 4).

Diese Europäische Norm befasst sich mit den Anforderungen an die sichere Verwendung der Maschine inklusive Beschicken, Schneiden, Entladen, Reinigung (Entfernen der Krumen) und Instandhaltung.

Diese Maschinen können manuell oder automatisch betrieben werden.

1.2 Folgende Maschinen fallen nicht unter den Anwendungsbereich dieser Norm:

- Testanlage in der Entwicklung beim Hersteller;

- Gattermaschinen mit mehreren sich horizontal bewegenden Messern;

- Haushaltsgeräte oder Maschinen für Allgemeingebrauch;

- Maschinen mit horizontal wirkenden Schneidesystemen;

- Maschine für das Schneiden oder Sägen von Scheiben in kleine rechteckige Stücke.

Die von dieser Norm abgedeckten signifikanten Gefährdungen sind in Abschnitt 4 beschrieben.

1.3 Bei der Erstellung dieser Norm wurde davon ausgegangen, dass die betreffenden Brotschneidmaschinen nur von geschultem Personal bedient werden und nicht mit einem Wasserstrahl zu reinigen sind.

1.4 Diese Europäische Norm ist nicht für Maschinen anzuwenden, die vor dem Erscheinungsdatum dieser Europäischen Norm hergestellt wurden.

Machines pour les produits alimentaires - Machines à couper le pain - Prescriptions relatives à la sécurité et à l'hygiène

Stroji za predelavo hrane – Rezalniki kruha – Varnostne in higienske zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 04-Oct-2005

- Withdrawal Date

- 02-Mar-2010

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 1 - Bakery equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Mar-2010

- Completion Date

- 03-Mar-2010

- Directive

- 98/37/EC - Machinery

Relations

- Merged Into

EN 13954:2005+A1:2010 - Food processing machinery - Bread slicers - Safety and hygiene requirements - Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 13954:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Bread slicers - Safety and hygiene requirements". This standard covers: 1.1 This document specifies safety and hygiene requirements for the design and manufacture of bread slicing machines of type 1 and 2 as defined in Clause 3. The intended use of these machines is to cut baked bread into slices. This document deals with all significant hazards, hazardous situations and events relevant to bread slicers machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This document covers requirements for the safe operation of the machine including: loading, cutting, unloading, cleaning, crumb removal and maintenance. These machines can be manually or automatically operated. 1.2 The following machines are excluded from the scope of this document: - experimental and testing machines under development by the manufacturer; - frame cutter machines with multiple blades moving horizontally; - domestic appliances and machines intended for use by the general public; - machines with horizontal circular cutting systems; - rectangular cutting machines for cutting or sawing of panel size products into small pieces. The significant hazards covered by this document are described in Clause 4. 1.4 In writing this document, it has been assumed that the bread slicers falling within the scope are operated only by trained personnel and that the machines are not intended to be cleaned with water jet. 1.5 This document applies to bread slicing machines which are manufactured before the date of publication by CEN of this document.

1.1 This document specifies safety and hygiene requirements for the design and manufacture of bread slicing machines of type 1 and 2 as defined in Clause 3. The intended use of these machines is to cut baked bread into slices. This document deals with all significant hazards, hazardous situations and events relevant to bread slicers machines, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This document covers requirements for the safe operation of the machine including: loading, cutting, unloading, cleaning, crumb removal and maintenance. These machines can be manually or automatically operated. 1.2 The following machines are excluded from the scope of this document: - experimental and testing machines under development by the manufacturer; - frame cutter machines with multiple blades moving horizontally; - domestic appliances and machines intended for use by the general public; - machines with horizontal circular cutting systems; - rectangular cutting machines for cutting or sawing of panel size products into small pieces. The significant hazards covered by this document are described in Clause 4. 1.4 In writing this document, it has been assumed that the bread slicers falling within the scope are operated only by trained personnel and that the machines are not intended to be cleaned with water jet. 1.5 This document applies to bread slicing machines which are manufactured before the date of publication by CEN of this document.

EN 13954:2005 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13954:2005 has the following relationships with other standards: It is inter standard links to EN 13954:2005+A1:2010, EN ISO 15494:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13954:2005 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13954:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2006

Stroji za predelavo hrane – Rezalniki kruha – Varnostne in higienske zahteve

Food processing machinery - Bread slicers - Safety and hygiene requirements

Nahrungsmittelmaschinen - Brotschneidemaschinen - Sicherheits- und

Hygieneanforderungen

Machines pour les produits alimentaires - Machines a couper le pain - Prescriptions

relatives a la sécurité et a l'hygiene

Ta slovenski standard je istoveten z: EN 13954:2005

ICS:

67.260 Tovarne in oprema za Plants and equipment for the

živilsko industrijo food industry

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 13954

NORME EUROPÉENNE

EUROPÄISCHE NORM

October 2005

ICS 67.260

English Version

Food processing machinery - Bread slicers - Safety and hygiene

requirements

Machines pour les produits alimentaires - Machines à Nahrungsmittelmaschinen - Brotschneidemaschinen -

couper le pain - Prescriptions relatives à la sécurité et à Sicherheits- und Hygieneanforderunden

l'hygiène

This European Standard was approved by CEN on 8 August 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13954:2005: E

worldwide for CEN national Members.

