EN 17346:2020

(Main)Ambient air - Standard method for the determination of the concentration of ammonia using diffusive samplers

Ambient air - Standard method for the determination of the concentration of ammonia using diffusive samplers

This document specifies a method for the sampling and analysis of NH3 in ambient air using diffusive sampling.

It can be used for NH3 measurements at ambient levels, but the concentration range and exposure time are sampler dependent, and the end user is therefore advised to match the sampler type to the measurement requirement and to follow the operating instructions provided by the manufacturer.

Außenluft - Messverfahren zur Bestimmung der Konzentration von Ammoniak mit Passivsammlern

Dieses Dokument legt ein Verfahren zur Probenahme und Analyse von NH3 in Außenluft mit Passivsammlern fest.

Es kann für NH3 Messungen bei Außenluftkonzentrationen verwendet werden; Konzentrationsbereich und Expositionszeit sind aber sammlerabhängig. Dem Anwender wird daher empfohlen, einen den Messanforderungen entsprechenden Sammlertyp zu wählen und sich an die Herstellerangaben zu halten.

Air ambiant - Méthode normalisée pour la détermination de la concentration en ammoniac au moyen d’échantillonneurs par diffusion

Le présent document spécifie une méthode pour l’échantillonnage et l’analyse du NH3 dans l’air ambiant à l’aide d’échantillonneurs par diffusion.

Elle peut être utilisée pour mesurer le NH3 aux niveaux ambiants, mais la gamme de concentrations et la durée d’exposition dépendent de l’échantillonneur. Il est donc conseillé à l’utilisateur final d’adapter le type d’échantillonneur aux exigences de mesure et de se conformer aux instructions d’utilisation fournies par le fabricant.

Kakovost zunanjega zraka - Standardna metoda za določevanje koncentracije amoniaka z difuzijskim vzorčenjem

General Information

- Status

- Published

- Publication Date

- 19-May-2020

- Withdrawal Date

- 29-Nov-2020

- Technical Committee

- CEN/TC 264 - Air quality

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 05-Dec-2025

- Completion Date

- 11-Feb-2026

Overview

EN 17346:2020 (CEN) - "Ambient air - Standard method for the determination of the concentration of ammonia using diffusive samplers" - specifies a standardized procedure for sampling and analyzing atmospheric ammonia (NH3) using diffusive (passive) samplers. Approved in May 2020, the standard is intended for ambient air quality monitoring at ambient NH3 levels. It emphasizes that concentration range and exposure time are sampler-dependent, so users must select and operate samplers according to manufacturer instructions and measurement needs.

Key topics and requirements

- Scope and applicability: Method for integrative (time‑averaged) NH3 measurements using diffusive samplers at ambient concentrations.

- Sampler types covered: tube‑type, badge‑type and radial diffusive samplers; detailed designs and guidance are provided in informative annexes.

- Sampling principle: passive uptake of NH3 by diffusion through a static air layer, membrane or porous material (no pumping).

- Calculation methods: determination of mass concentration and conversion to standard temperature and pressure conditions.

- Quality control / quality assurance (QC/QA): procedures to ensure data reliability, including extraction efficiency checks and routine QC.

- Performance and uncertainty: performance requirements, measurement uncertainty estimation and reporting requirements are specified, with an informative annex on uncertainty calculation.

- Annexes: include sampler design, extraction/analysis protocols, application ranges, summary of sampling-rate data and a normative method to estimate sampler sampling rate.

Practical applications

- Environmental monitoring networks assessing ambient ammonia concentrations for ecosystem protection and air quality management.

- Regulatory compliance and policy support where NH3 monitoring informs emission reduction and air‑pollution control strategies.

- Research studies on NH3 contributions to eutrophication, acidification, and secondary particulate matter formation (ammonium aerosols).

- Manufacturers and laboratories validating and deploying passive diffusive samplers for field surveys and long‑term monitoring campaigns.

- Community or low‑cost monitoring initiatives seeking time‑integrated NH3 data without continuous analyzers.

Who should use this standard

- Environmental agencies and national air quality monitoring programs

- Accredited analytical laboratories and field technicians

- Instrument manufacturers and sampler developers

- Researchers studying nitrogen deposition, atmospheric chemistry and PM formation

Related standards

- EN 13528-2 (referenced for passive sampler terminology and validation considerations)

- JCGM 200 (Guide for measurement uncertainty; referenced for uncertainty terminology and approach)

EN 17346:2020 provides practical, harmonized guidance for passive NH3 monitoring, enabling consistent ambient ammonia data useful for air quality assessment, regulatory compliance and environmental research.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 17346:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ambient air - Standard method for the determination of the concentration of ammonia using diffusive samplers". This standard covers: This document specifies a method for the sampling and analysis of NH3 in ambient air using diffusive sampling. It can be used for NH3 measurements at ambient levels, but the concentration range and exposure time are sampler dependent, and the end user is therefore advised to match the sampler type to the measurement requirement and to follow the operating instructions provided by the manufacturer.

