EN 13795-1:2019

(Main)Surgical clothing and drapes - Requirements and test methods - Part 1: Surgical drapes and gowns

Surgical clothing and drapes - Requirements and test methods - Part 1: Surgical drapes and gowns

This European Standard specifies information to be supplied to users and third party verifiers in addition to the usual labelling of medical devices (see EN 1041 and EN ISO 15223-1), concerning manufacturing and processing requirements. This European Standard gives information on the characteristics of single-use and reusable surgical gowns and surgical drapes used as medical devices for patients, clinical staff and equipment, intended to prevent the transmission of infective agents between clinical staff and patients during surgical and other invasive procedures. This European Standard specifies test methods for evaluating the identified characteristics of surgical drapes and gowns and sets performance requirements for these products.

EN 13795-1 does not cover requirements for resistance to penetration by laser radiation of products. Suitable test methods for resistance to penetration by laser radiation, together with an appropriate classification system, are given in EN ISO 11810.

EN 13795-1 does not cover requirements for incise drapes or films.

EN 13795-1 does not cover requirements for antimicrobial treatments for surgical gowns and drapes. Antimicrobial treatment may cause environmental risks such as resistance and pollution. However, antimicrobial treated surgical gowns and drapes fall under the scope of this standard with respect to their use as surgical gowns and drapes.

Operationskleidung und -abdecktücher - Anforderungen und Prüfverfahren - Teil 1: Operationsabdecktücher und -mäntel

Dieses Dokument legt die Informationen fest, die dem Anwender und Prüfer (Dritte) zu liefern sind, zusätzlich zu der normalen Kennzeichnung von Medizinprodukten (siehe EN 1041 und EN ISO 15223 1) bezüglich Anforderungen an die Herstellung und Aufbereitung. Dieses Dokument gibt Aufschluss über die Eigenschaften von Einmal und Mehrweg Operationsmänteln und abdecktüchern zur Verwendung als Medizinprodukte für Patienten, Klinikpersonal und Geräte, zum Schutz vor Übertragung infektiöser Agenzien zwischen Klinikpersonal und Patienten während operativer und anderer invasiver Eingriffe. Dieses Dokument legt Prüfverfahren zur Bewertung der bestimmten Eigenschaften von Operationsabdecktüchern und mänteln sowie die Anforderungen an diese Produkte fest.

Dieses Dokument befasst sich nicht mit Anforderungen an die Resistenz gegenüber der Penetration von Laserstrahlung von Produkten. Geeignete Prüfverfahren für die Resistenz gegen die Penetration durch Laserstrahlung zusammen mit einer geeigneten Klassifizierung sind in EN ISO 11810 angegeben.

Dieses Dokument befasst sich nicht mit Anforderungen für Inzisionsstreifen oder folien.

Dieses Dokument befasst sich nicht mit Anforderungen für antimikrobielle Behandlungen für Operations-mäntel und abdecktücher. Antimikrobielle Behandlung kann zu Umweltrisiken wie Resistenz und Ver-schmutzung führen. Jedoch müssen antimikrobiell behandelte Operationsmäntel und abdecktücher die Anforderungen dieses Dokuments bezüglich deren Verwendung als Operationsmäntel und abdecktücher erfüllen.

Vêtements et champs chirurgicaux - Exigences et méthodes d’essai - Partie 1 : Champs et casaques chirurgicaux

La présente Norme européenne spécifie les informations à fournir aux utilisateurs et aux vérificateurs tiers en plus de l’étiquetage usuel des dispositifs médicaux (voir l’EN 1041 et l’EN ISO 15223-1) concernant les exigences de fabrication et de traitement. La présente norme européenne fournit des informations sur les caractéristiques des champs chirurgicaux et des casaques chirurgicales, qu’ils soient à usage unique ou réutilisables, utilisés en tant que dispositifs médicaux pour les patients, le personnel médical et les équipements et destinés à empêcher la transmission d’agents infectieux entre le personnel chirurgical et les patients au cours des interventions chirurgicales et autres interventions invasives. La présente Norme européenne spécifie les méthodes d’essai permettant d’évaluer les caractéristiques identifiées des champs et casaques chirurgicaux et établit des exigences de performance pour ces produits.

La prEN 13795-1 n’aborde pas les exigences relatives à la résistance des produits à la pénétration par rayonnement laser. Des méthodes d’essai appropriées à la résistance à la pénétration par rayonnement laser ainsi qu’un système de classification adéquat sont donnés dans l’EN ISO 11810.

La prEN 13795-1 n’aborde pas les exigences relatives aux champs et aux films à inciser.

La prEN 13795-1 n’aborde pas les exigences relatives aux traitements antimicrobiens pour casaques et champs chirurgicaux. Le traitement antimicrobien peut présenter un risque pour l’environnement, notamment une résistance et une pollution environnementales. Cependant, les casaques et champs chirurgicaux soumis à un traitement antimicrobien sont couverts par le domaine d’application de la présente norme en ce qui concerne leur utilisation comme casaques et champs chirurgicaux.