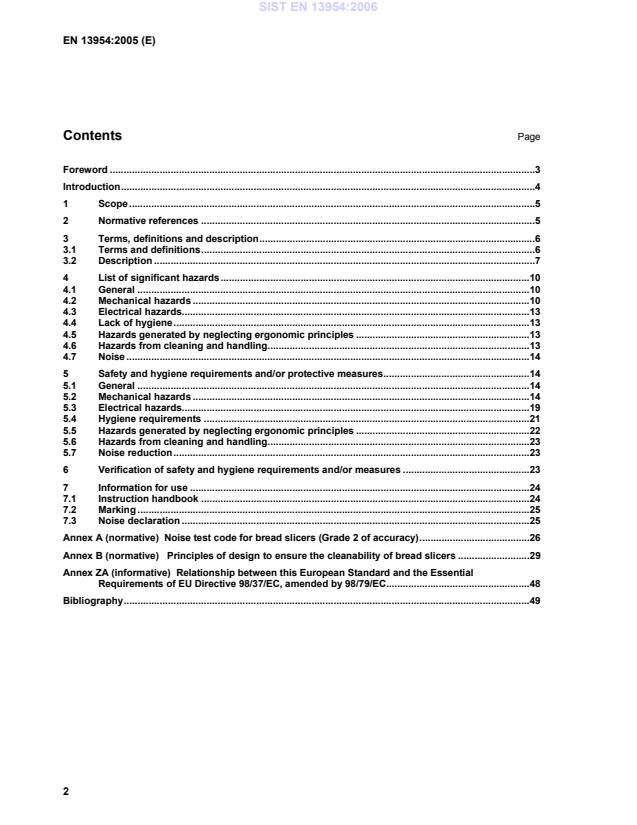

Contents Page

Foreword .3

Introduction.4

1 Scope .5

2 Normative references .5

3 Terms, definitions and description.6

3.1 Terms and definitions.6

3.2 Description .7

4 List of significant hazards.10

4.1 General .10

4.2 Mechanical hazards .10

4.3 Electrical hazards.13

4.4 Lack of hygiene.13

4.5 Hazards generated by neglecting ergonomic principles .13

4.6 Hazards from cleaning and handling.13

4.7 Noise .14

5 Safety and hygiene requirements and/or protective measures.14

5.1 General .14

5.2 Mechanical hazards .14

5.3 Electrical hazards.19

5.4 Hygiene requirements .21

5.5 Hazards generated by neglecting ergonomic principles .22

5.6 Hazards from cleaning and handling.23

5.7 Noise reduction.23

6 Verification of safety and hygiene requirements and/or measures .23

7 Information for use .24

7.1 Instruction handbook .24

7.2 Marking .25

7.3 Noise declaration .25

Annex A (normative) Noise test code for bread slicers (Grade 2 of accuracy).26

Annex B (normative) Principles of design to ensure the cleanability of bread slicers .29

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 98/37/EC, amended by 98/79/EC.48

Bibliography.49

Foreword

This European Standard (EN 13954:2005) has been prepared by Technical Committee CEN/TC 153 “Food

processing machinery — Safety and hygiene specifications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by April 2006, and conflicting national standards shall be withdrawn at the

latest by April 2006.

This European Standard has been prepared under a mandate given to CEN by the European Commission

and the European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

This European Standard is complementary to EN 14655:2005 that is covering bread slicing machines with

crescent blade(s) (type 3).

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic,

Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland

and United Kingdom.

Introduction

There are various types of bread slicing machines. They are divided mainly into the following types:

Type 1: Frame cutter machines with multiple blades moving vertically;

Type 2: Machines with rotary crescent (sickle) or circular blade fixed to a shaft with oscillating movement

and horizontal manual loading;

Type 3: Machines with crescent blade fixed to a shaft, with a rotating movement and vertical manual

loading;

Type 4: Machines with one or more rotating band blades.

This European Standard is a type C standard as stated in EN ISO 12100-1:2003.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are

indicated in the scope of this European Standard.

When provisions of this type C standard are different from those that are stated in type A or B standards, the

provisions of this type C standard take precedence over the provisions of the other standards, for machines

that have been designed and built according to the provisions of this type C standard.

