EN 12259-5:2002

(Main)Fixed firefighting systems - Components for sprinkler and water spray systems - Part 5: Water flow detectors

Fixed firefighting systems - Components for sprinkler and water spray systems - Part 5: Water flow detectors

This European standard specifies requirements for construction and performance and tests for water flow detectors for use in wet pipe automatic sprinkler systems conforming to EN 12845 «Fixed firefighting systems - Automatic sprinkler systems- Design and Installation» .

Auxiliary components and attachments to water flow detectors are not covered by this standard.

Ortsfeste Löschanlagen - Bauteile für Sprinkler- und Sprühwasseranlagen - Teil 5: Strömungsmelder

Diese Europäische Norm legt Anforderungen an Aufbau und Leistungseigenschaften sowie Prüfungen von Strömungsmeldern fest, die in automatischen Sprinkleranlagen (Nassanlagen) nach EN 12845 ¿Automatische Sprinkleranlagen - Planung und Einbau" ) eingesetzt werden.

Zusatz- und Befestigungselemente für Strömungsmelder werden in dieser Norm nicht behandelt.

Installations fixes de lutte contre l'incendie - Composants des systèmes sprinkleur et à pulvérisation d'eau - Partie 5: Indicateurs de passage d'eau

La présente Norme européenne spécifie les exigences relatives à la fabrication, aux performances et aux essais des indicateurs de passage d'eau destinés à être utilisés dans les systèmes automatiques du type sprinkleur conformes à l'EN 12845 " Installations fixes de lutte contre l'incendie - Systèmes automatiques du type sprinkleur - Conception et Installation " ).

La présente norme ne traite pas des composants complémentaires et des accessoires des indicateurs de passage d'eau.

Vgrajene naprave za gašenje – Sestavni deli sprinklerskih sistemov in sistemov s pršečo vodo – 5. del: Javljalniki vodnega pretoka

General Information

- Status

- Published

- Publication Date

- 17-Sep-2002

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 5 - Sprinkler systems

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 19-Jan-2023

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 09-Feb-2026

- Refers

ISO 188:1998 - Rubber, vulcanized or thermoplastic — Accelerated ageing and heat resistance tests - Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TS 14972:2011 - Fixed firefighting systems - Watermist systems - Design and installation - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12259-5:2002 is the CEN European standard for water flow detectors used in wet-pipe automatic sprinkler systems. It specifies construction, performance and testing requirements for detectors intended to work with systems designed to EN 12845. The standard does not cover auxiliary attachments to detectors. EN 12259-5:2002 is part of the EN 12259 series addressing components for sprinkler and water-spray firefighting systems.

Key topics and technical requirements

- Scope and purpose: Requirements for detectors that respond to a preset downstream flow rate and operate electrical contacts to signal water flow.

- Rated working pressure: Detectors shall be suitable for a minimum rated working pressure of 12 bar.

- Mechanical strength: Assemblies must withstand a hydrostatic test of 4× rated working pressure for 5 minutes without leakage, distortion or breakage (see Annex B).

- Materials and construction:

- Water-pressure-retaining parts limited to approved metals (cast iron, bronze, brass, monel, stainless steel, etc.) or equivalent materials. Aluminium and cast iron must not contact water.

- Components designed so parts that are normally disassembled cannot be reassembled incorrectly.

- Bearing and sliding parts must use corrosion-resistant materials (bronze, brass, stainless steel, etc.).

- Sealing and non‑metallic components:

- Non-reinforced elastomer seals have minimum tensile/elongation performance (e.g., tensile strength ~10 MPa and elongation ~300% as specified).

- Non-metallic parts must pass accelerated ageing (air oven and warm water) and show no cracking or warping (Annex C).

- Operational performance:

- Sensitivity: defined as minimum flow rate causing operation in the intended direction.

- Springs and diaphragms must survive 10 000 operational cycles without fracture (Annex F).

- Hydraulic friction (pressure loss), leak resistance, endurance, temperature and corrosion resistance (salt mist) are specified (Annexes H, I, J, G).

- Electrical requirements:

- Microswitches to IEC 61020‑6; earthing and electrical connections to EN 60335‑1.

- Conformity & quality control:

- Initial type testing and factory production control (FPC) provisions are included.

Applications and users

- Manufacturers of water flow detectors and sprinkler components - for product design, testing and certification.

