prEN 16578

(Main)Product Category Rules for ceramic sanitary appliances

Product Category Rules for ceramic sanitary appliances

This European Standard specifies sustainability requirements together with assessment methods and evaluation schemes for ceramic sanitary appliances, i.e. WC pans and WC suites in accordance with EN 997, urinals in accordance with EN 13407, wash basins in accordance with EN 14688, communal washing troughs in accordance with EN 14296 and bidets in accordance with EN 14528.

NOTE This European Standard may be applicable to other ceramic sanitary appliances.

Keramische Sanitärausstattungsgegenstände - Beurteilung der Nachhaltigkeit

Dieses Dokument stellt die Produktkategorieregel (PCR, en: Product Category Rule) für keramische Sanitär-ausstattungsgegenstände nach EN 15804:2012+ A1:2013 (im Folgenden EN 15804 genannt) bereit.

Das Dokument gilt für keramische Sanitärausstattungsgegenstände aus Halbporzellan und Feinfeuerton-werkstoffen. Keramische Sanitärausstattungsgegenstände umfassen z. B. WC-Becken und WC-Anlagen nach EN 997, Urinale nach EN 13407, Waschbecken nach EN 14688, Reihenwaschanlagen nach EN 14296 und Sitzwaschbecken nach EN 14528.

ANMERKUNG Dieses Dokument kann auf andere keramische Sanitärausstattungsgegenstände anwendbar sein.

Règles de définition des catégories de produits pour les appareils sanitaires

Le présent document fournit la Règle de catégorie de produits (PCR) pour Appareils sanitaires en céramique selon EN 15804:2012+ A1:2013 (le présent document sera nommé ci-dessous EN 15804).

Le document s’applique aux Appareils sanitaires en céramique fabriqués à partir de porcelaine vitrifiée (VC) et de grès fin (FFC). Les Appareils sanitaires en céramique sont par exemple des cuvettes de WC et des cuvettes à réservoir conformément à l’EN 997, des urinoirs muraux conformément à l’EN 13407, des lavabos conformément à l’EN 14688, des lavabos collectifs conformément à l’EN 14296 et des bidets conformément à l’EN 14528.

NOTE Le présent document peut être applicable à d’autres appareils sanitaires en céramique.

Pravila za kategorije proizvodov za keramično sanitarno opremo

General Information

- Status

- Not Published

- Publication Date

- 29-Nov-2020

- Withdrawal Date

- 30-May-2021

- Technical Committee

- CEN/TC 163 - Sanitary appliances

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 18-Jun-2020

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Jan-2023

Overview

prEN 16578 - Product Category Rules for ceramic sanitary appliances (CEN draft, 2019) defines sustainability requirements, assessment methods and evaluation schemes for ceramic sanitary appliances. It covers life cycle assessment (LCA) rules and Environmental Product Declaration (EPD) reporting for products such as WC pans and WC suites (EN 997), urinals (EN 13407), wash basins (EN 14688), communal washing troughs (EN 14296) and bidets (EN 14528). The document is intended to update and supersede EN 16578:2016 and may apply to other ceramic sanitary items.

Key Topics and Requirements

- Product Category Rules (PCR): Defines the content, structure and accessibility of the project report (PCR Part A) and product-specific EPD requirements (PCR Part B).

- Life Cycle Assessment (LCA): Calculation rules including declared/functional unit, system boundaries (modules A–D), inventory analysis, data collection, background data quality and cut-off criteria.

- Impact Indicators: Guidance on impact assessment indicators (global warming potential, ozone depletion, acidification, eutrophication, photochemical ozone formation, resource depletion, energy and water use, waste flows - as detailed in Annex A).

- Scenario and Module Rules: Treatment of modules A1–A3 (product stage), A4–D (transport, use, end-of-life and benefits), and rules for product group-specific LCA scenarios.

- Allocation Rules: Procedures for co-product allocation, multi-input processes, and allocation for reuse/recycling/recovery.

- Reference Service Life (RSL): Requirements for documenting assumed service life and use-phase scenarios.

- Product Rating & Ranking: Methodology to assess sustainability classes and a ranking/marking system that evaluates production-related values (pillar A) and use-phase parameters (pillar B).

