EN 12457-3:2002

(Main)Characterisation of waste - Leaching - Compliance test for leaching of granular waste materials and sludges - Part 3: Two stage batch test at a liquid to solid ratio of 2 l/kg and 8 l/kg for materials with high solid content and with particle size below 4 mm (without or with size reduction)

Characterisation of waste - Leaching - Compliance test for leaching of granular waste materials and sludges - Part 3: Two stage batch test at a liquid to solid ratio of 2 l/kg and 8 l/kg for materials with high solid content and with particle size below 4 mm (without or with size reduction)

This part of the European Standard specifies a compliance test providing information on leaching of granular wastes and sludges under the experimental conditions specified hereafter, and particularly a liquid to solid ratio of 2 l/kg dry matter and subsequently of 8 l/kg dry matter. It applies to waste which has a particle size below 4 mm without or with size reduction. The test procedure specified in this Standard produces an eluate which shall subsequently be characterised physically and chemically according to appropriate standard methods.

Charakterisierung von Abfällen - Auslaugung - Übereinstimmungsuntersuchung für die Auslaugung von körnigen Abfällen und Schlämmen - Teil 3: Zweistufiges Schüttelverfahren mit einem Flüssigkeits-/Feststoffverhältnis von 2 l/kg und 8 l/kg für Materialien mit hohem Feststoffgehalt und mit einer Korngröße unter 4 mm (ohne oder mit Korngrößenreduzierung)

Dieser Teil der Europäischen Norm legt eine Übereinstimmungsuntersuchung fest, die Informationen zur Auslaugung von körnigen Abfällen und Schlämmen unter den im weiteren genannten experimentellen Bedingungen und insbesondere bei einem Flüssigkeits-/Feststoffverhältnis von 2 l/kg Trockenmasse in einem ersten Schritt und anschließend 8 l/kg Trockenmasse in einem zweiten Schritt liefert. Er gilt für Abfälle mit einer Korngröße unter 4 mm ohne oder mit Korngrößenreduzierung (wie in 4.3.2 angegeben).

Diese Europäische Norm wurde erstellt, um vorwiegend anorganische Bestandteile von Abfällen zu untersuchen. Sie berücksichtigt weder die besonderen Eigenschaften von nicht-polaren organischen Bestandteilen noch die Folgen von mikrobiologischen Prozessen in organischen abbaubaren Abfällen.

Durch das in der vorliegenden Norm beschriebene Prüfverfahren werden Eluate hergestellt, die anschließend physikalisch und chemisch nach den entsprechenden Standardmethoden charakterisiert werden.

Dieses Verfahren gilt nur für Abfall und Schlämme mit einem hohen Feststoffgehalt: der Trockenmasssegehalt muss mindestens 33 % betragen. Zusätzlich ist in jedem Schritt das für die physikalische und chemische Charakterisierung des Eluats erforderliche Volumen des Eluats zu berücksichtigen. Außerdem muss der Mindesttrockenmassegehalt ausreichend groß sein, um eine akzeptable Durchmischung des Auslaugungsmittels mit der Messprobe zu ermöglichen.

ANMERKUNG 1 Dieses Verfahren kann nicht für Materialien mit einem Wassergehalt oder Wasseraufnahmevermögen angewendet werden, die eine gute Durchmischung des Feststoffes mit der vorher bestimmten Menge der Flüssigkeit nicht ermöglichen.

ANMERKUNG 2 Dieses Verfahren kann nicht für Materialien angewendet werden, die mit dem Auslaugungsmittel reagieren, was z. B. zu starken Gasemissionen, einer Verfestigungswirkung oder einer übermäßigen Wärmefreisetzung führen kann.

