EN 15424:2007

(Main)Sterilization of medical devices - Low temperature steam and formaldehyde - Requirements for development, validation and routine control of a sterilization process for medical devices

Sterilization of medical devices - Low temperature steam and formaldehyde - Requirements for development, validation and routine control of a sterilization process for medical devices

1.1 Inclusions

1.1.1 This European Standard specifies requirements for the development, validation and routine control of a Low Temperature Steam and Formaldehyde (LTSF) sterilization process for medical devices.

NOTE Although the scope of this standard is limited to medical devices, it specifies requirements and provides guidance that may be applicable to other products and equipment.

1.1.2 This European Standard is intended to be applied by process developers, manufacturers of sterilization equipment, manufacturers of medical devices to be sterilized and the organizations with responsibility for sterilizing medical devices. (See EN ISO 14937:2000, Table E.1)

1.1.3 This European Standard covers sterilization processes which use a mixture of low temperature steam and formaldehyde as sterilant, and which are working below ambient pressure only.

1.2 Exclusions

1.2.1 Sterilization processes validated and controlled in accordance with the requirements of this standard should not be assumed to be effective in inactivating the causative agents of spongiform encephalopathies such as scrapie, bovine spongiform encephalopathy and Creutzfeld-Jakob disease. Specific recommendations have been produced in particular countries for the processing of materials potentially contaminated with these agents.

1.2.2 This standard does not specify requirements for designating a medical device as "STERILE". Such requirements are given in EN 556-1.

1.2.3 This standard does not specify a quality management system for the control of all stages of production of medical devices.

NOTE Attention is drawn to the standards for quality management systems (see EN ISO 13485) that control all stages of production or reprocessing of medical devices including the sterilization process. It is not a requirement of this standard to have a complete quality management system during manufacture or reprocessing, but those elements of such a system that are required are normatively referenced at appro

Sterilisation von Medizinprodukten - Niedertemperatur-Dampf-Formaldehyd - Anforderungen an die Entwicklung, Validierung und Routineüberwachung von Sterilisationsverfahren für Medizinprodukte

Stérilisation des dispositifs médicaux - Vapeur d'eau à basse température et au formaldéhyde - Exigences pour le développement, la validation et le contrôle de routine des procédés de stérilisation

1.1 Inclusions

1.1.1 La présente Norme européenne spécifie les exigences relatives à la mise au point, à la validation et au contrôle de routine d'un procédé de stérilisation à la vapeur et au formaldéhyde à température basse (LTSF) pour les dispositifs médicaux.

NOTE Bien que le domaine d'application de la présente norme se limite aux dispositifs médicaux, elle spécifie les exigences et fournit un guide qui peut être applicable à d'autres produits et équipements.

1.1.2 La présente Norme européenne est destinée à être appliquée par les personnes chargées de la mise au point des procédés, les fabricants d’équipements de stérilisation, les fabricants de dispositifs médicaux destinés à être stérilisés et les organisations responsables de la stérilisation des dispositifs médicaux (voir EN ISO 14937:2000, Tableau E.1).

1.1.3 La présente Norme européenne couvre les procédés de stérilisation employant un mélange de vapeur et de formaldéhyde à température basse en tant que stérilisant et fonctionnant uniquement en dessous de la pression ambiante.

1.2 Exclusions

1.2.1 Il convient que les procédés de stérilisation validés et contrôlés conformément aux exigences de la présente norme ne soient pas supposés efficaces pour l'inactivation des agents responsables des encéphalopathies spongiformes telles que la tremblante du mouton, l'encéphalopathie spongiforme bovine et la maladie de Creutzfeld-Jacob. Des recommandations spécifiques ont été formulées dans certains pays pour le traitement des matériaux potentiellement contaminés par ces agents.

1.2.2 La présente norme ne spécifie pas d’exigence pour qualifier un dispositif médical de « STERILE ». De telles exigences sont fournies dans l’EN 556-1.

1.2.3 La présente norme ne spécifie pas de système de management de la qualité pour le contrôle de toutes les étapes de production des dispositifs médicaux.