1 Scope

1.1 This European Standard specifies safety and hygiene requirements for the design and manufacture of

bread slicing machines of type 1 and 2 as defined in Clause 3.

The intended use of these machines is to cut baked bread into slices.

This European Standard deals with all significant hazards, hazardous situations and events relevant to bread

slicers machines, when they are used as intended and under conditions of misuse which are reasonably

foreseeable by the manufacturer (see Clause 4).

This European Standard covers requirements for the safe operation of the machine including: loading, cutting,

unloading, cleaning, crumb removal and maintenance.

These machines can be manually or automatically operated.

1.2 The following machines are excluded from the scope of this document:

experimental and testing machines under development by the manufacturer;

frame cutter machines with multiple blades moving horizontally;

domestic appliances and machines intended for use by the general public;

machines with horizontal circular cutting systems;

rectangular cutting machines for cutting or sawing of panel size products into small pieces.

The significant hazards covered by this document are described in Clause 4.

1.3 In drafting this European Standard, it has been assumed that the bread slicers falling within the scope

are operated only by trained personnel and that the machines are not intended to be cleaned with water jet.

1.4 This European Standard is not applicable to bread slicing machines which are manufactured before the

date of publication of this European Standard.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper

limbs

EN 349, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body

EN 614-1:1995, Safety of machinery — Ergonomic design principles — Part 1: Terminology and general

principles

EN 953:1997, Safety of machinery — Guards — General requirements for design and construction of fixed

and movable guards

EN 954-1:1996, Safety of machinery — Safety related parts of control systems — Part 1: General principles

for design

EN 1088:1995, Safety of machinery — Interlocking devices associated with guards — Principles for design

and selection

EN 1672-2:2005, Food processing machinery — Basic concepts — Part 2: Hygiene requirements

EN 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements

(IEC 60204-1:1997)

EN 60529:1991, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989)

EN 61310-1, Safety of machinery — Indication, marking and actuation — Part 1: Requirements for visual,

auditory and tactile signals (IEC 61310-1:1995)

EN 61496-1:1997, Safety of machinery — Electro-sensitive protective equipment — Part 1: General

requirements and tests (IEC 61496-1:1997, modified)

EN ISO 3744:1995, Acoustics — Determination of sound power levels of noise sources using sound

pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994)

EN ISO 4287:1998, Geometrical product Specifications (GPS) — Surface texture: Profile method — Terms,

definitions and surface texture parameters (ISO 4287:1997)

EN ISO 4871, Acoustics — Declaration and verification of noise emission values of machinery and equipment

(ISO 4871:1996)

EN ISO 11201, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound

pressure levels at a work station and at other specified positions — Engineering method in an essentially free

field over a reflecting plane (ISO 11201:1995)

EN ISO 11688-1:1997, Acoustics — Recommended practice for the design of low-noise machinery and

equipment — Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12001, Acoustics — Noise emitted by machinery and equipment — Rules for the drafting and

presentation of a noise test code (ISO 12001:1996)

EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic

terminology, methodology (ISO 12100-1:2003)

EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2:

Technical principles (ISO 12100-2:2003)

3 Terms, definitions and description

3.1 Terms and definitions

For the purposes of this European Standard, the terms and definitions given in EN ISO 12100-1:2003 and the

following apply.

3.1.1

type 1 machines

bread slicers with reciprocating multiple blades moving vertically

3.1.2

type 2 machines

machines with rotary crescent (sickle) or circular blade fixed to a shaft with oscillating or rotating movement

and horizontal manual loading

3.2 Description

3.2.1 Type 1 machines

Type 1 bread slicers usually consist of a frame supporting the following main elements (see example in

Figure 1):

Figure 1.1 — type 1a Figure 1.2 — type 1b

Figure 1.3 — type 1c

Key

1 crumb tray;

2 discharge area or device;

3 cutting device: multiple blades which have reciprocating motion;

4 infeed area or device;

5 feed device (e.g. pusher, special conveyor belt), which pushes and guides the loaf of bread for the cutting

action;

6 drive mechanisms;

7 electrical controls.

Figure 1 — Example of a bread slicer of type 1

According to the way the bread is brought to the slicing tool, the following distinctions are made:

Type 1a "hand operated machines" (Figure 1.1): the loaf of bread is pushed by a manual pusher. The

machine is equipped with a lever which acts at the same time as a start/stop control device.

Type 1b "automatic machines" (Figure 1.2): the bread is pushed by a power operated mechanical pusher.

A control device allows to activate the blades and the pusher until the bread is totally cut and the pusher

has come back to the feeding position. Then the machine stops and the cycle is finished. The next loaf of

bread is placed manually in front of the pusher.

Type 1c "automatic machines with continuous feeding" (Figure 1.3): the machine is fed manually or

continuously and the loaves of bread are brought to the blades by (a) conveyor belt(s).

