EN 12921-1:2005

(Main)Machines for surface cleaning and pre-treatment of industrial items using liquids or vapours - Part 1: Common safety requirements

Machines for surface cleaning and pre-treatment of industrial items using liquids or vapours - Part 1: Common safety requirements

1.1 This standard applies to machines for surface cleaning and pre-treatment - in the following called "cleaning machines" - of industrial items using liquids or vapours, i. e. stationary machines and related equipment for automated and manual cleaning and pre-treatment processes.

NOTE Cleaning machines are operated with or without heating, for example as dipping or spraying or vapour condensation process, where additional using of ultrasound is possible. These cleaning machines could be designed as single-zone or multi-zone machine, chamber machines, drum cleaning machine, low lift truck machines, round time machines or tunnel (continuous) machines.

To the extent of this document, cleaning machines for industrial items are considered as an assembly of the following equipment:

¾ pump(s) and/or other mechanical system of agitation, recirculation and spraying of cleaning liquid;

¾ forced ventilation system;

¾ heating system with temperature control;

¾ condensation system;

¾ filtration and separation system and/or solid particles extraction from the liquid;

¾ conveyor and/or handling system for the items to be processed;

¾ product handling systems and reciprocators which are part of the cleaning machine;

¾ control and/or monitoring systems;

¾ liquid handling system.

1.2 This standard deals with the common significant hazards, hazardous situations and events relevant to cleaning machines for industrial items using liquids or vapours when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of cleaning machines for industrial items using liquids or vapours and related common devices and should be used in connection with other parts of the prEN 12921-series. The specific requirements specified in part 2 and following parts of prEN 12921 take precedence over the respective requirements in prEN 12921.

NOTE In addition, where a cleaning mac

Maschinen zur Oberflächenreinigung und -vorbehandlung von industriellen Produkten mittels Flüssigkeiten oder Dampfphasen - Teil 1: Allgemeine Sicherheitsanforderungen

Diese Norm behandelt alle signifikanten Gefährdungen, die auf Anlagen zur Oberflächenreinigung und -vorbehandlung von industriellen Produkten zutreffen, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden. Diese Norm gilt für alle neuen Anlagen und deren Ausrüstung, die zum Reinigen und zur Vorbehandlung von Oberflächen von industriellen Produkten verwendet werden sollen, d.h. für folgende Prozesse: Anlagen, in denen wäßrige Reinigungsflüssigkeiten verwendet werden; Anlagen, in denen brennbare Flüssigkeiten verwendet werden.

Machines de nettoyage et de pré-traitement de pièces industrielles utilisant des liquides ou des vapeurs - Partie 1 : Prescriptions générales de sécurité

1.1 La présente norme s'applique aux machines de nettoyage et de pré-traitement - ci-après désignées "machines de nettoyage" - de pièces industrielles utilisant des liquides ou des vapeurs, c'est-à-dire les machines fixes et les équipements annexes destinés à être utilisés pour des procédés de nettoyage et de pré traitement automatisés et manuels.

NOTE Les machines de nettoyage fonctionnent avec ou sans chauffage, par exemple, par procédé d'immersion, de pulvérisation ou de condensation de vapeur, où l'utilisation supplémentaire d'ultrasons est possible. Lesdites machines de nettoyage peuvent être conçues comme des machines à une seule zone ou à zones multiples, des machines à compartiment, des machines de nettoyage à tambour, des machines de type chariot élévateur à petite levée, des machines de type "round time" ou des machines tunnel (continues).

Dans le contexte du présent document, les machines de nettoyage pour pièces industrielles sont considérées comme des assemblages constitués des équipements suivants :

- pompe(s) et/ou autre système mécanique d'agitation, de recyclage et de pulvérisation du liquide de nettoyage ;

- système de ventilation forcée ;

- système de chauffage avec régulation de la température ;

- système de condensation ;

- système de filtration et de séparation et/ou extraction de particules solides du liquide ;

- transporteur et/ou système de manutention pour les pièces à traiter ;

- systèmes de manutention de produits et réciprocateurs faisant partie intégrante de la machine de nettoyage ;

- systèmes de commande et/ou de surveillance ;

- système de manutention du liquide

Naprave za površinsko čiščenje in predobdelavo industrijskih proizvodov s pomočjo tekočin ali par - 1. del: Splošne varnostne zahteve

General Information

- Status

- Withdrawn

- Publication Date

- 17-May-2005

- Withdrawal Date

- 25-May-2010

- Technical Committee

- CEN/TC 271 - Surface treatment equipment - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-May-2010