- Documentation & Evidence: Requirements for laboratory results, technical data, manufacturing environmental/health information, packaging, installation, maintenance and end-of-life.

Practical Applications

- Manufacturers use prEN 16578 to prepare compliant EPDs and to demonstrate product sustainability performance for ceramic sanitary appliances.

- LCA practitioners and EPD program operators apply the PCR and calculation rules to ensure consistent, comparable environmental declarations.

- Architects, specifiers, green procurement teams and sustainability consultants use resulting EPDs and the standard’s rating system to compare products and support green building decisions and public procurement.

- Product development teams leverage the LCA and allocation rules to identify hotspots (materials, energy, waste) and prioritize eco-design improvements.

Related Standards

- EN 997 - WC pans and WC suites

- EN 13407 - Urinals

- EN 14688 - Wash basins

- EN 14296 - Communal washing troughs

- EN 14528 - Bidets

- EN 16578:2016 - previous edition (to be superseded)

This standard is essential for consistent, transparent sustainability reporting of ceramic sanitary appliances and for stakeholders seeking reliable LCA-based product comparisons and EPDs.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

prEN 16578 is a draft published by the European Committee for Standardization (CEN). Its full title is "Product Category Rules for ceramic sanitary appliances". This standard covers: This European Standard specifies sustainability requirements together with assessment methods and evaluation schemes for ceramic sanitary appliances, i.e. WC pans and WC suites in accordance with EN 997, urinals in accordance with EN 13407, wash basins in accordance with EN 14688, communal washing troughs in accordance with EN 14296 and bidets in accordance with EN 14528. NOTE This European Standard may be applicable to other ceramic sanitary appliances.

This European Standard specifies sustainability requirements together with assessment methods and evaluation schemes for ceramic sanitary appliances, i.e. WC pans and WC suites in accordance with EN 997, urinals in accordance with EN 13407, wash basins in accordance with EN 14688, communal washing troughs in accordance with EN 14296 and bidets in accordance with EN 14528. NOTE This European Standard may be applicable to other ceramic sanitary appliances.

prEN 16578 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 16578 has the following relationships with other standards: It is inter standard links to EN 16578:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 16578 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2019

Pravila za kategorije proizvodov za keramično sanitarno opremo

Product Category Rules for ceramic sanitary appliances

Produktkategorieregeln für keramische Sanitärausstattungsgegenstände

Appareils sanitaires en céramique - Évaluation du développement durable

Ta slovenski standard je istoveten z: prEN 16578

ICS:

91.140.70 Sanitarne naprave Sanitary installations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

August 2019

ICS 91.140.70 Will supersede EN 16578:2016

English Version

Product Category Rules for ceramic sanitary appliances

Appareils sanitaires en céramique - Évaluation du Keramische Sanitärausstattungsgegenstände -

développement durable Beurteilung der Nachhaltigkeit

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 163.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 16578:2019 E

worldwide for CEN national Members.