Operacijska oblačila in pokrivala - Zahteve in preskusne metode - 1. del: Operacijska pokrivala in plašči

Ta evropski standard določa informacije, ki jih je treba poleg običajnega označevanja medicinskih pripomočkov (glej standarda EN 1041 in EN ISO 15223-1) podati uporabnikom in tretjim strankam, ki izvajajo preverjanje, in sicer v zvezi z zahtevami za proizvodnjo in obdelovanje. Ta evropski standard podaja informacije o lastnostih operacijskih plaščev in pokrival za enkratno in večkratno uporabo, ki se uporabljajo kot medicinski pripomočki za paciente, zdravstveno osebje in opremo ter so namenjeni za preprečevanje prenosa infekcijskih agentov med zdravstvenim osebjem in pacienti med kirurškimi in drugimi invazivnimi postopki. Ta evropski standard določa preskusne metode za ocenjevanje identificiranih lastnosti operacijskih pokrival in plaščev ter čistih oblačil in določa zahteve glede zmogljivosti teh proizvodov.

Standard EN 13795-1 ne zajema zahtev za odpornost proizvodov na penetracijo z laserskim sevanjem. Ustrezne preskusne metode za odpornost na penetracijo z laserskim sevanjem skupaj z ustreznim sistemom razvrščanja so podane v standardu EN ISO 11810.

Standard EN 13795-1 ne zajema zahtev za incizijska pokrivala ali folije.

Standard EN 13795-1 ne zajema zahtev za protimikrobne obdelave za operacijske plašče in pokrivala. Protimikrobna obdelava lahko povzroči tveganja za okolje, kot npr. odpornost in onesnaženost. Vendar pa protimikrobno obdelani operacijski plašči in pokrivala spadajo na področje uporabe tega standarda glede na to, da se uporabljajo kot operacijski plašči in pokrivala.

General Information

- Status

- Withdrawn

- Publication Date

- 02-Apr-2019

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 205 - Non-active medical devices

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 29-Jan-2025

- Completion Date

- 11-Feb-2026

- Directive

- 93/42/EEC - Medical devices

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 09-Feb-2022

- Effective Date

- 14-Dec-2011

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 13795-1:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Surgical clothing and drapes - Requirements and test methods - Part 1: Surgical drapes and gowns". This standard covers: This European Standard specifies information to be supplied to users and third party verifiers in addition to the usual labelling of medical devices (see EN 1041 and EN ISO 15223-1), concerning manufacturing and processing requirements. This European Standard gives information on the characteristics of single-use and reusable surgical gowns and surgical drapes used as medical devices for patients, clinical staff and equipment, intended to prevent the transmission of infective agents between clinical staff and patients during surgical and other invasive procedures. This European Standard specifies test methods for evaluating the identified characteristics of surgical drapes and gowns and sets performance requirements for these products. EN 13795-1 does not cover requirements for resistance to penetration by laser radiation of products. Suitable test methods for resistance to penetration by laser radiation, together with an appropriate classification system, are given in EN ISO 11810. EN 13795-1 does not cover requirements for incise drapes or films. EN 13795-1 does not cover requirements for antimicrobial treatments for surgical gowns and drapes. Antimicrobial treatment may cause environmental risks such as resistance and pollution. However, antimicrobial treated surgical gowns and drapes fall under the scope of this standard with respect to their use as surgical gowns and drapes.

This European Standard specifies information to be supplied to users and third party verifiers in addition to the usual labelling of medical devices (see EN 1041 and EN ISO 15223-1), concerning manufacturing and processing requirements. This European Standard gives information on the characteristics of single-use and reusable surgical gowns and surgical drapes used as medical devices for patients, clinical staff and equipment, intended to prevent the transmission of infective agents between clinical staff and patients during surgical and other invasive procedures. This European Standard specifies test methods for evaluating the identified characteristics of surgical drapes and gowns and sets performance requirements for these products. EN 13795-1 does not cover requirements for resistance to penetration by laser radiation of products. Suitable test methods for resistance to penetration by laser radiation, together with an appropriate classification system, are given in EN ISO 11810. EN 13795-1 does not cover requirements for incise drapes or films. EN 13795-1 does not cover requirements for antimicrobial treatments for surgical gowns and drapes. Antimicrobial treatment may cause environmental risks such as resistance and pollution. However, antimicrobial treated surgical gowns and drapes fall under the scope of this standard with respect to their use as surgical gowns and drapes.

EN 13795-1:2019 is classified under the following ICS (International Classification for Standards) categories: 11.140 - Hospital equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13795-1:2019 has the following relationships with other standards: It is inter standard links to EN 13795:2011+A1:2013, EN 13795-1:2025, EN ISO 13938-1:1999, EN ISO 139:2005/A1:2011, EN 29073-3:1992, EN ISO 139:2005, EN ISO 11737-1:2018, EN ISO 22612:2005, EN ISO 811:2018, EN ISO 22610:2006, EN ISO 9073-10:2004, EN 14683:2025, EN 13795:2011. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13795-1:2019 is associated with the following European legislation: EU Directives/Regulations: 2007/47/EC, 93/42/EEC; Standardization Mandates: M/295. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13795-1:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Nadomešča:

SIST EN 13795:2011+A1:2013

Operacijska oblačila in pokrivala - Zahteve in preskusne metode - 1. del:

Operacijska pokrivala in plašči

Surgical clothing and drapes - Requirements and test methods - Part 1: Surgical drapes

and gowns

Operationskleidung und -abdecktücher - Anforderungen und Prüfverfahren - Teil 1:

Operationsabdecktücher und -mäntel

Vêtements et champs chirurgicaux - Exigences et méthodes d’essai - Partie 1 : Champs

et casaques chirurgicaux

Ta slovenski standard je istoveten z: EN 13795-1:2019

ICS:

11.140 Oprema bolnišnic Hospital equipment

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13795-1

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 11.140 Supersedes EN 13795:2011+A1:2013

English Version

Surgical clothing and drapes - Requirements and test

methods - Part 1: Surgical drapes and gowns

Vêtements et champs chirurgicaux - Exigences et Operationskleidung und -abdecktücher -

méthodes d'essai - Partie 1 : Champs et casaques Anforderungen und Prüfverfahren - Teil 1:

chirurgicaux Operationsabdecktücher und -mäntel

This European Standard was approved by CEN on 24 October 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13795-1:2019 E

worldwide for CEN national Members.

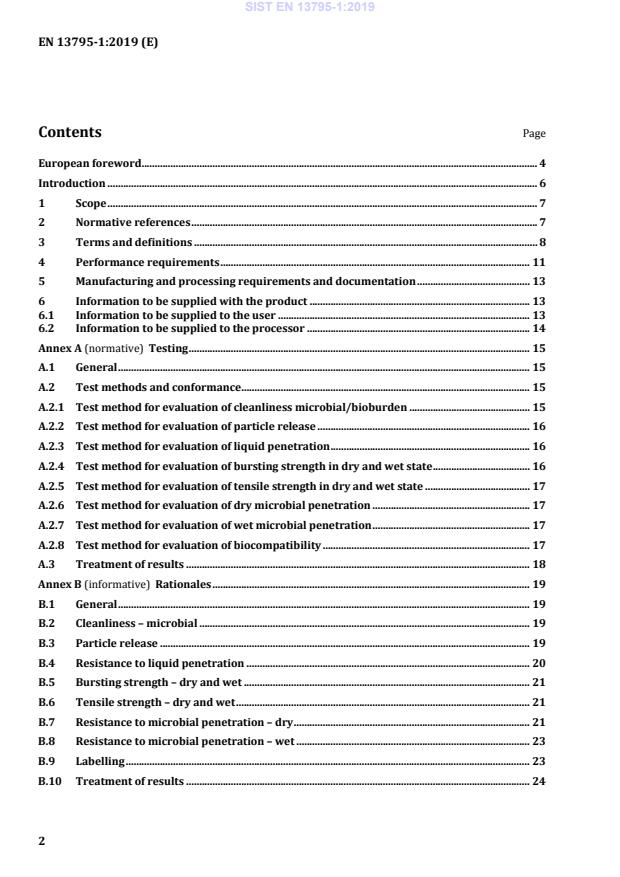

Contents Page

European foreword . 4

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Performance requirements . 11

5 Manufacturing and processing requirements and documentation . 13

6 Information to be supplied with the product . 13

6.1 Information to be supplied to the user . 13

6.2 Information to be supplied to the processor . 14

Annex A (normative) Testing . 15

A.1 General . 15

A.2 Test methods and conformance . 15

A.2.1 Test method for evaluation of cleanliness microbial/bioburden . 15

A.2.2 Test method for evaluation of particle release . 16

A.2.3 Test method for evaluation of liquid penetration . 16

A.2.4 Test method for evaluation of bursting strength in dry and wet state . 16

A.2.5 Test method for evaluation of tensile strength in dry and wet state . 17

A.2.6 Test method for evaluation of dry microbial penetration . 17

A.2.7 Test method for evaluation of wet microbial penetration . 17

A.2.8 Test method for evaluation of biocompatibility . 17

A.3 Treatment of results . 18

Annex B (informative) Rationales . 19

B.1 General . 19

B.2 Cleanliness – microbial . 19

B.3 Particle release . 19

B.4 Resistance to liquid penetration . 20

B.5 Bursting strength – dry and wet . 21

B.6 Tensile strength – dry and wet . 21

B.7 Resistance to microbial penetration – dry . 21

B.8 Resistance to microbial penetration – wet . 23

B.9 Labelling . 23

B.10 Treatment of results . 24

Annex C (informative) Information on further characteristics . 25

C.1 Comfort . 25

C.2 Adhesion for fixation for the purpose of wound isolation . 25

C.3 Liquid control . 25

C.4 Flammability . 26

C.5 Electrostatic discharge . 26

Annex D (informative) Environmental aspects . 27

Annex E (informative) Guidance to users for selecting products . 28

E.1 Performance levels . 28

E.2 Functional design. 28

E.2.1 General . 28

E.2.2 Critical and less critical areas . 28

E.2.3 Size . 29

E.2.4 Accessories . 29

E.2.5 Comfort . 29

E.2.5.1 General . 29

E.2.5.2 Surgical gowns . 29

E.2.5.3 Surgical drapes . 30

E.3 Practical trials . 30

Annex ZA (informative) Relationship between this European standard and the essential

requirements of Directive 93/42/EEC [1993 OJ L 169] aimed to be covered . 31

Bibliography . 32

European foreword

This document (EN 13795-1:2019) has been prepared by Technical Committee CEN/TC 205 “Non-

active medical devices”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2019, and conflicting national standards shall

be withdrawn at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

Together with EN 13795-2:2019, this document supersedes EN 13795:2011+A1:2013.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this

document.