ANMERKUNG 3 Durch das Zerkleinern von Abfall werden neue Oberflächen freigesetzt, was

Caractérisation des déchets - Lixiviation - Essai de conformité pour lixiviation des déchets fragmentés et des boues - Partie 3: Essai en bâchée double avec un rapport liquide-solide de 2 l/kg et de 8 l/kg pour des matériaux à forte teneur en solides et une granulatité inférieure à 4 mm (sans ou avec réduction de la granularité)

La présente partie de la Norme européenne spécifie un essai de conformité fournissant des informations sur la lixiviation des déchets fragmentés et des boues dans les conditions expérimentales spécifiées ci après, et en particulier un rapport liquide/solide de 2 l/kg de matière sèche dans un premier temps puis de 8 l/kg de matière sèche dans un second temps. Cet essai s'applique aux déchets ayant une granularité inférieure à 4 mm sans ou avec réduction de la granularité (comme spécifié en 4.3.2).La présente Norme européenne a principalement été conçue pour étudier les constituants inorganiques des déchets. Elle ne tient pas compte des caractéristiques particulières des constituants organiques non polaires ni des conséquences de l'évolution microbiologique des déchets organiques dégradables.Le mode opératoire d'essai spécifié dans la présente Norme européenne permet d'obtenir un éluat qui doit ensuite être caractérisé du point de vue physique et chimique selon des méthodes normalisées appropriées.Ce mode opératoire s'applique uniquement aux déchets et aux boues à forte teneur en solide : le taux de matière sèche doit être au moins supérieur à 33 %. En outre la quantité nécessaire d'éluat pour effectuer la caractérisation physique et chimique de celui-ci doit être obtenue. Le taux minimal de matière sèche doit être suffisamment important pour permettre de bien mélanger le lixiviant et la prise d'essai.

NOTE 1 Ce mode opératoire ne peut pas être appliqué aux matières ayant une teneur en eau ou une affinité avec l'eau telle qu'il est impossible de bien mélanger le solide avec la quantité prédéterminée de liquide.

NOTE 2 Ce mode opératoire ne peut pas être appliqué aux matériaux réagissant avec le lixiviant, ce qui donnerait, par exemple, une émission gazeuse excessive, un effet de solidification ou à un dégagement de chaleur trop élevé.

NOTE 3 En fragmentant le matériau, de nouvelles surfaces sont exposées, ce qui peut conduire à un changement des propriétés de lixiv

Karakterizacija odpadkov - Izluževanje - Preskus skladnosti za izluževanje granuliranih odpadkov in blata - 3. del: Dvostopenjski šaržni preskus pri razmerju tekoče/trdno 2 l/kg in 8 l/kg za materiale z visoko vsebnostjo suhe snovi in z velikostjo delcev pod 4 mm (brez drobljenja ali z njim)

General Information

- Status

- Published

- Publication Date

- 17-Sep-2002

- Withdrawal Date

- 29-Jun-2003

- Technical Committee

- CEN/TC 444 - Environmental characterization

- Drafting Committee

- CEN/TC 444/WG 1 - Leaching tests

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 02-Dec-2023

- Completion Date

- 02-Dec-2023

- Directive

- 99/31/EC - Landfill of waste

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

EN 12457-3:2002 - Overview

EN 12457-3 is a CEN compliance test standard for the characterisation of waste by leaching. It defines a two-stage batch leaching test for granular waste materials and sludges with particle size below 4 mm (with or without size reduction). The test uses sequential liquid-to-solid ratios of L/S = 2 l/kg (first stage) and L/S = 8 l/kg (second stage) to produce eluates that are subsequently characterised by physical and chemical analysis. The procedure is intended primarily for inorganic constituent assessment under specified laboratory conditions.

Key topics and technical requirements

- Scope and applicability

- Applies to granular wastes and sludges with high solid content (dry matter content > 33%).

- Suitable for materials with particle size < 4 mm (either inherent or after size reduction).

- Not intended for liquid wastes, or for characterisation of non‑polar organics or microbiologically driven leaching processes.