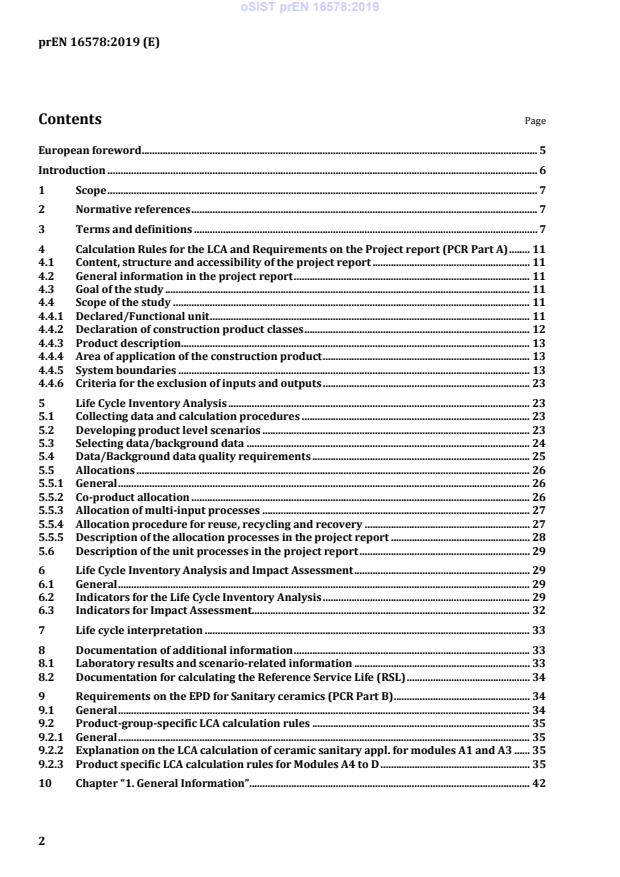

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 7

4 Calculation Rules for the LCA and Requirements on the Project report (PCR Part A) . 11

4.1 Content, structure and accessibility of the project report . 11

4.2 General information in the project report . 11

4.3 Goal of the study . 11

4.4 Scope of the study . 11

4.4.1 Declared/Functional unit . 11

4.4.2 Declaration of construction product classes . 12

4.4.3 Product description . 13

4.4.4 Area of application of the construction product . 13

4.4.5 System boundaries . 13

4.4.6 Criteria for the exclusion of inputs and outputs . 23

5 Life Cycle Inventory Analysis . 23

5.1 Collecting data and calculation procedures . 23

5.2 Developing product level scenarios . 23

5.3 Selecting data/background data . 24

5.4 Data/Background data quality requirements . 25

5.5 Allocations . 26

5.5.1 General . 26

5.5.2 Co-product allocation . 26

5.5.3 Allocation of multi-input processes . 27

5.5.4 Allocation procedure for reuse, recycling and recovery . 27

5.5.5 Description of the allocation processes in the project report . 28

5.6 Description of the unit processes in the project report . 29

6 Life Cycle Inventory Analysis and Impact Assessment . 29

6.1 General . 29

6.2 Indicators for the Life Cycle Inventory Analysis . 29

6.3 Indicators for Impact Assessment . 32

7 Life cycle interpretation . 33

8 Documentation of additional information . 33

8.1 Laboratory results and scenario-related information . 33

8.2 Documentation for calculating the Reference Service Life (RSL) . 34

9 Requirements on the EPD for Sanitary ceramics (PCR Part B) . 34

9.1 General . 34

9.2 Product-group-specific LCA calculation rules . 35

9.2.1 General . 35

9.2.2 Explanation on the LCA calculation of ceramic sanitary appl. for modules A1 and A3 . 35

9.2.3 Product specific LCA calculation rules for Modules A4 to D . 35

10 Chapter “1. General Information”. 42

11 Chapter “2. Product” . 42

11.1 Product description . 42

11.2 Application . 43

11.3 Technical Data . 43

11.4 Placing on the market/Application rules. 43

11.5 Delivery status . 45

11.6 Base materials/Ancillary materials . 45

11.7 Manufacture. 46

11.8 Environment and health during manufacturing . 48

11.9 Product processing/Installation . 48

11.10 Packaging . 48

11.11 Condition of use . 48

11.12 Environment and health during use . 49

11.13 Reference service life . 49

11.14 Extraordinary effects. 49

11.15 Re-use phase . 50

11.16 Disposal . 50

11.17 Further information . 50

12 Chapter “3. LCA: Calculation rules” . 50

12.1 Declared Unit . 50

12.2 System boundary . 50

12.3 Estimates and assumptions . 53

12.4 Cut-off criteria . 53

12.5 Background data . 53

12.6 Data quality . 53

12.7 Period under review . 54

12.8 Allocation . 54

12.9 Comparability . 54

13 Chapter “4. LCA: Scenarios and additional technical information” . 54

14 Chapter “5. Results of the LCA” . 59

15 Chapter “6. LCA Interpretation” . 68

16 Chapter “7. Requisite evidence” . 71

17 Chapter “8. References” . 72

18 Chapter “9. Product Rating” . 73

18.1 General . 73

18.2 Principle of Rating . 73

18.3 Rating of WCs and WC Suites . 74

18.4 RATING OF URINALS . 75

18.5 RATING OF FURTHER CERAMIC SANITARY APPLIANCES . 75

19 Ranking system . 76

19.1 General . 76

19.2 Marking and product designation . 77

19.3 Assessment of the rating /sustainability class . 77

19.3.1 Assessment of pillar A — production and construction related environmental values . 77

19.3.2 Assessment of pillar B — use phase related parameters . 80

19.3.3 Assessment of product rating . 81

Annex A (informative) Principle Example . 82

A.1 Introduction. 82

A.2 Global warming potential (GWP) . 82

A.3 Depletion potential of the stratospheric ozone layer (ODP) . 82

