EN 1568-1:2018

(Main)Fire extinguishing media - Foam concentrates - Part 1: Specification for medium expansion foam concentrates for surface application to water-immiscible liquids

Fire extinguishing media - Foam concentrates - Part 1: Specification for medium expansion foam concentrates for surface application to water-immiscible liquids

This European Standard specifies requirements for chemical and physical properties, and minimum performance requirements of medium expansion foams suitable for surface application to water-immiscible liquids. Requirements are also given for marking.

WARNING - Any type approval according to this standard is invalidated by any change in composition of the approved product.

Some concentrates conforming to this part of EN 1568 can also conform to other parts and therefore can also be suitable for application as low and/or high expansion foams.

Feuerlöschmittel - Schaummittel - Teil 1: Anforderungen an Schaummittel zur Erzeugung von Mittelschaum zum Aufgeben auf mit Wasser nicht mischbaren Flüssigkeiten

Diese Europäische Norm legt Anforderungen an chemische und physikalische Eigenschaften und Mindestanforderungen an die Leistungsfähigkeit von Mittelschäumen fest, die für die Aufgabe auf mit Wasser nicht mischbare Flüssigkeiten geeignet sind. Anforderungen an die Kennzeichnung sind ebenfalls festgelegt.

WARNUNG - JEDER TYP-PRÜFBESCHEID NACH DIESER NORM WIRD BEI ÄNDERUNG DER ZUSAMMENSETZUNG DES GEPRÜFTEN PRODUKTES UNGÜLTIG.

Einige diesem Teil von EN 1568 entsprechende Schaummittel können auch mit den anderen Teilen übereinstimmen und deshalb auch für die Anwendung als Schwer und/oder Leichtschäume geeignet sein.

Agents extincteurs - Émulseurs - Partie 1 : Spécifications pour les émulseurs moyen foisonnement destinés à une application à la surface de liquides n’ayant pas d’affinité pour l’eau

La présente Norme européenne spécifie les exigences en matière de propriétés chimiques, physiques et de performances minimales des émulseurs moyen foisonnement convenant à une application à la surface de liquides n’ayant pas d’affinité pour l’eau. Des exigences concernant les marquages sont également fournies.

AVERTISSEMENT - Toute homologation de type conforme à la présente norme est invalidée dès lors qu’une modification est apportée à la composition du produit homologué.

Il se peut que certains émulseurs conformes à la présente partie de l’EN 1568 soient également conformes à d’autres parties de cette série de normes et qu’ils conviennent donc à une application comme émulseurs bas et/ou haut foisonnement.

Gasila - Penila - 1. del: Specifikacija za penila za srednjo peno za površinsko uporabo pri tekočinah, netopnih v vodi

V tem osnutku evropskega standarda so določene zahteve glede kemijskih in fizikalnih lastnosti ter minimalne zahteve glede delovanja srednjeekspanzijskih pen, primernih za površinsko uporabo pri tekočinah, ki se ne mešajo z vodo. Navedene so tudi zahteve za označevanje.

Tipsko odobritev morajo izvesti neodvisni laboratoriji tretjih oseb.

OPOZORILO: Vsakršna tipska odobritev v skladu s tem standardom je neveljavna, če pride do kakršne koli spremembe v sestavi odobrenega izdelka.

OPOMBA Nekateri koncentrati, ki so skladni s tem delom standarda EN 1568, so lahko skladni tudi z drugimi deli in so zato lahko primerni za uporabo kot nizko- in/ali visokoekspanzijske pene.

General Information

- Status

- Published

- Publication Date

- 27-Feb-2018

- Withdrawal Date

- 29-Nov-2019

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 3 - Fire extinguishing media - Foam

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 28-Feb-2018

- Due Date

- 01-Dec-2017

- Completion Date

- 28-Feb-2018

Relations

- Effective Date

- 07-Mar-2018

- Effective Date

- 07-Mar-2018

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1568-1:2018 (CEN) specifies requirements for medium expansion foam concentrates intended for surface application to water‑immiscible liquids (Class B fires). The standard defines the chemical and physical property limits, minimum performance criteria, sampling and test methods, and required marking and documentation.

