EN 13160-7:2003

(Main)Leak detection systems - Part 7: General requirements and test methods for interstitial spaces, leak protecting linings and leak protecting jackets

Leak detection systems - Part 7: General requirements and test methods for interstitial spaces, leak protecting linings and leak protecting jackets

This standard specifies the type test of the interstitial space and the general requirements and test methods for leak protecting linings and leak protecting jackets which are parts of leak detection systems.

Leckanzeigesysteme - Teil 7: Allgemeine Anforderungen und Prüfverfahren für Überwachungsräume, Leckschutzauskleidung und Leckschutzummantelungen

Diese Europäische Norm legt die Typprüfung des Überwachungsraums und die allgemeinen Anforderungen und Prüfverfahren für Leckschutzauskleidungen und Leckschutzummantelungen, die Teile von Leckanzeigesystemen sind, fest.

Systèmes de détection de fuites - Partie 7: Exigences générales et méthodes d'essais pour les espaces interstitiels, pour revêements intérieurs et revêtements extérieurs protecteurs de fuites

La présente norme spécifie l'essai de type de l'espace interstitiel ainsi que les prescriptions générales et les méthodes d'essai relatives aux inhibiteurs de propulseurs et aux revêtements protecteurs de fuites qui font partie intégrante des systèmes de détection de fuites.

Sistemi za kontrolo tesnosti - 7. del: Splošne zahteve in metode za kontrolo vmesnih prostorov, notranjih in zunanjih tesnih oblog

General Information

- Status

- Withdrawn

- Publication Date

- 27-May-2003

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Drafting Committee

- CEN/TC 393/WG 2 - Leak detecting devices for tanks and pipes

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 06-Jul-2016

- Completion Date

- 09-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 18-Jul-2012

- Refers

EN ISO 24345:2012 - Resilient floor coverings - Determination of peel resistance (ISO 24345:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Intertek Testing Services NA Inc.

Intertek certification services in North America.

UL Solutions

Global safety science company with testing, inspection and certification.

ANCE

Mexican certification and testing association.

Sponsored listings

Frequently Asked Questions

EN 13160-7:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Leak detection systems - Part 7: General requirements and test methods for interstitial spaces, leak protecting linings and leak protecting jackets". This standard covers: This standard specifies the type test of the interstitial space and the general requirements and test methods for leak protecting linings and leak protecting jackets which are parts of leak detection systems.

This standard specifies the type test of the interstitial space and the general requirements and test methods for leak protecting linings and leak protecting jackets which are parts of leak detection systems.

EN 13160-7:2003 is classified under the following ICS (International Classification for Standards) categories: 23.020.01 - Fluid storage devices in general; 23.040.99 - Other pipeline components; 29.260.20 - Electrical apparatus for explosive atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13160-7:2003 has the following relationships with other standards: It is inter standard links to EN 13160-7:2016, EN ISO 24345:2012, EN ISO 75-2:2013, EN 915:1996, EN ISO 178:2019, EN ISO 8501-1:2007, EN 4343:2002, EN ISO 179-2:2020, EN 495-5:2013, EN 976-2:1997, EN 1107-2:2001, EN ISO 75-1:2020, EN ISO 179-1:2023, EN 13160-2:2003, ENV 1991-4:1995. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13160-7:2003 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 73/23/EEC, 89/106/EEC, 92/31/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13160-7:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