3.2.2 Type 2 machines

A type 2 bread slicing machine consists of a machine frame supporting the following main elements: (see

example in Figure 2):

Key

1 feed device in a feed trough;

2 blade housing;

3 rotary (sickle) crescent or circular blade;

4 discharge trough;

5 crumb tray

Figure 2 — Bread slicing machine of type 2 with discharge trough

The machine housing holds associated drives, electrical and/or hydraulic and pneumatic components,

depending on the machine type.

Type 2 bread slicing machines in the scope of this document may be equipped with

an in-feed conveyor belt,

a discharge conveyor belt, and

an oiling mechanism for the blade.

The bread to be cut is laid upon the feed device and transported to the cutting chamber to be cut. The slices

are discharged into the discharge trough or onto a conveyor.

4 List of significant hazards

4.1 General

This clause contains all the significant hazards, hazardous situations and events, as far as they are dealt with

in this document, identified by risk assessment as significant for this type of machinery and which require

action to eliminate or reduce the risk.

4.2 Mechanical hazards

4.2.1 The significant mechanical hazards for type 1 machines are:

cutting hazard;

drawing in hazard;

shearing hazard;

loss of stability.

The examples shown in Figure 3 illustrates 4 danger zones associated with these hazards:

Zone 1: Access to cutting side of blades through infeed area.

Hazards of cutting.

Zone 2: Access to cutting side of blades through discharge area.

Hazards of cutting.

Zone 3: Access to cutting side of blades and to other moving parts of the machine through the crumb

tray opening, when it is removed.

Hazards of shearing, drawing in, cutting.

Zone 4: Access to all moving parts (e.g. drive mechanisms) through other sides of the machine.

Hazards of shearing, drawing in.

Figure 3.a Figure 3.b

Figure 3.c

Key

1 Zone 1

2 Zone 2

3 Zone 3

4 Zone 4

Figure 3 — Danger zones of bread slicers of type 1

4.2.2 The significant mechanical hazards for type 2 machines are listed below:

crushing hazard;

shearing hazard;

severing hazard;

entanglement hazard;

cutting hazard;

drawing-in hazard;

loss of stability.

The example shown in Figure 4 illustrates 8 danger zones associated with these hazards:

Zone 1: Movement of the feed device in feed trough.

Crushing or shearing and cutting or severing hazard to fingers or hand.

Zone 2: Rotating blade in cutting area, access from feed trough.

Entanglement, cutting or severing hazard to fingers or hand.

Zone 3: Rotating blade in cutting area, access via discharge trough.

Entanglement, cutting or severing hazard to fingers or hand.

Zone 4: Rotating blade in the blade housing.

Cutting or severing hazard to fingers or hand.

Breakage of blade or detachment of blade mounting.

Hazard caused by ejected parts.

Zone 5: Rotating blade, access via the crumb tray.

Entanglement, cutting or severing hazard to fingers or hand.

Zone 6: Drive mechanisms of blade and feed device/ bread holder.

Crushing, shearing or drawing-in hazard to fingers or hand.

Zone 7: Outlet conveyor belt.

Entanglement, drawing-in or crushing hazard to fingers or hand.

Zone 8: Unintentional or intentional closing of machine parts.

Crushing hazard to fingers or hand.

Key

1 Zone 1

2 Zone 2

3 Zone 3

4 Zone 4

5 Zone 5

6 Zone 6

7 Zone 7

8 Zone 8

Figure 4 — Danger zones on a bread slicing machine of type 2 with discharge trough and outlet

conveyor belt

4.3 Electrical hazards

Hazard of electric shock from direct or indirect contact with live components.

Hazard of external influences on electrical equipment (e.g. cleaning with water and dust generated by slicing

the bread).

4.4 Lack of hygiene

Lack of hygiene can create a risk to human health and unacceptable alteration of foodstuff e.g. contamination

by microbial growth or foreign materials.

4.5 Hazards generated by neglecting ergonomic principles

Risk of injury or chronic damage to the body resulting from harmful body postures during operation, cleaning

and maintenance.

4.6 Hazards from cleaning and handling

Cutting while cleaning, whereas the blades are stopped.

Cutting while removing the blade assembly.

4.7 Noise

Bread slicers can generate airborne noise which can result in hearing damage and in accidents due to

interference with speech communication and due to interference with the perception of acoustic signals.

5 Safety and hygiene requirements and/or protective measures

5.1 General

Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition,

the machine shall be designed according to the principles of EN ISO 12100-2 for hazards relevant but not

significant which are not dealt with by this document.