Important: any change in composition of an approved concentrate invalidates the original type approval.

Key topics and technical requirements

The standard covers testing and specification areas including:

- Physical/chemical properties: sediment content, freezing point, viscosity, pH and surface tension of foam concentrates and solutions.

- Stability and separation: stability/separation test to ensure product homogeneity over storage and temperature cycles.

- Expansion and drainage: determination of medium expansion ratio and drainage time before and after temperature conditioning.

- Fire performance: standardized test fire procedures for extinguishing and burn‑back resistance on water‑immiscible fuels.

- Occupational health & ecotoxicology: information and testing requirements to address human and environmental safety.

- Documentation and marking: technical data sheet and mandatory container markings to identify formulation, batch, freezing point, mixing ratios, safety and handling data.

Normative and informative annexes provide detailed test procedures (e.g., sampling, viscosity measurement for pseudo‑plastic concentrates, temperature conditioning, surface tension, freezing point, stability/separation, and fire test arrangements).

Notable updates from the previous edition:

- Introduction of freezing point and stability/separation tests.

- Inclusion of occupational health and ecotoxicological testing.

- Removal of the interfacial tension and spreading coefficient test.

Applications and users

EN 1568-1:2018 is used by:

- Foam concentrate manufacturers for product specification, quality control, and type approval.

- Fire‑protection equipment manufacturers integrating foam systems.

- Testing laboratories executing standardized performance and compliance tests.

- Fire safety engineers and procurement officers specifying foam for industrial sites (petrochemical plants, terminals), airports, marine and firefighting brigades.

- Regulators and certification bodies verifying conformity and safe use.

Because some concentrates conforming to Part 1 may also meet other parts of EN 1568, a concentrate can be suitable for low and/or high expansion applications as well.

Related standards

- EN 1568 (other parts): Part 2 (high expansion), Part 3 (low expansion - water‑immiscible), Part 4 (low expansion - water‑miscible).

- Other fire‑extinguishing media standards referenced in EN 1568 series (e.g., powders, CO2, halogenated agents).

Keywords: EN 1568-1:2018, medium expansion foam, foam concentrates, fire extinguishing media, surface application, water‑immiscible liquids, CEN, foam testing, freezing point, stability test.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1568-1:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fire extinguishing media - Foam concentrates - Part 1: Specification for medium expansion foam concentrates for surface application to water-immiscible liquids". This standard covers: This European Standard specifies requirements for chemical and physical properties, and minimum performance requirements of medium expansion foams suitable for surface application to water-immiscible liquids. Requirements are also given for marking. WARNING - Any type approval according to this standard is invalidated by any change in composition of the approved product. Some concentrates conforming to this part of EN 1568 can also conform to other parts and therefore can also be suitable for application as low and/or high expansion foams.

This European Standard specifies requirements for chemical and physical properties, and minimum performance requirements of medium expansion foams suitable for surface application to water-immiscible liquids. Requirements are also given for marking. WARNING - Any type approval according to this standard is invalidated by any change in composition of the approved product. Some concentrates conforming to this part of EN 1568 can also conform to other parts and therefore can also be suitable for application as low and/or high expansion foams.

EN 1568-1:2018 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1568-1:2018 has the following relationships with other standards: It is inter standard links to EN 1568-1:2008/AC:2010, EN 1568-1:2008, ISO 3310-1:2016, EN ISO 3219-2:2021, EN 1568-3:2018, EN 1568-2:2018, EN ISO 3104:2023, EN ISO 3696:1995, EN ISO 23753-1:2019, EN ISO 3219-1:2021, EN 1568-4:2018, EN 1715-4:1997, EN ISO 11348-2:2008, EN 12065:1997, EN 13565-2:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1568-1:2018 is associated with the following European legislation: EU Directives/Regulations: 305/2011. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1568-1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Feuerlöschmittel - Schaummittel - Teil 1: Anforderungen an Schaummittel zur Erzeugung von Mittelschaum zum Aufgeben auf mit Wasser nicht mischbaren FlüssigkeitenAgents extincteurs - Émulseurs - Partie 1: Spécifications pour les émulseurs moyen foisonnement destinés à une application à la surface de liquides n’ayant pas d’affinité pour l’eauFire extinguishing media - Foam concentrates - Part 1: Specification for medium expansion foam concentrates for surface application to water-immiscible liquids13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 1568-1:2018SIST EN 1568-1:2018en,fr,de01-maj-2018SIST EN 1568-1:2018SLOVENSKI