This document specifies a method for the sampling and analysis of NH3 in ambient air using diffusive sampling. It can be used for NH3 measurements at ambient levels, but the concentration range and exposure time are sampler dependent, and the end user is therefore advised to match the sampler type to the measurement requirement and to follow the operating instructions provided by the manufacturer.

EN 17346:2020 is classified under the following ICS (International Classification for Standards) categories: 13.040.20 - Ambient atmospheres. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 17346:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2020

Kakovost zunanjega zraka - Standardna metoda za določevanje koncentracije

amoniaka z difuzijskim vzorčenjem

Ambient Air Quality - Standard method for the determination of the concentration of

ammonia by diffusive sampling

Außenluftqualität - Messverfahren zur Bestimmung der Konzentration von Ammoniak mit

Passivsammlern

Air ambiant - Méthode normalisée pour la détermination de la concentration d'ammoniac

au moyen d'échantillonneurs par diffusion

Ta slovenski standard je istoveten z: EN 17346:2020

ICS:

13.040.20 Kakovost okoljskega zraka Ambient atmospheres

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 17346

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2020

EUROPÄISCHE NORM

ICS 13.040.20

English Version

Ambient air - Standard method for the determination of

the concentration of ammonia using diffusive samplers

Air ambiant - Méthode normalisée pour la Außenluft - Messverfahren zur Bestimmung der

détermination de la concentration en ammoniac au Konzentration von Ammoniak mit Passivsammlern

moyen d'échantillonneurs par diffusion

This European Standard was approved by CEN on 13 April 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2020 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 17346:2020 E

worldwide for CEN national Members.

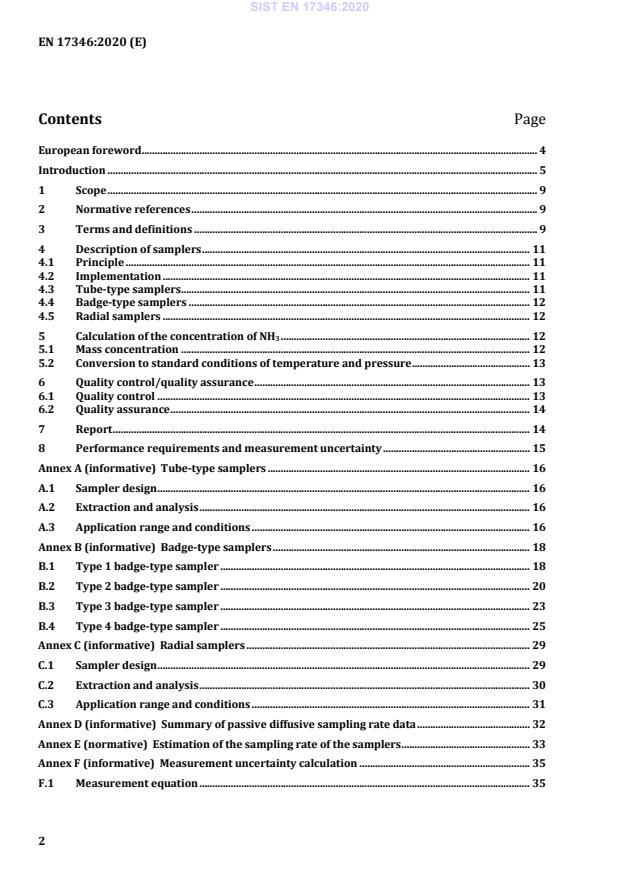

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 9

2 Normative references . 9

3 Terms and definitions . 9

4 Description of samplers . 11

4.1 Principle . 11

4.2 Implementation . 11

4.3 Tube-type samplers. 11

4.4 Badge-type samplers . 12

4.5 Radial samplers . 12

5 Calculation of the concentration of NH . 12

5.1 Mass concentration . 12

5.2 Conversion to standard conditions of temperature and pressure . 13

6 Quality control/quality assurance . 13

6.1 Quality control . 13

6.2 Quality assurance . 14

7 Report . 14

8 Performance requirements and measurement uncertainty . 15

Annex A (informative) Tube-type samplers . 16

A.1 Sampler design . 16

A.2 Extraction and analysis . 16

A.3 Application range and conditions . 16

Annex B (informative) Badge-type samplers . 18

B.1 Type 1 badge-type sampler . 18

B.2 Type 2 badge-type sampler . 20

B.3 Type 3 badge-type sampler . 23

B.4 Type 4 badge-type sampler . 25

Annex C (informative) Radial samplers . 29

C.1 Sampler design . 29

C.2 Extraction and analysis . 30

C.3 Application range and conditions . 31

Annex D (informative) Summary of passive diffusive sampling rate data . 32

Annex E (normative) Estimation of the sampling rate of the samplers . 33

Annex F (informative) Measurement uncertainty calculation . 35

F.1 Measurement equation . 35

F.2 Combined standard uncertainty . 35

F.3 Expanded relative uncertainty . 36

F.4 Uncertainty contributions . 36

Bibliography . 41

European foreword

This document (EN 17346:2020) has been prepared by Technical Committee CEN/TC 264 “Air quality”,