Sterilizacija medicinskih pripomočkov - Para nizke temperature in formaldehid - Zahteve za razvoj, validacijo in rutinsko kontrolo sterilizacijskih postopkov za medicinske pripomočke

General Information

- Status

- Withdrawn

- Publication Date

- 03-Apr-2007

- Withdrawal Date

- 21-Jun-2011

- Technical Committee

- CEN/TC 204 - Sterilization of medical devices

- Drafting Committee

- CEN/TC 204 - Sterilization of medical devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 22-Jun-2011

- Completion Date

- 22-Jun-2011

- Directive

- 93/42/EEC - Medical devices

Relations

- Effective Date

- 14-May-2011

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 15424:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sterilization of medical devices - Low temperature steam and formaldehyde - Requirements for development, validation and routine control of a sterilization process for medical devices". This standard covers: 1.1 Inclusions 1.1.1 This European Standard specifies requirements for the development, validation and routine control of a Low Temperature Steam and Formaldehyde (LTSF) sterilization process for medical devices. NOTE Although the scope of this standard is limited to medical devices, it specifies requirements and provides guidance that may be applicable to other products and equipment. 1.1.2 This European Standard is intended to be applied by process developers, manufacturers of sterilization equipment, manufacturers of medical devices to be sterilized and the organizations with responsibility for sterilizing medical devices. (See EN ISO 14937:2000, Table E.1) 1.1.3 This European Standard covers sterilization processes which use a mixture of low temperature steam and formaldehyde as sterilant, and which are working below ambient pressure only. 1.2 Exclusions 1.2.1 Sterilization processes validated and controlled in accordance with the requirements of this standard should not be assumed to be effective in inactivating the causative agents of spongiform encephalopathies such as scrapie, bovine spongiform encephalopathy and Creutzfeld-Jakob disease. Specific recommendations have been produced in particular countries for the processing of materials potentially contaminated with these agents. 1.2.2 This standard does not specify requirements for designating a medical device as "STERILE". Such requirements are given in EN 556-1. 1.2.3 This standard does not specify a quality management system for the control of all stages of production of medical devices. NOTE Attention is drawn to the standards for quality management systems (see EN ISO 13485) that control all stages of production or reprocessing of medical devices including the sterilization process. It is not a requirement of this standard to have a complete quality management system during manufacture or reprocessing, but those elements of such a system that are required are normatively referenced at appro

1.1 Inclusions 1.1.1 This European Standard specifies requirements for the development, validation and routine control of a Low Temperature Steam and Formaldehyde (LTSF) sterilization process for medical devices. NOTE Although the scope of this standard is limited to medical devices, it specifies requirements and provides guidance that may be applicable to other products and equipment. 1.1.2 This European Standard is intended to be applied by process developers, manufacturers of sterilization equipment, manufacturers of medical devices to be sterilized and the organizations with responsibility for sterilizing medical devices. (See EN ISO 14937:2000, Table E.1) 1.1.3 This European Standard covers sterilization processes which use a mixture of low temperature steam and formaldehyde as sterilant, and which are working below ambient pressure only. 1.2 Exclusions 1.2.1 Sterilization processes validated and controlled in accordance with the requirements of this standard should not be assumed to be effective in inactivating the causative agents of spongiform encephalopathies such as scrapie, bovine spongiform encephalopathy and Creutzfeld-Jakob disease. Specific recommendations have been produced in particular countries for the processing of materials potentially contaminated with these agents. 1.2.2 This standard does not specify requirements for designating a medical device as "STERILE". Such requirements are given in EN 556-1. 1.2.3 This standard does not specify a quality management system for the control of all stages of production of medical devices. NOTE Attention is drawn to the standards for quality management systems (see EN ISO 13485) that control all stages of production or reprocessing of medical devices including the sterilization process. It is not a requirement of this standard to have a complete quality management system during manufacture or reprocessing, but those elements of such a system that are required are normatively referenced at appro