- Test principle

- Two-stage serial batch extraction: first at L/S = 2 l/kg, then at L/S = 8 l/kg (cumulative contact).

- Produces eluates that must be analysed using standard analytical methods.

- Sampling, preparation and limits

- Sampling strategy, sample preparation and appropriate mixing are specified to ensure representative eluates.

- The test is not applicable where mixing with the predetermined leachant is impossible, or where material reacts excessively (gas release, solidification, heat).

- Crushing/size reduction may expose new surfaces and alter leaching behaviour - this is addressed in the standard.

- Analysis and documentation

- Eluates are characterised physically and chemically according to referenced methods (pH, metals, anions, TOC, etc.).

- Detailed reporting and blank tests are required for result interpretation.

Practical applications

- Compliance checking against regulatory or landfill acceptance criteria.

- Pre‑disposal characterisation of construction/demolition waste, sludges and other granular waste streams.

- Input for risk assessment, waste classification, and decisions on reuse, recycling or disposal routes.

- Quality control in waste treatment facilities and environmental laboratories.

Who uses this standard

- Environmental laboratories and testing service providers

- Waste management companies, landfill operators and recycling facilities

- Environmental consultants and site remediation teams

- Regulators and compliance officers within EU/EFTA jurisdictions

Related standards and references

- EN 12457 series (Parts 1, 2 and 4) - alternative single‑stage and L/S procedures

- ENV 12506, ENV 13370 - eluate analysis methods

- EN 12880, EN ISO 3696, EN ISO 5667-3, ISO 11465, ISO 5725-5 - sampling, water quality and analytical quality control

EN 12457-3 is a practical, harmonised method for generating representative eluates from high‑solid granular wastes and sludges under defined L/S conditions, enabling consistent compliance testing and decision-making for waste management.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12457-3:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Characterisation of waste - Leaching - Compliance test for leaching of granular waste materials and sludges - Part 3: Two stage batch test at a liquid to solid ratio of 2 l/kg and 8 l/kg for materials with high solid content and with particle size below 4 mm (without or with size reduction)". This standard covers: This part of the European Standard specifies a compliance test providing information on leaching of granular wastes and sludges under the experimental conditions specified hereafter, and particularly a liquid to solid ratio of 2 l/kg dry matter and subsequently of 8 l/kg dry matter. It applies to waste which has a particle size below 4 mm without or with size reduction. The test procedure specified in this Standard produces an eluate which shall subsequently be characterised physically and chemically according to appropriate standard methods.

This part of the European Standard specifies a compliance test providing information on leaching of granular wastes and sludges under the experimental conditions specified hereafter, and particularly a liquid to solid ratio of 2 l/kg dry matter and subsequently of 8 l/kg dry matter. It applies to waste which has a particle size below 4 mm without or with size reduction. The test procedure specified in this Standard produces an eluate which shall subsequently be characterised physically and chemically according to appropriate standard methods.