the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2020, and conflicting national standards shall

be withdrawn at the latest by November 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Atmospheric ammonia (NH ) is a pollutant of major environmental concern with adverse effects on

forests, species composition of semi-natural ecosystems and soils [1-4]. Emission and deposition of NH

can contribute significantly to total nitrogen deposition to the environment, contributing to

eutrophication (nutrient enrichment) and acidification (oxidation of NH to nitrate resulting in release of

+

H ions) of land and freshwaters, leading to a reduction in both soil and water quality, loss of biodiversity

and ecosystem change [5-10].

In addition to these effects, NH3 is the major precursor for neutralization of atmospheric acids, affecting

the long-range transport distance of both SO and NO and leading to the formation of secondary particles

2 x

(primarily ammonium sulphate and ammonium nitrate) [11-13]. These particles have multiple impacts

including effects on atmospheric visibility, radiative scattering (and the greenhouse effect) and on human

health.

The recognition of NH as an important air pollutant led to its inclusion in international agreements to

reduce air pollutant emissions, first under the 1999 UNECE Gothenburg Protocol and then the National

Emissions Ceilings Directive (NECD) (2001/81/EC) of the EU. The target of both these agreements is that

NH emissions should not exceed emission ceilings set for EU member states, with a particular focus on

reducing the extent of critical loads exceedance for acidification and eutrophication effects. Revision of

the Gothenburg Protocol (2012) and the NEC Directive (2016) include new, more stringent emission

ceilings for 2020 that seek more environmental protection and improvement in air quality than has so

far been committed, including the introduction of an emissions ceiling for particulate matter (PM). Under

the 2012 UNECE Gothenburg Protocol, EU member states have to jointly cut their emissions of NH by

6 % and particles by 22 % between 2005 and 2020. As a precursor of PM, controlling NH is important to

reducing particle emissions of PM and PM . A recent study employing three chemical transport models

2,5 10

found that the models underestimated the formation of ammonium particles and concluded that the role

of NH on PM is larger than originally thought [14]. Thus the implementation of 2020 targets detailed

above may not be enough to deliver compliance with proposed particle limit values, and further local

measures may be required to be compliant.

Other legislations to abate NH emissions include the Industrial Emissions Directive (IED) (2010/75/EU)

which requires pig and poultry farms (above stated size thresholds) to reduce emissions using Best

Available Techniques. For the protection of vegetation and ecosystems, new revised “Critical Levels” (CL)

3 3

of NH concentrations were adopted in 2007 (see Table 1), of 1 µg/m and 3 µg/m annual mean for the

protection of lichens/bryophytes and higher plants under field conditions, respectively, which replaced

3 3

the previous CL annual mean value of 8 µg/m . A monthly critical level of 23 µg /m was retained as a

provisional value in order to deal with the possibility of high peak emissions during periods of manure

application (e.g. in spring) ([15]). In Germany, the recommended exposure limit for the protection of

ecosystems is 10 µg/m (TA Luft, Annex 1, [16]).

Table 1 — Summary of upper limits of NH concentrations for protection of ecosystems under

field conditions

Concentration Specification Types of locality

(µg/m )

1 UNECE Critical Level (annual mean) for Sensitive ecosystems in

lower plants (lichens, bryophytes) which the lichens and

bryophytes are important

components, e.g. designated

sites for nature

conservation and protection

of sensitive species, e.g.

Natura 2000 sites

3 UNECE Critical Level (annual mean) for Sensitive ecosystems in

higher plants which the higher plants are

important components, e.g.

designated sites for nature

conservation and protection

of sensitive species, e.g.

Natura 2000 sites

10 German First General Administrative Near installations

Regulation Pertaining the Federal

Immission Control Act Maximum near

installations where ecological

monitoring undertaken.

23 UNECE critical level (monthly mean) – for In close proximity to

peak emission periods such as in months emission sources

where slurry spreading takes place.

Improving knowledge on levels of NH in the ambient air and near sources is therefore important for the

assessment of:

— environmental effects on ecosystems (Contribution to eutrophication and acidification processes);

— contributions to the formation of PM and PM ;

10 2,5

— effectiveness of current and future abatement measures to reduce NH emissions.

The simplest to the latest state-of–the-art techniques for measurement of atmospheric NH are presented

in Table 2.

