EN 16119:2021

(Main)LPG equipment and accessories - Sealing caps and plugs for LPG cylinder and pressure vessel valves - Specification and testing

LPG equipment and accessories - Sealing caps and plugs for LPG cylinder and pressure vessel valves - Specification and testing

This document specifies the design, testing and marking requirements for caps and plugs used to form a pressure tight seal with liquefied petroleum gas (LPG) cylinder valves and pressure vessel valves. Sealing caps and plugs provide an additional seal for self-closing and manually operated valves.

Protection caps or dust caps and tamper evident seals that do not form an additional seal as part of their design are excluded from the scope of this document.

Cylinder valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance with EN ISO 14245 and EN ISO 15995.

Pressure vessel valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance with EN 13175. Occasional liquid withdrawal valve caps and plugs are excluded from the scope of this document.

Reusable and single use sealing caps and plugs are included in this document.

This document does not exclude the use of other designs that provide an equivalent level of safety.

NOTE The term “pressure vessel” does not include LPG tank vehicles, also called “road tankers”, in CEN/TC 286 standards.

Flüssiggas-Geräte und Ausrüstungsteile - Dichtkappen und Dichtstopfen für Flaschen und Druckbehälter für Flüssiggas (LPG) - Spezifikation und Prüfungen

Dieses Dokument legt die Anforderungen an die Auslegung, Prüfung und Kennzeichnung von Kappen und Stopfen fest, die zur Herstellung einer druckdichten Abdichtung für Ventile für Flaschen und Druckbehälter für Flüssiggas (LPG, en: liquefied petroleum gas) verwendet werden. Dichtkappen und Dichtstopfen stellen eine zusätzliche Abdichtung für selbstschließende und handbetätigte Ventile sicher.

Schutzkappen oder Schmutzkappen und Originalverschlüsse, bei denen die Herstellung einer zusätzlichen Abdichtung nicht Bestandteil ihrer Auslegung ist, fallen nicht in den Anwendungsbereich dieses Dokuments.

Flaschenventilkappen und stopfen können für nach EN ISO 14245 und EN ISO 15995 hergestellte Ventile für die Flüssigphase und Gasphase verwendet werden.

Druckbehälterventilkappen und stopfen können für nach EN 13175 hergestellte Ventile für die Flüssigphase und Gasphase verwendet werden. Kappen und Stopfen für Ventile für die gelegentliche Entnahme aus der Flüssigphase. sind vom Anwendungsbereich des Dokuments ausgeschlossen.

Wiederverwendbare Dichtkappen und Einwegdichtkappen und -stopfen sind im Anwendungsbereich des Dokuments enthalten.

Dieses Dokument schließt die Verwendung anderer Auslegungen, die ein gleichwertiges Sicherheitsniveau sicherstellen, nicht aus.

ANMERKUNG Der Begriff „Druckbehälter“ umfasst keine LPG-Tankfahrzeuge, auch in Normen des CEN/TC 286 „Straßentankwagen“ genannt.

Équipements pour GPL et leurs accessoires - Bouchons et obturateurs d'étanchéité pour robinets de bouteilles et vannes de réservoirs sous pression - Spécifications et essais

Le présent document spécifie les exigences de conception, d'essai et de marquage applicables aux bouchons et obturateurs utilisés pour former un joint étanche à la pression au niveau des robinets de bouteilles et des vannes de réservoirs sous pression de gaz de pétrole liquéfié (GPL). Les bouchons et obturateurs d'étanchéité assurent une étanchéité supplémentaire sur les robinets et vannes à fermeture automatique et manuelle.

Les capuchons protecteurs/bouchons anti-poussière et les garanties d'inviolabilité qui, de par leur conception, ne sont pas étanches n'entrent pas dans le domaine d'application du présent document.

Les bouchons et obturateurs des robinets de bouteilles peuvent être utilisés avec des robinets pour liquides et gaz fabriqués conformément à l'EN ISO 14245 et à l'EN ISO 15995.

Les bouchons et obturateurs des vannes de réservoirs sous pression peuvent être utilisés avec des vannes pour liquides et gaz fabriquées conformément à l'EN 13175. Le présent document ne traite pas des bouchons et obturateurs des clapets de reprise liquide.

Le présent document couvre à la fois les bouchons et obturateurs d'étanchéité réutilisables et à usage unique.

Le présent document n'exclut pas l'utilisation d'autres conceptions assurant un niveau de sécurité équivalent.