EN 15424:2007 is classified under the following ICS (International Classification for Standards) categories: 11.080.01 - Sterilization and disinfection in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15424:2007 has the following relationships with other standards: It is inter standard links to EN ISO 25424:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15424:2007 is associated with the following European legislation: EU Directives/Regulations: 93/42/EEC; Standardization Mandates: M/BC/CEN/89/9. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15424:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sterilization of medical devices - Low temperature steam and formaldehyde - Requirements for development, validation and routine control of a sterilization process for medical devicesStérilisation des dispositifs médicaux - Vapeur d'eau a basse température et au formaldéhyde - Exigences pour le développement, la validation et le contrôle de routine des procédés de stérilisationSterilisation von Medizinprodukten - Niedertemperatur-Dampf-Formaldehyd - Anforderungen an die Entwicklung, Validierung und Routineüberwachung von Sterilisationsverfahren für MedizinprodukteTa slovenski standard je istoveten z:EN 15424:2007SIST EN 15424:2007en,fr,de11.080.01Sterilizacija in dezinfekcija na splošnoSterilization and disinfection in generalICS:SLOVENSKI

STANDARDSIST EN 15424:200701-september-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15424April 2007ICS 11.080.01 English VersionSterilization of medical devices - Low temperature steam andformaldehyde - Requirements for development, validation androutine control of a sterilization process for medical devicesStérilisation des dispositifs médicaux - Développement,validation et contrôle de routine des procédés destérilisation - Vapeur d'eau à basse température et auformaldéhydeSterilisation von Medizinprodukten - Niedertemperatur-Dampf-Formaldehyd - Anforderungen an die Entwicklung,Validierung und Routineüberwachung vonSterilisationsverfahren für MedizinprodukteThis European Standard was approved by CEN on 17 February 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15424:2007: E

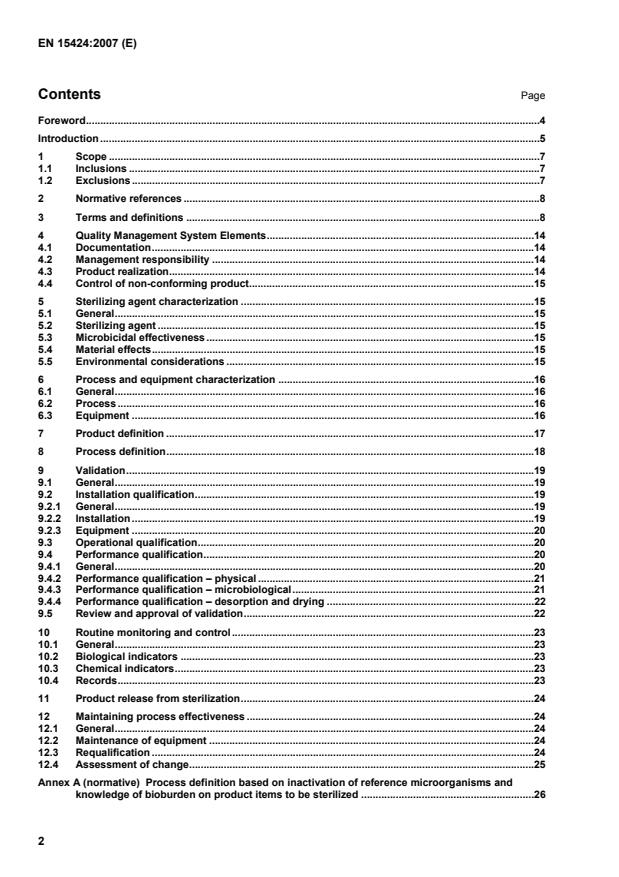

Process definition based on inactivation of reference microorganisms and knowledge of bioburden on product items to be sterilized.26

Process definition based on inactivation of reference microorganisms.27 B.1 General.27 B.1.1 Overkill approach.27 B.1.2 Penetration characteristics into medical devices.27 B.2 Test procedure.28 B.2.1 General.28 B.2.2 Biological indicators.28 B.2.3 Test systems.28 B.2.4 Load configuration.28 B.2.5 Testing.28 Annex C (informative)