Table 2 — Measurement methods suitable for determination of atmospheric NH gas and

ammonium particle concentrations

Monitoring Methods Time resolution References

Integrative methods: passive

Passive diffusion samplers daily to monthly [17]

[18]

[19]

[20]

Integrative methods: active

Simple denuder systems with offline chemical analysis daily to monthly [17]

[19]

[21]

Annular denuder systems (ADS) with offline chemical hourly to daily [22]

analysis

Conditional sampling with denuders at different heights weekly to monthly [23]

(COTAG)

Continuous: wet chemistry methods

Annular Denuder Systems with online analysis hourly or better [24]

depending on set-

Membrane stripping with online analysis

up

Steam Jet Aerosol Collector Systems for gas and aerosol hourly or better [25]

depending on set-

[26]

up

Continuous: optical methods

Differential Optical Absorption Spectrometry (DOAS) hourly or better [27]

depending on set-

up

Tunable Diode Laser Absorption Spectrometry and hourly or better [28]

Quantum Cascade Laser (TDL and QCL AS, respectively) depending on set-

up

Photoacoustic spectrometry hourly or better [29]

depending on set-

up

Chemiluminescence with catalytic conversion hourly or better [30]

depending on set-

up

Integrative atmospheric sampling methods such as passive diffusion samplers and active samplers

provide measurement of concentrations of NH averaged over the chosen sampling time. The diffusive

samplers used include those that are available commercially and those that have been developed in-

house by organisations to meet specific research requirements. A full validation of diffusive sampling

methods for NH in accordance with the European Standard (EN 13528-2 [31]) would be costly and

would also require specialist facilities only available at well-equipped large metrological institutes.

Validation of the quantitative measurement of NH through comparison with “reference” methods is

problematic for NH as there is no currently accepted and defined reference method. Automatic

continuous analysers for NH , employing spectroscopic or other techniques (Table 2) are available

commercially, but there is a lack of robust published calibration data and procedures for reliable field

measurements under ambient concentrations and conditions [32].

1 Scope

This document specifies a method for the sampling and analysis of NH in ambient air using diffusive

sampling.

It can be used for NH measurements at ambient levels, but the concentration range and exposure time

are sampler dependent, and the end user is therefore advised to match the sampler type to the

measurement requirement and to follow the operating instructions provided by the manufacturer.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/ui

3.1

combined standard measurement uncertainty

combined standard uncertainty

standard measurement uncertainty that is obtained using the individual standard measurement

uncertainties associated with the input quantities in a measurement model

[SOURCE: JCGM 200:2012, 2.31] [33]

3.2

extraction efficiency

ratio of the mass of analyte extracted from a sampling device to that applied

3.3

diffusive sampler

device which is capable of taking samples of gases or vapours from the atmosphere at a rate controlled

by a physical process such as gaseous diffusion through a static air layer or a porous material and/or

permeation through a membrane, but which does not involve the active movement of air through the

device

Note 1 to entry: Active normally refers to the pumped movement of air.

[SOURCE: EN 13528-2:2002, 3.6] [31]

3.4

diffusive sampling rate

diffusive uptake rate

rate at which the diffusive sampler collects a particular gas or vapour from the atmosphere

3 3

Note 1 to entry: The sampling rate is usually expressed in units of (m /h), (ml/min) or (cm /min).

3 3 –8

Note 2 to entry: cm /min may be converted to SI units of m /s by factor 1,67 × 10 .

3.5

expanded measurement uncertainty

product of a combined standard measurement uncertainty and a factor larger than the number one

Note 1 to entry: The factor depends upon the type of probability distribution of the output quantity in a

measurement model and on the selected coverage probability.

Note 2 to entry: The term “factor” in this definition refers to a coverage factor.

[SOURCE: JCGM 200:2012, 2.35]

3.6

field blank

unused sampler, taken from the same batch used for NH monitoring, handled in the same way as a

sampler that is used for NH monitoring, except it is not used for collecting a sample

Note 1 to entry: Adapted from EN 14902:2005, 3.1.6.

Note 2 to entry: The results from the analysis of field blanks are used to identify contamination of the sample

arising from handling in the field and during transport.

[SOURCE: EN 1540:2011, 3.3.8] [34]

Note 3 to entry: A transport blank is considered to be a special case of a field blank. A transport blank is taken to

the exposure site, left unopened and returned to the laboratory immediately after placement or collection of the

samplers. Transport blanks may be used when regular field blanks reveal an unacceptable level of ammonium to

investigate the possibility of contamination of samplers during transport. This blank is only used for quality control

purposes.

3.7

laboratory blank

sealed sampler drawn from the same batch as the samplers being used for NH monitoring which is stored

for the duration of the sampling period and is analysed at the same time as the exposed samplers

3.8

measurement uncertainty

uncertainty of measurement

non-negative parameter characterizing the dispersion of the quantity values being attributed to a

measurand, based on the information used

Note 1 to entry: For notes to the definition the reader is referred to the parent document JCGM 200:2012.