A.4 Acidification potential of land and water (AP) . 83

A.5 Eutrophication potential (EP) . 83

A.6 Formation potential of tropospheric ozone photochemical oxidants (POCP) . 84

A.7 Abiotic depletion potential for non-fossil resources (ADPE) . 85

A.8 Abiotic depletion potential for fossil resources (ADPF) . 87

A.9 Use of renewable primary energy (PERE) . 87

A.10 Use of renewable primary energy resources used as raw materials (PERM) . 88

A.11 Total use of renewable primary energy resources (PERT). 88

A.12 Use of non-renewable primary energy (PENRE). 88

A.13 Use of non-renewable primary energy resources used as raw materials (PENRM) . 88

A.14 Total use of non-renewable primary energy resources (PENRT) . 88

A.15 Use of secondary material (SM) . 88

A.16 Use of renewable secondary fuels (RSF) . 88

A.17 Use of non-renewable secondary fuels (NRSF) . 89

A.18 Use of net fresh water (FW) . 89

A.19 Hazardous waste disposed (HWD) . 89

A.20 Non-hazardous waste disposed (NHWD) . 89

A.21 Radioactive waste disposed (RWD) . 90

A.22 Components for re-use (CRU) . 90

A.23 Materials for recycling (MFR) . 90

A.24 Materials for energy recovery (MER) . 91

A.25 Exported electrical energy (EEE) . 91

A.26 Exported thermal energy (ETE) . 91

European foreword

This document (prEN 16578:2019) has been prepared by Technical Committee CEN/TC 163 “Sanitary

appliances”, the secretariat of which is held by UNI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 16578:2016.

The previous version was revised completely to reach the goal of a product category rule.

Introduction

This document supports the (harmonized) European Standards on ceramic sanitary appliances

elaborated by CEN/TC 163 on assessing the sustainability for these products.

This document provides a Product Category Rule (PCR) for sustainability assessment of ceramic

sanitary appliances according to EN 15804 using a life cycle approach and a sustainability ranking

system for ceramic sanitary appliances.

This document cites the standard EN 15804:2012+A1:2013 in many sections. This document will be

named below as EN 15804. Certain clauses of the standard texts have been omitted for reasons of

readability, however, not with the intention to compromise the conformity of this document with

EN 15804. Those clauses are marked as [.].

The ranking system includes sustainability classes to express the performance of ceramic sanitary

appliances. The link between these classes and the assessment of the products form a framework of

evaluation schemes.

Evaluation schemes enable the comparison of different ceramic sanitary appliances.

Clauses 4 to 8 specify the calculation rules in accordance with EN 15804 for the Life Cycle Assessment

(LCA) of Environmental Products Declarations (EPD) according to prEN 16578 for Ceramic Sanitary

Appliances as well as the requirements on the project report to the Life Cycle Assessment.

Clauses 9 to 18 specify the product specific calculation rules for a declared functional unit for a single

product or a product group of Ceramic Sanitary Appliances.

Clause 19 specifies a system with sustainability classes to express the performance of ceramic sanitary

appliance(s).

1 Scope

This document provides the Product Category Rule (PCR) for Ceramic Sanitary Appliances in

accordance with EN 15804:2012+ A1:2013 (this document will be named below as EN 15804).

The document applies for Ceramic Sanitary Appliances made out of Vitreous China (VC) and Fine Fire

Clay (FFC). Ceramic Sanitary Appliances are e.g. WC pans and WC suites in accordance with EN 997,

urinals in accordance with EN 13407, wash basins in accordance with EN 14688, communal washing

troughs in accordance with EN 14296 and bidets in accordance with EN 14528.