Guidance on application of this European Standard.30 C.1 Scope.30 C.2 Normative references.30 C.3 Terms and definitions.30 C.4 Quality management system elements.30 C.5 Sterilizing agent characterization.30 C.5.1 Neutralization.30 C.5.2 Studies of microbial inactivation.31 C.6 Process and equipment characterization.31 C.7 Product definition.31 C.7.1 General.31 C.7.2 Design considerations for medical devices intended for sterilization.32 C.7.3 Packaging considerations.32 C.8 Process definition.32 C.8.1 General.32 C.8.2 Influence on product and packaging.33 C.8.3 Determination of process effectiveness.33 C.9 Validation.34 C.9.1 General.34 C.9.2 Installation qualification (IQ).34 C.9.3 Operational qualification (OQ).35 C.9.4 Performance qualification (PQ).36 C.9.5 Documentation and approval of validation.37 C.10 Routine monitoring and control.37 C.11 Product release from sterilization.38 C.11.1 General.38 C.11.2 Product release using biological indicators.38 C.11.3 Parametric release.38 C.12 Maintaining process effectiveness.38 C.12.1 Change control.38 C.12.2 Requalification.39 Annex D (informative)

Environmental aspects regarding development, validation and routine control of Low Temperature Steam and Formaldehyde processes.40 D.1 General.40 D.2 Formaldehyde (brief description).40 D.3 Environmental impact of formaldehyde.40 D.4 Other environmental burdens.41 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 93/42/EEC Medical devices.44 Bibliography.45

Introduction A sterile medical device is one which is free of viable microorganisms. European Standards, which specify requirements for validation and routine control of a sterilization process require, when it is necessary to supply a sterile medical device, that adventitious microbiological contamination of a medical device prior to sterilization be minimized. Even so, medical devices produced under standard manufacturing conditions in accordance with the requirements for quality management systems (see EN ISO 13485) or which have been subjected to a cleaning process as part of their reprocessing in a health care establishment may, prior to sterilization, have microorganisms on them, albeit in low numbers. Such products are non-sterile. The purpose of sterilization is to inactivate the microbiological contaminants and thereby transform the non-sterile products into sterile ones. The kinetics of inactivation of a pure culture of microorganisms by physical and/or chemical agents used to sterilize medical devices can generally best be described by an exponential relationship between the numbers of microorganisms surviving and the extent of treatment with the sterilizing agent; inevitably this means that there is always a finite probability that a microorganism may survive regardless of the extent of treatment applied. For a given treatment, the probability of survival is determined by the number and resistance of microorganisms and by the environment in which the organisms exist during treatment. It follows that the sterility of any one product in a population subjected to sterilization cannot be guaranteed and the sterility of a processed population is defined in terms of the probability of there being a viable microorganism present on a product item. This standard describes requirements which will enable the demonstration that a low temperature steam and formaldehyde sterilization process intended to sterilize medical devices has appropriate microbicidal activity, and that this activity is both reliable and reproducible, such that the relationship for the inactivation of microorganisms can be extrapolated with reasonable confidence to low levels of probability of there being a viable microorganism present on a product after sterilization. This standard does not specify the maximal value to be taken by this probability; specification of this probability is given in EN 556-1.

Requirements of the quality management system for medical device design/development, production, installation and servicing are given in EN ISO 13485. The standard for quality management systems recognizes that, for certain processes used in manufacturing or reprocessing, the effectiveness cannot be fully verified by subsequent inspection and testing of the product. Sterilization is an example of such a process. For this reason, sterilization processes are validated for use, the performance of the sterilization process monitored routinely and the equipment maintained. Exposure to a properly validated, accurately controlled sterilization process is not the only factor associated with the provision of reliable assurance that the product is sterile and, in this regard, suitable for its intended use. Attention is therefore given to a number of factors including: a) the microbiological status of incoming raw materials and/or components, b) the validation and routine control of any cleaning and disinfection procedures used on the product,

c) the control of the environment in which the product is manufactured, assembled and packaged, d) the control of equipment and processes, e) the control of personnel and their hygiene, f) the manner and materials in which the product is packaged, and, g) the conditions under which the product is transported and stored.

1.1.2 This European Standard is intended to be applied by process developers, manufacturers of sterilization equipment, manufacturers of medical devices to be sterilized and the organizations with responsibility for sterilizing medical devices. (See EN ISO 14937:2000, Table E.1) 1.1.3 This European Standard covers sterilization processes which use a mixture of low temperature steam and formaldehyde as sterilant, and which are working below ambient pressure only. 1.2 Exclusions 1.2.1 Sterilization processes validated and controlled in accordance with the requirements of this standard should not be assumed to be effective in inactivating the causative agents of spongiform encephalopathies such as scrapie, bovine spongiform encephalopathy and Creutzfeld-Jakob disease. Specific recommendations have been produced in particular countries for the processing of materials potentially contaminated with these agents. 1.2.2 This standard does not specify requirements for designating a medical device as "STERILE". Such requirements are given in EN 556-1.