STANDARDSIST EN 1568-1:2008/AC:2010SIST EN 1568-1:20081DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1568-1

February

t r s z ICS

s uä t t rä s r Supersedes EN

s w x zæ sã t r r zEnglish Version

Fire extinguishing media æ Foam concentrates æ Part

sã Specification for medium expansion foam concentrates for surface application to wateræimmiscible liquids Agents extincteurs æ Émulseurs æ Partie

s ã Spécifications pour les émulseurs moyen foisonnement destinés à une application à la surface de liquides n 5ayant pas d 5affinité pour l 5eau

Feuerlöschmittel æ Schaummittel æ Teil

sã Anforderungen an Schaummittel zur Erzeugung von Mittelschaum zum Aufgeben auf mit Wasser nicht mischbaren Flüssigkeiten This European Standard was approved by CEN on

s October

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s w x zæ sã t r s z ESIST EN 1568-1:2018

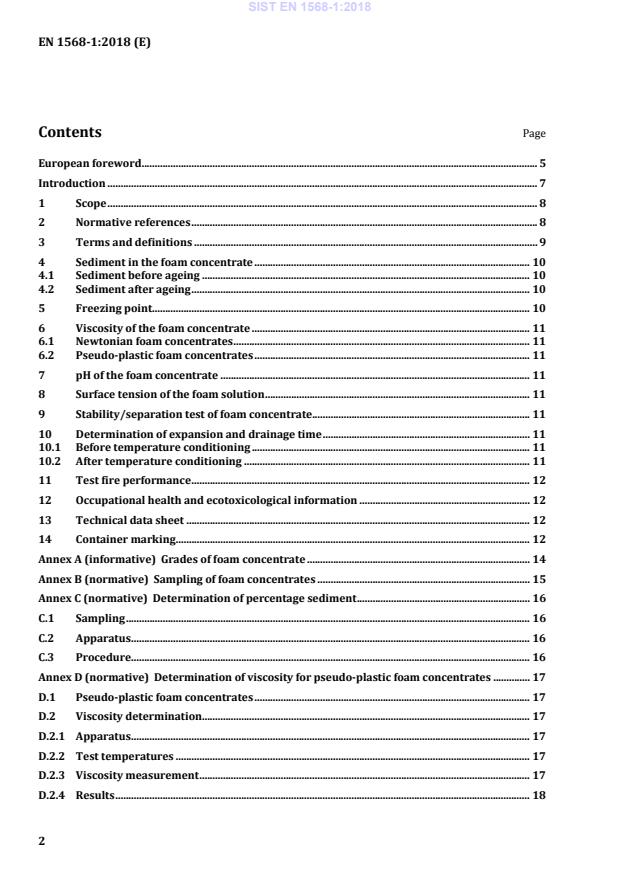

Grades of foam concentrate . 14 Annex B (normative)

Sampling of foam concentrates . 15 Annex C (normative)

Determination of percentage sediment . 16 C.1 Sampling . 16 C.2 Apparatus . 16 C.3 Procedure. 16 Annex D (normative)

Determination of viscosity for pseudo-plastic foam concentrates . 17 D.1 Pseudo-plastic foam concentrates . 17 D.2 Viscosity determination. 17 D.2.1 Apparatus . 17 D.2.2 Test temperatures . 17 D.2.3 Viscosity measurement . 17 D.2.4 Results . 18 SIST EN 1568-1:2018