- Fire-protection designers and specifiers - to select compliant detectors for EN 12845 systems.

- Test laboratories and certification bodies - for type testing and production surveillance.

- Installers, maintenance teams and facility managers - for understanding performance, installation, marking and maintenance requirements.

- Authorities having jurisdiction (AHJs) - for compliance checks in commercial and industrial buildings.

Related standards

- EN 12845 - Design & installation of automatic sprinkler systems (primary application context).

- Other parts of EN 12259 (Part 1–12) - related components: sprinklers, alarm valves, water motor alarms, deluge equipment, etc.

- Normative references cited in EN 12259-5 include IEC 60335-1 and IEC 61020-6, and various ISO standards for materials and testing.

Keywords: EN 12259-5:2002, water flow detectors, fixed firefighting systems, sprinkler systems, EN 12845, performance tests, construction requirements, microswitch, corrosion resistance.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12259-5:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Components for sprinkler and water spray systems - Part 5: Water flow detectors". This standard covers: This European standard specifies requirements for construction and performance and tests for water flow detectors for use in wet pipe automatic sprinkler systems conforming to EN 12845 «Fixed firefighting systems - Automatic sprinkler systems- Design and Installation» . Auxiliary components and attachments to water flow detectors are not covered by this standard.

This European standard specifies requirements for construction and performance and tests for water flow detectors for use in wet pipe automatic sprinkler systems conforming to EN 12845 «Fixed firefighting systems - Automatic sprinkler systems- Design and Installation» . Auxiliary components and attachments to water flow detectors are not covered by this standard.

EN 12259-5:2002 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12259-5:2002 has the following relationships with other standards: It is inter standard links to EN IEC 60335-1:2023, ISO 188:1998, EN 594:1995, EN 395:1993/AC:1995, EN 14861:2004, EN 12510:2001, EN 12845:2015+A1:2019, CEN/TS 14972:2011, EN 12845:2015, EN 16925:2018, EN 17451:2024, EN 12259-15:2025, CEN/TS 12101-11:2022, EN 12845:2004+A2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12259-5:2002 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/109. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12259-5:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Ortsfeste Löschanlagen - Bauteile für Sprinkler- und Sprühwasseranlagen - Teil 5: StrömungsmelderInstallations fixes de lutte contre l'incendie - Composants des systemes sprinkleur et a pulvérisation d'eau - Partie 5: Indicateurs de passage d'eauFixed firefighting systems - Components for sprinkler and water spray systems - Part 5: Water flow detectors13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 12259-5:2002SIST EN 12259-5:2002en01-december-2002SIST EN 12259-5:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12259-5September 2002ICS 13.220.20English versionFixed firefighting systems - Components for sprinkler and waterspray systems - Part 5: Water flow detectorsInstallations fixes de lutte contre l'incendie - Composantsdes systèmes d'extinction du type Sprinkleur et àpulvérisation d'eau - Partie 5: Indicateurs de passage d'eauOrtsfeste Löschanlagen - Bauteile für Sprinkler- undSprühwasseranlagen - Teil 5: StrömungsmelderThis European Standard was approved by CEN on 10 August 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12259-5:2002 ESIST EN 12259-5:2002