- Completion Date

- 26-May-2010

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 12921-1:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Machines for surface cleaning and pre-treatment of industrial items using liquids or vapours - Part 1: Common safety requirements". This standard covers: 1.1 This standard applies to machines for surface cleaning and pre-treatment - in the following called "cleaning machines" - of industrial items using liquids or vapours, i. e. stationary machines and related equipment for automated and manual cleaning and pre-treatment processes. NOTE Cleaning machines are operated with or without heating, for example as dipping or spraying or vapour condensation process, where additional using of ultrasound is possible. These cleaning machines could be designed as single-zone or multi-zone machine, chamber machines, drum cleaning machine, low lift truck machines, round time machines or tunnel (continuous) machines. To the extent of this document, cleaning machines for industrial items are considered as an assembly of the following equipment: ¾ pump(s) and/or other mechanical system of agitation, recirculation and spraying of cleaning liquid; ¾ forced ventilation system; ¾ heating system with temperature control; ¾ condensation system; ¾ filtration and separation system and/or solid particles extraction from the liquid; ¾ conveyor and/or handling system for the items to be processed; ¾ product handling systems and reciprocators which are part of the cleaning machine; ¾ control and/or monitoring systems; ¾ liquid handling system. 1.2 This standard deals with the common significant hazards, hazardous situations and events relevant to cleaning machines for industrial items using liquids or vapours when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of cleaning machines for industrial items using liquids or vapours and related common devices and should be used in connection with other parts of the prEN 12921-series. The specific requirements specified in part 2 and following parts of prEN 12921 take precedence over the respective requirements in prEN 12921. NOTE In addition, where a cleaning mac

1.1 This standard applies to machines for surface cleaning and pre-treatment - in the following called "cleaning machines" - of industrial items using liquids or vapours, i. e. stationary machines and related equipment for automated and manual cleaning and pre-treatment processes. NOTE Cleaning machines are operated with or without heating, for example as dipping or spraying or vapour condensation process, where additional using of ultrasound is possible. These cleaning machines could be designed as single-zone or multi-zone machine, chamber machines, drum cleaning machine, low lift truck machines, round time machines or tunnel (continuous) machines. To the extent of this document, cleaning machines for industrial items are considered as an assembly of the following equipment: ¾ pump(s) and/or other mechanical system of agitation, recirculation and spraying of cleaning liquid; ¾ forced ventilation system; ¾ heating system with temperature control; ¾ condensation system; ¾ filtration and separation system and/or solid particles extraction from the liquid; ¾ conveyor and/or handling system for the items to be processed; ¾ product handling systems and reciprocators which are part of the cleaning machine; ¾ control and/or monitoring systems; ¾ liquid handling system. 1.2 This standard deals with the common significant hazards, hazardous situations and events relevant to cleaning machines for industrial items using liquids or vapours when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of cleaning machines for industrial items using liquids or vapours and related common devices and should be used in connection with other parts of the prEN 12921-series. The specific requirements specified in part 2 and following parts of prEN 12921 take precedence over the respective requirements in prEN 12921. NOTE In addition, where a cleaning mac

EN 12921-1:2005 is classified under the following ICS (International Classification for Standards) categories: 25.220.10 - Surface preparation; 25.220.20 - Surface treatment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12921-1:2005 has the following relationships with other standards: It is inter standard links to EN 12921-1:2005+A1:2010, EN 12921-3:2005+A1:2008, EN 12921-4:2005+A1:2008, EN ISO 389-9:2009, EN 12921-2:2005+A1:2008; is excused to EN 12921-2:2005, EN 12921-3:2005, EN 12921-4:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12921-1:2005 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/BC/CEN/88/13. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12921-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Maschinen zur Oberflächenreinigung und -vorbehandlung von industriellen Produkten mittels Flüssigkeiten oder Dampfphasen - Teil 1: Allgemeine SicherheitsanforderungenMachines de nettoyage et de pré-traitement de pieces industrielles utilisant des liquides ou des vapeurs - Partie 1 : Prescriptions générales de sécuritéMachines for surface cleaning and pre-treatment of industrial items using liquids or vapours - Part 1: Common safety requirements97.080Aparati za nego talFloor treatment appliancesICS:Ta slovenski standard je istoveten z:EN 12921-1:2005SIST EN 12921-1:2005en01-julij-2005SIST EN 12921-1:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12921-1May 2005ICS 25.220.10; 25.220.20English versionMachines for surface cleaning and pre-treatment of industrialitems using liquids or vapours - Part 1: Common safetyrequirementsMachines de nettoyage et de pré-traitement de piècesindustrielles utilisant des liquides ou des vapeurs - Partie 1: Prescriptions générales de sécuritéMaschinen zur Oberflächenreinigung und -vorbehandlungvon industriellen Produkten mittels Flüssigkeiten oderDampffasen - Teil 1: Allgemeine SicherheitsanforderungenThis European Standard was approved by CEN on 24 March 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12921-1:2005: ESIST EN 12921-1:2005