1.2.3 This standard does not specify a quality management system for the control of all stages of production of medical devices.

NOTE It is not a requirement of this standard to have a complete quality management system during manufacture or reprocessing, but those elements of such a system that are required are normatively referenced at appropriate places in the text. Attention is drawn to the standards for quality management systems (see EN ISO 13485) that control all stages of production or reprocessing of medical devices including the sterilization process. Further guidance is given in E.2 of EN ISO 14937:2000. 1.2.4 This standard does not specify requirements for occupational safety associated with the design and operation of LTSF sterilization facilities. NOTE 1 Safety requirements for sterilizers are specified in EN 61010-2-040. NOTE 2 Attention is also drawn to the existence in some countries of regulations stipulating safety requirements. 1.2.5 This European Standard does not cover analytical methods for determining levels or residues of formaldehyde and/or its reaction products. NOTE 1 Attention is drawn to EN 14180. NOTE 2 Attention is drawn to the possible existence in some countries of statutory regulation specifying limits for the level of formaldehyde residues on medical devices and products. 1.2.6 This European Standard does not cover preparatory measures that may be necessary before sterilization such as cleaning, disinfection and packing. NOTE For re-sterilizable medical devices, the manufacturer(s) of these devices should supply information on the preparatory measures (see EN ISO 17664).

EN ISO 11138-1, Sterilization of health care products - Biological indicators - Part 1: General requirements (ISO 11138-1:2006) EN ISO 11138-5:2006, Sterilization of health care products - Biological indicators - Part 5: Biological indicators for low-temperature steam and formaldehyde sterilization processes (ISO 11138-5:2006) EN ISO 11140, Sterilization of health care products - Chemical indicators (Parts as appropriate) EN ISO 11737-1, Sterilization of medical devices - Microbiological methods - Part 1: Determination of a population of microorganisms on products (ISO 11737-1:2006) EN ISO 11737-2, Sterilization of medical devices - Microbiological methods - Part 2: Tests of sterility performed in the validation of a sterilization process (ISO 11737-2:1998) EN ISO 13485, Medical devices - Quality management systems - Requirements for regulatory purposes (ISO 13485:2003) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 adjustment

correction of a measurement device or system to indicate the value as established by calibration 3.2 aeration part or parts of the sterilization process in which defined conditions are used such that formaldehyde and its reaction products are desorbed from the medical device, and which can be performed within the sterilizer, within a separate room or chamber, or by a combination of the two

[3.3 of EN 14180:2003 ] 3.3 air removal removal of air from the sterilizer chamber and sterilization load to facilitate sterilant penetration

[3.3 of EN 14180:2003] 3.4 bioburden population of viable microorganisms on or in product and/or sterile barrier system

[2.2 of ISO/TS 11139:2006]

[2.4 of ISO/TS 11139:2006]

3.7 change control assessment and determination of the appropriateness of a proposed alteration to product or procedure

[2.5 of ISO/TS 11139:2006] 3.8 chemical indicator

test system that reveals change in one or more predefined process variables based on a chemical or physical change resulting from exposure to a process

[2.6 of ISO/TS 11139:2006] 3.9 conditioning treatment of product within the sterilization cycle, but prior to the holding time, to attain a predetermined temperature and humidity throughout the sterilization load

[3.7 of EN 14180:2003] 3.10

desorption

removal of the sterilant from the chamber and the load at the end of the exposure time

[3.11 of EN 14180:2003] 3.11 D value time or dose required to achieve inactivation of 90 % of a population of the test microorganism under stated conditions

[2.11 of ISO/TS 11139:2006] NOTE For LTSF sterilization the D value is given in minutes. 3.12 environmental control engineering and/or procedural systems to maintain conditions in defined areas within specified limits NOTE Such systems may include air and fluid filters, surface disinfection, personnel attire and administrative procedures [2.16 of ISO/TS 11139:2006].

