CEN/TR 15522-2:2006

(Main)Oil spill identification - Waterborne petroleum and petroleum products - Part 2: Analytical methodology and interpretation of results

Oil spill identification - Waterborne petroleum and petroleum products - Part 2: Analytical methodology and interpretation of results

This Technical Report (TR) describes a methodology to identify waterborne oils spilled in marine, estuarine and aquatic environments by comparing samples from spills with those of suspected sources . It provides detailed analytical and processing specifications for identifying waterborne oil spills and their correlation to suspected sources. When suspected sources are not available, the methodology may be used to characterise the spill as far as possible with respect to the oil type.

This methodology is restricted to petroleum and petroleum products containing a significant proportion of

HC-components with a boiling point above 200 °C. Examples are: Crude oils, condensates, light fuel oils, diesel oils, residual bunker oils, lubricants, and mixtures of bilge and sludge samples. Still, the general concepts described in this methodology have a limited applicability for some kerosenes and some condensates, but may not be applicable for gasoline

NOTE This method is not intended for oil spills to groundwater and soil. The chromatograms of oil extracted from soil and found in ground water may contain reduced and/or additional peaks compared to the source sample. Including such samples in this method makes it necessary to add extraction methods and to describe which compounds are possibly reduced and/or which additional peaks can be expected to change the final conclusion from a probable match into a match. This is beyond the scope of this guideline, however, when case samples completely match according to this method, the method is valid for those samples.

Identifizierung von Ölverschmutzungen - Rohöl und Mineralölerzeugnisse aus dem Wasser - Teil 2: Analytische Methodik und Interpretation der Ergebnisse

Identification des pollutions pétrolières - Pétrole et produits pétroliers dans l'eau - Partie 2 : Méthodologie analytique et interprétation des résultats

Prepoznavanje razlitij olj - Nafta in naftni proizvodi v vodi - 2. del: Analitske metode in podajanje rezultatov

General Information

- Status

- Withdrawn

- Publication Date

- 31-Oct-2006

- Withdrawal Date

- 02-Oct-2012

- Technical Committee

- CEN/SS S27 - Waste - Characterization, treatment and streams

- Drafting Committee

- CEN/SS S27 - Waste - Characterization, treatment and streams

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Oct-2012

- Completion Date

- 03-Oct-2012

Relations

- Effective Date

- 08-Oct-2012

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

CEN/TR 15522-2:2006 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Oil spill identification - Waterborne petroleum and petroleum products - Part 2: Analytical methodology and interpretation of results". This standard covers: This Technical Report (TR) describes a methodology to identify waterborne oils spilled in marine, estuarine and aquatic environments by comparing samples from spills with those of suspected sources . It provides detailed analytical and processing specifications for identifying waterborne oil spills and their correlation to suspected sources. When suspected sources are not available, the methodology may be used to characterise the spill as far as possible with respect to the oil type. This methodology is restricted to petroleum and petroleum products containing a significant proportion of HC-components with a boiling point above 200 °C. Examples are: Crude oils, condensates, light fuel oils, diesel oils, residual bunker oils, lubricants, and mixtures of bilge and sludge samples. Still, the general concepts described in this methodology have a limited applicability for some kerosenes and some condensates, but may not be applicable for gasoline NOTE This method is not intended for oil spills to groundwater and soil. The chromatograms of oil extracted from soil and found in ground water may contain reduced and/or additional peaks compared to the source sample. Including such samples in this method makes it necessary to add extraction methods and to describe which compounds are possibly reduced and/or which additional peaks can be expected to change the final conclusion from a probable match into a match. This is beyond the scope of this guideline, however, when case samples completely match according to this method, the method is valid for those samples.

This Technical Report (TR) describes a methodology to identify waterborne oils spilled in marine, estuarine and aquatic environments by comparing samples from spills with those of suspected sources . It provides detailed analytical and processing specifications for identifying waterborne oil spills and their correlation to suspected sources. When suspected sources are not available, the methodology may be used to characterise the spill as far as possible with respect to the oil type. This methodology is restricted to petroleum and petroleum products containing a significant proportion of HC-components with a boiling point above 200 °C. Examples are: Crude oils, condensates, light fuel oils, diesel oils, residual bunker oils, lubricants, and mixtures of bilge and sludge samples. Still, the general concepts described in this methodology have a limited applicability for some kerosenes and some condensates, but may not be applicable for gasoline NOTE This method is not intended for oil spills to groundwater and soil. The chromatograms of oil extracted from soil and found in ground water may contain reduced and/or additional peaks compared to the source sample. Including such samples in this method makes it necessary to add extraction methods and to describe which compounds are possibly reduced and/or which additional peaks can be expected to change the final conclusion from a probable match into a match. This is beyond the scope of this guideline, however, when case samples completely match according to this method, the method is valid for those samples.