EN 12457-3:2002 is classified under the following ICS (International Classification for Standards) categories: 13.030.10 - Solid wastes; 13.030.20 - Liquid wastes. Sludge. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12457-3:2002 has the following relationships with other standards: It is inter standard links to CEN/TR 16192:2020, EN 24049:1993, EN ISO 11465:2025, EN 14399-4:2005, EN ISO 3696:1995, EN ISO 5667-3:2024, EN 16457:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12457-3:2002 is associated with the following European legislation: EU Directives/Regulations: 99/31/EC; Standardization Mandates: M/326. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12457-3:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.OXåHYDQMHCharakterisierung von Abfällen - Auslaugung - Übereinstimmungsuntersuchung für die Auslaugung von körnigen Abfällen und Schlämmen - Teil 3: Zweistufiges Schüttelverfahren mit einem Flüssigkeits-/Feststoffverhältnis von 2 l/kg und 8 l/kg für Materialen mit hohem Feststoffgehalt und mit einer Korngröße unter 4 mm (ohne oder mit Korngrößereduzierung)Caractérisation des déchets - Lixiviation - Essai de conformité pour lixiviation des déchets fragmentés et des boues - Partie 3: Essai en bâchée double avec un rapport liquide-solide de 2 l/kg et de 8 l/kg pour des matériaux a forte teneur en solides et une granularité inférieure a 4 mm (sans ou avec réduction de la granularité)Characterisation of waste - Leaching - Compliance test for leaching of granular waste materials and sludges - Part 3: Two stage batch test at a liquid to solid ratio of 2 l/kg and 8 l/kg for materials with high solid content and with particle size below 4 mm (without or with size reduction)13.030.20Liquid wastes. Sludge13.030.10Trdni odpadkiSolid wastesICS:Ta slovenski standard je istoveten z:EN 12457-3:2002SIST EN 12457-3:2004en01-januar-2004SIST EN 12457-3:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12457-3September 2002ICS 13.030.10; 13.030.20English versionCharacterization of waste - Leaching - Compliance test forleaching of granular waste materials and sludges - Part 3: Twostage batch test at a liquid to solid ratio of 2 l/kg and 8 l/kg formaterials with high solid content and with particle size below 4mm (without or with size reduction)Caractérisation des déchets - Lixiviation - Essai deconformité pour lixiviation des déchets fragmentés et desboues - Partie 3: Essai en bâchée double avec un rapportliquide-solide de 2 l/kg et de 8 l/kg pour des matériaux àforte teneur en solides et une granulatité inférieure à 4 mm(sans ou avec réduction de la granularité)Charakterisierung von Abfällen - Auslaugung -Übereinstimmungsuntersuchung für die Auslaugung vonkörnigen Abfällen und Schlämmen - Teil 3: ZweistufigesSchüttelverfahren mit einem Flüssigkeits-/Feststoffverhältnis von 2 l/kg und 8 l/kg für Materialen mithohem Feststoffgehalt und mit einer Korngröße unter 4 mm(ohne oder mit Korngrößereduzierung)This European Standard was approved by CEN on 17 August 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12457-3:2002 ESIST EN 12457-3:2004

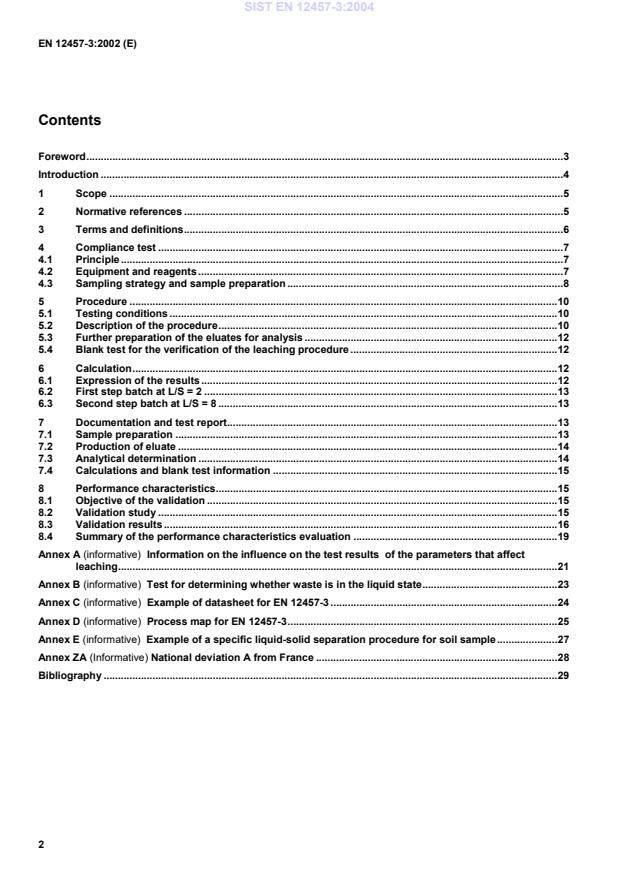

Information on the influence on the test results

of the parameters that affectleaching.21Annex B (informative)