NOTE Le terme « réservoir sous pression » n'inclut pas les véhicules-citernes pour GPL, également appelés « camions-citernes » dans les normes du CEN/TC 286.

Oprema in pribor za utekočinjeni naftni plin (UNP) - Tesnilne kape in čepi za ventile jeklenk in tlačnih posod za UNP - Specifikacija in preskušanje

Ta evropski standard določa zahteve za zasnovo, preskušanje in označevanje za kape in pokrove, ki se uporabljajo za tesnjenje pri ventilih jeklenk in tlačnih posod za utekočinjeni naftni plin (UNP). Tesnilne kape in pokrovi zagotavljajo dodatno tesnilo za samozaporne in ročno upravljane ventile.

Kape proti prahu in tesnila, ki jih ni mogoče nedovoljeno odpreti, ki ne zagotavljajo dodatnega tesnila kot del njihove zasnove, ne spadajo na področje uporabe tega evropskega standarda.

Kape in pokrovi ventilov jeklenk se lahko uporabljajo z ventili za tekočine in hlape, proizvedenimi v skladu s standardoma EN ISO 14245 in EN ISO 15995.

Kape in pokrovi ventilov tlačnih posod se lahko uporabljajo z ventili za tekočine in hlape, proizvedenimi v skladu s standardom EN ISO 13175. Kape in pokrovi ventilov za občasen odvzem tekočine ne spadajo na področje uporabe tega evropskega standarda.

Ta evropski standard zajema tesnilne kape in pokrove za večkratno in enkratno uporabo.

Ta evropski standard ne izključuje uporabe drugih vrst kap in pokrovov, ki zagotavljajo enakovredno stopnjo varnosti.

OPOMBA: Izraz »tlačna posoda« ne zajema vozil s posodo za utekočinjeni naftni plin (imenovanih tudi »cestne cisterne«), navedenih v standardih CEN/TC 286.

General Information

- Status

- Published

- Publication Date

- 21-Dec-2021

- Withdrawal Date

- 29-Jun-2022

- Technical Committee

- CEN/TC 286 - Liquefied petroleum gas equipment and accessories

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 22-Dec-2021

- Due Date

- 28-Feb-2022

- Completion Date

- 22-Dec-2021

Relations

- Effective Date

- 29-Dec-2021

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

EN 16119:2021 - Overview

EN 16119:2021 is the CEN standard that specifies design, testing and marking requirements for sealing caps and plugs used to form a pressure‑tight seal with liquefied petroleum gas (LPG) cylinder and pressure vessel valves. It applies to both reusable and single‑use sealing caps/plugs and covers performance under defined operating temperatures (minimum −20 °C, optional −40 °C special requirements, maximum 65 °C). Protection/dust caps and tamper‑evident devices that do not provide an additional pressure seal are excluded. The standard supersedes EN 16119:2013 and introduces requirements such as external leak tightness and UV resistance.

Key topics and requirements

- Scope and exclusions: Sealing caps/plugs for cylinder valves (compatible with EN ISO 14245, EN ISO 15995) and pressure vessel valves (compatible with EN 13175). Road tanker valves and occasional liquid withdrawal valve caps are excluded.

- Materials and compatibility: Materials in contact with LPG must be chemically and physically compatible with propane/butane per EN ISO 11114‑1/2. Requirements cover metallic and non‑metallic material selection, corrosion resistance, UV resistance and avoidance of dezincification.

- Design: Thread standards, external leak tightness, means of attachment for reusable caps, and tamper‑evidence considerations.

- Testing and inspection:

- LPG resistance and tightened parameters vs. previous edition

- Water resistance

- Ageing and combined ageing (UV, rain)

- Hydraulic strength tests (different criteria for reusable vs single‑use)

- Endurance test and a pressure test after endurance

- Torque test

- Marking, documentation and packaging: Required markings and supporting documentation to ensure traceability and correct use.

- Environmental considerations: Encourages suppliers with environmental policies and references EN ISO 14021/14024/14025.