CEN/TR 15522-2:2006 is classified under the following ICS (International Classification for Standards) categories: 75.080 - Petroleum products in general. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 15522-2:2006 has the following relationships with other standards: It is inter standard links to CEN/TR 15522-2:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 15522-2:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2008

Prepoznavanje razlitij olj - Nafta in naftni proizvodi v vodi - 2. del: Analitske

metode in podajanje rezultatov

Oil spill identification - Waterborne petroleum and petroleum products - Part 2: Analytical

methodology and interpretation of results

Identifizierung von Ölverschmutzungen - Rohöl und Mineralölerzeugnisse aus dem

Wasser - Teil 2: Analytische Methodik und Interpretation der Ergebnisse

Identification des pollutions pétrolieres - Pétrole et produits pétroliers dans l'eau - Partie

2 : Méthodologie analytique et interprétation des résultats

Ta slovenski standard je istoveten z: CEN/TR 15522-2:2006

ICS:

13.020.40 Onesnaževanje, nadzor nad Pollution, pollution control

onesnaževanjem in and conservation

ohranjanje

13.060.99 Drugi standardi v zvezi s Other standards related to

kakovostjo vode water quality

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

TECHNICAL REPORT

CEN/TR 15522-2

RAPPORT TECHNIQUE

TECHNISCHER BERICHT

November 2006

ICS 75.080

English Version

Oil spill identification - Waterborne petroleum and petroleum

products - Part 2: Analytical methodology and interpretation of

results

Identification des pollutions pétrolières - Pétrole et produits Identifizierung von Ölverschmutzungen - Rohöl und

pétroliers dans l'eau - Partie 2 : Méthodologie analytique et Mineralölerzeugnisse aus dem Wasser - Teil 2: Analytische

interprétation des résultats Methodik und Interpretation der Ergebnisse

This Technical Report was approved by CEN on 25 September 2006. It has been drawn up by the Technical Committee CEN/BT/TF 120.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2006 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 15522-2:2006: E

worldwide for CEN national Members.