[SOURCE: JCGM 200:2012, 2.26]

3.9

standard measurement uncertainty

standard uncertainty

measurement uncertainty expressed as a standard deviation

[SOURCE: JCGM 200:2012, 2.30]

4 Description of samplers

4.1 Principle

The diffusive sampler is exposed in air for a measured time period. NH migrates through the sampler

along a diffusion path of defined dimensions and is collected by reaction onto an acid sorbent.

Determining the sampling rate is essential when deploying diffusive NH samplers in the field, either by:

— calculation based on Fick’s first law of diffusion (see EN 13528-3 [35] and Annex E),

— calibration by exposure to standard atmospheres, or

— co-located calibration studies against another well characterized NH measurement method in the

field.

NOTE Denuders can be used as a cost effective surrogate reference method until there are improvements in

the continuous optical methods.

Details of these approaches shall be documented.

Samplers can be provided with manufacturer measured sampling rates. Samplers in networks often have

on-going measurements of sampling rates. Users can calculate a locally derived sampling rate. Sampling

rates are also documented in literature [see [36], and Annex D].

The sampling rate in the field is a function of local meteorology. Samplers can be deployed with protective

shelters to minimize meteorological influences. When doing so, the user shall apply a suitable protocol to

ensure a consistent approach for all samplers. Ideally, the effect of the shelter on the sampler

performance should be characterized.

4.2 Implementation

Samplers shall be sealed and stored under cool conditions, for example at temperatures between 0 °C and

4 °C, in the dark, in order to minimize any undesired reactions before and after deployment. After

deployment, samplers shall be analysed as soon as possible, according to manufacturer’s specifications.

Disposable gloves shall be worn at all times, including during deployment in the field. This serves to

protect the samples from contamination by contact with the skin. It is also advised to avoid breathing

directly on the samples, as exhaled breath contains NH .

Since there are different sampler designs, each common sampler type is briefly described below.

4.3 Tube-type samplers

The tube-type samplers are hollow cylindrical tubes oriented vertically. A cap at the top end holds in

place either a cellulose filter paper, glass fibre filter or stainless steel grid, which is coated with a sorbent

that collects the gas of interest. This type of sampler is characterized by a high length to cross sectional

area ratio [15, 37]. To collect NH , sorbents used include citric, phosphoric, phosphorous, sulphuric and

tartaric acid [38]. The analysis is carried out using various methods including ion chromatography, flow

injection analysis with detection of conductivity and spectrophotometry.

There is one commonly used design of tube type samplers, the 3,5 cm short membrane diffusion tube.

For more information, see Annex A.

4.4 Badge-type samplers

The badge-type samplers have a lower length to area ratio of the sample body, with enhanced sensitivity

over the tube-type samplers [15, 37]. There are many badge-type samplers in use with different

geometry. Due to the short diffusion path length, they have a gas permeable barrier at the inlet to prevent

wind-induced turbulent diffusion (wind shortening effect on sampling rate). The sorbents used to collect

ammonia are the same as employed with tube-type samplers, and the following analytical assessment is

performed by using the same techniques.

For more information, see Annex B.

4.5 Radial samplers

The radial-type sampler has a cylindrical outer surface that acts as a permeation barrier through which

NH diffuses [39]. NH molecules move axially parallel towards an absorbent bed that is also cylindrical

3 3

and coaxial to the diffusive surface. This type of sampler uses phosphoric acid as a sorbent. Exposed

samplers are analysed using various methods, including spectrophotometry, and ion chromatography.

For more information, see Annex C.

5 Calculation of the concentration of NH

5.1 Mass concentration

The concentration of NH in ambient air under actual conditions of sampling is calculated using

Formula (1):

M

mm−

NH

3 sb

c= .

M e⋅⋅υ t

+

NH

(1)

where

c is the concentration of NH at ambient conditions in µg/m ;

is the molar mass of NH in g/mol;

M 3

NH

+

is the molar mass of NH in g/mol;

M 4

+

NH

m is the mass of ammonium found in the sample in µg;

s

m is the mass of ammonium found in the mean laboratory blank in µg;

b

NOTE 1 In normal operations the transport and field blanks are expected to record similar masses of

ammonium compared to the laboratory blank. In cases where the transport and/or field blank is higher than

the laboratory blank the transport or field blank can be used for the subtraction. This information needs to be

clearly documented.

υ 3

is the sampling rate at ambient conditions during sampling in m /h;

e is the efficiency of extraction of ammonium;

NOTE 2 It is not necessary to include the efficiency of extraction of ammonium if this efficiency is shown not

be significantly different from 100 % or if it is already included into the estimation of the sampling rate.

t is the sampling time in h.

NOTE 3 The sampling rate can be in µg/(nmol/mol)/min, in which case c is expressed in units of nmol/mol.