Test for determining whether waste is in the liquid state.23Annex C (informative)

Example of datasheet for EN 12457-3.24Annex D (informative)

Process map for EN 12457-3.25Annex E (informative)

Example of a specific liquid-solid separation procedure for soil sample.27Annex ZA (Informative) National deviation A from France.28Bibliography.29SIST EN 12457-3:2004

The laboratorysample is the final sample from the point of view of sample collection but it is the initial sample from the point of view of thelaboratory.NOTE 2Several laboratory samples can be prepared and sent to different laboratories or to the same laboratory for differentpurposes.

When sent to the same laboratory, the set is generally considered as a single laboratory sample and is documentedas a single sample.3.14 test samplesample, prepared from the laboratory sample, from which test portions are removed for testing or for analysis( IUPAC definition )3.15 test portionamount or volume of the test sample taken for analysis, usually of known weight or volume ( IUPAC definition )4 Compliance test4.1 PrincipleThe sample material, which originally or after pre-treatment has a particle size below 4 mm as defined in 4.3.2, isbrought into contact with water (4.2.15) under defined conditions. This test is a serial batch leaching test consistingof two steps. This European Standard is based on the assumption that equilibrium or near-equilibrium is achievedbetween the liquid and solid phases during the test duration (see 5.2.1). The solid residue is separated by filtration.The properties of the eluates are measured using methods developed for water analysis adapted to meet criteriafor analysis of eluates (ENV 12506, ENV 13370 and others under development).After the test the leaching conditions in terms of pH, conductivity and optionally redox potential dictated by thewaste are recorded.NOTEThese parameters often control the leaching behaviour of wastes and are therefore important for checking theleaching test.4.2 Equipment and reagents4.2.1Glass or high density polyethylene (HDPE)/polypropylene (PP) bottles in accordance with EN ISO 5667-3,with a nominal volume of 500 ml for the first step and a nominal volume of 2 litre for the second step, glass bottleshaving caps of inert material, for example PTFE (polytetrafluoroethylene). Rinsing is compulsory.NOTE 1For inorganic constituents HDPE/PP bottles are preferred, except for samples analysed for mercury.NOTE 2The volume of 500 ml and 2 litre respectively are selected in combination with the mass MD of 175 gram asspecified in 4.3.4 in order to minimise headspace. In case of material with low density, deviation from this requirement can benecessary while still attempting to minimise headspace. This deviation should be documented in the test report.SIST EN 12457-3:2004

5 °C according to ISO 11465 or for sludges according to EN 12880. Thisdetermination shall be made in parallel on a test portion different from the test portion for leaching. The dry mattercontent ratio is calculated as follows :DR = 100

MD/MW(1)whereDRis the dry matter content ratio (%) ;MDis the mass of the dried test portion (kg) ;Mwis the mass of undried test portion (kg).The moisture content ratio (MC in %) is calculated as follows :MC = 100

(MW - MD)/MD(2)NOTE 1The basis for the calculation of the moisture content is the mass of the dry residue in this European Standard, asspecified in ISO 11465 (for the determination of the water content of soil). It is to be noted that in EN 12880 (for thedetermination of water content of sludges), the water content is calculated on the basis of the raw mass.NOTE 2The above moisture content determination could be not accurate enough in some cases (e.g. large amount ofvolatile or unstable compounds). In such cases a direct determination of the true water content should be performed and themoisture content calculated accordingly.4.3.4 Preparation of test portionPrepare from the test sample a test portion with a total mass MW (measured with an accuracy of 0,1 g) containing0,175 kg

0,005 kg of dry mass (MD). Use a sample splitter (4.2.14) or apply coning and quartering to split thesample.SIST EN 12457-3:2004

