EN 17119:2018

(Main)Non-destructive testing - Thermographic testing - Active thermography

Non-destructive testing - Thermographic testing - Active thermography

This document defines the procedures for non-destructive testing using active thermography.

These testing procedures can be applied to different materials (e.g. composites, metals and coatings) and are appointed, but not limited to the:

— detection of discontinuities (e.g. voids, cracks, inclusions, delaminations);

— determination of layer or part thicknesses;

— determination and comparison of thermophysical properties.

This standard is describing data acquisition and analysis principles for active thermography and is giving an informative guideline for appropriate selection of the excitation source. Acceptance criteria are not defined in this standard.

Active thermography is applied in industrial production (e.g. compound materials, vehicle parts, engine parts, power plant parts, joining technology, electronic devices) and in maintenance and repair (e.g. aerospace, power plants, civil engineering).

Zerstörungsfreie Prüfung - Thermografische Prüfung - Aktive Thermografie

Essais non destructifs - Analyse thermographique - Thermographie active

Neporušitveno preskušanje - Termografsko preskušanje - Aktivna termografija

Ta dokument določa postopke za neporušitveno preskušanje z aktivno termografijo. Ti postopki preskušanja se lahko uporabljajo za različne materiale (npr. kompozite, kovine in prevleke) ter so med drugim namenjeni za: – zaznavanje nehomogenosti (npr. praznin, razpok, vključitev, razslojevanja); – ugotavljanje debeline sloja ali dela; – ugotavljanje in primerjavo termofizikalnih lastnosti. Ta standard opisuje zajemanje podatkov in načela analize za aktivno termografijo in podaja informativno smernico za ustrezno izbiro vira vzbujanja. Merila sprejemljivosti v tem standardu niso opredeljena. Aktivna termografija se uporablja v industrijski proizvodnji (kompozitni materiali, deli vozil, deli motorjev, deli elektrarn, tehnologija spajanja, elektronske naprave itd.) ter pri vzdrževanju in popravilih (aeronavtika, elektrarne, gradbeni inženiring itd.).

General Information

- Status

- Published

- Publication Date

- 31-Jul-2018

- Withdrawal Date

- 27-Feb-2019

- Technical Committee

- CEN/TC 138 - Non-destructive testing

- Drafting Committee

- CEN/TC 138/WG 11 - Infrared thermographic testing

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 24-Sep-2024

- Completion Date

- 11-Feb-2026

Relations

- Refers

EN 16714-3:2016 - Non-destructive testing - Thermographic testing - Part 3: Terms and definitions - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 16714-1:2016 - Non-destructive testing - Thermographic testing - Part 1: General principles - Effective Date

- 28-Jan-2026

- Refers

CEN/TR 14748:2004 - Non-destructive testing - Methodology for qualification of non-destructive tests - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 17119:2018 - Non‑destructive testing - Thermographic testing - Active thermography (CEN) defines standardized procedures for applying active thermography as a non‑destructive testing (NDT) method. The standard describes principles for data acquisition and analysis, outlines excitation options, and gives informative guidance on selecting excitation sources. It covers use on a range of materials (composites, metals, coatings) for detection of discontinuities (voids, cracks, inclusions, delaminations), measurement of layer/part thicknesses, and comparison of thermophysical properties. Note: acceptance criteria are not defined in this standard.

Key Topics and Requirements

- Scope and intent

- Procedures for active thermography in industrial inspection and maintenance.

- Applicable to production and service environments (e.g., aerospace, automotive, power plants, civil engineering, electronics).

- Data acquisition techniques

- Use of an infrared (IR) camera to record thermograms; synchronization between excitation source and image capture.

- Temporal excitation types: pulse thermography, step thermography, lock‑in (modulated) thermography.

- Spatial excitation types: local, two‑dimensional (surface), and whole‑volume excitation.

- Typical setups: reflection and transmission configurations; static and dynamic acquisition.