5.2 Conversion to standard conditions of temperature and pressure

The mass concentration of NH in air is calculated at the ambient temperature and pressure during

exposure using Formula (1). This mass concentration shall be referred to at standard conditions of

temperature and pressure, as required in Directive 2008/50/EC [40] and defined e.g. by EN 16339 [41],

using Formula (2):

T 101,3

cc=⋅⋅

STP

293 P

(2)

where

c is the concentration of NH at standard temperature and pressure in µg/m ;

STP 3

c is the concentration of NH at ambient conditions in µg/m ;

T is the average temperature during exposure in K;

P is the average pressure during exposure in kPa.

NOTE Temperature and pressure data can be obtained from nearby meteorological stations.

6 Quality control/quality assurance

6.1 Quality control

For each series of analyses, the following control checks shall be performed and recorded:

a) inspection of each sampler before and after exposure, reject those with visible damage or

contamination and record this information in the report;

b) analysis for each batch of samplers, field blanks, transport blanks and/or laboratory blanks to detect

contamination of samplers during transport, in the field and during subsequent storage and

handling;

c) analysis of calibration solutions to determine instrument drift and appropriate re-calibration at

regular intervals, e.g. at the start of each day . If a check of the calibration response is outside the

expected performance criteria of the instrument, then a further investigation is required to

demonstrate that it is functioning correctly.

NOTE For a linear calibration curve, a check can be carried out using at least 3 points (zero, 50 % of calibration

range and full scale).

At regular intervals, the following control checks shall be performed and registered:

d) analysis of reagent solutions to determine variations of reagent blank levels;

e) determination of extraction efficiency by spiking coated samplers with known masses of ammonium

followed by the determination of their recoveries;

f) duplicate analysis of sample extracts to check analytical repeatability;

g) analysis of samples taken in parallel at one field site to check reproducibility;

h) checking the sensitivity of the analytical method used (e.g. the slope of the calibration curve). For

routine NH monitoring with diffusive samplers, it is necessary to complement with other quality

control checks (e.g. instrument drift) that will ensure proper analysis over time;

i) for new samplers and any re-used components of diffusive samplers, employment of a protocol to

check for the absence of ammonium.

Corrective actions shall be taken in case of exceedance of internal quality control limits set by the user, in

order to ensure the quality of the NH measurement results, and in accordance with the QA/QC

procedures of the laboratory.

6.2 Quality assurance

A competent body (or bodies) shall perform the method. The competent body (or bodies) performing the

method shall be able to demonstrate that work is in conformity with the requirements of internationally

accepted standards for test laboratories.

NOTE 1 EN ISO/IEC 17025 [42] is the harmonized internationally accepted standard that applies.

NOTE 2 A formal accreditation by a member body of the European Accreditation Organization to

EN ISO/IEC 17025 is a demonstration of conformity.

7 Report

The test report shall contain at least the following information:

— the type of sampler used;

— the complete identification of the sampler(s);

— the sampling location(s), and sampling period(s);

— the average barometric pressure and average temperature during sampling, if relevant;

NOTE 1 The average barometric pressure and temperature can be obtained from available data from nearby

meteorological stations.

— any unusual features noted during the measurements;

— the value(s) of the NH sampling rate(s) used with uncertainty statement and reference;

— the method of analysis used;

— the analytical results;

— the NH concentrations determined accompanied by an uncertainty statement;

— any deviations from procedures described in this European Standard;

— the responsible person checking the analysis, the calculation of the test results and their

uncertainties shall be identified.

NOTE 2 Any other metadata such as personnel involved in deployment and analysis can be included.

Information about the following items needs not to be included in the report but shall be made available

upon request:

— the date of preparation and method of preparation of the sampler; or, if commercial samplers are

used, the identification code of the series of samplers;

— results for field/transport blanks;

— sampling height.

8 Performance requirements and measurement uncertainty

The parameters given in Table 3 have been identified to contribute to the uncertainty of concentrations

of NH measured by diffusive sampling and subsequent analysis.

Table 3 — Uncertainty parameters and minimum requirements for a single exposure period for

diffusive samplers

Uncertainty source Symbol Criterion

Volume of air sampled

Sampling rate υ Relative uncertainty ≤ 10 %

Sampling time t Relative uncertainty ≤ 0,2 %

Average air temperature during T Relative uncertainty ≤ 2 %

exposure for conversion to

standard temperature and

pressure

Average air pressure during P Relative uncertainty ≤ 2 %

exposure for conversion to

standard temperature and

pressure

Mass of ammonium determined

Extraction efficiency E Is included in the effective sampling rate, or

when calculated separately the relative

uncertainty shall be ≤ 5 %

Concentration in calibration m Relative uncertainty ≤ 3 %, excluding zero

CS

standards concentration

Lack-of-fit of calibration function δ Relative residuals over the calibration

i

range ≤ 2 %, excluding zero

Response drift between D ≤ 5 %

calibrations

Analytical repeatability R ≤ 5 %

A recent laboratory study showed that the expanded uncertainty of tube-type and badge-type samplers

is within the range of 10-12 %, whereas the expanded uncertainty of radial-type samplers is within the

range of 15-23 %, for 1-23 µg/m . The tube-type and badge-type samplers were exposed for 4 weeks,

while the radial-type samplers were exposed for 2 weeks [36].