MD/DR(3)whereDRis the dry matter content ratio (%) ;MDis the mass of the dried test portion (kg) ;Mwis the mass of undried test portion (kg).NOTEIn view of the minimum requirements of sample volume for analytical purposes, it can be necessary to use a largertest portion size and a correspondingly larger volume of leachant. This deviation from this European Standard should bedocumented in the test report.5 Procedure5.1 Testing conditionsThe compliance test for leaching shall be carried out at room temperature (20

5) °C.5.2 Description of the procedure5.2.1 First leaching step Place the test portion with the total mass Mw corresponding to 0,175 kg

0,005 kg of dry mass MD in the bottle(4.2.1) of 500 ml. Add an amount of leachant (L2) establishing a liquid to solid ratio (L/S) = 2 l/kg

2 % during the first extraction.Care should be taken to obtain good mixing of solid and liquid.L2 = ( 2 – MC/100 )

MD(4)WhereL2is the volume of leachant used (in l) ;MDis the dry mass of the test portion (in kg) ;MCis the moisture content ratio (in %). Place the capped bottle in an agitation device (4.2.2). Agitate for 6 h

0,5 h. During the extraction care should be taken to prevent settlement of solids in the bottle. Excessive abrasion leading to significant particle size reduction shall be avoided.NOTESome wastes generate gas when they are wetted. Examples are waste incineration fly ash and sand blasting wastewhich may contain metallic particles. If gas emission occurs, careful opening of the bottle a few times during the leaching canprevent too high pressure. Such opening should be documented in the test report.5.2.2 First liquid-solid separation step Allow the suspended solids to settle for 15 min

5 min.SIST EN 12457-3:2004

2 %. Since adifferent bottle is used for the second step, the additional leachant shall be used to rinse out the first bottle, therinse leachant being collected in the second bottle. Care should be taken to obtain good mixing of solid andliquid.L8 =

MD(5)WhereL8is the volume of leachant used (in l) ;MDis the dry mass of the test portion (in kg) ; Place the capped bottle in an agitation device (4.2.2). Agitate for 18 h

0,5 h. During the extraction care should be taken to prevent settlement of solids in the bottle. Excessive abrasion leading to significant particle size reduction shall be avoided.NOTESome wastes generate gas when they are wetted. Examples are waste incineration fly ash and sand blasting wastewhich may contain metallic particles. If gas emission occurs, careful opening of the bottle a few times during the leaching canprevent too high pressure. Such opening should be reported.5.2.4 Second liquid-solid separation step Allow the suspended solids to settle for 15 min

5 min. Filter the eluate almost completely over a 0,45 µm membrane filter using a vacuum or pressure filtration device(4.2.3). Rinsing of the filter with water or another solvent is not allowed after filtration.NOTE 1When volatile components have to be analysed, vacuum filtration should not be used.When filtration as specified above is not possible in less than one hour with an eluate flow rate of at least30 ml/cm2/hour, a liquid-solid separation procedure, specific for the considered case, shall be applied and reportedSIST EN 12457-3:2004

75 mS/cm) are leached, acidification of the eluatescan lead to precipitation of salts. This can be avoided by diluting such samples 5 to 10 times prior to acidification. This additionaldilution should be taken into account in the calculations. A quantity of the undiluted sample should be acidified and retained incase the 5 to 10 dilution takes the sample below the detection limit for some determinands. Such procedure should bedocumented in the test report5.4 Blank test for the verification of the leaching procedureBlank tests shall be carried out. A 0,44 l (first step) and a 1,50 l (second step) volumes of leachant are submitted tothe whole procedure (except the sieving step, the fragmentation step and the splitting step but including the eluatesanalysis step).The two eluates of this blank test shall fulfill the following minimum requirements : in each eluate of the blank test,the concentration of each considered element shall be less than 20 % of the concentration determined in the eluateof the tested waste or less than 20 % of the concentration in the eluate of a limit value to which the measurementresult is to be compared. The elements to be considered are all the elements which are to be determined in theeluate of the tested waste.If the above requirements are not fulfilled, it is necessary to reduce the contamination.The blank test results shall not be substracted from the results of the waste leaching test.NOTEThe above provisions for the blank test do not take into account the sieving step, the fragmentation step and thesplitting step. In order to minimise the possible contamination during these three steps, it is recommended to process a