Temperature conditioning of foam concentrates . 19 E.1 General . 19 E.2 Low temperature conditioning . 19 E.2.1 Apparatus . 19 E.2.2 Procedure . 19 E.3 High temperature conditioning . 19 E.3.1 Apparatus . 19 E.3.2 Procedure . 19 E.4 Division into top and bottom half-samples . 20 E.4.1 Apparatus . 20 E.4.2 Procedure . 21 Annex F (normative)

Determination of surface tension . 22 F.1 Solution of foam concentrate . 22 F.2 Procedure — Surface tension . 22 Annex G (normative)

Determination of expansion and drainage time . 23 G.1 Apparatus . 23 G.2 Temperature conditions . 23 G.3 Procedure . 23 G.4 Simulated fresh and sea water . 24 Annex H (normative)

Determination of test fire performance . 28 H.1 General . 28 H.2 General conditions . 28 H.2.1 Test series and criteria for success . 28 H.2.1.1 Foam concentrates not compatible with sea water. 28 H.2.1.2 Foam concentrates compatible with sea water . 28 H.2.2 Temperature and wind speed . 28 H.2.3 Records . 29 H.2.4 Foam solution. 29 H.2.5 Fuel . 29 H.3 Fire test . 30 H.3.1 Apparatus . 30 H.3.2 Test procedure . 30 Annex I (informative)

Description of a radiation measurement method . 32 I.1 Evaluation . 32 I.2 General arrangement of test . 32 I.3 Technical data for radiometers) . 33 SIST EN 1568-1:2018

Freezing point determination . 36 J.1 General . 36 J.2 Equipment required . 36 J.3 Procedure. 36 J.4 Example of a temperature against time curve for evaluation . 37 Annex K (normative)

Stability/Separation test of foam concentrate. 38 K.1 General . 38 K.2 Apparatus . 38 K.3 Procedure. 38 Annex L (normative)

Occupational health and ecotoxicological testing . 39 Annex M (informative)

Example for a technical data sheet . 40 Annex N (informative)

A-deviations . 42 Bibliography . 44

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1 25 %/50 % drainage time time taken for 25 %/50 % of the volume of the original foam solution to drain out of the generated foam 3.2 expansion (E) expansion value expansion ratio ratio of the volume of foam to the volume of the foam solution from which it was made 3.3 low expansion foam foam which has an expansion ratio less than 20 3.4 medium expansion foam foam which has an expansion ratio greater than or equal to 20 but less than 200 3.5 high expansion foam foam which has an expansion ratio greater than or equal to 200 3.6 fire-fighting foam aggregate of air filled bubbles formed from a foam solution used for fire-fighting 3.7 foam concentrate liquid which is diluted with water to produce foam solution Note 1 to entry: Annex A gives information on grades of foam concentrate. 3.8 foam solution solution of foam concentrate in water SIST EN 1568-1:2018

«1 4 Sediment in the foam concentrate 4.1 Sediment before ageing Any sediment in the foam concentrate sampled in accordance with Annex B, but not aged in accordance with C.1, shall be dispersible through a 180 not more than 0,25 % when tested in accordance with Annex C. 4.2 Sediment after ageing Any sediment in the foam concentrate sampled in accordance with Annex B, and aged in accordance with C.1, shall be dispersible through a 180 not more than 1,0 % when tested in accordance with Annex C. 5 Freezing point The freezing point of the foam concentrate sampled in accordance with Annex B shall be determined in accordance with Annex J. SIST EN 1568-1:2018