NOTE For hazards which are to be reduced by the application of the B level standard EN 294, EN 349, EN 614-1,

EN 953, EN 954-1, EN 1088, EN 60204-1, EN 61310-1, EN 61496-1 and EN ISO 12100, the manufacturer should carry

out a risk assessment to establish the requirements of that standard which are to be applied. This specific risk assessment

is part of the general risk assessment of the machine.

Where the means of reducing the risk is by the physical arrangement or positioning of the installed machine,

the manufacturer shall include in the information for use a reference to the reduction means to be provided,

and to any limiting value of the requirement, and, if appropriate, to the means of verification.

Where the means of reducing the risk is by a safe system of working the machinery, the manufacturer shall

include in the Information for use details of the system and of the elements of training required by the

operating personnel.

5.2 Mechanical hazards

5.2.1 Mechanical hazards for type 1 machine

5.2.1.1 General

Where interlocking guards are required, they shall be at least with interlocking devices without guard locking

and comply with 4.2.1, Clauses 5 and 6 of EN 1088:1995.

Safety related parts of the control system shall be not less than category 1 of EN 954-1:1996.

Guards shall comply with EN 953 and EN 294.

5.2.1.2 Zone 1: Infeed area

5.2.1.2.1 Type 1a machines (hand operated)

The slicing area shall be protected by the combination of the machine frame and the following:

either by the provision of an interlocked guard complying with EN 294:1992, Table 4;

or by a frame preventing from unintentional contact with the blades, generally as shown in Figure 5

having a minimum depth of 120 mm (distance from edge of frame to slicing blades).

Key

1 cutting side of slicing blades

2 frame

d distance from edge of frame to slicing blades

Figure 5 – Minimum distance

The operating lever shall command the start function of the blades. If the lever is released the machine shall

stop and the lever shall return to the rest position ("hold-to-run").

The design of the bread pusher and the comb shall prevent access to the blades at the end of the pusher’s

movement.

On machines where the frame supporting the blades moves relative to the machine frame, the crushing

hazard between the blade frame and the machine frame shall be avoided. To achieve this, the maximum

clearance between the blade frame and the machine frame, where accessible, shall be less than 4 mm.

5.2.1.2.2 Type 1b machines (automatic)

The slicing blades and in-feed device shall be protected by one of the following methods:

an interlocking guard, which prevents access to the cutting side of the blades and the infeed device;

or

a control guard, complying with 5.4.9 of EN 953:1997, which when closed prevents access to the cutting

side of the blades and the infeed device and initiates the operation of the blades and the in-feed device;

or

an active opto-electronic protective device (AOPD) of type 2 in accordance with EN 61496-1:1997,

included in a category 3 circuit as defined by EN 954-1:1996.

In all cases, the dimensions of any openings in the guard shall be in accordance with Table 4 of EN 294:1992.

Opening of the guard or actuation of the active opto-electronic protective device shall cause the machine to

stop in the shortest possible time, but in no case exceed 1 s.

5.2.1.2.3 Type 1c machines (automatic with continuous feeding)

The slicing blades and in-feed device shall be protected by an interlocking guard. The safety distance from the

edge of the bread in-feed opening to the nearest danger zone shall be greater than or equal to 850 mm. The

height of the opening of the tunnel shall be limited to 200 mm.

An alternative solution consists in fitting active opto-electronic protective device (see EN 61496-1:1997)

included in a category 3 circuit as defined by EN 954-1:1996

Opening of the guard or actuation of the active opto-electronic protective device shall cause the machine to

stop in the shortest possible time, but in no case exceed 1 s.

5.2.1.3 Zone 2: Discharge area

On the discharge side, only the uncutting sides of the blades shall be exposed. To prevent access to the

cutting side of the blades, the gap between or around individual blades shall be less than 25 mm.

The crushing hazard between the blade frame and the machine frame shall be avoided. To achieve this, the

maximum clearance between the blade frame and the machine frame, where accessible, shall be less than

4 mm, or the clearance between the blade frame and the machine frame shall be in accordance with EN 349.

5.2.1.4 Zone 3: Crumb tray

Means shall be implemented to reduce risks to personnel after removal of the crumb tray.

For “automatic” (type 1b) and “automatic with continuous feeding” (type 1c) machines, access to the cutting

side of the blades and to other moving parts shall be prevented. This can be achieved by designing the inside

of the machine to comply with Table 4 of EN 294:1992. If not, the crumb tray shall be interlocked.

For “hand operated” machines (type 1a), if removal of the crumb tray allows access to the cutting side of the

slicing blades and to other moving parts, they shall either conform to the requirements of an automatic

machine or fit a warning sign (see examples in Figure 6) in accordance with EN 61310-1.

Figure 6 — Example of warning signs

5.2.1.5 Zone 4: Drive mechanisms

Access to drive mechanisms shall be prevented. This can be achieved by housing them within the machine

frame. Any opening in the machine frame shall have a fixed or interlocking guard.