[3.13 of EN 14180:2003] 3.14 establish determine by theoretical evaluation and confirm by experimentation

[2.17 of ISO/TS 11139:2006] 3.15 exposure time time between introducing the sterilant into the chamber and start of the desorption phase

[3.14 of EN 14180:2003] 3.16 fault one or more of the process parameters which lies outside of its/their specified tolerance(s)

[2.19 of ISO/TS 11139:2006] 3.17 FBIO value product of the logarithm of the initial population of microorganisms and the D value NOTE The FBIO value may be used to express the "total resistance" of the biological indicator. 3.18 holding time period for which the temperature, the steam pressure and the formaldehyde concentration of steam are held within pre-set values and their tolerances to achieve the required inactivation efficacy in the sterilizer chamber NOTE The holding time follows immediately after the equilibration time [3.15 of EN 14180:2003]. 3.19 inoculated carrier supporting material on or in which a defined number of test microorganisms have been deposited 3.20 installation qualification [IQ] process of obtaining and documenting evidence that equipment has been provided and installed in accordance with its specification

[2.22 of ISO/TS 11139:2006] 3.21 medical device instrument, apparatus, implement, machine, appliance, implant, in vitro reagent or calibrator, software, material or other similar or related article, intended by the manufacturer to be used, alone or in combination, for human beings for one or more of the specific purpose(s) of: diagnosis, prevention, monitoring, treatment or alleviation of disease, diagnosis, monitoring, treatment, alleviation of or compensation for an injury,

process of obtaining and documenting evidence that installed equipment operates within predetermined limits when used in accordance with its operational procedures

[2.27 of ISO/TS 11139:2006] 3.24 parametric release declaration that a product is sterile, based on records demonstrating that the process parameters were delivered within specified tolerances

[2.29 of ISO/TS 11139:2006] 3.25 performance qualification (PQ) process of obtaining and documenting evidence that the equipment, as installed and operated in accordance with operational procedures, consistently performs in accordance with pre-determined criteria and thereby yields product meeting its specification

[2.30 of ISO/TS 11139:2006] 3.26 process challenge device (PCD) item designed to constitute a defined resistance to a sterilization process and used to assess performance of the process

[2.33 of ISO/TS 11139:2006]

NOTE The device is designed so that an inoculated carrier or chemical indicator can be put in the place which is the most difficult to reach by sterilizing agent(s). The indicator should not interfere with the function of the process challenge device. 3.27 process parameter specified value for a process variable

[2.34 of ISO/TS 11139:2006]

[EN ISO 9000] NOTE For the purposes of sterilization standards, product is tangible and can be raw material(s), intermediate(s), sub-assembly (ies) and health care product(s) [2.36 of ISO/TS 11139:2006]. 3.30 recognized culture collection depository authority under the Budapest Treaty on The International Recognition of the Deposit of Microorganisms for the purpose of Patent and Regulation

[2.38 of ISO/TS 11139:2006] 3.31 reference measuring point point where the temperature sensor for the sterilization cycle control is located

[3.29 of EN 14180:2003] 3.32 reference microorganism microbial strain obtained from a recognized culture collection

[2.39 of ISO/TS 11139:2006] 3.33 requalification repetition of part of validation for the purpose of confirming the continued acceptability of a specified process

[2.40 of ISO/TS 11139:2006] 3.34

residues challenge device

item used to assess the desorption efficacy of the sterilization cycle 3.35 services supplies from an external source, necessary for the correct function of sterilizing equipment EXAMPLE Electricity, water, compressed air, drainage [2.41 of ISO/TS 11139:2006]. 3.36 specify stipulate in detail within an approved document

[2.42 of ISO/TS 11139:2006]

[3.31 of EN 14180:2003] NOTE Sterilant is generated by vaporizing the microbicidal solution and feeding it into the sterilizer chamber.