Grades of foam concentrate Foam concentrates are graded as follows: a) protein foam concentrates (P): these are liquids derived from hydrolysed protein materials; b) fluoroprotein foam concentrates (FP): these are protein concentrates with added fluorinated surface active agents; c) synthetic foam concentrates (S): these are based upon mixtures of hydrocarbon surface-active agents and do not contain fluoro organic compounds; d) alcohol resistant foam concentrates (AR): these can be suitable for use on hydrocarbon fuels, and additionally are resistant to breakdown when applied to the surface of water-miscible liquid fuels. Some alcohol resistant foam concentrates can precipitate a polymeric membrane on the surface of alcohol; e) aqueous film-forming foam concentrates (AFFF): these are generally based on mixtures of hydrocarbon surfactants and fluorinated surface active agents and have the ability to form an aqueous film on the surface of some hydrocarbon fuels; f) film-forming fluoroprotein foam concentrates (FFFP): these are fluoroprotein foam concentrates which have the ability to form an aqueous film on the surface of some hydrocarbon fuels; g) fluorine free foam concentrates (F3): these foam concentrates are dedicated to meet extinguishing performance ratings and are targeting applications similar to AFFF and/or AR-foams without using fluoroorganic compounds. These foam concentrates are based upon mixtures of hydrocarbon surface-active agents and non-fluorine containing stabilizers. SIST EN 1568-1:2018

Sampling of foam concentrates The samples for testing shall be delivered by the supplier in completely filled sealable containers. The samples for testing shall be taken and delivered by the supplier using a method which provides a representative sample of the foam concentrate to be tested. NOTE Nominal 25-l containers are convenient. SIST EN 1568-1:2018

Determination of percentage sediment C.1 Sampling NOTE See Clause 4. Use a sample prepared in accordance with Annex B. Place approximately 1 l of the sample in a suitable container of nominal capacity sufficient to provide an ullage of 5 % to 10 % of the container volume. Seal the container. Ensure that any sediment is dispersed by agitating the sample container. Take two samples, testing one immediately at a temperature of (20 ± 5) °C, the other after ageing for (24 ± 2) h at (60 ± 2) °C in a completely filled container without access to air. C.2 Apparatus C.2.1 Graduated centrifuge tubes. NOTE The centrifuge tubes described in ISO 3734 are suitable. C.2.2 Centrifuge, operating at (6 000 ± 600) m s «2. NOTE The centrifuge described in ISO 3734 is suitable. C.2.3 180

conforming to ISO 3310-1. C.2.4 Plastic wash bottle. C.3 Procedure C.3.1 Centrifuge each sample of the concentrate for 10 min. Determine the volume of the sediment and report it as a percentage of the volume of the centrifuged sample. C.3.2 Wash the contents of the centrifuge tube onto the sieve and check whether the sediment can be dispersed through the sieve by the jet from the plastic wash bottle. SIST EN 1568-1:2018

Determination of viscosity for pseudo-plastic foam concentrates NOTE

The procedure is described in EN ISO 3219:1994, Annex A or B. D.1 Pseudo-plastic foam concentrates Pseudo-plastic foam concentrates have a viscosity which decreases with increasing shear rate at constant temperature. NOTE Pseudo-plastic foam concentrates are a particular class of non-Newtonian foam concentrate. D.2 Viscosity determination D.2.1 Apparatus D.2.1.1 Rotational viscometer in accordance with EN ISO 3219 with the following parameters: — maximum shear stress

· 75 Pa; — maximum shear rate

· 600 s «1. The viscometer shall be fitted with a temperature control unit which can maintain the sample temperature within ± 1 °C of the required temperature. D.2.2 Test temperatures The viscosity of the foam concentrate shall be measured from 20 °C, to and including the lowest temperature for use claimed by the manufacturer in steps of 10 °C. A fresh sample shall be used for each temperature. D.2.3 Viscosity measurement If the sample contains suspended air bubbles the sample shall be centrifuged for 10 min using the apparatus specified in C.2.1 and C.2.2 before the sample is applied in the apparatus. The test should be performed in accordance with the following test procedure: 1) adjust the temperature control unit; 2) set the gap; 3) apply the sample; 4) minimum 10 min waiting period (no shear) to reach temperature equilibrium; 5) 1 min pre-shearing at 600 s «1; 6) 1 min waiting period without shearing; 7) measure the shear stress for 10 s at each shear rate starting at the lowest shear rate (preferable at 75 s «1). SIST EN 1568-1:2018

Temperature conditioning of foam concentrates E.1 General If the foam concentrate is claimed by the supplier not to be adversely affected by storage at