5.2.2 Mechanical hazards for type 2 machines

5.2.2.1 Guards and interlocking devices

5.2.2.1.1 General

Guards shall comply with EN 953 and EN 294.

Interlocking devices shall comply with EN 1088.

Unless specified otherwise in specific clauses, safety related parts of the interlocking system associated with

interlocking devices of guards shall be, in accordance with EN 954-1, not less than:

category 3 for guards preventing from access to the rotating blade and

category 1 for other guards.

Under normal stopping conditions, the blade shall come to a standstill in such a position that the cutting edge

of the blade does not protrude into the cutting area.

5.2.2.1.2 Specific requirements for interlocking devices without guard locking, associated with

guards preventing from access to the blade

This solution shall only be used if after activation of the device the blade stops within the shortest stopping

time from the following: 0,5 s, or a half rotation for a rotating blade/a half cycle of oscillating blades. If

necessary for achieving these objectives a braking device shall be provided. Otherwise the interlocking device

shall be with guard locking in accordance with 5.2.2.1.3.

The interlocking device shall be activated after opening of the guard by more than 10 mm. The specified

stopping time shall also be achieved after actuation of the emergency stop, or in the event of a power failure.

Instruction for use shall recommend regular inspection and maintenance, and define the elements to be check

in order to maintain operating effectiveness of the braking device.

5.2.2.1.3 Specific requirements for interlocking devices with guard locking, associated with guards

preventing from access to the blade

The unlocking shall not depend on a timer, but on standstill monitoring. The safety related parts of the

monitoring system shall be not less than category 1 in accordance with EN 954-1:1996.

The locking shall be effective even in the event of a power failure.

5.2.2.2 Zone 1: Movement of the feed device in feed trough

Unless hazards can be eliminated by design in accordance with 4.2 of EN ISO 12100-2:2003 access shall be

prevented by the use of a control guard according to 5.4.9 of EN 953:1997.

5.2.2.3 Zone 2: Rotating blade in cutting area, access from feed trough

As far as this hazard is not dealt with by the safety measures for zone 1, access into the danger zones in the

cutting area shall be prevented:

either by an interlocking guard with guard locking over the feed trough according to 3.25.5 of

EN ISO 12100-1:2003 (see 5.2.2.1.3)

or by an interlocking guard without guard locking (see 5.2.2.1.2).

Movable guards shall be interlocked with the drive of the blade.

The movable guards may also be designed as control guards according to 5.4.9 of EN 953:1997.

If the vertical end face of the feed trough is open and the feed device/bread holder (or pusher) do not prevent

access, the length L of the feed trough shall be at least 850 mm according to Table 4 of EN 294:1992 (see

Figure 7). If the opening of the feed trough or the space released by the pusher is larger than 120 mm (see

Table 4 of EN 294:1992), the length of the infeed trough shall be at least 1 200 mm.

Key

L ≥ 850 mm or 1 200 mm (see 5.2.2.3)

L ≥ 1 200 mm (see 5.2.2.4)

when the feed trough or discharge trough are open faced

where

L = Distance from the edge of the guard (cover) on the infeed side and the blade

L = Distance from the edge of the guard (cover) on the outlet side and the blade

Figure 7 — Safety measures on type 2 bread slicing machines

5.2.2.4 Zone 3: Rotating blade in cutting area, access via discharge through

Access shall be prevented by the use of:

either an interlocking guard with guard locking (cover) according to 3.25.5 of EN ISO 12100-1:2003

(see 5.2.2.1.3)

or by an interlocking guard without guard locking (see 5.2.2.1.2).

The discharge trough shall be guarded or the aperture on the discharge side shall be designed according to

Table 4 of EN 294:1992. If the opening of the discharge trough is larger than 120 mm (see Table 4 of

EN 294:1992), the length L of the discharge trough shall be at least 1 200 mm (see Figure 7).

With a distance to the blade plane greater than or equal to 1 200 mm and an aperture less than or equal to

120 mm, the trough end may be open.

The movable guard may be designed as a control guard according to 5.4.9 of EN 953:1997.

5.2.2.5 Zone 4: Rotating blade in the blade housing

Rotating blade

Access to the rotating blade shall be prevented by a blade housing. Doors and flaps in the blade housing

shall be designed as interlocking guards with guard locking (see 5.2.2.1.3) according to 3.25.5 of

EN ISO 12100-1:2003 or an interlocking guard if the blades could only be reached after they come to a

standstill;

Breakage of blade or detachment of blade mounting

The connection between the blade and its shaft shall be positive or the design of the mounting system

shall prevent the blade from detachment during operation (e.g. by self-tightening means). The blade

housing shall be designed for retaining the blade or ejected parts in case of detachment.