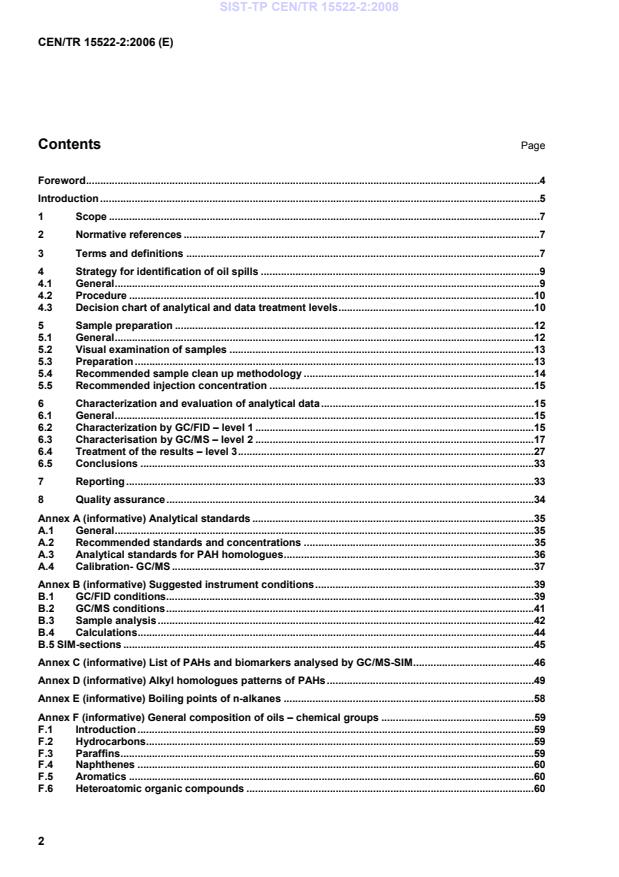

Contents Page

Foreword.4

Introduction .5

1 Scope .7

2 Normative references .7

3 Terms and definitions .7

4 Strategy for identification of oil spills .9

4.1 General.9

4.2 Procedure .10

4.3 Decision chart of analytical and data treatment levels.10

5 Sample preparation .12

5.1 General.12

5.2 Visual examination of samples .13

5.3 Preparation .13

5.4 Recommended sample clean up methodology .14

5.5 Recommended injection concentration .15

6 Characterization and evaluation of analytical data.15

6.1 General.15

6.2 Characterization by GC/FID – level 1 .15

6.3 Characterisation by GC/MS – level 2 .17

6.4 Treatment of the results – level 3.27

6.5 Conclusions .33

7 Reporting .33

8 Quality assurance.34

Annex A (informative) Analytical standards .35

A.1 General.35

A.2 Recommended standards and concentrations .35

A.3 Analytical standards for PAH homologues.36

A.4 Calibration- GC/MS .37

Annex B (informative) Suggested instrument conditions.39

B.1 GC/FID conditions.39

B.2 GC/MS conditions.41

B.3 Sample analysis.42

B.4 Calculations.44

B.5 SIM-sections .45

Annex C (informative) List of PAHs and biomarkers analysed by GC/MS-SIM.46

Annex D (informative) Alkyl homologues patterns of PAHs.49

Annex E (informative) Boiling points of n-alkanes .58

Annex F (informative) General composition of oils – chemical groups .59

F.1 Introduction.59

F.2 Hydrocarbons.59

F.3 Paraffins.59

F.4 Naphthenes .60

F.5 Aromatics .60

F.6 Heteroatomic organic compounds .60

F.7 Resins.60

F.8 Asphaltenes .60

Annex G (informative) Weathering of oils spilled at sea.61

G.1 Introduction.61

G.2 Evaporation.62

G.3 Dissolution .64

G.4 Re-distribution of chemical composition.65

G.5 Biodegradation .66

G.6 Contamination / in-homogeneity .67

G.7 Evaluation of weathering.67

G.8 Optional - Semi-quantitative distribution of PAH homologues - weathering check.69

Annex H (informative) Characteristic Features of Different Oil Types in Oil Spill Identification .70

H.1 Introduction.70

H.2 Light fuel oil (gas oil, diesel, fuel No 2).70

H.3 Lubricating oil.75

H.4 Heavy fuel oil (HFO, Bunker C, Fuel No 6).79

H.5 Waste oil (bilge oil, sludge, slops).87

H.6 Crude oil .93

H.7 Conclusion .98

Annex I (informative) Example of the evaluation of an oil case .100

I.1 Introduction.100

I.2 GC/FID results.100

I.3 GC/MS results .102

I.4 Conclusion .106

Bibliography.107

Foreword

This document (CEN/TR 15522-2:2006) has been prepared by CEN/BT/TF 120 “Oil spill identification”, the

secretariat of which is held by SN.

Introduction

This Technical Report gives a recommendation on a forensic methodology for identifying waterborne oils. The

methodology may be a support to the legal process as evidence for prosecuting offenders ("potential

responsible party" – PRP). This methodology is a technical revision of the Nordtest Method NT CHEM 001

(1991) "Oil spill identification".

This methodology is described by the following CEN documents:

Part 1 – Sampling: describes sampling techniques and the handling of oil samples prior to their arrival at the

forensic laboratory;

Part 2 – Methodology: covers the general concepts and laboratory procedures of oil spill identification

methodology, analytical techniques, data processing, data treatment, and interpretation/evaluation of results.

Oil spill identification and oil comparison is a complex methodology due to the large variation in samples and

oil spill situations, which can be encountered. Part 1 is a compilation of instructions and experiences from

experts all over the world and will guide the user in sampling, storing and delivering oil samples. Part 2 will

guide the reader through the process by dividing the methodology into 3 tiered levels. It prescribes how to

prepare and analyse oil samples with GC/FID and, if necessary, with GC-low-resolution mass spectrometry.

Differences found between samples are only relevant if a difference is larger than the analytical variance of

the method. Therefore good analytical performance and strict quality assurance are essential. In the annexes

of part 2, relevant information concerning different types of oil and oil comparison is presented.

The main purpose of the methodology described in this Technical Report (TR) is to identify oil spills in marine,

estuarine and other aquatic environments by comparing samples from spills with those of suspected sources.

In oil spill identification cases, both the oil spill and also suspected source(s) may not necessarily be

homogeneous in nature e.g. due to the changing/variable nature of oil in the bilge tanks or e.g. mixing of oil

spills from several sources in a case of a larger incident. The risk therefore exists that the chemical

composition of the reference samples may not be related to that of the spill. In such cases oil spill

fingerprinting methodologies in general will have its limitations and may not necessarily lead to firm

conclusions. To minimise the danger for “false negative” matches, good sampling practice, and particularly the

need to obtain appropriate reference/suspect source samples, is therefore crucial (as described in Part 1

Sampling).