For the expanded uncertainty of Ferm-type samplers, see VDI 3869-4 [43].

Annex A

(informative)

Tube-type samplers

A.1 Sampler design

There is one commonly used design of tube-type samplers, the 3,5 cm short membrane diffusion tube,

see Figure A.1.

Figure A.1 — Tube-type sampler

The tube-type sampler is a hollow cylindrical tube oriented vertically. A cap at the top end holds in place

either a filter paper or stainless steel grid, which is coated with an absorbent that collects the gas of

interest. For NH sampling, a number of acids have been used, including citric, phosphoric, phosphorous,

sulphuric and tartaric acid [44]. The lower end of the tube is capped with a membrane [45].

The tube-type sampler has a gas permeable membrane placed at the inlet to establish a turbulent free

layer of air inside the sampler [46]. The membrane does however impose an additional resistance against

gas diffusion, which should be taken into account when deriving a sampler’s effective sampling rate.

A.2 Extraction and analysis

Acid impregnated grids in diffusion tubes are usually extracted into ultrapure water [47] and analysed

using an ion chromatographic method, and this method of analysis is available from commercial

laboratories. Other laboratories use different techniques, for example, Sutton et al. [18] used flow

injection analysis method with detection of conductivity ([48]).

A.3 Application range and conditions

The application range and conditions recommended for use by manufacturers or by researchers are

summarized below in Table A.1.

Table A.1 — Performance data of tube-type sampler

Value(s)

Sampling rate 2,5 to 3,5 ml/min

Working range 1 – 35 µg/m

Sampling period Weekly – 8 weeks

Detection limit Approximately 1,5 µg/m for 4 week

exposure

External influences: Influence of wind speed < 10 % up to

4,5 m/s using protection shelters

wind speed

T: no influence between 10 – 30 °C

temperature

RH: no influence between 20 – 80 %

relative humidity

Storage Before use: 8 weeks from preparation

Interferences Potential volatile aerosol particles

+

containing NH on the permeable

membrane. Avoided by removing

membrane after sampling and sealing

the inlet with a clean cap

Expanded uncertainty 12 % at 1 μg/m level, laboratory

conditions

More detailed information is available in [49].

Annex B

(informative)

Badge-type samplers

B.1 Type 1 badge-type sampler

B.1.1 Sampler design

The type 1 badge-type sampler collects NH molecules onto an absorbent material impregnated with

phosphoric acid. Thus, NH is trapped as ammonium phosphate on the absorbent material. A schematic

of the sampler is shown in Figure B.1. It consists of a polypropylene housing (sampler case) with an inner

diameter of 23 mm and a length of 20 mm. The opening is equipped with a wind protection (glass fibre

and steel screen) to reduce the effect of wind on the sampling rate. In addition, the samplers should be

installed in a protective shelter to minimize the effects from the environmental factors (e.g. wind, rain,

sunlight, etc.), see Figure B.2.

Key

1 cap

2 glass fibre

3 steel screen

4 sampler case

5 fixed cap

Figure B.1 — Schematic of type 1 badge-type sampler

Figure B.2 — Protective shelter for sampler (left) and mounting sampler with clips (right)

B.1.2 Extraction and analysis

By reaction with phenol and alkaline sodium hypochlorite indophenol is produced, a blue dye. The

reaction is accelerated by the addition of sodium nitroprusside as a catalyst. Two types of solution may

be used:

— solution I: 10 g of phenol, 50 mg of sodium nitroprusside, made up to 1 l with ultrapure water;

— solution II: 5 g sodium hydroxide, 4,2 ml sodium hypochlorite (12 % available chlorine) made up to

1 l with ultrapure water (resistivity greater or equal to 18 MΩ·cm at 298 K).

The glass fibre filter is removed from the sampler and transferred to a 10 ml polypropylene tube. 2,0 ml

of water is added and thoroughly shaken by a vortex. Hereafter, 1,0 ml of reagent I and 1,0 ml of reagent

2 are added. After 30 min of colour development, the sample is centrifuged and the absorption of the

colour is measured spectrophotometrically at 630 nm.