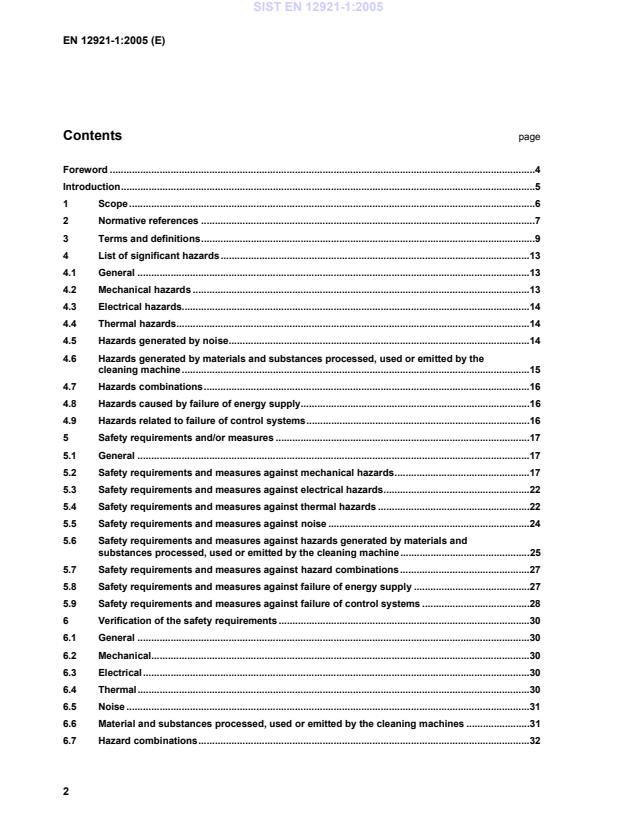

National references to exposure limit values.37 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.38 Bibliography.39

Although a cleaning machine, as an integral whole, formally does not fall under the scope of the ATEX Directive 94/9/EC, the standard is based upon a fundamental risk analysis according to this directive. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom. SIST EN 12921-1:2005

When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard. This European Standard consists of the following parts: Part 1: Common safety requirements Part 2: Safety of machines using water based cleaning liquids Part 3: Safety of machines using flammable cleaning liquids Part 4: Safety of machines using halogenated solvents SIST EN 12921-1:2005

1 Scope 1.1 This standardapplies to machines for surface cleaning and pre-treatment – in the following called "cleaning machines" – of industrial items using liquids or vapours, i. e. stationary machines and related equipment for automated and manual cleaning and pre-treatment processes. NOTE

Cleaning machines are operated with or without heating, for example as dipping or spraying or vapour condensation process, where additional using of ultrasound is possible. These cleaning machines could be designed as single-zone or multi-zone machine, chamber machines, drum cleaning machine, low lift truck machines, round time machines or tunnel (continuous) machines. To the extent of this document, cleaning machines for industrial items are considered as an assembly of the following equipment: pump(s) and/or other mechanical system of agitation, recirculation and spraying of cleaning liquid; forced ventilation system; heating system with temperature control; condensation system; filtration and separation system and/or solid particles extraction from the liquid; conveyor and/or handling system for the items to be processed; product handling systems and reciprocators which are part of the cleaning machine; control and/or monitoring systems; liquid handling system. 1.2 This European Standard deals with the common significant hazards, hazardous situations and events relevant to cleaning machines for industrial items using liquids or vapours when they are used as intended and under the conditions foreseen by the manufacturer (see clause 4). This part of the standard defines the common safety requirements for all kinds of cleaning machines for industrial items using liquids or vapours and related common devices and should be used in connection with other parts of the EN 12921-series. The specific requirements specified in part 2 and following parts of EN 12921 take precedence over the respective requirements in EN 12921. NOTE

In addition, where a cleaning machine is not covered by a specific part of this document, part 1 of EN 12921 can be used to establish the approach for dealing with the relevant risks. Specific hazards which are related to the type of cleaning liquid used are dealt with in the following documents: EN 12921-2 for water based cleaning liquids; EN 12921-3 for flammable cleaning liquids; prEN 12921-4 for halogenated solvents. 1.3 This standard is not applicable to: mobile portable cleaning; SIST EN 12921-1:2005

combination of machines and service equipment, working as one integrated production unit, subject to an overall control system 3.6 danger points defined locations in the danger zone of machines where persons can be injured by movements of parts of machines tools of machines or parts of tools items or parts of items materials being processed. NOTE