When suspected sources are not available, this methodology may be used to characterise the spill as far as

possible with respect to oil type. The identification of the type of oil in a sample can be essential for several

reasons:

if the origin of an oil pollution event is unknown, the investigating authorities must be advised on where to

find a possible source. In case of a “mystery” spill, the mere differentiation between pure, unused

products or crude oil and waste oil (bilge residues, sludge, slops) is valuable information. Oils must be

identified rapidly in such cases because the chances of identifying sources generally decrease with time;

meaning of analytical results, i.e. their contribution to the overall evidence in criminal proceedings,

depends very much on the types of oil that are involved in oil spills. Depending on these types, the search

can be more or less focused on a few possible sources, or even a single one;

in court trials, the differentiation between pure products and waste oil may be highly important because it

allows conclusions to be drawn regarding the cause of an oil discharge, e.g. technical failure,

inadvertence, intention;

conclusions obtained from the defensible identification of spilled oil and their correlation to suspected

sources will not, however, on their own identify the "potential responsible party" (PRP), but is often a

critical part of, and a support to, the legal process.

In these guidelines, some activities are marked as “Optional”. These are suggestions to supplementary

diagnostic documentations, e.g. in cases where there may still be uncertainty in drawing conclusions based on

the “standard” recommended methodology.

The first draft of the methodology was evaluated through a Round Robin study organised by the CEN/BT/TF

120 Oil Spill Identification. This test was limited to crude oils and heavy fuel oils. Two more recent Round

Robin tests organised by RIZA in the Netherlands, where fifteen laboratories participated, covered cases with

light fuel oil distillates (diesel oils,) and bilge water samples (a mixture of gas oils and lube oil). Findings from

these RR-tests have been taken into account for refining the suggested methodology.

1 Scope

This Technical Report (TR) describes a methodology to identify waterborne oils spilled in marine, estuarine

and aquatic environments by comparing samples from spills with those of suspected sources . It provides

detailed analytical and processing specifications for identifying waterborne oil spills and their correlation to

suspected sources. When suspected sources are not available, the methodology may be used to characterise

the spill as far as possible with respect to the oil type.

This methodology is restricted to petroleum and petroleum products containing a significant proportion of

HC-components with a boiling point above 200 °C. Examples are: Crude oils, condensates, light fuel oils,

diesel oils, residual bunker oils, lubricants, and mixtures of bilge and sludge samples. Still, the general

concepts described in this methodology have a limited applicability for some kerosenes and some

condensates, but may not be applicable for gasoline

NOTE This method is not intended for oil spills to groundwater and soil. The chromatograms of oil extracted from soil

and found in ground water may contain reduced and/or additional peaks compared to the source sample. Including such

samples in this method makes it necessary to add extraction methods and to describe which compounds are possibly

reduced and/or which additional peaks can be expected to change the final conclusion from a probable match into a match.

This is beyond the scope of this guideline, however, when case samples completely match according to this method, the

method is valid for those samples.

2 Normative references

The following referenced documents are indispensable for the application of this European Standard. For

dated references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

CEN/TR 15522-1, Oil spill identification – Waterborne petroleum and petroleum products – Part 1: Sampling

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

chain of custody

line of actions taken for samples from spill and suspected sources at court for safe surveillance and storing; to

ensure that the samples have not been tampered with or altered accidentally

3.2

contamination

all changes in oil composition which take place during/after the spillage, by mixing with additional compounds,

including natural products

3.3

critical difference (CD)

value less than or equal to which the absolute difference between two test results obtained under repeatability

conditions may be expected to be with a probability of 0,95; the critical difference is defined as CD= ((mean x

r )/(100)

95%

3.4

diagnostic ratios

ratios between the peak height or peak area of single compounds or compound groups selected by their

diversity in chemical composition in petroleum and petroleum products and on their known behaviour in

weathering processes

3.5

identity

no differences observed in the chromatographic patterns of GC/FID and GC/MS apart from those changes

introduced after the spill (weathering, degradation etc.)

3.6

inconclusive

when differences in chromatographic patterns and diagnostic ratios of the samples submitted for comparison

are larger than the analytical variance of the method and may only, to some extent, be explained by external

factors like weathering, contamination, heterogeneity of the samples or too low an amount of sample material

NOTE Differences may be due to e.g. heterogeneities of the oil either within the spill or within the suspected source

(e.g. within the ship tank), that is not reflected in the available samples analysed, or differences are present because the

samples do not originate from the same source.