EN 13795 consists of the following parts, under the general title Surgical clothing and drapes —

Requirements and test methods:

— Part 1: Surgical drapes and gowns

— Part 2: Clean air suits

The following changes have been introduced:

a) The product ‘clean-air suit’ has been moved to Part 2 of the EN 13795 standard series because of

distinctive requirements and test methods;

b) Alignment of the document title and the Scope;

c) Revision of the Normative references and the Bibliography;

d) Alignment of the Clause ‘Terms and definitions’;

e) Review of the performance requirements in Table 1 and Table 2 especially with regard to

‘Cleanliness - Particulate matter’ and ‘Linting’, which have been combined as ‘Particle release;

f) Movement of former Clause 5 ‘Testing’ to A.1 and editorial alignment;

g) Revision of Clause ‘Manufacturing and processing requirements‘ by adding of documentary

requirements and a section for the introduction of a QM system;

h) Enhancement and improved structuring of Clause ‘Information to be supplied by the manufacturer

or processor’;

i) Deletion of the former Annex A ‘Details of significant changes between this document and the

previous edition’ which consisted of 3 parts;

j) Complete revision and extension of Annex A ‘Testing’ (formerly Annex B ‘Test methods’);

k) Inclusion of a new Annex B ‚Rationales‘ which provides precise reasons for the essential

requirements of this document and which is intended for users aware of the subject of this

document, but who have not participated in its development;

l) Deletion of the former Annex C ‘Prevention of infection in the operating room‘;

m) Revision and extension of Annex C (formerly Annex D) ‘Information on further characteristics‘; e.g.

inclusion of a Clause on ‚ Flammability‘ and ‘Electrostatic discharge’;

n) Inclusion of a new Annex D ‘Environmental aspects’;

o) Inclusion of a new Annex E ‘Guidance to users for selecting products‘;

p) Revision of Annex ZA on the relationship to the Medical Device Directive (93/42/EEC);

q) Complete editorial revision.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

Introduction

The transmission of infective agents during invasive surgical procedures can occur in several ways (see

informative Annex B).

Surgical drapes, including the intended use as a sterile field, and surgical gowns are used to minimize

the spread of infective agents to and from patients’ operating wounds, thereby helping to prevent post-

operative wound infections (see Annex B).

The performance required of coverings for patients, clinical staff and equipment varies with, for

example, the type and duration of the procedure, the degree of wetness of the operation field, the

degree of mechanical stress on the materials and the susceptibility of the patient to infection.

The use of surgical gowns with resistance to the penetration of liquids can also diminish the risk to the

operating staff from infective agents carried in blood or body fluids.

This document is intended to assist the communication between manufacturers and third parties with

regard to material or product characteristics and performance requirements.

Therefore, Annex B provides comprehensive information on characteristics, measurement of

performance and performance requirements. Annex C clarifies that this document does not include

environmental provisions. Annex D provides information on characteristics regarded relevant in

context with surgical gowns and drapes, however but not covered normatively (i.e. without applicable

performance requirements). Annex E explains the concept of performance levels and provides guidance

to users for selecting products.

This document focuses on Essential Requirements arising from the Medical Device Directive

93/42/EEC, which are applicable to surgical drapes and gowns. The requirements and guidance in this

document are expected to be of help to manufacturers and users when designing, processing, assessing

and selecting products. It is the intention of this document to ensure the same level of safety from

single-use and reusable surgical clothing and drapes throughout their useful life.

Surgical gowns are used to minimize the transmission of infective agents between patients and clinical

staff during surgical and other invasive procedures. Hereby, surgical gowns contribute to the clinical

condition and the safety of patients as well as to the safety and health of users following up essential

requirement 1 of Directive 93/42/EEC on Medical Devices. This document addresses the same level of

protection for patients and users (i.e. the surgical team) by not differentiating the performance

requirements for surgical gowns respectively. However, this document does not formally address any

basic health and safety requirements of the Directive 89/686/EEC or Regulation (EU) 2016/425 on

Personal Protective Equipment and does not provide specific guidance for surgical gowns intended by

the manufacturer for dual use as medical device and personal protective equipment.

1 Scope

This document specifies information to be supplied to users and third party verifiers in addition to the

usual labelling of medical devices (see EN 1041 and EN ISO 15223-1), concerning manufacturing and

processing requirements. This document gives information on the characteristics of single-use and

reusable surgical gowns and surgical drapes used as medical devices for patients, clinical staff and

equipment, intended to prevent the transmission of infective agents between clinical staff and patients

during surgical and other invasive procedures. This document specifies test methods for evaluating the

identified characteristics of surgical drapes and gowns and sets performance requirements for these

products.