Practical applications and users

Who uses EN 16119:2021:

- LPG equipment manufacturers designing or producing caps and plugs

- Test laboratories performing compliance and type testing

- Procurement and QA teams specifying components for cylinders and pressure vessels

- Safety engineers, inspectors and regulators ensuring applied components meet safety and leak tightness requirements

Practical benefits:

- Ensures pressure‑tight sealing to reduce leak and safety risks

- Provides a common technical benchmark for procurement and certification

- Improves durability and suitability across temperature ranges and environmental exposure

Related standards

Relevant referenced standards include:

- EN ISO 11114‑1 / EN ISO 11114‑2 (material compatibility)

- EN 549 (rubber materials)

- EN 751‑1/2/3 (sealing materials for threaded joints)

- EN 13175 (pressure vessel valves)

- EN ISO 14245, EN ISO 15995 (cylinder valve types)

- EN 15202 (operational dimensions)

Keywords: EN 16119:2021, sealing caps, plugs, LPG cylinder valves, pressure vessel valves, specification and testing, LPG accessories, UV resistance, external leak tightness.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 16119:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "LPG equipment and accessories - Sealing caps and plugs for LPG cylinder and pressure vessel valves - Specification and testing". This standard covers: This document specifies the design, testing and marking requirements for caps and plugs used to form a pressure tight seal with liquefied petroleum gas (LPG) cylinder valves and pressure vessel valves. Sealing caps and plugs provide an additional seal for self-closing and manually operated valves. Protection caps or dust caps and tamper evident seals that do not form an additional seal as part of their design are excluded from the scope of this document. Cylinder valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance with EN ISO 14245 and EN ISO 15995. Pressure vessel valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance with EN 13175. Occasional liquid withdrawal valve caps and plugs are excluded from the scope of this document. Reusable and single use sealing caps and plugs are included in this document. This document does not exclude the use of other designs that provide an equivalent level of safety. NOTE The term “pressure vessel” does not include LPG tank vehicles, also called “road tankers”, in CEN/TC 286 standards.

This document specifies the design, testing and marking requirements for caps and plugs used to form a pressure tight seal with liquefied petroleum gas (LPG) cylinder valves and pressure vessel valves. Sealing caps and plugs provide an additional seal for self-closing and manually operated valves. Protection caps or dust caps and tamper evident seals that do not form an additional seal as part of their design are excluded from the scope of this document. Cylinder valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance with EN ISO 14245 and EN ISO 15995. Pressure vessel valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance with EN 13175. Occasional liquid withdrawal valve caps and plugs are excluded from the scope of this document. Reusable and single use sealing caps and plugs are included in this document. This document does not exclude the use of other designs that provide an equivalent level of safety. NOTE The term “pressure vessel” does not include LPG tank vehicles, also called “road tankers”, in CEN/TC 286 standards.

EN 16119:2021 is classified under the following ICS (International Classification for Standards) categories: 23.060.99 - Other valves. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16119:2021 has the following relationships with other standards: It is inter standard links to EN 16119:2013, EN ISO 11114-2:2021, EN 12165:2024, EN 15202:2019, EN 12420:2024, EN 751-1:1996, EN ISO 14024:2018, EN 751-2:1996, EN ISO 11114-1:2020, EN 12164:2024, EN ISO 14025:2010, EN 751-3:2022+A1:2023, EN 13175:2019+A1:2020, EN ISO 14021:2016, EN 13952:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16119:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2022

Nadomešča:

SIST EN 16119:2013

Oprema in pribor za utekočinjeni naftni plin (UNP) - Tesnilne kape in čepi za

ventile jeklenk in tlačnih posod za UNP - Specifikacija in preskušanje

LPG equipment and accessories - Sealing caps and plugs for LPG cylinder and pressure

vessel valves - Specification and testing

Flüssiggas-Geräte und Ausrüstungsteile - Dichtkappen und Dichtstopfen für Flaschen

und Behälter für Flüssiggas (LPG) - Spezifikation und Prüfungen

Équipements pour GPL et leurs accessoires - Bouchons d'étanchéité mâles et femelles

pour robinets de bouteilles et réservoirs - Spécifications et essais

Ta slovenski standard je istoveten z: EN 16119:2021

ICS:

23.020.32 Tlačne posode Pressure vessels

23.020.35 Plinske jeklenke Gas cylinders

83.140.50 Tesnila Seals

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16119

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2021

EUROPÄISCHE NORM

ICS 23.060.99 Supersedes EN 16119:2013

English Version

LPG equipment and accessories - Sealing caps and plugs

for LPG cylinder and pressure vessel valves - Specification

and testing

Équipements pour GPL et leurs accessoires - Bouchons Flüssiggas-Geräte und Ausrüstungsteile - Dichtkappen

et obturateurs d'étanchéité pour robinets de bouteilles und Dichtstopfen für Flaschen und Druckbehälter für

et vannes de réservoirs sous pression - Spécifications Flüssiggas (LPG) - Spezifikation und Prüfungen

et essais

This European Standard was approved by CEN on 22 November 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16119:2021 E

worldwide for CEN national Members.