B.1.3 Application range and conditions

Table B.1 — Performance data of type 1 badge-type sampler

Parameter Value(s)

Sampling rate 31,5 ml/min at 20 °C

Working range 0,5 – 30 µg/m

Sampling period 2 – 4 weeks

Detection limit 0,2 µg/m for a one month exposure period

External influences: Influence of wind speed < 10 % up to 4,5 m/s

using protection shelters

Wind speed

No influence between 10 to 30 °C

Temperature

No influence between 20 to 80 %

Humidity

Storage Before use: 6 months

After exposure: 4 months

Interferences Ammonium particles are not collected

Expanded uncertainty 29,3 % at a 1 to 5 μg/m level

B.2 Type 2 badge-type sampler

B.2.1 Sampler design

The type 2 badge-type diffusive sampler [46] (Figure B.3) is made up of a circular polyethylene vial

(26 mm height, 27 mm diameter) with one open end. An internal ridge (G, 17 mm height) supports a filter

(F, 24 mm diameter). The filter is coated with an acid such as citric acid, which serves to capture the NH ,

and is held in place with a polyethylene ring (E, 6 mm height). The open end is capped with a polyethylene

cap with a hole punched out in the centre (D, 23 mm diameter), which holds in place a white PTFE

(polytetrafluoroethylene (PTFE)) membrane (C, 27 mm diameter, 5 µm pore size) allowing gaseous NH

to diffuse through. This end is positioned facing downwards. The membrane-cap end of the sampler is

sealed with a top protective cap (B), which is removed prior to exposure. At the end of exposure, the

membrane cap plus membrane are removed and replaced with a replacement solid cap (A).

Key

A replacement solid cap F filter paper

B top protective cap G internal ridge to support filter paper

C 5 µm PTFE membrane (27 mm diameter) H extended body for ease of handling

D cap with hole for membrane I Velcro® for attachment to holder

E support ring (6 mm height)

Figure B.3 — Schematic view of type 2 badge-type sampler

The type 2 badge-type sampler geometry permits an optimized sampling rate for long-term sampling (1-

2 months) plus high sensitivity to allow measurements down to low concentrations (<1 µg/m NH ) in

background areas. The membrane inlet is placed directly at the mouth of the sampler, which minimizes

the formation of a boundary layer in front of the membrane, whilst achieving a stable, turbulent-free

diffusion path length behind the membrane.

To make handling easier, the sampler body was extended behind the coated filter. The PTFE membrane

and membrane cap are removed at end of exposure and sampler capped with replacement cap provided.

Velcro® is the trade name or trademark of a product. This information is given for the convenience of users of

this European Standard and does not constitute an endorsement by CEN of the product named. Equivalent

products may be used if they can be shown to lead to the same results.

This serves to avoid potential contamination arising from possible volatilisation of volatile ammonium

salts on the outside of the PTFE membrane during exposure.

B.2.2 Extraction and analysis

B.2.2.1 General

Exposed samples are stored at 4 °C until analysis. In order to avoid potential contamination during the

extraction process, care should be taken in handling the type 2 badge-type samplers and components.

B.2.2.2 Extraction of acid coated filter paper

The following steps are used for analyte extraction:

1) using forceps, lift the plastic retainer ring out of the type 2 badge-type sampler.

2) place the open end of the type 2 badge-type sampler over a 20 ml pot (or other suitable container)

and tap the sampler very gently against the pot until the coated filter paper drops out into the pot. If

the paper does not drop out, then use a pair of clean forceps and remove the coated filter paper very

carefully.

3) add 3 ml deionised water to the filter paper in the pot. Cap the pot with a clean cap, label with sample

name and leave to extract for at least one hour. Repeat this extraction with all of the samples

(including a suitable number of type 2 badge-type sampler blanks), noting the time at which the

extraction process commenced.

4) using a pair of clean forceps (rinse the forceps with deionised water in between different samples),

pinch an edge of the filter paper and dunk it up and down in the extractant a few times to ensure that

all the chemical species of interest enters into the extractant, and that the solution is well mixed.

5) for analysis using flow injection systems, 1,5 ml of extracted solution is decanted into 3 ml

autosampler tubes. Care should be taken to ensure that any bits of loose fibres coming off the filter

paper are not decanted into the autosampler tubes, which may cause blockage.

B.2.2.3 Analysis of ammonium

B.2.2.3.1 Flow Injection Conductivity Ammonium Analysers

The extracted samples are analysed using a system based on selective dialysis of ammonium across a

membrane at high pH with subsequent analysis of conductivity (see Figure B.4). The calibration range

normally used is 0 - 10 mg/l (0,1 mg/l, 1 mg/l and 10 mg/l calibration standards), and the calibration

concentrations used are 0,2 mg/l (low range), 0,9 mg/l (high range), 2 (low range) and 9 mg/l (high

range). It may be necessary to dilute the extracted samples and repeat the analysis if they are outside the

calibration range.

Measuring characteristics:

— dynamic range 5 – 30 000 µg/l;

— resolution 5 µg/l;

— accuracy 5 %.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...