This document does not cover requirements for resistance to penetration by laser radiation of products.

Suitable test methods for resistance to penetration by laser radiation, together with an appropriate

classification system, are given in EN ISO 11810.

This document does not cover requirements for incision drapes or films.

This document does not cover requirements for antimicrobial treatments for surgical gowns and

drapes. Antimicrobial treatment can cause environmental risks such as resistance and pollution.

However, antimicrobial treated surgical gowns and drapes fall under the scope of this document with

respect to their use as surgical gowns and drapes.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 811:2018, Textiles - Determination of resistance to water penetration - Hydrostatic pressure test

(ISO 811:2018)

EN 29073-3:1992, Textiles - Test methods for nonwovens - Part 3: Determination of tensile strength and

elongation

EN ISO 139:2005, Textiles — Standard atmospheres for conditioning and testing (ISO 139:2005 +

Amd. 1:2011)

EN ISO 9073-10:2004, Textiles - Test methods for nonwovens - Part 10: Lint and other particles

generation in the dry state (ISO 9073-10:2003)

EN ISO 10993-1:2009, Biological evaluation of medical devices - Part 1: Evaluation and testing within a

risk management process (ISO 10993-1:2009)

EN ISO 11737-1:2018, Sterilization of medical devices — Microbiological methods — Part 1:

Determination of a population of microorganisms on products (ISO 11737-1:2018)

EN ISO 13938-1:1999, Textiles - Bursting properties of fabrics - Part 1: Hydraulic method for

determination of bursting strength and bursting distension (ISO 13938-1:1999)

Impacted by EN ISO 139:2005+A1:2011

EN ISO 22610:2006, Surgical drapes, gowns and clean air suits, used as medical devices, for patients,

clinical staff and equipment - Test method to determine the resistance to wet bacterial penetration (ISO

22610:2006)

EN ISO 22612:2005, Clothing for protection against infectious agents - Test method for resistance to dry

microbial penetration (ISO 22612:2005)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

colony forming unit

CFU

unit by which the culturable number of microorganisms is expressed

Note 1 to entry: The culturable number is the number of microorganisms, single cells or aggregates, able to

form colonies on a solid nutrient medium.

3.2

cleanliness

freedom from unwanted foreign matter

Note 1 to entry: Such matter can be microorganisms, organic residues or particulate matter.

3.2.1

cleanliness — microbial

freedom from population of viable micro-organisms on a product and/or a package

Note 1 to entry: In practical use, microbial cleanliness is often referred to as ‘bioburden’.

3.3

critical product area

product area with a greater probability to be involved in the transfer of infective agents to or from the

wound, e.g. front and sleeves of surgical gowns

3.4

infective agent

micro-organism that has been shown to cause wound infections or that might cause infection in a

member of the surgical team or the patient

3.5

less critical product area

product area less likely to be involved in the transfer of infective agents to or from the wound

3.6

manufacturer

natural or legal person with responsibility for the design, manufacture, packaging and labelling of a

device before it is placed on the market under his own name, regardless of whether these operations

are carried out by that person himself or on his behalf by a third party

Note 1 to entry: For more details, refer to the Medical Device Directive 93/42/EEC.

3.7

particle release

release of fibre fragments and other particles during mechanical stress simulating handling and use

3.8

performance level

discrete standard defined to classify products according to the performance requirements of this

document

Note 1 to entry: With the introduction of two performance levels, this document acknowledges the fact that

products are challenged to differing extents during surgical procedures, dependent upon the duration, mechanical

stress and liquid challenge throughout the surgical procedure.

3.8.1

standard performance

classification addressing minimum performance requirements for various characteristics of products

used as medical devices in invasive surgical procedures

3.8.2

high performance

classification addressing elevated performance requirements for various characteristics of products

used as medical devices in invasive surgical procedures

Note 1 to entry: Examples of surgical procedures where elevated performance level should be considered are

those where extensive exposure to liquid, mechanical stresses or longer surgical procedures can be expected.

3.9

processor

natural or legal person who processes products so that their performance complies with the

requirements of this document

Note 1 to entry: A processor who places a product on the market is a manufacturer in the sense of this

document.

Note 2 to entry: A processor of reusable products is often referred to as a ‘reprocessor’ and processing reusable

products is often referred to as ‘reprocessing’ (as e.g. in Medical Device Directive 93/42/EEC). References in

EN 13795-2 and this document to ‘processors’ include ‘reprocessors’ and to ‘processing’ include ‘reprocessing’.

3.10

product

surgical gown, surgical drape including equipment covering

Note 1 to entry: In cases of surgical packs, each gown or drape is regarded as a product.

3.11

resistance to liquid penetration

ability of material to withstand the penetration of liquid(s) from one side of the material through to the

other

3.12

resistance to microbial penetration

ability of material(s) to withstand penetration of micro-organisms from one side of the material

through to the other

3.12.1

dry penetration

effect of a combination of air movement and mechanical action by vibration on microbial penetration in

dry condition

3.12.2

wet penetration

effect of combination of wetness, pressure and rubbing on microbial penetration

3.13

reusable product

product intended by the manufacturer to be reprocessed and reused

3.14

single-use product

product intended to be used once only for a single patient

3.15

sterile field

area created by sterile surgical drape material where aseptic technique is practised

Note 1 to entry: A sterile field can be practised e.g. on a back table.