- Data processing and analysis

- Time‑domain and frequency‑domain processing methods to enhance defect detectability.

- Use of derived images (amplitude, phase, derivative, contrast) to interpret subsurface features.

- System and personnel considerations

- Specifications for test systems and guidance on required synchronization and imaging sequences.

- Recommendation for personnel qualification and documentation (test performance and reporting).

- Informative guidance

- Annex material provides practical excitation technique descriptions and selection guidance.

Applications - Who Uses This Standard

- NDT technicians and inspection engineers implementing thermographic testing programs.

- Manufacturers of composite parts, vehicle and engine components, electronic assemblies and coatings.

- Maintenance, repair and overhaul (MRO) teams in aerospace, power generation, transportation and civil infrastructure.

- Quality managers developing inspection procedures for production lines and in‑service inspections.

Related Standards

- EN 16714‑1: General principles for thermographic testing

- EN 16714‑2: Equipment

- EN 16714‑3: Terms and definitions

- EN 15042‑2: Photothermic thickness measurement

- CEN/TR 14748: Methodology for qualification of NDT methods

Keywords: EN 17119:2018, active thermography, thermographic testing, non‑destructive testing (NDT), infrared camera, pulse thermography, lock‑in thermography, inspection procedures.

Get Certified

Connect with accredited certification bodies for this standard

IMP NDT d.o.o.

Non-destructive testing services. Radiography, ultrasonic, magnetic particle, penetrant, visual inspection.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Q Techna d.o.o.

NDT and quality assurance specialist. 30+ years experience. NDT personnel certification per ISO 9712, nuclear and thermal power plant inspections, QA/

Sponsored listings

Frequently Asked Questions

EN 17119:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Non-destructive testing - Thermographic testing - Active thermography". This standard covers: This document defines the procedures for non-destructive testing using active thermography. These testing procedures can be applied to different materials (e.g. composites, metals and coatings) and are appointed, but not limited to the: — detection of discontinuities (e.g. voids, cracks, inclusions, delaminations); — determination of layer or part thicknesses; — determination and comparison of thermophysical properties. This standard is describing data acquisition and analysis principles for active thermography and is giving an informative guideline for appropriate selection of the excitation source. Acceptance criteria are not defined in this standard. Active thermography is applied in industrial production (e.g. compound materials, vehicle parts, engine parts, power plant parts, joining technology, electronic devices) and in maintenance and repair (e.g. aerospace, power plants, civil engineering).

This document defines the procedures for non-destructive testing using active thermography. These testing procedures can be applied to different materials (e.g. composites, metals and coatings) and are appointed, but not limited to the: — detection of discontinuities (e.g. voids, cracks, inclusions, delaminations); — determination of layer or part thicknesses; — determination and comparison of thermophysical properties. This standard is describing data acquisition and analysis principles for active thermography and is giving an informative guideline for appropriate selection of the excitation source. Acceptance criteria are not defined in this standard. Active thermography is applied in industrial production (e.g. compound materials, vehicle parts, engine parts, power plant parts, joining technology, electronic devices) and in maintenance and repair (e.g. aerospace, power plants, civil engineering).

EN 17119:2018 is classified under the following ICS (International Classification for Standards) categories: 19.100 - Non-destructive testing. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17119:2018 has the following relationships with other standards: It is inter standard links to EN 16714-3:2016, EN 16714-2:2016, EN 15042-2:2006, EN 16714-1:2016, CEN/TR 14748:2004, EN 17501:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 17119:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2018

Neporušitveno preskušanje - Termografsko preskušanje - Aktivna termografija

Non-destructive testing - Thermographic testing - Active thermography

Zerstörungsfreie Prüfung - Thermografische Prüfung - Aktive Thermografie

Essais non destructifs - Analyse thermographique - Thermographie active

Ta slovenski standard je istoveten z: EN 17119:2018

ICS:

19.100 Neporušitveno preskušanje Non-destructive testing

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17119

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2018

EUROPÄISCHE NORM

ICS 19.100

English Version

Non-destructive testing - Thermographic testing - Active

thermography

Essais non destructifs - Analyse thermographique - Zerstörungsfreie Prüfung - Thermografische Prüfung -

Thermographie active Aktive Thermografie

This European Standard was approved by CEN on 20 April 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2018 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17119:2018 E

worldwide for CEN national Members.