NOTE This document can be applicable to other ceramic sanitary appliances.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 997:2018, WC pans and WC suites with integral trap

EN 13407, Wall-hung urinals — Functional requirements and test methods

EN 14528, Bidets — Functional requirements and test methods

EN 14688, Sanitary appliances — Wash basins — Functional requirements and test methods

EN 15804:2012+ A1:2013, Sustainability of construction works — Environmental product declarations —

Core rules for the product category of construction products

EN ISO 14025, Environmental labels and declarations — Type III environmental declarations — Principles

and procedures

EN ISO 14044, Environmental Management — Life cycle assessment — Requirements and guidelines

(ISO 14044)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at http://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

abiotic depletion potential for fossil resources

measures the gradual depletion of non-renewable fossil resources

Note 1 to entry: An example is raw oil.

3.2

abiotic depletion potential for non-fossil resources

measures the gradual depletion of non-renewable non-fossil resources

Note 1 to entry: An example is clay.

3.3

acidification potential of land and water

sums contributions of sulphuric acid and nitric acid to acid rain, acid snow and acid deposition

Note 1 to entry: It includes sulphur oxides (SO , SO ) and nitrogen oxides (N O, NO and NO ).

2 3 2 2

3.4

auxiliary

production tool, e.g. casting moulds, sponges and supports

3.5

ceramics

inorganic non-metallic material which is typically moulded from raw materials at room temperature

and gains its characteristic physical properties during a firing process (after the moulding)

Note 1 to entry: The term “ceramic materials for sanitary appliances” covers both vitreous china and fine fire

clay materials.

3.6

construction product

item manufactured or processed for incorporation in construction works

[SOURCE: EN 15804:2012+ A1:2013]

3.7

consumption

use of materials or energy within a defined time frame

3.8

cost in use

expenses incurred while using the product

3.9

declared unit

quantity of a construction product for use as a reference unit

Note 1 to entry: Usual units for mass is t, for quantity is piece.

3.10

depletion potential of the stratospheric ozone layer

measures depletion of stratospheric ozone needed for protection against UV radiation

Note 1 to entry: This includes chlorofluorocarbons (CFCs).

3.11

energy management

system to monitor, control and evaluate the type of power supply as well as the energy consumption of

a product

3.12

eutrophication potential

measures dissolved oxygen depletion by undesirable forms of biomass, such as algae

Note 1 to entry: This includes various forms of nitrogen and phosphorus.

3.13

formation potential of tropospheric ozone photochemical oxidants

puts all smog-producing chemicals on the same equivalent

3.14

glazed ceramic

ceramic body with a surface layer of silicon oxide compound applied before the firing process and

chemically bonded during firing

Note 1 to entry: The glaze deemed to be a part of the ceramics and not a separate coating.

3.15

global warming potential

puts all greenhouse gases on the same denominator

Note 1 to entry: Greenhouse gases include CO , CH , N O and CFCs.

2 4 2

3.16

gypsum

dehydrate natural gypsum as used for plaster moulds

3.17

hazardous substance

solid, liquid or gas that can harm people, other living organisms, property or the environment

3.18

life cycle

consecutive and interlinked stages of a construction products life, from raw material acquisition or

generation from natural resources to final disposal

3.19

maintenance

all actions to maintain or repair in order a product to continue its declared function

3.20

production

industrial process consisting of different steps in the manufacture of goods

3.21

production system

collection of unit processes with elementary and product flows, performing one or more defined

functions, and which determines the life cycle of a product

3.22

raw material

single material or a mixture of different materials (e.g. feedstock, ceramic body) as being the basic

material of which a product is manufactured

3.23

recycling

use of material as secondary material outside the boundary of the production system

Note 1 to entry: Examples are recycled gypsum of plaster moulds.

3.24

renewable energy

energy from renewable non-fossil sources

Note 1 to entry: Non-fossil sources are, for example, wind, solar, aerothermal, geothermal, hydrothermal and

ocean energy, hydropower, biomass, landfill gas, sewage treatment plant gas, electricity generation through

exhaust gas heat etc.