3.16

surgical drape

drape covering the patient or equipment to prevent transfer of infective agents

3.17

surgical gown

gown worn by a member of a surgical team to prevent transfer of infective agents

3.18

surgical procedure

surgical intervention performed by a surgical team

3.18.1

invasive surgical procedure

surgical procedure penetrating skin or mucosa

4 Performance requirements

To comply with this document, products shall meet all the requirements specified in this document

including Tables 1 or 2 (as appropriate to the product), when tested according to Annex A of this

document throughout their useful life.

The biocompatibility of the product shall be evaluated and approved for acceptable risk.

If the manufacturer does not differentiate product areas, all areas shall meet the requirements for

critical product areas.

If the intended purpose of a medical device specifies the use as a sterile field the requirements for

surgical drapes and equipment covers apply as per Table 2.

For general information on testing and details on the test methods given in this clause including

Tables 1 and 2 and their application for the purpose of this document, see Annex A.

NOTE 1 Performance requirements are specified depending on product area and performance level. However,

for some characteristics the performance requirement will apply for all performance levels and product areas of

the medical device.

NOTE 2 Information on characteristics, which cannot be properly evaluated (as ‘adhesion for fixation for the

purpose of wound isolation’ or ‘liquid control’) or which are not regarded normative (as ‘comfort’) is given in

Annex C.

Table 1 — Characteristics to be evaluated and performance requirements for surgical gowns

Requirement

Test method Standard performance High performance

(for normative

Characteristic Unit

Less Less

references see

Critical Critical

critical critical

Clause 2) product product

product product

area area

area area

Microbial penetration Not Not

a a

EN ISO 22612 CFU

≤ 300 ≤ 300

— Dry required required

Microbial penetration Not Not

I b b c

EN ISO 22610

B ≥ 2,8 6,0

— Wet required required

CFU/

Cleanliness microbial /

EN ISO 11737-1 ≤ 300 ≤ 300 ≤ 300 ≤ 300

Bioburden

100 cm

log

Particle release EN ISO 9073-10 ≤ 4,0 ≤ 4,0 ≤ 4,0 ≤ 4,0

(lint

count)

cm H O

Liquid penetration EN ISO 811 ≥ 20 ≥ 10 ≥ 100 ≥ 10

Bursting strength —

EN ISO 13938-1 kPa ≥ 40 ≥ 40 ≥ 40 ≥ 40

Dry

Requirement

Test method Standard performance High performance

(for normative

Characteristic Unit

Less Less

references see

Critical Critical

critical critical

Clause 2)

product product

product product

area area

area area

Bursting strength — Not Not

EN ISO 13938-1 kPa ≥ 40 ≥ 40

Wet required required

Tensile strength — Dry EN 29073-3 N ≥ 20 ≥ 20 ≥ 20 ≥ 20

Tensile strength — Not Not

EN 29073-3 N ≥ 20 ≥ 20

Wet required required

a Test conditions: challenge concentration 10 CFU/g talcum and 30 min vibration time.

b The Least Significant Difference (LSD) for I when estimated using EN ISO 22610, was found to be 0,98 at the

B

95 % confidence level. This is the minimum difference needed to distinguish between two materials thought to

be different. Thus materials varying by up to 0,98 IB are probably not different; materials varying by more than

0,98 IB probably are different. (The 95 % confidence levels means that an observer would be correct 19 times

out of 20 to accept these alternatives.)

c IB = 6,0 for the purpose of this document means: no penetration. IB = 6,0 is the maximum achievable value.

Table 2 — Characteristics to be evaluated and performance requirements for surgical drapes

Requirement

Test method

Standard performance High performance

(for normative

Characteristic Unit

references see

Critical Less critical Critical Less critical

Clause 2)

product product product product

area area area area

Microbial penetration Not Not

a a

EN ISO 22612 CFU

≤ 300 ≤ 300

— Dry required required

Microbial penetration Not Not

I b b c

EN ISO 22610

B ≥ 2,8 6,0

— Wet required required

CFU/

Cleanliness microbial /

EN ISO 11737-1 ≤ 300 ≤ 300 ≤ 300 ≤ 300

Bioburden

100 cm

log

Particle release EN ISO 9073-10 ≤ 4,0 ≤ 4,0 ≤ 4,0 ≤ 4,0

(lint

count)

cm H O

Liquid penetration EN ISO 811 ≥ 30 ≥ 10 ≥ 100 ≥ 10

Bursting strength —

EN ISO 13938-1 kPa ≥ 40 ≥ 40 ≥ 40 ≥ 40

Dry

Requirement

Test method

Standard performance High performance

(for normative

Characteristic Unit

references see

Critical Less critical Critical Less critical

Clause 2) product product product product

area area area area

Bursting strength — Not Not

EN ISO 13938-1 kPa ≥ 40 ≥ 40

Wet required required

Tensile strength — Dry EN 29073-3 N ≥ 15 ≥ 15 ≥ 20 ≥ 20

Tensile strength — Not Not

EN 29073-3 N ≥ 15 ≥ 20

Wet required required

a Test conditions: challenge concentration 10 CFU/g talcum and 30 min vibration time.

b The Least Significant Difference (LSD) for IB when estimated using EN ISO 22610, was found to be 0,98 at the

95 % confidence level. This is the minimum difference needed to distinguish between two materials thought to

be different. Thus materials varying by up to 0,98 I are probably not different; materials varying by more than

B

0,98 IB probably are different. (The 95 % confidence level means that an observer would be correct 19 times out

of 20 to accept these alternatives.)

c I = 6,0 for the purpose of this document means: no penetration. I = 6,0 is the maximum achievable value.