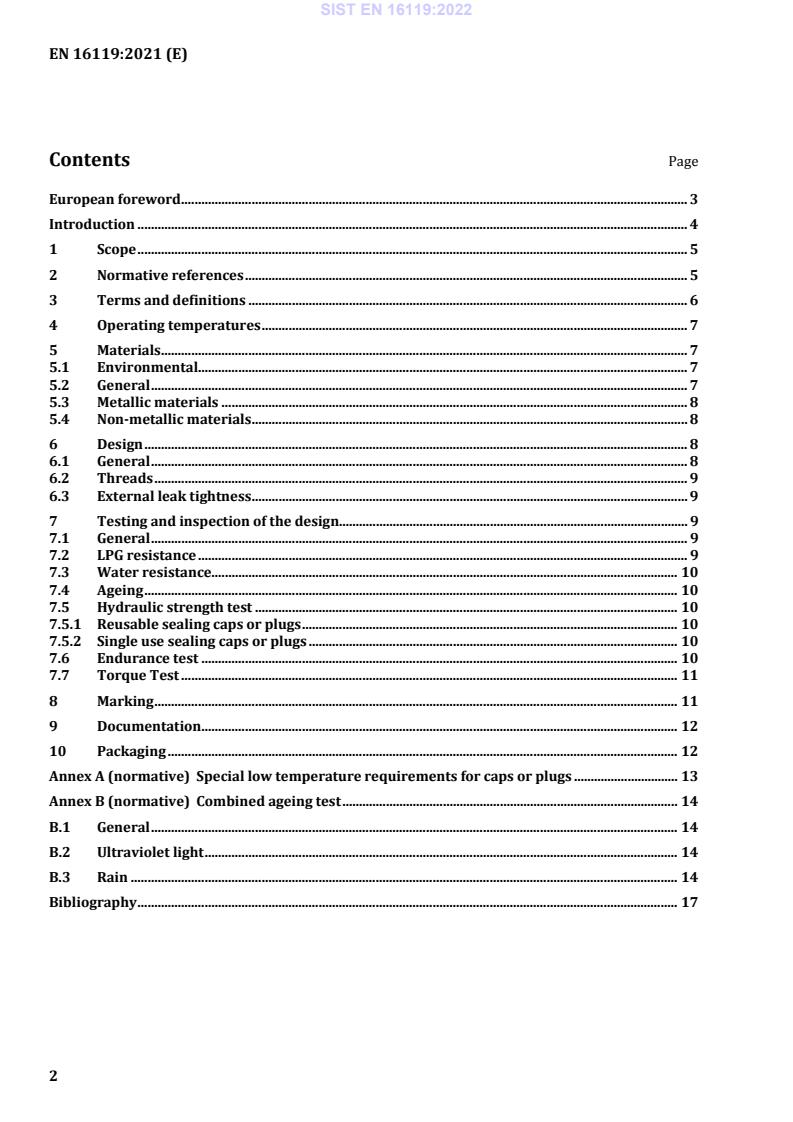

Contents Page

European foreword . 3

Introduction . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Operating temperatures . 7

5 Materials . 7

5.1 Environmental. 7

5.2 General . 7

5.3 Metallic materials . 8

5.4 Non-metallic materials . 8

6 Design . 8

6.1 General . 8

6.2 Threads . 9

6.3 External leak tightness . 9

7 Testing and inspection of the design. 9

7.1 General . 9

7.2 LPG resistance . 9

7.3 Water resistance . 10

7.4 Ageing . 10

7.5 Hydraulic strength test . 10

7.5.1 Reusable sealing caps or plugs . 10

7.5.2 Single use sealing caps or plugs . 10

7.6 Endurance test . 10

7.7 Torque Test . 11

8 Marking . 11

9 Documentation . 12

10 Packaging . 12

Annex A (normative) Special low temperature requirements for caps or plugs . 13

Annex B (normative) Combined ageing test . 14

B.1 General . 14

B.2 Ultraviolet light . 14

B.3 Rain . 14

Bibliography . 17

European foreword

This document (EN 16119:2021) has been prepared by Technical Committee CEN/TC 286 “LPG

equipment and accessories”, the secretariat of which is held by NSAI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2022, and conflicting national standards shall be

withdrawn at the latest by June 2022.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 16119:2013.