portionof the laboratory sample through the sieving device, the fragmentation device and through the splitting device before thepreparation of the test sample and to discard such material thereafter. This provision does not cover the situation described inthe notes under 4.2.5 and 4.2.6.6 Calculation6.1 Expression of the resultsThe analysis of the two eluates produced by the leaching test provides the concentrations of the constituents ineach of the two eluates, expressed in mg/l. The final results are expressed as the amount of constituent leachedrelative to the total mass of the sample, in mg/kg of dry matter.SIST EN 12457-3:2004

[(L2 / MD) + (MC / 100)](6)WhereA2is the release of a constituent at a L/S = 2 (in mg/kg of dry matter) ;C2is the concentration of a particular constituent in the eluate (in mg/l) (5.3.2) ;L2is the volume of leachant used (in l) ;MCis the moisture content ratio as defined in 3.12, expressed as a percentage of the drymass (4.3.2) andcalculated as in 4.3.3 ;MDis the dry mass of the test portion (in kg) (4.3.4).6.3 Second step batch at L/S = 8Calculate the cumulative release :A2-10 = C2 x ( VE1 / MD ) + C8 x [ (L2 + L8 – VE1 ) / MD + ( MC /100 ) ](7)WhereA2-10is the cumulative release at a cumulative L/S of 10 ;C8is the concentration of a particular constituent in the eluate from the second extraction (in mg/l)(5.3.2) ;L8is the volume of leachant applied in the second extraction (in l) ;VE1is the volume of eluate recovered from the first extraction (in l) ;MCis the moisture content ratio as defined in 3.12, expressed as a percentage of the dry mass (4.3.2)and calculated as in 4.3.3 ;MDis the dry mass of the test portion (in kg) (4.3.4).7 Documentation and test reportIn order to comply with this European Standard, the following information shall be documented in such a way thatthey are immediately available on request. In the following list, at least, the items marked with an asterisk (*) shallbe included in the test report. All the deviation from the minimum requirements of this European Standard shall alsobe documented in the test report7.1 Sample preparation reference to this European Standard* ; nature of the waste (e.g. granular waste, sludge)* ; reference of the laboratory sample* and of the accompanying documents* stipulated in the sampling standard ; date of reception in the laboratory of the laboratory sample* ; address of the laboratory and name(s) of the responsible person(s)* ;SIST EN 12457-3:2004

preparation of the testportion from the laboratory sample

before the leaching test); the leaching test itself and the experimental parameter variations as allowed by the tolerances; the chemical analysis (uncertainty in the determination of concentration in the eluates).In the interlaboratory exercise to establish the uncertainty of the compliance leaching test, the contributions of thefirst two items listed above were not included. The results of the validation study are relevant to all activities carriedout on the laboratory sample including its preparation from the primary field sample.8.2 Validation studyThe validation of EN 12457-3 was carried out with 11 - 14 European laboratories on two types of waste materials.One of the wastes was tested according to the four parts of EN 12457. The wastes selected for the validation werechosen to represent a range of wastes as broad as possible, because the standard will find general applicationacross many different types of waste materials. In the validation work of parts 2 and 4, all the wastes were tested.In the validation work of parts 1 and 3, only a selection from these 7 wastes were tested (detailed information canbe found in the final report on the Validation study mentioned in the Bibliography).In the validation study the following starting points were used: The laboratory samples were all taken from one large batch of the different wastes according to th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...