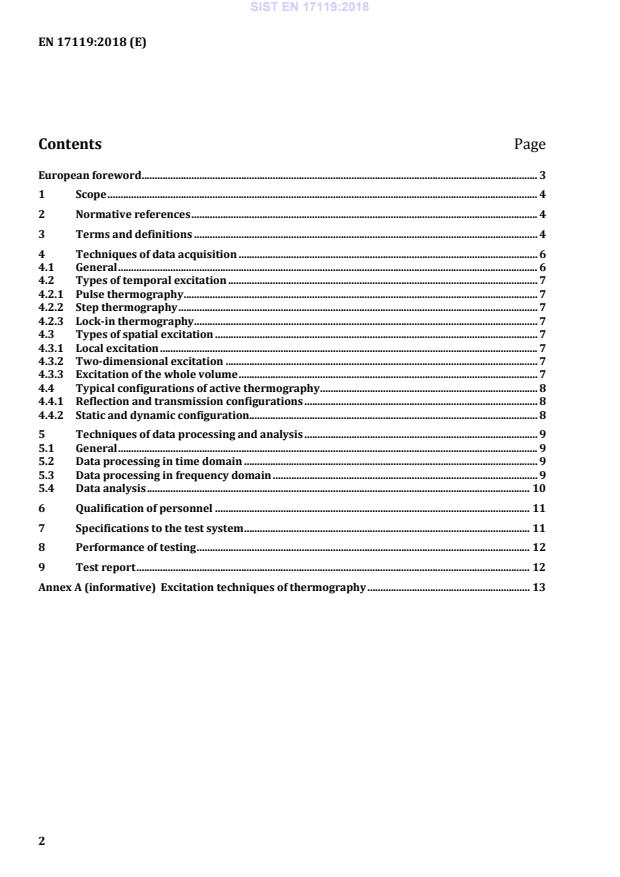

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Techniques of data acquisition . 6

4.1 General . 6

4.2 Types of temporal excitation . 7

4.2.1 Pulse thermography . 7

4.2.2 Step thermography . 7

4.2.3 Lock-in thermography . 7

4.3 Types of spatial excitation . 7

4.3.1 Local excitation . 7

4.3.2 Two-dimensional excitation . 7

4.3.3 Excitation of the whole volume . 7

4.4 Typical configurations of active thermography . 8

4.4.1 Reflection and transmission configurations . 8

4.4.2 Static and dynamic configuration. 8

5 Techniques of data processing and analysis . 9

5.1 General . 9

5.2 Data processing in time domain . 9

5.3 Data processing in frequency domain . 9

5.4 Data analysis . 10

6 Qualification of personnel . 11

7 Specifications to the test system . 11

8 Performance of testing . 12

9 Test report . 12

Annex A (informative) Excitation techniques of thermography . 13

European foreword

This document (EN 17119:2018) has been prepared by Technical Committee CEN/TC 138 “Non-

destructive testing”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2019, and conflicting national standards

shall be withdrawn at the latest by February 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and the United Kingdom.

1 Scope

This document defines the procedures for non-destructive testing using active thermography.

These testing procedures can be applied to different materials (e.g. composites, metals and coatings)

and are appointed, but not limited to the:

— detection of discontinuities (e.g. voids, cracks, inclusions, delaminations);

— determination of layer or part thicknesses;

— determination and comparison of thermophysical properties.

This standard is describing data acquisition and analysis principles for active thermography and is

giving an informative guideline for appropriate selection of the excitation source. Acceptance criteria

are not defined in this standard.