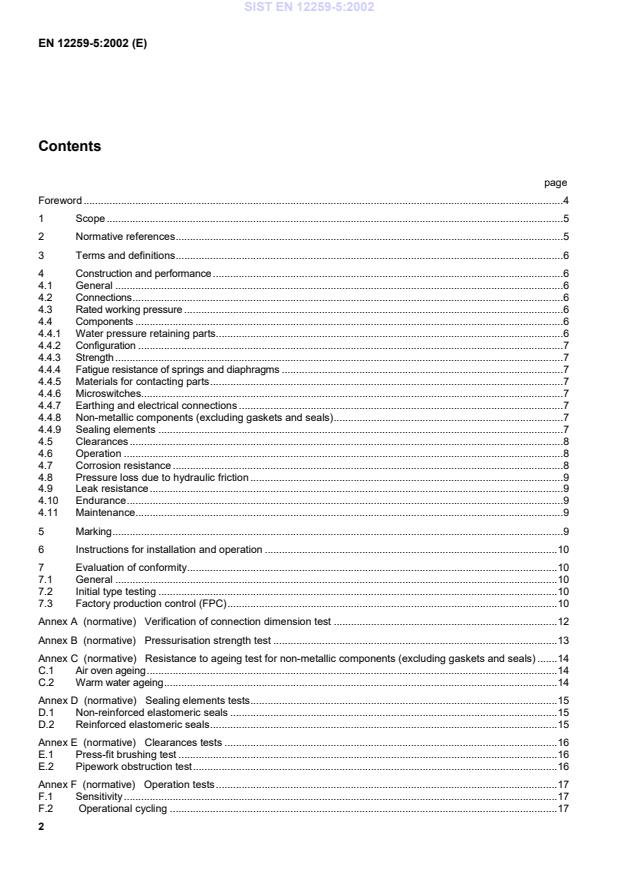

(normative)

Verification of connection dimension test.12Annex B

(normative)

Pressurisation strength test.13Annex C

(normative)

Resistance to ageing test for non-metallic components (excluding gaskets and seals).14C.1Air oven ageing.14C.2Warm water ageing.14Annex D

(normative)

Sealing elements tests.15D.1Non-reinforced elastomeric seals.15D.2Reinforced elastomeric seals.15Annex E

(normative)

Clearances tests.16E.1Press-fit brushing test.16E.2Pipework obstruction test.16Annex F

(normative)

Operation tests.17F.1Sensitivity.17F.2 Operational cycling.17SIST EN 12259-5:2002

(normative)

Salt mist corrosion resistance test.20G.1Reagents.20G.2Apparatus.20G.3Procedure.20Annex H

(normative)

Hydraulic friction pressure loss test.21Annex I

(normative)

Leakage resistance test.22Annex J

(normative)

Endurance test.23Annex K

(informative)

Typical testing schedule and example of test specimen number of water flow detectors.24Annex ZA

(informative)

Clauses of this European Standard addressing essential requirements or other provisionsof EU Directives.28Bibliography.32SIST EN 12259-5:2002

1) In preparation.SIST EN 12259-5:2002

- Part 2: Nuts with specified proof load values; coarse thread.

2) In preparationSIST EN 12259-5:2002

GeneralThe water flow detector shall be suitable for installation, without modification. It shall be possible to removecompletely the water flow detector from the piping without leaving obstructions in the pipe.Unless otherwise indicated by the supplier the flow switch shall be evaluated for suitability with tube in accordancewith ISO 65.4.2

ConnectionsThe dimensions of all connections shall be specified by the water flow detector supplier.Verification of the specified dimensions shall be tested as specified in annex A.4.3

Rated working pressureThe rated working pressure of water flow detectors shall be not less than 12 bar.4.4

Components4.4.1

Water pressure retaining partsThe water pressure retaining parts of the detectors (other than gaskets or seals) shall be made of cast iron, bronze,brass, monel metal, stainless steel, titanium, aluminium alloy or materials having equivalent physical and mechanicalproperties.

Aluminium alloy and cast iron shall not be in contact with the water.SIST EN 12259-5:2002

ConfigurationThe design of any component, which may be normally disassembled during servicing, shall be such that it cannotbe reassembled wrongly.4.4.3

Strength4.4.3.1The installed water flow detector shall withstand, without leakage, permanent distortion or breakage ofcomponents, an internal hydrostatic pressure of four times the rated working pressure, for a period of 5 min, whentested in accordance with annex B.4.4.3.2The calculated load of any fastener, excluding the force required to compress the gasket, shall notexceed the minimum tensile strength specified in ISO 898-1 and ISO 898-2, when the water flow detector ispressurised to four times the rated working pressure. The area of the application of pressure shall be calculated asfollows:-if a full-face gasket is used, the area of force application is that extending out to line defined by the inner edgeof the bolts; for example in a flanged connection;-if a toroidal sealing ring or ring gasket is used, the area of force application is that extending out to the centreline of the toroidal sealing ring or ring gasket.4.4.4

Fatigue resistance of springs and diaphragmsSprings and diaphragms shall not fracture or rupture during 10 000 cycles of normal operation when tested inaccordance with the operational cycling test in F.2.4.4.5

Materials for contacting partsAny part and its bearing, excluding seals, gaskets and diaphragms, where rotation or sliding motion is required,shall be made of bronze, brass, monel metal, stainless steel, titanium or materials having equivalent physical andmechanical properties.4.4.6