3.38 sterilant injection

single or repeated stage beginning with the introduction of sterilant into the evacuated sterilizer chamber and ending when the set operating pressure has been attained

[3.32 of EN 14180:2003] 3.39 sterile free from viable microorganisms

[2.43 of ISO/TS 11139:2006] 3.40 sterility state of being free from viable microorganisms NOTE In practice, no such absolute statement regarding the absence of microorganisms can be proven [ISO/TS 11139:2006, 2.45] 3.41 sterilization validated process used to render a product free from viable microorganisms

NOTE In a sterilization process, the nature of microbial inactivation is described by an exponential function. Therefore the presence of a viable microorganism(s) on any individual item can be expressed in terms of probability. While this probability can be reduced to a very low number, it can never be reduced to zero [2.47 of ISO/TS 11139:2006]. 3.42 sterilization cycle predetermined sequence of operating stages performed in a sterilizer for the purpose of sterilization and desorption

[3.37 of EN 14180:2003] 3.43 sterilization load product to be, or that has been, sterilized together using a given sterilization process

[2.48 of ISO/TS 11139:2006] 3.44 sterilization process series of actions or operations to achieve the specified requirements for sterility and for reduction of sterilant residues to an acceptable level [2.49 of ISO/TS 11139:2006]

3.45 sterilizing agent physical or chemical entity, or combination of entities having sufficient microbicidal activity to achieve sterility under defined conditions

[2.50 of ISO/TS 11139:2006] NOTE The sterilizing agent is the condensate film, generated by condensation of the sterilant on the surface of the medical devices to be sterilized.

3.46 survivor curve graphical representation of the inactivation of a population of microorganisms with increasing exposure to a microbicidal agent under stated conditions

[2.51 of ISO/TS 11139:2006] 3.47 validation documented procedure for obtaining, recording and interpreting the results required to establish that a process will consistently yield product conforming to predetermined specifications

[2.55 of ISO/TS 11139:2006] 4 Quality Management System Elements 4.1 Documentation 4.1.1 Procedures for each phase of the development, validation, routine control, and product release from sterilization shall be specified. 4.1.2 Documents and records required by this European Standard shall be reviewed and approved by designated personnel (see 4.2.1). Documents and records shall be controlled in accordance with an established quality management system, such as EN ISO 13485. 4.2 Management responsibility 4.2.1 The responsibility and authority for implementing and performing the procedures described in this European Standard shall be specified. Responsibility shall be assigned to competent personnel in accordance with an established quality management system, such as EN ISO 13485. 4.2.2 If the requirements of this European Standard are undertaken by different organizations with separate quality management systems, the responsibilities and authority of each party shall be specified. 4.3 Product realization 4.3.1 Procedures for purchasing shall be specified. These procedures shall conform to an established quality management system, such as EN ISO 13485 4.3.2 Procedures for identification and traceability of product shall be specified. These procedures shall conform to an established quality management system, such as EN ISO 13485. NOTE EN ISO 13485 details requirements for design reviews.

NOTE 1 The characteristics of LTSF processes and of low temperature steam and formaldehyde are well known after decades of practical use and development. Development of new processes may however necessitate new studies. NOTE 2 If characterization studies of a sterilizing agent with a non-traditional formaldehyde mixture is necessary, these studies can be undertaken under formal design and development controls (see EN ISO 13485). 5.2 Sterilizing agent A specification for the microbicidal solution and for the process to generate the sterilizing agent shall be generated. This shall include, if appropriate, conditions for storage to maintain the microbicidal solution within its specification for the duration of any stated shelf life. NOTE 1 For further guidance see EN 14180:2003, 10.3. NOTE 2 The LTSF-sterilization process is a modified steam sterilization process. A formaldehyde solution (microbicidal solution) is evaporated into a gas mixture containing steam and formaldehyde. The microbicidal activity is achieved by the condensate film on the surface of the medical devices to be sterilized.

5.3 Microbicidal effectiveness Data shall be available to demonstrate the microbicidal effectiveness of the sterilizing agent in the process. The microbicidal effectiveness of LTSF and its use in processes has been comprehensively documented and is available in literature. NOTE Manufacturers of sterilizers should have these data available for their customers. 5.4 Material effects The effects of low temperature steam and formaldehyde on materials, both in the sterilizer and in products, are generally well known after decades of practical use. However, when new materials are introduced the effects of sterilizing agent exposure (repeated when applicable) shall be assessed and documented. 5.5 Environmental considerations The potential impact on the environment of the use of formaldehyde in the sterilization process shall be assessed and measures to protect the environment shall be identified. This assessment, including potential impact (if any) and measures for control (if id

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...