Stationary blade

If the housing is open, the blade shall not move by gravity.

5.2.2.6 Zone 5: Rotating blade, access via the crumb tray opening

Access to the blade via the crumb tray opening shall be protected either by distances complying with Table 4

of EN 294:1992 or the crumb tray shall be interlocked.

5.2.2.7 Zone 6: Drive mechanisms of blade and feed device/bread holder

Access to the drive mechanisms shall be prevented by the use of either fixed or interlocked movable guards

according to 3.2 or 3.3 of EN 953:1997. If guards have to be dismantled frequently for the purpose of

changing the operating process or for the purpose of cleaning, they shall be interlocked (see 5.2.2.1).

5.2.2.8 Zone 7: Outlet conveyor belt

Access to the inrunning nips between the belt and rotating rollers shall be prevented by a fixed guard with

dimensions complying with Table 4 of EN 294:1992.

5.2.2.9 Zone 8: Unintentional or intentional closing of machine parts

Movable machine components (e.g. hoods or covers) shall be prevented from slamming shut, e.g. by

providing a counter weight or a spring which, when open, ensures that the hood or cover swings back to a

position beyond top dead centre.

The protective hoods or covers shall be provided with a grab handles.

5.2.2.10 Handling devices

The manufacturer shall provide devices e.g. handles, safety cages for the handling of blades.

For fitting and removal of the blade, if this requires specific tools, they shall be provided by the manufacturer.

The manufacturer shall include in the instruction for use an advice concerning the safe disposal of blade, for

instance wearing protective gloves.

5.2.3 Loss of stability

Machines shall be designed not to tip or fall and shall comply with 5.2.3.1 to 5.2.3.2 as applicable.

For machines designed to be fixed to the floor, the instruction handbook shall indicate the values of forces at

the fixing points and the dimensions of the fixing elements.

5.1.3.1 Free standing machines without castors shall not tip or fall when tilted 10¯ from the horizontal

plane in the most unfavourable direction.

5.1.3.2 Free standing machines with castors shall have at least two castors (or sets of castors) fitted with

a locking device, and shall comply with the provisions of 5.2.3.1.

5.3 Electrical hazards

5.3.1 General

The electrical equipment shall comply with EN 60204-1, with the following precision and complements.

5.3.2 Safety requirements related to electromagnetic phenomena

Machines shall have sufficient immunity to electromagnetic disturbances to enable them to operate safely as

intended and not fail to danger when exposed to the levels and types of disturbances intended by the

manufacturer.

The manufacturer of the machines shall design, install and wire the requirement and sub-assemblies taking

into account the recommendations of the suppliers of these sub-assemblies.

5.3.3 Protection against electric shock (see Clause 6 of EN 60204-1:1997)

The electrical equipment shall comply with Clause 6 of EN 60204-1:1997.

5.3.4 Power circuits (see 7.2.3 of EN 60204-1:1997)

Devices for detection and interruption of over-current have to be applied to each live conductor in compliance

with EN 60204-11997, 7.2.3. In case of single phase machines, such device is required for the earthed neutral

conductor.

5.3.5 protection against earth faults in control circuits (see 9.4.3.1 of EN 60204-1:1997)

For machinery supplied from a single-phase conductor and an earthed neutral conductor, there is no

requirement for double pole interruption of the control circuit. The single pole interruption shall be in the phase

conductor.

5.3.6 Emergency stop (see 9.2.5.4 of EN 60204-1:1997)

For type 1: The normal OFF switch shall be easily reachable from the operator position. Unless the stopping

time is less than 1 s, an emergency-stop control of category 0 or 1 according to EN 60204-1, easily accessible

from the normal operator position, shall be fitted.

For type 2: An emergency stop is not necessary, providing that the guards are interlocked with guard locking.

If not, an emergency stop control of category 0 or 1 according to EN 60204-1, easily accessible from the

normal operator position, shall be fitted.

5.3.7 Motor enclosures (see 15.2 of EN 60204-1:1997)

Where a motor has a degree of protection lower than IP23 it shall be mounted inside an enclosure that

guarantees a minimum degree of protection IP23 according to EN 60529:1991.

5.3.8 Other electric requirements for type 2 machines

Unless otherwise specified, the safety related parts of the control systems shall be not less than category

3 of EN 954-1:1996;

the normal stop device shall be to category 0 or 1 in accordance with 9.2.2 of EN 60204-1:1997;

the level of performance of safety devices shall be consistent with the control system into which they are

integrated;

control actuating devices, signals and display elements shall have a minimum degree of protection IP54

according to EN 60529:1991;

where interlocking systems have movable parts, these shall be protected from contamination with dough,

crumbs, dry ingredients, oil, moisture, etc.;

where these interlocking systems may be exposed to liquid agents, oil etc., e.g. during cleaning or

maintenance, they shall be protected to an appropriate IP rating (e.g. IPX5 of 12.3 of EN 60204-1:1997);

the whole machine housing shall have a minimum degree of protection IP23 according to

EN 60529:1991.