3.25

safety in use

characteristic of the level of risks associated with the installation and use of the product

3.26

secondary fuel

fuel recovered from previous use or from waste which substitutes primary fuels

3.27

secondary material

material recovered from previous use or from waste which substitutes primary materials

Note 1 to entry: Secondary material is measured at the point where the secondary material enters the

production system from another production system.

Note 2 to entry: Materials recovered from previous use or from waste from one production system and used as

an input in another production system are secondary materials e.g. use of milled scrap technical ceramics as raw

material for ceramics sanitary appliances.

Note 3 to entry: Examples for secondary materials (to be measured at the boundary of the production system)

are recycled sanitary appliances, tiles or technical ceramics.

3.28

transport

movement of goods (e.g. products, raw materials) from one location to another

3.29

total production

means the production of saleable ceramic sanitary appliances

Note 1 to entry: Usual unit is t/a.

3.30

user friendly

characteristic of the level of product ease of use

3.31

waste management

collection, transport, processing, recycling or disposal of waste materials and their monitoring and

recycling

3.32

water saving

reduction in water use accomplished by implementation of water conservation, water reduction or

water efficiency measures

4 Calculation Rules for the LCA and Requirements on the Project report

(PCR Part A)

4.1 Content, structure and accessibility of the project report

The project report represents the systematic and comprehensive summary of project documentation

with the objective of supporting the verification of an EPD. The project report shall document that the

information on which the Life Cycle Assessment is based as well as the additional information contained

in an EPD meet the requirements of this document.

The project report shall contain all of the data and information of importance for the details published

in the EPD and required in this set of rules. Particular care shall be given to comprehensible

explanations as to how the data and information declared in the EPD arises from the Life Cycle

Assessment and how — if declared — the reference service life (RSL) was established.

The structure of the project report shall follow the structure of this PCR document based on EN 15804.

The project report shall be accessible to the verifier under the conditions of confidentiality (see

EN ISO 14025).

The project report is not part of the public communication.

4.2 General information in the project report

The project report shall contain the following general information:

— the client commissioning the Life Cycle Assessment, internal or external Life Cycle analysts;

— the report date;

— Indications that the Life Cycle Assessment was performed in agreement with the requirements of

these Product Category Rules with reference to EN 15804.

4.3 Goal of the study

The goal of the study shall be outlined in the project report as regards the following:

— reasons for performing the study;

— intended use;

— Target group, i.e. whether the information and data for an EPD is intended for business-to-business

and/or business-to-consumer communication.

4.4 Scope of the study

4.4.1 Declared/Functional unit

The Life Cycle Assessment of the construction product shall be calculated for a declared or functional

unit as specified in Clause 12 for the product group which includes the product to be declared.

If the entire life cycle of the construction product is to be declared, a functional unit shall be referred to

in conformance with EN 15804.

If the entire life cycle is declared, it is imperative that a reference service life (RSL) is indicated; see

PA.8.2.

Usually, the declared unit refers to the product “cradle to factory gate”. If a manufacturer sells and

declares a system, the declared unit may also refer to the product “as installed” i.e. to the construction

lot (see also 4.4.5.2).

A declared/functional unit shall be declared in the exact unit(s) specified in the PCR, and not partially,

3 2

e.g. 0,1 m insulating material. Standard units can, however, be declared (e.g. 1 m of a defined

thickness and density of an insulating material), whereby conversion to the declared/functional unit

designated in the PCR shall be possible. Details are described by Clause 9 for a given Ceramic

Sanitary Appliance.

The selected declared or functional unit shall be documented in the project report. In addition, a mass

conversion factor of the declared unit shall be indicated.

4.4.2 Declaration of construction product classes

The classification of construction products and their respective EPDs can significantly reduce the effort

associated with drawing up an EPD. The following nomenclature applies:

1) Manufacturer declaration:

1a) Declaration of a specific product from a manufacturer’s plant;

1b) Declaration of a specific product as an average from several of the manufacturer’s plants;

1c) Declaration of an average product from a manufacturer’s plant;

1d) Declaration of an average product as an average from several of the manufacturer’s plants.