Active thermography is applied in industrial production (e.g. compound materials, vehicle parts, engine

parts, power plant parts, joining technology, electronic devices) and in maintenance and repair (e.g.

aerospace, power plants, civil engineering).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 16714-1, Non-destructive testing - Thermographic testing - Part 1: General principles

EN 16714-2, Non-destructive testing - Thermographic testing - Part 2: Equipment

EN 16714-3, Non-destructive testing - Thermographic testing - Part 3: Terms and definitions

EN 15042-2:2006, Thickness measurement of coatings and characterization of surfaces with surface

waves - Part 2: Guide to the thickness measurement of coatings by photothermic method

CEN/TR 14748, Non-destructive testing - Methodology for qualification of non-destructive tests

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 16714-3, EN 15042-2:2006

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

amplitude image

image of the spatial distribution of the amount of radiation emitted by the body at a frequency f

3.2

derivative image

image of the spatial distribution of the first or higher order temporal derivative of the temperature

response to excitation

3.3

dynamic temperature contrast

local distribution of the temporally varying temperature difference relative to a reference temperature

3.4

lock-in thermography

modulated thermography

energy is introduced periodically in time at the modulation frequency f , e.g., in a sinusoidal manner

LI

3.5

phase image

image of the spatial distribution of the temporal delay of the temperature response at a frequency f

3.6

pulse thermography

energy is introduced by means of a short pulse that can be considered as a Dirac pulse

3.7

step thermography

energy source is switched on or/and off for a defined time during which thermal diffusion can occur

3.8

thermal diffusion length

µ

characteristic length of heat diffusion after pulsed or during periodic introduction of energy at a

frequency f

µ = sqrt (α/πf)

3.9

thermal diffusivity

α

represents the temporal and spatial diffusion of thermal energy (heat) inside a body

Note 1 to entry: In thermodynamics, a is used as symbol.

Note 2 to entry: Depending on the material α might not be isotropic.

3.10

thermal effusivity

e

represents the temperature change of a material as a reaction to a transient input of energy

Note 1 to entry: In thermodynamics, b is used as symbol.

Note 2 to entry: Depending on the material e might not be isotropic.

3.11

thermal reflection coefficient

R

c

measure for the reflection of thermal waves (related to the model of thermal diffusion waves) at the

interface between two layers having different thermal effusivities e and e

1 2

R = (e – e ) / (e + e )

c 1 2 1 2

3.12

thermal transmission coefficient

T

c

measure for the transmission of thermal waves (related to the model of thermal diffusion waves) at the

interface between two layers having different thermal effusivities e and e

1 2

T = 2 e / (e + e )

c 1 1 2

4 Techniques of data acquisition

4.1 General

In active thermography, an additional artificial or natural energy source is applied introducing a time

dependent heat flux inside the test specimen. This is only done for the purpose of testing (principle see

Figure 1).

Figure 1 — Principle of active thermography

Thermal excitation can be generated in the test object with different energy sources based on various

effects such as:

— absorption of optical radiation (e.g. light or infrared) and/or microwaves;

— electromagnetic induction and/or electric current;

— conversion of mechanical waves (e.g. ultrasonic);

— convection (e.g. hot/cold air);

— conduction (e.g. hot blanket).

Discontinuities inside the test object may affect the heat generation and propagation process and

become indirectly visible by recording the emitted radiation with an infrared camera (IR camera). A

controller can provide synchronization between energy source and image recording. Generally, a

sequence consisting of a number of images is recorded, which may be analysed subsequently.

4.2 Types of temporal excitation

4.2.1 Pulse thermography

For excitation, an energy source is used that provides a short pulse (e.g. flash lamp or a laser). Short

means that it can be considered as a Dirac pulse and that the duration of the pulse is significantly less

than the time needed for recording a thermal signature of the defects or of the rear side of the layer.

The image sequence may be analysed in time domain, as described in 5.2, or in frequency domain, as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...