B B

5 Manufacturing and processing requirements and documentation

5.1 The manufacturer and processor shall document that the requirements of this document are met

and that the fitness for the intended purpose has been established for each use, both for single-use and

reusable medical devices.

5.2 The manufacturer/processor shall establish, document, implement and maintain a formal quality

management system, which includes risk management and maintain its effectiveness. This quality

management system shall include requirements throughout product realization, including

development, design, manufacture, testing, packaging, labelling, distribution and, for reusable products,

processing and life-cycle control.

Inputs for product realization shall include the outputs from risk management.

A quality system such as EN ISO 13485 is recommended, in case of processing of reusable products

applied in accordance with EN 14065.

Packaging for terminally sterilized medical devices is recommended according to EN ISO 11607 series

of standards.

For testing processes, quantitative physical, chemical and/or biological tests are preferred.

5.3 A clinical evaluation for surgical drapes and gowns shall be carried out and shall consider the

performance of the full draping and gowning system to establish fitness for purpose. The evaluation

shall include the critical review of the applicable clinical literature and the results of post market

surveillance and vigilance.

6 Information to be supplied with the product

6.1 Information to be supplied to the user

6.1.1 In addition to the information to be supplied according to the Medical Device Directive

93/42/EEC, if the manufacturer or processor differentiates between critical and less critical areas of the

product, he/she shall supply information to identify them.

6.1.2 The following additional information shall be supplied on request:

a) the identity or information on the test methods used;

b) the results of testing and test conditions for the characteristics given in Clause 4.

6.1.3 The manufacturer shall inform the user of residual risks due to any shortcomings of the

protection measures adopted.

6.1.4 The manufacturer shall provide sufficient information about intended use of the product or

product system when conducting a surgical procedure. This shall include information on the

performance level of the product.

6.1.5 The manufacturer shall provide information on the flammability of the product and fire risks in

relation with it on request.

6.2 Information to be supplied to the processor

6.2.1 For reusable products the manufacturer shall obtain information to be supplied to the processor

on the number of reuses based on standardized processes, together with information on measures for

maintaining the technical and functional safety of the medical device and packaging.

6.2.2 For products to be terminally sterilized, the manufacturer shall supply instructions for the

sterilization processes to be applied.

Annex A

(normative)

Testing

A.1 General

A.1.1 Testing for evaluation of the performance of products shall be done according to the test

methods specified in A.2. All test results and test conditions shall be recorded and retained.

A.1.2 Testing shall be performed on the finished product. If the product is to be used after

sterilization, testing shall be performed on products after sterilization with the exception of microbial

cleanliness. Testing shall include potential weak spots.

NOTE 1 Performance requirements can vary in relation to the areas of the product and the risk of involvement

in the transfer of infective agents to or from the wound.

NOTE 2 To ensure product performance, combinations of materials or products in systems can be used.

NOTE 3 In particular, all types of joints in critical areas such as, e.g. seams in sleeves of surgical gowns, are

regarded as potential weak spots.

A.1.3 During manufacture and processing, testing shall be conducted according to the requirements of

the manufacturer's and processor's quality system.

A.1.4 Alternative test methods for monitoring may be used provided that they are validated and

address the same characteristic and that the results have been shown to correlate with the test methods

given in this document.

A.1.5 Where the test methods of this document do not specify the atmosphere for pre-conditioning,

conditioning and testing, the specifications of EN ISO 139 shall be applied. Prior to testing, the samples

shall be conditioned in the relaxed state.

A.2 Test methods and conformance

A.2.1 Test method for evaluation of cleanliness microbial/bioburden

For evaluation of cleanliness — microbial, the product shall be tested according to EN ISO 11737-1.

NOTE EN ISO 11737-1 does not provide a fixed test method but specifies requirements for test methods and

test mechanisms. The requirements of EN ISO 11737-1 are such that different test methods developed in

accordance with it provide comparable results.

Five specimens shall be tested. The results shall be expressed as CFU/100 cm . Report the individual

and U (see A.3). U shall be equal to or less than the performance

results and determine Md q q

requirements in Tables 1 and 2.

A.2.2 Test method for evaluation of particle release

For evaluation of particle release, the product shall be tested according to EN ISO 9073-10.

NOTE 1 EN ISO 9073-10 allows for the test method to be conducted in a laminar flow hood. It is important to

validate that laminar flow is occurring if equipment required for the test is located in the hood.