2) Manufacturer group declaration:

2a) Declaration of a specific product as an average from several manufacturers’ plants;

2b) Declaration of an average product as an average from several manufacturers’ plants.

A standard or reference product can also be declared which describes a specific (usually typical)

product.

Unless otherwise specified in Clause 12 applicable to a construction product, classification and,

therefore, the declared unit for one or several products can take the following form:

— the values of the Life Cycle Assessment can be derived from the declared product for any product in

the class via rules to be documented, e.g. for comparable products of varying density, or

— an “average” or “representative” product is declared, or

— the product with the most environmental impact is declared as representative for a class.

To be indicated in the project report:

— Calculation rules for forming averages in a declaration based on averaged data, e.g. when a

declared/functional unit has been defined for:

— a group of similar products from various manufacturers, or

— the same product from various production locations,

— Representativeness of the average used in relation to the assessed products.

4.4.3 Product description

The declared product shall be described with regards to its technical and functional specifications.

4.4.4 Area of application of the construction product

The area of application for the declared product shall be described.

4.4.5 System boundaries

4.4.5.1 General

The system boundaries of the EPDs according to this document follow the modular structure in line

with EN 15804.

[EN 15804:2012+A1:2013, 6.2]: “The environmental information of an EPD covering all life cycle stages

(“cradle to grave”) shall be subdivided into the information module groups A1–A3, A4–A5, B1–B5, B6–

B7, C1–C4 and module D.

Information modules within any of the life cycle stages are communicated depending on the types of

EPD as specified in [EN 15804:2012+A1:2013, 6.2]. They include impacts and aspects related to the

modules in which they occur (i.e. production, transport, waste processing and end-of-life stage) Losses

or wastage are also considered in the modules in which they occur).”

Figure 1 —Building life cycle stages

4.4.5.2 A1–A3, Product stage, Information modules

[EN 15804:2012+A1:2013, 6.2.2]: “The product stage includes:

— A1 raw material extraction and processing, processing of secondary material input (e.g. recycling

processes),

— A2 transport to the manufacturer,

— A3 manufacturing,

including provision of all materials, products and energy, as well as waste processing up to the end-of-

waste state ([EN 15804:2012+A1:2013],6.3.4.5 and Annex B) or disposal of final residues during the

product stage.”

[EN 15804:2012+A1:2013, 6.3.4.2]: “The product stage is an information module required to be

included in the EPD. […] The system boundary to nature is set to include those processes that provide

the material and energy inputs into the system and the following manufacturing and transport

processes up to the factory gate as well as the processing of any waste arising from those processes.

In the case of input of secondary materials or energy recovered from secondary fuels, the system

boundary between the system under study and the previous system (providing the secondary

materials) is set where outputs of the previous system, e.g. materials, products or energy or building

elements, reach the end-of-waste stage (see also [EN 15804:2012+A1:2013], 6.3.4.5 and Annex B).

Flows leaving the system at the end-of-waste boundary of the product stage (A1–A3) shall be allocated

as co-products […].”

The use of energy carriers such as electricity, combustibles or fuels should be considered in the module

where the energy carrier is used.

The flows crossing into the system at the A1–A3 boundary are determined as follows:

— Production waste that is recycled without any modification of the material inherent characteristics

(i.e. closed-loop or open-loop considered closed loop) can be considered as recycled within

Modules A1–A3. This is only possible up to the volume that was used as input in production. A co-

product allocation is necessary for production waste exceeding the volumes used as input in

Modules A1–A3.

— Co-product allocation is necessary for production waste where the materials are reused (i.e. open-

loop recycling).

— Heat and power from energy recovery of production waste in Modules A1–A3 can be considered

closed-loop within Module A1–A3 if they are used at the same quality within Modules A1–A3 and

only to the maximum amount in MJ as is required of the respective energy quality in MJ during

production (assumption: overall manufacturing, A1–A3, considered as a module). A co-product

allocation is necessary for energy surpluses exceeding the MJ considered closed-loop.