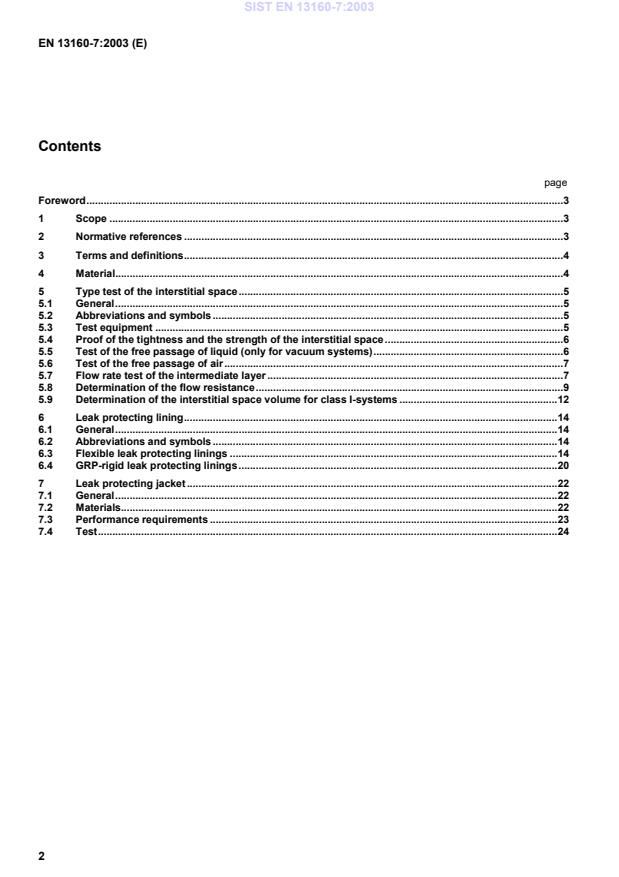

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sistemi za kontrolo tesnosti - 7. del: Splošne zahteve in metode za kontrolo vmesnih prostorov, notranjih in zunanjih tesnih oblogLeckanzeigesysteme - Teil 7: Allgemeine Anforderungen und Prüfverfahren für Überwachungsräume, Leckschutzauskleidung und LeckschutzummantelungenSystemes de détection de fuites - Partie 7: Exigences générales et méthodes d'essais pour les espaces interstitiels, pour reveements intérieurs et revetements extérieurs protecteurs de fuitesLeak detection systems - Part 7: General requirements and test methods for interstitial spaces, leak protecting linings and leak protecting jackets23.020.01Fluid storage devices in generalICS:Ta slovenski standard je istoveten z:EN 13160-7:2003SIST EN 13160-7:2003en01-december-2003SIST EN 13160-7:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13160-7May 2003ICS 23.020.01; 23.040.99; 29.260.20English versionLeak detection systems - Part 7: General requirements and testmethods for interstitial spaces, leak protecting linings and leakprotecting jacketsSystèmes de détection de fuites - Partie 7: Exigencesgénérales et méthodes d'essais pour les espacesinterstitiels, pour revêements intérieurs et revêtementsextérieurs protecteurs de fuitesLeckanzeigesysteme - Teil 7: Allgemeine Anforderungenund Prüfverfahren für Überwachungsräume,Leckschutzauskleidung und LeckschutzummantelungenThis European Standard was approved by CEN on 11 March 2003.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13160-7:2003 ESIST EN 13160-7:2003

900 mm.The test sample shall include any seams/welds and intermediate layer and shall have at least two test nozzles at adistance of 1500 mm apart.5.5.2EvaluationThe test is deemed to have been passed if the leak detector triggers an alarm, after the quantity of liquid, calculatedaccording to EN 13160–2:2003, Equation (3), has entered the interstitial space.SIST EN 13160-7:2003

100 mm, thickness 10 mm;two quadratic steel pressure plates 150 mm

150 mm, thickness 10 mm, with a hole of 10 mm each in the cornersphere. One steel plate has a hole in the middle of the plate with a diameter of 6 mm and a fitting with a diameter of6 mm is also welded on in the middle of the plate;four locking screws, 8 mm;compression device, with an accuracy of 1 %;air impermeable foil, e. g. PE 0,75 mm thickness;environmental chamber;vacuum pump;SIST EN 13160-7:2003

100 mm.5.7.4EvaluationThe test shall be deemed to have been passed, if the air current back pressure emanating from the intermediate layeris not less than - 1 kPa (10 mbar) at a volume flow of (85 ± 15) l/h of air.For protecting the lining the intermediate layer shall be tested at 1,3 times the maximum possible surface pressure(pMS) – but a minimum of 50 kPa (0,5 bar).For protecting the jacket the intermediate layer shall be tested at 1,3 times the maximum possible surface pressure(pMS) – but a minimum of 100 MPa (1000 bar).Maximum possible surface pressure according to Equation (1):pMS =

g

h + pPA(1)5.7.5Test methodThe test shall be carried out at a temperature of (20 ± 5) C. First the initial thickness of the intermediate layers (s1)shall be measured with the thickness tester. After the measurement the intermediate layers shall be laid between thetwo test plates. Through the upper test plate the test samples shall be charged with the help of the compressiondevice: for linings with the calculated maximum possible surface pressure (pMS), but a minimum of 50 kPa; for jackets with 1,3 times the maximum possible surface pressure (pMS), but a minimum of 100 MPa.After reaching the steady state condition but not before a minimum period of 14 days has elapsed the residualthickness (s2) shall be measured and the test equipment shall be installed in the environmental chamber. The testsamples shall be charged further with the maximum possible surface pressure (pMS) and the measurement of thethickness shall be repeated at the limiting temperatures of the given operating conditions as mentioned in 5.1 ofEN 13160-1:2003. The steady state condition has been reached, if two measurements of the residual thickness (s2)made at intervals of 24 h do not differ by more than 1 % from the thickness (s1). If after 90 days the steady statecondition has not been achieved the test has failed. Following this test the intermediate layers shall be pressed withthe help of the pressure plates and the locking screws until half of the residual thickness of the intermediate layers (s3)has been achieved or the pressure exceeds 2

pMS.At the fittings, located in the middle of the plate, a vacuum pump with an inserted measuring device for pressure, egu-tube, shall be connected. At the exit of the vacuum pump a valve for throttling the volume flow shall be installed, sothat the volume flow can be adjusted to the given value of 85 l/h through the secondary measuring device for thevolume flow. The length of the connecting line of the manometer to the fittings of the interstitial space shall be250 mm. The flexible connecting lines at the connection of the vacuum pump and the measuring device for thevolume flow shall be realized with an internal diameter of 6 mm.The total length of the connecting line from the fittings to the vacuum pump shall be max. 1 m for the measurements.After installation of the test equipment as mentioned above and in Figure 1 the flow resistance shall be taken from themeasuring device for pressure after turning-on the vacuum pump and adjusting the volume flow to 85 l/h. Themeasurement shall be repeated at each test sample. The mean of the measured values shall be compared with thelimiting value of -1 kPa.SIST EN 13160-7:2003

500 mm with four test nozzles installed at a distance of 400 mm has to be put at disposal. One testnozzle serves as the opening of ventilation. At a second test nozzle a vacuum pump shall be installed with amanometer inserted, e. g. a u-tube. The length of the connecting line of the manometer up to the connecting nozzleshall be 250 mm.The sides of the test specimen shall be closed gas tight. At the exit of the vacuum pump a flow control valve shallbe installed, so that the volume flow can be adjusted by the downstream volume indicator to the given value of85 l/h (Figure 2). The flexible interconnection lines for the connection of the leak detector and the volume indicatorshall be designed with an inside diameter of 6 mm. The entire length of the interconnection line of the connectingnozzle up to the u-tube shall be 1 m for the measurement.Dimensions in millimetresKey1 Test nozzle

4 mm2 Measuring device for pressure3 Vacuum pump with constant volume flow of 85 l/h4 Measuring instrument for volume flow5 Interstitial space of the test sampleFigure 2 — Suitability test of the construction of the interstitial spaceWith tanks, the tests for determination of the flow resist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...