— Addition of external leak tightness term and definition

— Introduction of requirement for UV resistance

— Parameters for LPG resistance have been tightened

— Introduction of pressure test after endurance test

— Environmental checklist deleted

In this document the unit bar is used, due to its universal use in the gas industry. It should, however, be

5 5

noted that bar is not an SI unit, and that the corresponding SI unit for pressure is Pa (1 bar = 10 Pa = 10

N/m ).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

This document calls for the use of substances and procedures that may be injurious to health and/or the

environment if adequate precautions are not taken. It refers only to technical suitability and does not

absolve the user from legal obligations at any stage.

It is recommended that companies using this document develop an environmental management policy.

For guidance see ISO 14000 series.

Protection of the environment is a key political issue in Europe and elsewhere. For TC 286 this is covered

in CEN/TS 16765 [4] LPG equipment and accessories - Environmental considerations for CEN/TC 286

standards, and this Technical Specification should be read in conjunction with this document. The

Technical Specification provides guidance on the environmental aspects to be considered regarding

equipment and accessories produced for the LPG industry and the following is addressed:

a) design;

b) manufacture;

c) packaging;

d) use and operation; and

e) disposal.

It has been assumed in the drafting of this document that the execution of its provisions is entrusted to

appropriately qualified and experienced people.

All pressures are gauge pressures unless otherwise stated.

This document requires measurement of material properties, dimensions and pressures. All such

measurements are subject to a degree of uncertainty due to tolerances in measuring equipment etc. It

may be beneficial to refer to the leaflet, Measurement uncertainty leaflet SP INFO 2000:27 [3].

1 Scope

This document specifies the design, testing and marking requirements for caps and plugs used to form a

pressure tight seal with liquefied petroleum gas (LPG) cylinder valves and pressure vessel valves. Sealing

caps and plugs provide an additional seal for self-closing and manually operated valves.

Protection caps or dust caps and tamper evident seals that do not form an additional seal as part of their

design are excluded from the scope of this document.

Cylinder valve caps and plugs can be used with valves for liquid and vapour manufactured in accordance

with EN ISO 14245 and EN ISO 15995.

Pressure vessel valve caps and plugs can be used with valves for liquid and vapour manufactured in

accordance with EN 13175. Occasional liquid withdrawal valve caps and plugs are excluded from the

scope of this document.

Reusable and single use sealing caps and plugs are included in this document.

This document does not exclude the use of other designs that provide an equivalent level of safety.

NOTE The term “pressure vessel” does not include LPG tank vehicles, also called “road tankers”, in CEN/TC 286

standards.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 549, Rubber materials for seals and diaphragms for gas appliances and gas equipment

EN 751-1, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water - Part 1: Anaerobic jointing compounds

EN 751-2, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water - Part 2: Non-hardening jointing compounds

EN 751-3, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and

hot water - Part 3: Unsintered PTFE tapes

EN 12164, Copper and copper alloys - Rod for free machining purposes

EN 12165, Copper and copper alloys - Wrought and unwrought forging stock

EN 12420, Copper and copper alloys - Forgings

EN 13175, LPG equipment and accessories — Specification and testing for Liquefied Petroleum Gas (LPG)

tank valves and fittings

EN 15202, LPG equipment and accessories - Essential operational dimensions for LPG cylinder valve outlet

and associated equipment connections

EN ISO 11114-1, Gas cylinders - Compatibility of cylinder and valve materials with gas contents - Part 1:

Metallic materials (ISO 11114-1)

EN ISO 11114-2, Gas cylinders - Compatibility of cylinder and valve materials with gas contents - Part 2:

Non-metallic materials (ISO 11114-2)

EN ISO 14021, Environmental labels and declarations - Self-declared environmental claims (Type II

environmental labelling) (ISO 14021)

EN ISO 14024, Environmental labels and declarations - Type I environmental labelling - Principles and

procedures (ISO 14024)

EN ISO 14025, Environmental labels and declarations - Type III environmental declarations - Principles and

procedures (ISO 14025)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

liquefied petroleum gas

LPG

low pressure liquefied gas composed of one or more light hydrocarbons which are assigned to UN 1011,

UN 1075, UN 1965, UN 1969 or UN 1978 only and which consists mainly

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...