If an allocation procedure different from co-product allocation is chosen for flows that reach the system

at the boundary A1–A3, or data sets are chosen where allocation procedures are unknown, this

procedure has to be justified or clarified as a data set limitation. Ideally, data sets should be used that

clarify allocation procedures. The resulting material and energy flows are to be described transparently

in the project report with regard to the amounts of materials and energy within Module A1–A3.

This rule applies subject to other approaches in future interpretive standards from the product TCs for

implementation of EN 15804.

[EN 15804:2012+A1:2013, 6.3.4.2]: “Loads and benefits from allocated co-products shall not be

declared in Module D (see [EN 15804:2012+A1:2013] 6.3.4.6). If such a co-product allocation is not

possible, other methods may be chosen and shall be justified. Therefore, as a general rule, potential

loads or benefits from A1–A3 will not appear in Module D.

The product stage includes [in detail]:

— A1 Extraction and processing of raw materials (e.g. mining processes) and bio-mass production

and processing (e.g. agricultural or forestry operations);

— A1 Reuse of products or materials from a previous product system;

— A1 Processing of secondary materials used as input for manufacturing the product, but not

including those processes that are part of the waste processing in the previous product system;

— A1 Generation of electricity, steam and heat from primary energy resources, including extraction,

refining and transport thereof;

— A1 Energy recovery and other recovery processes from secondary fuels, but not including those

processes that are part of waste processing in the previous product system;

— A2 Transportation up to the factory gate and internal transport;

— A3 Production of ancillary materials or pre-products;

— A3 Manufacturing of products and co-products;

— A3 Manufacturing of packaging;

— A1–A3 Processing up to the end-of-waste state or disposal of final residues including any

packaging not leaving the factory gate with the product.

Regardless of the geographical coverage of a product system, the rules for defining the end-of-waste

state of this document apply.

NOTE The output of waste during this life cycle stage [could] reach the end-of-waste state when it complies

with the conditions described in EN 15804:2012+A1:2013, 6.3.4.5, end-of-life stage. They are then allocated as co-

products as [EN 15804:2012+A1:2013], 6.4.3.2.”

[EN 15804:2012+A1:2013, 6.2]: “Modules A1, A2 and A3 may be declared as an aggregated Module A1–

3.”

4.4.5.3 A4–A5, Construction stage, Information modules

[EN 15804:2012+A1:2013, 6.2.3]: “The construction process stage includes:

— A4 Transport to the building site;

— A5 Installation in the building;

including provision of all materials, products and energy, as well as waste processing up to the end-of-

waste state or disposal of final residues during the construction process stage. These information

modules also include all impacts and aspects related to any losses during this construction process

stage (i.e. production, transport and waste processing and disposal of the lost products and materials).”

When a product is sold as a system, e.g. as an age including the installation materials, then the entire

production of all components and product residues that might occur in A5 are to be declared in A1–A3.

The transport of the system to the site is to be declared in A4. The installation inclusive waste treatment

is to be declared in A5.

[EN 15804:2012+A1:2013, 6.3.4.3]: “The construction stage includes the optional information modules

for:

— A4 Transportation from the production gate to the construction site

— A4–A5 Storage of products, including the provision of heating, cooling, humidity control etc.

— A4–A5 Wastage of construction products (additional production processes to compensate for the

loss of wastage of products)

— A4–A5 Waste processing of the waste from product packaging and product wastage during the

construction process up to the end-of-waste state or disposal of final residues

If no specific information for the R -value (see [EN 15804:2012+A1:2013] 6.5.6) of the incineration

plant is available, it is assumed that packaging materials (and potential product waste from the

installation process) are treated thermally in a plant with R < 0,6. When available, US incineration data

should be included with proper justification in this calculation and used as the default standard

assumption. Thus, the combustion process (loads) for the pack-aging is to be declared in module A5, the

resulting benefits in module D.”

[EN 15804:2012+A1:2013, 6.3.4.3]:

“A5 Installation of the product in the building including manufacture and transportation of ancillary

materials and any energy or water required for installation or operation of the construction site. This

module also includes on-site operations to the product.”

4.4.5.4 B1–B5, Use stage information modules related to the basic fabric

[EN 15804:2012+A1:2013, 6.2.4]: “The use stage, related to the building fabric includes:

— B1 Use or application of the insta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...