3.7

non-match

when differences in chromatographic patterns and diagnostic ratios of the samples submitted for comparison

are distinct and larger than the analytical variance of the method and they cannot be explained by external

factors like weathering, contamination and heterogeneity. The samples are distinctly different

3.8

positive match

when differences in chromatographic patterns and diagnostic ratios of the samples submitted for comparison

are lower than the analytical variance of the method or can clearly be explained by weathering. The samples

are identical beyond reasonable doubt

3.9

probable match

when differences in chromatographic patterns and diagnostic ratios of the samples submitted for comparison

are larger than the analytical variances of the method, but can be explained by external factors like

contamination or heterogeneity of the samples

EXAMPLE Comparing lubricating oil with the lubricating oil part of a bilge sample may lead to a probable match.

3.10

repeatability (r)

precision under repeatability conditions

[ISO 5725-2]

3.11

repeatability conditions

conditions where independent test results are obtained by the same method on identical test material in the

same laboratory by the same operator (panel leader) using the same equipment within short intervals of time

[ISO 5725-2]

3.12

repeatability limit (r95%)

value less than or equal to the difference between two test results obtained under repeatability conditions

which may be expected to be within a probability of 0,95

[ISO 5725-2]

3.13

waterborne oil

petroleum and petroleum products borne by water or available in the water column from marine, estuarial and

aquatic environments (includes lakes and rivers but excludes groundwater)

3.14

weathering

all changes in oil composition which take place after the spillage, including evaporation, dissolution,

emulsification, oxidation and biological decomposition. See also Annex G

4 Strategy for identification of oil spills

4.1 General

Identification of spilled oils in the context of this CEN Technical Report implies the comparison of the total

chemical composition of the spilled oil with that of candidate source samples.

NOTE Identity, per se requires all measurable data to be the same. This definition is practically and technically

impossible to fulfill and instead, the definition of identity is rephrased in operational terms: two samples are identical if no

differences in the analysed GC/FID and GC/MS data are present that cannot be explained by weathering. The task of

looking for differences in chemical composition instead of proving similarity is conceptually more logical and easier to

comply with. According to this, only distinct differences between samples can be proved, whereas identity per se cannot.

Therefore, only when no differences between samples are observed should identity be concluded as being beyond

reasonable doubt.

Identity should be tested by analyzing and comparing the detailed chemical composition of the selected

samples by chemical fingerprinting of a suite of generic and diagnostic petroleum compounds. If no or only

insignificant differences (i.e. differences being smaller than the analytical variance) are observed, identity

should be concluded as being beyond reasonable doubt. On the other hand, if true differences (i.e differences

not related to changes in the chemical composition introduced after the spill, e.g. from weathering etc.), that

are larger than the variance of the analysis are observed within these diagnostic compounds, it should be

concluded that the samples are different.

In the European community oil comparison is performed by laboratories, which analyse oil samples daily, but

also by laboratories, which only compare samples a few times a year. Common practice has traditionally been

to analyse samples qualitatively and then compare the chromatograms and ion chromatograms visually. The

outcome of such comparisons depends on the experience of the analyst. Laboratories, which rarely analyse

oil samples, may experience difficulties in reaching the right conclusions, therefore, this guideline introduces

the use of diagnostic ratios. The selection of the ratios is based on the known weathering behavior of

compounds and the diversity in chemical composition of oils from different wells and oil types [14]. To reduce

the variance, ratios are generated by using the area or peak height of compounds, which are recorded by the

same m/z value and that are within the same reasonable retention time range. The resulting ratios are

compared using the repeatability limit (3.12) as a test method. For those laboratories who work daily on a

“quantitative analytical” level, and that have good laboratory routines for doing “exact” quantification of the

recommended diagnostic peaks, the ratios recommended in these guidelines may be established based on

exact quantitative analysis.

For the comparison of the diagnostic ratios from the GC/MS data, 29 diagnostic ratios, generated from

diagnostic PAH compounds and biomarkers, that are robust against weathering have been selected to cope

with the differences in oil samples and oil types. Whereas most of the ratios may be used when crude oil,

bunker oil and bilge samples are involved, only a limited number may be useful for lighter fuel oils (e.g.

kerosene, parafin, diesel, gas oil) because some of the high boiling biomarkers may not be present in such

light refined products. In identification cases where the oil spill has been exposed to a low degree of

weathering, 3 ratios of acyclic isoprenoids (the n-C17 /pristane, n-C18 /phytane and pristane/phytane ratios)

from the GC/FID analyses and 4 suggested ratios of the sesquiterpanes (in the C13 to C16 area) may also

be included for comparison of diagnostic ratios if a weathering check shows that these compounds have not

been exposed to weathering.