5.4 Hygiene requirements

5.4.1 General

Bread slicers shall be designed and manufactured in accordance with EN 1672-2and Annex B of this

document.

The three different areas shown in the examples of Figure 8 are defined in EN 1672-2. The precise boundary

between the zones depends on the detailed design of the machine but in general they are at least as follows:

5.4.2 Food area

The food area is as follows:

the in-feed surfaces, in contact with bread;

the slicing surfaces;

the out-feed surfaces in contact with bread;

the inside of the crumb tray.

5.4.3 Splash area

The splash area is as follows:

the surfaces which come into contact with the crumbs, except the crumb tray.

5.4.4 Non food area

The non food area is as follows:

the remaining surfaces of the machine which do not come into contact with the product.

Figure 8.a Figure 8.b

Key

food area

splash area

non food area

Figure 8 — Hygiene areas

5.5 Hazards generated by neglecting ergonomic principles

Harmful body postures during maintenance and cleaning as well as when filling and emptying the machine

shall be avoided.

Suitably positioned means to allow the use of lifting devices and/or transport carriages shall be provided for

installation, removal and transport of any part of the bread slicer weighing more than 25 kg.

Pushing and pulling efforts in case of manual feeding shall not exceed 150 N.

Control devices shall be placed within proper reach distance for the operator as stated in Annex A of

EN 614-1:1995.

5.6 Hazards from cleaning and handling

The manufacturer shall define procedures and personal protective equipment (PPE) to be used for avoiding

the hazards or reducing the risks due to the cleaning or handling of the blades/blade assemblies.

5.7 Noise reduction

The noise emission of bread slicers shall be reduced at the design stage to low levels by applying noise

reduction measures at source as given in EN ISO 11688-1. The success of the applied noise reduction

measures is assessed on the basis of the actual noise emission values (see Annex A) in relation to other

machines of the same family.

6 Verification of safety and hygiene requirements and/or measures

This clause contains the methods for verification of the compliance with the safety requirements of this

document. As far as the criteria for acceptance and the conditions during verification are not self-evident, they

can also be found in the Table 1.

Table 1 – Verification

Relevant clause Method of verification

5.2.1.1 By design verification, measurement of the dimensions and functional test

5.2.1.2 By design verification, visual inspection, measurement of the dimensions and functional test

5.2.1.3 By visual inspection and measurement of the dimensions

5.2.1.4 By visual inspection and measurement of the dimensions

5.2.1.5 By visual inspection

5.2.2.1 By design verification, visual inspection, measurement of the dimensions and functional test

5.2.2.2 By design verification, visual inspection, measurement of the dimensions and functional test

5.2.2.3 By design verification, visual inspection, measurement of the dimensions and functional test

5.2.2.4 By design verification, visual inspection, measurement of the dimensions and functional test

5.2.2.5 By design verification, visual inspection, measurement of the dimensions and functional test

5.2.2.6 By measurement of the dimensions and functional test

5.2.2.7 By visual inspection and functional test

5.2.2.8 By visual inspection and measurement of the dimensions

5.2.2.9 By visual inspection and functional test

5.2.2.10 By visual inspection and functional test

5.2.3 By tilting test at 10° for free standing machines and verification of the instruction handbook

By design verification, visual inspection and by testing in accordance with Clause 19 of

EN 60204-1:1997

5.3

Visual inspection and functional test of emergency stop control, if existing

Visual inspection and functional test of normal stop control

5.4 In accordance with Clause 6 of EN 1672-2:2005

5.5 By measurement of the forces, by inspection of the visibility of the indicators, buttons etc.

5.6 Visual inspection

5.7 By measurement according to Annex A.

7 Information for use

7.1 Instruction handbook

The manufacturer shall provide an instruction handbook in accordance with 6.5 of EN ISO 12100-2:2003.

In particular, the instruction handbook shall provide:

the provisions for handling, transportation, storage, installation, starting up;

information on residual risks, and recommended personal protective equipment (PPE) including an

instruction, that cut resistant gloves shall be worn when changing the cutting tools and when carrying out

any work in the vicinity of the cutting tools;

the provisions for cleaning: the cleaning products to be used, the recommended implements, the

procedures and frequency, any necessary warning (for example, cleaning shall be done once the

machine is stopped, using a brush, a plastic scraper, a duster, a vacuum cleaner, …, metallic implements

are not recommended);

the capacity of the machine;

the value of forces at the fixing points if the machine is fixed;

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...