As specified in EN ISO 9073-10, ten specimens, five for each side of the material, shall be tested. The

result of the test, i.e. the coefficient of linting, shall be calculated for particles in the size range 3 µm to

25 µm and reported as log of the count value. Report the individual results and determine M and U

d q

(see A.3). U shall be equal to or less than the performance requirements in Tables 1 and 2.

q

NOTE 2 Particles of this size range are considered to be capable of carrying microorganisms.

A.2.3 Test method for evaluation of liquid penetration

For evaluation of liquid penetration, the product shall be tested according to EN ISO 811.

The following specific amendments to the procedure in EN ISO 811 apply for the purpose of this

document:

a) the test area shall be 100 cm ;

b) the rate of increase of water pressure shall be (10 ± 0,5) cm/min;

c) the temperature of the water shall be (20 ± 2) °C;

d) the side of the product in contact with the test liquid shall be the outer side.

Five specimens shall be tested. Report the individual results and determine M and L (see A.3). L shall

d q q

be equal to or greater than the performance requirements in Tables 1 and 2.

As the test may be stopped once, the test limit hydrostatic pressure is exceeded or the measurement

capability of the instrument is exceeded, the value to be used in the median and lower quartile

calculations for hydrostatic pressure testing shall be the lower of the breakthrough number or the

upper measurement capability if this has been exceeded.

A.2.4 Test method for evaluation of bursting strength in dry and wet state

For evaluation of bursting strength, the product shall be tested according to EN ISO 13938-1. The size of

the test area shall be 10 cm (35,7 mm diameter). The preparation of samples for wet state testing shall

be performed according to EN 29073-3.

The test conditions should be specified in the test report.

If there are differences in the test results of both sides of material, both sides should be tested and the

results should be recorded.

Five specimens shall be tested. The pressure needed to break or compromise the barrier of the sample

shall be reported. Report the individual results and determine M and L (see A.3). L shall be equal to or

d q q

greater than the performance requirements in Tables 1 and 2.

A.2.5 Test method for evaluation of tensile strength in dry and wet state

For evaluation of tensile strength, the product shall be tested according to EN 29073-3 in the wet and

dry states both in longitudinal and in lateral directions.

Five specimens shall be tested for each direction. The pressure needed to break or compromise the

barrier of the sample shall be reported. Report the individual results and determine M and L (see A.3).

d q

L shall be equal to or greater than the performance requirements in Tables 1 and 2.

q

A.2.6 Test method for evaluation of dry microbial penetration

For evaluation of dry microbial penetration, the product shall be tested according to EN ISO 22612.

If both sides of the material to be tested are different, the side intended to cover the contamination

source during medical use as stated by the manufacturer shall be exposed to the inoculated donor in the

test.

NOTE The side intended to cover the contamination source during medical use is, e.g. the inner side of a

surgical gown or the patient or equipment side of a surgical drape.

If the product has an antimicrobial treatment, it shall be mentioned in the test report since it can

influence the results.

Ten specimens shall be tested. Report the individual results and determine Md and Uq (see A.3). Uq shall

be equal to or less than the performance requirements in Tables 1 and 2.

A.2.7 Test method for evaluation of wet microbial penetration

For evaluation of wet microbial penetration, the product shall be tested according to EN ISO 22610.

If both sides of the material to be tested are different, the side intended to cover the contamination

source during medical use as stated by the manufacturer shall be exposed to the inoculated donor in the

test.

NOTE The side intended to cover the contamination source during medical use is, e.g. the inner side of a

surgical gown or the patient or equipment side of a surgical drape.

If the product has a known antimicrobial treatment, it shall be mentioned in the test report since it can

influence the results.

Five specimens shall be tested. Report the results as per EN ISO 22610 including barrier index I as per

B

EN ISO 22610:2006, C.4. The barrier index I shall be equal to or higher than the performance

B

requirements in Tables 1 and 2.

A.2.8 Test method for evaluation of biocompatibility

The manufacturer shall complete the evaluation of the surgical drape/gown according to

EN ISO 10993-1:2009 and report the results of the evaluation.

A.3 Treatment of results

In order to determine whether a sample conforms to the performance requirements of this document, it

is necessary to convert the replicate results from a test into an acceptance value (or test statistic). The

median (M ) was the chosen value (see Rationale Annex), together with one of two test statistics a) the

d

lower quartile value (L )for minimum performance (PR ) and b) the upper quartile (U ) for maximum

q min q

performance (PR ).

max

For conformance of the product can be determined:

— L ≥ PR (see Tables 1 and 2)

q min

— U ≤ PR (see Tables 1 and 2)

q max

— M , L and U (or any percentile value)

d q q

by using the following general method.

th

To calculate the k percentile (where k is 25 for identifying the lower quartile number and 75 for

identifying the upper quartile value):

1. Order all the values in the data set from the smallest to largest.

2. Multiply k percent by the total number of values, n. This product is called the index.

3. If the index obtained in step 2 is not a whole number, round it up to the nearest whole number and

go to step 4a. If the index obtained in step 2 is a whole number, go to step 4b.

4a. Count the values in your data set from left to right (from the smallest to the largest value) until you

th

reach the number indicated by step 3. The corresponding value in the data set is the k percentile.

4b. Count the values in your data set from left to right until you reach the number

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...