Before integrating the compounds applied for calculating the diagnostic ratios, a visual inspection of the

diagnostic ion chromatograms (see 6.3.5.2 – 6.3.5.4) should be carried out to eliminate some of the

recommended diagnostic peaks that may not be present in sufficient concentrations, used to establish robust

diagnostic ratios. Also, a visual comparison of the ion chromatograms is advised to enable exclusion of

obviously different samples. After the comparison study of diagnostic ratios(see 6.4), a visual, one by one

comparison of the printed ion chromatograms of the relevant samples should also be carried out to verify

(ground-truth) the conclusion.

4.2 Procedure

When an oil spill has been discovered, samples should be taken from the current spill and from any potential

responsible parties such as suspected ships or other sources. All samples should be sent either via an

authorised “Sampling Co-ordinator” or directly to a forensic laboratory for oil spill identification.

The oil spill identification methodology is comprised of:

sampling from the spill and from the suspected sources. When suspected sources are not available,

methodology may be used to characterise the spill as far as possible with respect to the oil type. The

sampling shall be carried out in accordance with CEN/TR 15522-1;

visual description of samples, see 5.2;

preparation of samples, see 5.3;

gas chromatography combined with flame ionization detection (GC/FID) screening of all involved samples.

Evaluation of the chromatograms and calculation of diagnostic ratios, see 4.3.2 and 6.2;

gas chromatography combined with mass spectrometry (GC/MS) fingerprinting of samples. Evaluation of

the chromatograms and calculation of diagnostic ratios, see 4.3.3 and 6.3;

comparison of diagnostic ratios, see 6.4;

conclusions and reporting see clause 7.

4.3 Decision chart of analytical and data treatment levels

4.3.1 General

The identification system for oil spills is divided into three levels of decisions, see Figure 1.

4.3.2 GC/FID screening (level 1)

After sample preparation (see 5.3), the chemical fingerprinting analysis in the laboratory starts with the

GC/FID screening analysis of all samples, i.e. both samples of spilled oils and suspected sources. The data

from this screening should be used for:

characterising the oil sample(s) by obtaining the overall boiling (carbon) range of the oils, i.e. the total

distribution of hydrocarbons including n-alkanes from C to C if present, see 6.2.1. For an overview of

10 40

boiling points of n-alkanes, see Annex E;

visual inspections of the chromatograms for possible characteristic features and a tentative classification

to a type of the spilled oil if possible, see Annex H;

establishing selected acyclic isoprenoid ratios readily determined using GC/FID, see 6.2.2.1.

If the chromatograms are different and those differences are possibly caused by weathering a “weathering

check”, either by a chromatographic overlay manipulation or by normalising the distribution of n-alkanes to

non-weathered compounds is recommended, see 6.2.2.2 and Annex G.

If the GC chromatograms from the spill samples compared to the suspected sources show differences in the

hydrocarbon distribution, the unresolved complex mixture distribution and/or the acyclic isoprenoid ratios (see

criteria in 6.2.2.1.) that obviously are not caused by weathering (non-matched samples), should be ruled out

and eliminated from additional levels of analysis (see Figure 1). If there are any doubts, the samples should

be analysed in accordance with level 2.

See also Annex H, on the evaluation of the GC-screening results (comparison of unresolved envelopes).

4.3.3 GC/MS fingerprinting (level 2)

At this level, analysis of spill and candidate source samples using gas chromatography combined with mass

spectrometry that generally operates in the selected ion monitoring mode (GC/MS-SIM) should be performed.

This analysis is useful for determining the content and distributions of a suite of diagnostic petroleum

biomarkers and PAH target analytes. Data from this analysis should be used for:

visual inspection of the ion profiles in the chromatograms for possible characteristic features, and an oil

type classification of the spilled oil, see Annex H;

generating a suite of diagnostic ratios based on an evaluation of the presence and “robustness” of the

diagnostic PAHs and biomarkers described in 6.3.5.

To give additional diagnostic information, a semi-quantitative histogram established from a suite of selected

PAH homologues may be used as a supplementary diagnostic fingerprint and as a check on the weathering of

the PAH homologues (optional), see Annex G, Clause 8.

4.3.4 Evaluation of data (level 3)

At level 3, the results obtained from level 1 and 2 should be used for:

assessing the impact of weathering based on a weathering check of n-alkane data from level 1 and the

semi-quantitative distribution of the PAH groups from level 2. The weathering checks are performed

optionally;

deciding which diagnostic ratio can be used for comparison based on oil type and analytical variance, and

which samples should be reanalysed because of heterogeneity, see 6.4.2;

comparison of diagnostic ratios data using repeatability limit, see 6.4.3;

visual comparison of generated ion chromatograms to check the results of the ratio comparison (ground-

truth all data).