« u r °C, condition the sample in accordance with E.2 and then in accordance with E.3; otherwise, condition only in accordance with E.3. E.2 Low temperature conditioning E.2.1 Apparatus E.2.1.1 Freezing chamber,

± 3) °C. E.2.1.2 Sample containers, in accordance with Annex B. NOTE More than one container might be needed to condition sufficient volume of foam concentrate for subsequent testing. E.2.2 Procedure

± 3) °C. Do not agitate the content of the container(s) at any time until the sample of foam concentrate has been divided into top and bottom half-samples (see E.4). Place the sample container(s) in the freezing chamber and maintain at the required temperature for (24 ± 1) h. At the end of this period store the container(s) for not less than 48 h and not more than 96 h in an ambient temperature of (20 ± 5) °C. Repeat three times so that there are four cycles of freezing and thawing before testing. E.3 High temperature conditioning E.3.1 Apparatus E.3.1.1 Oven, capable of achieving a temperature of (60 ± 3) °C. E.3.2 Procedure Set the temperature of the oven to (60 ± 3) °C. If the foam concentrate sample has not been conditioned in accordance with E.2 use foam concentrate sample in accordance with Annex B; otherwise use containers conditioned in accordance with E.2. Do not agitate the content of the container(s) at any time until the sample of foam concentrate has been divided into top and bottom half-samples (see E.4). Place the container(s) in the oven and maintain at the required temperature for 7 days. At the end of this period store the container(s) for not less than 48 h and not more 96 h in an ambient temperature of (20 ± 5) °C. SIST EN 1568-1:2018

Key 1 air pressure pipe 2 delivery pipe diameter (8 to15) mm 3 detachable cone and plate, diameter (25 to 35)mm, height (40 to 50)mm, distance between cone and plate (10 to 12) mm 4 sample container approximately 25 l 5 top sample 6 bottom sample Figure E.1 — Example of a suitable equipment to divide the conditioned foam concentrate into top and bottom half-samples E.4.2 Procedure Mount the divider device to the sample container. Adjust the delivery pipe in a vertical direction so that the inlet of the delivery pipe is positioned below the surface, at a vertical distance of approximately 1/3 into the top half-sample. Pressurize the sample container carefully and start collecting the top half-sample foam concentrate into the empty top half-sample container. Interrupt the pressurizing just before the foam liquid surface reaches the inlet of the delivery pipe. Lower the delivery pipe another 1/3 into the top half-sample and repeat the procedure twice. At the end of the dividing process, the top half-sample shall have been collected from three levels. The bottom half-sample should preferably be kept in the original sample container. Before subsequent testing starts of the top and bottom half-samples for Clauses 8 and 10, the top half-container and the bottom half-sample container shall be agitated in order to provide a homogenous foam sample. SIST EN 1568-1:2018

Determination of surface tension F.1 Solution of foam concentrate NOTE See Clause 8. Solution of foam concentrate, at the recommended usage concentration in demineralized water. F.2 Procedure — Surface tension Determine the surface tension of the solution at a temperature of (20 ± 3) °C using the ring or plate method of ISO 304. In the test report state which method (ring or plate) was used. SIST EN 1568-1:2018

Determination of expansion and drainage time G.1 Apparatus NOTE See Clause 10. G.1.1 Collecting vessel (see Figure G.1) of volume V approximately 200 l and accurately known to ± 2 l equipped with a bottom discharge facility which ensures a complete emptying. G.1.2 Foam-making equipment with nozzle as shown in Figures G.2 and G.3 which when tested with water has a flow rate of 3,1 l/min to 3,4 l/min at a nozzle pressure of (5,0 ± 0,1) bar. G.1.3 Stop clock or other timing device. G.2 Temperature conditions Carry out the tests under the following temperature conditions: — air temperature: (20 ± 5) °C; — foam solution temperature: (17,5 ± 2,5) °C. G.3 Procedure G.3.1 Prepare two samples of foam concentrate in accordance with Annex B. Condition one in accordance with Annex E, to give a total of three samples (non-conditioned, bot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...