MicroswitchesMicro switches where incorporated shall be in accordance with IEC 61020-6.4.4.7

Earthing and electrical connectionsEarthing and electrical connections shall be in accordance with EN 60335-1.4.4.8

Non-metallic components (excluding gaskets and seals)After ageing in accordance with annex C there shall be no cracking, warping, creep or other signs of deteriorationof non-metallic components and the water flow detector shall meet the operational and leak resistancerequirements of 4.6 and 4.9 when tested in accordance with annexes F and I.Separate samples shall be subjected to the tests in C.1 and C.2.4.4.9

Sealing elements4.4.9.1

Non-reinforced elastomer sealing elementsAny non-reinforced elastomer sealing element, other than gaskets, shall conform to the following:a) either minimum tensile strength 10 MPa and minimum ultimate elongation 300 %; orSIST EN 12259-5:2002

Change in volume of the specimens shall not be greater than 20 %.4.4.9.2

Reinforced elastomer sealing elementsAny reinforced elastomer sealing element shall be capable of being flexed without cracking or breaking and shallhave a change of volumetric expansion not greater than 20 %, when tested in accordance with D.2.4.5

ClearancesNOTEClearances are necessary between moving parts and between moving and stationary part so that corrosion ordeposits of foreign matter within an assembly will not render the water flow detector sluggish in action or inoperative.4.5.1Press-fit bushings shall conform to the appropriate clauses of ISO 49 when tested in accordance with E.1.4.5.2Any water flow detector vane shall operate by over-riding an 8 mm diameter rod attached to the inside ofthe pipewall along the pipe length when tested in accordance with E.2.4.6

Operation4.6.1When tested in accordance with annex F, the waterflow detector shall not operate to give a signal at all atflows below 10 l/min; and, for all flows above 80 l/min the flow detector shall operate to give a continuous signal.Any adjustable or fixed time delay device incorporated in the water flow detector shall not delay any signal for morethan 30 s. Any interruption of the water flow rate to below 10 l/min shall cause the delay device to resetautomatically to its initial state.4.6.2The water flow detector shall operate during 10 000 cycles of normal operation, after which it shall meet therequirements of 4.6.1 at 1 bar when tested in accordance with F.1. The electrical contact and insulation resistanceof the electrical part of the water flow detector shall remain within the manufacturer’s specification when tested inaccordance with F.2.1 and F.2.2 respectively.4.6.3The water flow detector shall be capable of normal operation between the temperature limits of 2 °C and68 °C after which it shall meet the requirement of 4.6.1 when tested in accordance with F.3.

After the test thereshall be no sign, on visual examination, of cracking or failure of any vane.4.7

Corrosion resistanceThe water flow detector shall meet the requirements of 4.6.1 at 1 bar and the electrical contact resistance andinsulation resistance of the electrical part shall remain within the manufacturer’s specification when tested inaccordance with annex G.SIST EN 12259-5:2002

Leak resistanceAn installed water flow detector shall withstand without leakage, permanent distortion or structural failure, aninternal pressure equal to two times the rated working pressure or 25 bar whichever is the greater for a period of5 min when tested in accordance with annex I.4.10

EnduranceThe water flow detector and its moving parts shall operate at the flow velocity 10 m/s for 90 min without anypermanent distortion, detachment or breakage when tested in accordance with annex J.4.11 MaintenanceThe water flow detector shall be designed to permit cleaning and maintenance without the use of special tools.5

MarkingThe water flow detector shall be marked as follows:a) name or mark of the supplier;b) distinctive model number, catalogue designation or equivalent marking;c) external wall thickness of connecting pipe;d) electrical current and voltage ratings;e) rated working pressure in bar;f) the actual year of manufacture; or¾ for water flow detector produced in the last three months of a calendar year the following year date; or¾ for water flow detectors produced in the first six months of a calendar year the previous year date;g)minimum operating flow in l/min at which the devices operates;h)direction of indicated flow;i)factory of origin, if manufacture is at two or more factories;j)the number of this European Standard.The marking shall be in figures or letters at least 4,8 mm high and either:k)cast directly on the water flow detector; orl)on a metal label with raised or depressed characters (for example by etching, casting or stamping) that ismechanically att

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...