The results from all analytical levels should be assessed and the conclusions should be reported for the

combined results of the test methodology used, see clause 6.5. Results should be specified either as a

Positive Match, Probable Match, Inconclusive or Non-Match.

Note These categories represent four operational and technical defensible conclusion terms (3.6-3.9) to identify or

differentiate between oils from a spill and any available candidate sources.

Figure 1 — Protocol/decision chart for oil spill identification

5 Sample preparation

5.1 General

The same sample preparation procedure should be followed for both GC/FID and GC/MS analysis, i.e. the

same extracts should be analysed for both analyses. The sample preparation does not generally require

asphaltene removal or separation of e.g. aliphatic from aromatic i.e., analysis of a ‘whole oil’ aliquot is

recommended.

The present methodology is based on semi-quantitative analysis (i.e. no internal standards are added), for

establishing diagnostic ratios.

5.2 Visual examination of samples

Colour, odour, viscosity and content of any free water and debris should be visually noted and reported. It is

also recommended that each sample is photographed in order to document its "as-received" condition. Any

pieces of wood, fabric, feathers or other debris should be removed from the sample with a pair of tweezers

and noted in the report.

5.3 Preparation

5.3.1 General

If a sample contains a significant amount of oil/emulsion, and an aliquot on the sample cannot be immediately

o

prepared after arriving at the laboratory, the sample bottle should be stored in a refrigerator at (5 ± 2) C.

Sample preparation should be carried out as soon as possible, preferably within a week, particularly in cases

concerning emulsions.

If a sample contains primarily water and it cannot be immediately extracted, dichloromethane (DCM) should

be immediately added after arrival, (e.g. 10 ml to a 1 l water sample). After shaking, the sample should be

o

stored in a refrigerator at (5 ± 2) C. Further sample preparation should be carried out as soon as possible,

preferably within a week.

5.3.2 Water samples

If samples consist primarily of water (no visual oil on the surface), the oily water is transferred to a separating

funnel. Use dichloromethane (DCM) .Depending on the amount of oil, the sample should be extracted one by

one or serially (e.g. 60 ml, 30 ml and 30 ml of solvent if the sample volume is 1 l, less volume if the water

sample is smaller). The sample bottle is rinsed inside with DCM before pouring it into the water sample for

extraction. The extract is dried with sodium sulphate and diluted or concentrated to a suitable injection

concentration. If a concentration step is needed use a gentle evaporation technique (e.g. Kudena Danish,

Turbo Vap, N-Evap).

5.3.3 Oil samples from polytetrafluoroethylene (PFTE) net

PFTE net is recommended for sampling thin oil films [39]. The oil should be thoroughly rinsed off the PFTE

1 1

net using DCM or the PFTE net can be extracted in DCM . After drying with sodium sulphate, the extract

should be diluted or concentrated to a suitable injection concentration.

5.3.4 Thick oil and emulsified oil samples

Samples consisting primarily of water or emulsified oil should be allowed to equilibrate at room temperature.

Any free water should be decanted into a separating funnel. The oil/emulsion fraction is gently homogenised

before an aliquot, 20 mg to 50 mg, is weighed in a tarred volumetric flask (5 ml) and diluted with DCM to the

final volume. The extract should be dried with sodium sulphate. Samples consisting of solid oil, e.g. high

elastic/viscous HFO, should be adjusted to room temperature. When homogeneity is questionable, take two

aliquots, 20 mg to 50 mg, at different spots and treat the aliquots as different samples.

5.3.5 Tar balls and emulsified lumps

Oils weathered for a long time at sea and/or on shore may form very viscous oil lumps (“tar balls”) often

centimetres in diameter. Their exposure to weathering may not be homogenous thus in such cases, it is

If DCM is not allowed, use another appropriate solvent e.g. hexane.

Teflon is example of a suitable commercially available product. This information is given for the convenience of users

of this CEN Technical Report and does not constitute an endorsement by CEN of this product. An example is Teflon net

manufactured by SEFAR – Internet: www.sefar.com (Sefar Fluortex Product ref.09-150/36).

recommended to split the lump and obtain two aliquot samples of oil (20 mg to 50 mg each), one from the

middle (inside) of the lump and one from the more exposed surface of the lump. Samples should be diluted in

DCM as described in 5.3.4 before analysis by GC/FID and eventually GC/MS in order to obtain information

about the variability in component composition within the sample.

5.3.6 Samples from oiled birds, fish and other animals

Samples from oiled birds, fish and other animals should be handled with the necessary care and precaution

(e.g. to prevent carryover of contageous diseases). Visible oil on birds or sea animals should be wiped off

using a piece of PFTE net. The PFTE net should be rinsed with DCM and the extract should be filtrated

through a glass fibre filter to take away feathers and other particles. A clean up should be performed as

described below to remove lipids and other polar substances before analysis by GC/FID and eventually

GC/MS. If the oil cannot be wiped off, the feathers may be rinsed with hexane and followed by an extract

clean up procedure as described in 5.4.2. When homogeneity is questionable, take aliquots from different

areas and treat the aliquots as different samples.

5.4 Recommended sample clean up methodology

5.4.1 General

Matrix interferences may be caused by contaminants that are co-extracted from the sample. Since biogenic

materials and other naturally occurring materials may cause interferences, alumina and/or silica clean up is

recommended for petroleum analyses to eliminate matrix interference prior to GC/MS and GC/FID analysis.

If the purpose of the clean up is to remove polar compounds from the extract, it is recommended to use a pre-

packed silica column (see 5.4.3, [16]). If, e.g. heavy bunker oil is involved, silica clean-up may also be used to

remove the high amount of asphalthenes in order not to deteriorate the instrumental conditions (injector,

column and detector).

5.4.2 Biogenic materials

If the contamination of e.g. lipids or fatty acids is very high, it may be necessary to clean the extracts using an

alumina column before the silica column.

The alumina column should be prepared just prior to use: Pack the tip of a 19 mm ID column with a small

piece of glass wool. Add ca 25 ml DCM to the column. Weigh 20,0 g of alumina into the beaker and add 30 ml

of DCM . Swirl to remove any bubbles. Slowly pour the alumina into the column while rinsing the beaker with

DCM . Allow to settle. Add approximately 2 g of sodium sulphate. Drain the DCM from the column until the

head of the liquid in the column is just above the sodium sulphate. Close the stopcock to stop solvent flow.

Add 50 ml of hexane and drain to the top of the packing material. Transfer the 1 ml sample extract (in DCM)

onto the column. Rinse out the extract vial with 1 ml DCM and immediately add it to the column. Allow the

sample to drain to the top of the packing material. Add 100 ml of DCM and slowly drain the column

(approximately 2 ml/min). Collect the eluate in a 250 ml EM-flask. Concentrate the extract to 1 ml and do a

solvent exchange as described below in 5.4.3. Alternative clean up procedures are described in [25].

5.4.3 Polar compounds from oil extracts

If sample clean up is necessary due to a high content of polar compounds, pre-packed Bond Elut silica

columns (500 mg of silica, e.g. Varian, Supelco or Isolute) are recommended. Displace the solvent (DCM )

with hexane by adding 1 ml of hexane and concentrate to a volume of 1 ml. This step should be repeated

three times. Rinse the vial walls frequently with hexane to ensure that all the extraction solvent is displaced.

The 1 ml sample is now ready for silica column clean up. The sample should be fractionated on the prepacked

silica columns. Three bed volumes of the hexane eluant should be used. The extract should be concentrated

to 1 ml and transferred to a GC-vial. The efficiency of the silica clean up has been tested by [16].

5.5 Recommended injection concentration

Oil samples contain a range of compounds in a range of concentrations. In an oil spill case both high and low

concentration levels of compounds (diagnostic ratios) have to be evaluated. It is recommended, for the

comparison of samples, that spill and source samples have about the same injection concentration as a large

concentration difference may influence the final comparison. Therefore, it is recommended to use a mid-level

injection concentration that should be tested during the validation of the instrument/method. The mid-level

injection concentration may be determined by analysing the calibration range of an alkane standard mixture

(see Annex A) and a crude oil (e.g. SINTEF Oil Mixture, see 6.2.2.1) to find the best peak shape for both high

and low level compounds, and a sufficient S/N ratio (see 6.4.3.1) for the low level biomarkers in one injection.

6 Characterization and evaluation of analytical data

6.1 General

When evaluating analytical data, it is important to have a good understanding of how a variety of weathering

processes such as: evaporation, dissolution, photo-chemical oxidation, microbial degradation, wax-

enrichment/-depletion, etc., may influence the analytical results, see Annex G. Within a course of hours to

days after an oil spill, evaporation may cause considerable changes in the chemical composition and physical

properties of the spilled oil, which has to be taken into account when interpreting the defensible oil spill

identification analysis [39].

Samples should be compared visually by comparison of ratios. Basically

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...