Danger points can exist, for example, on gear, chain and worm drives, V-belt, flat belt, pulling and supporting elements on continuous conveyors, spoke wheels and fly wheels, shafts and shaft ends, rollers, slides, push rods and similar parts, tools and clamping devices. Particular points of danger are: crushing and shearing points trapping points inrunning nips cutting, punching and impact points. 3.7 ESPD electro-sensitive protective device 3.8 flammable cleaning liquid liquid able to undergo an exothermic reaction with air when ignited NOTE

A liquid can only burn when the molecules of the liquid are in intimate contact with oxygen from the air. Ignition is possible when the liquid generates a concentration of vapour in air, or the flammable liquid is present as a suspension of fine droplets in air (aerosol). 3.9 forced ventilation air exchange achieved by fans or by other powered means which removes from the machines vapours, fumes, gases, mist, etc. 3.10 halogenated solvent organic solvent containing at least one halogen atom per molecule and not having a flash point as determined by standard methods SIST EN 12921-1:2005

These halogenated solvents used in industry generally contain a small quantity of stabilising agents (anti-acid, anti-oxidant, etc.). 3.11 heating system system fitted to the machine in order to raise the temperature of the cleaning liquid above the local ambient temperature 3.12 heat source any energy source in contact with the cleaning liquid which can lead to an increase of the temperature of the cleaning liquid NOTE

Heat sources are e. g.: heating system; ultrasonic waves; pumping energy; stored heat of items; mechanical agitation; heating from electrical conductors, motors heat caused by magnetic fields; refrigeration system; sunrays. 3.13 hold-to-run control device control device which initiates and maintains operation of machine elements only as long as the manual control (actuator) is actuated. The manual control (actuator) automatically returns to the stop position when released 3.14 immersion process

operation where the item to be cleaned is placed in a tank containing a cleaning liquid which comes into contact with the entire surface of the item in order to achieve the required result by dispersion of contaminants into the cleaning liquid 3.15 items

parts whose surfaces are treated in the cleaning machine NOTE

The word item is used for workpieces processed individually, or in bulk, or on jigs or in baskets. 3.16 liquid agitation machine machine for an immersion process where the cleaning liquid is moved by e. g.: pump(s) with adequate, submerged or not, nozzles, jets or inlet openings, propeller 3.17 maximum admissible cleaning liquid capacity maximum mass and volume of cleaning liquid which can be filled into the cleaning machine 3.18 maximum admissible design temperature maximum temperature value of the cleaning liquid the cleaning machine is designed for SIST EN 12921-1:2005

The surface pre-treatment process is applied to remove e. g. corrosive products, mill scale, burrs, as well as for generating conversions layers (non-metallic, frequently inorganic layers on metal surfaces). 3.28 thermal cut-off safety device which cuts off the heating system or any heat source in order to avoid over temperature 3.29 tunnel machine cleaning machine consisting of a housing for continuous movement of items to be processed with openings for feeding in and out items 3.30 turntable machine closed cleaning machine with a rotating platform for processing items SIST EN 12921-1:2005

Additional specific hazards are mentioned in EN 12921-2, EN 12921-3 and EN 12921-4. NOTE

Information on the method of risk analysis is given in EN 1050. 4.2 Mechanical hazards 4.2.1 Crushing, shearing, cutting, entanglement, drawing-in, impact These hazards may result from the mechanical interfaces of the following equipment especially with cleaning machines: moving parts (e. g. covers, doors, including conveyor systems e. g.: chain, belt and roller type); product handling system (e. g. hazards from inrunning nips); product handling systems and reciprocators which are part of the cleaning machine; fans and automatic damper adjusters (e. g. injuries caused by over-running of fan blades); automatic equipment or systems (e. g. power driven turntables for items, reciprocators). 4.2.2 High pressure fluid ejection These hazards are related to: overpressure; rupture of the piping or joints due to failure, breakdown, vibrations, corrosion. NOTE

The hazards under this sub-clause are of a mechanical nature, but the aggravating effects of the nature of the cleaning liquid should be considered. It is recommended to refer to 4.7. SIST EN 12921-1:2005

These hazards may occur, for instance, by fall of items while loading/unloading or during the process. NOTE

The hazards under this sub-clause are of a mechanical nature but the aggravating effects of the nature of the cleaning liquid should be considered. It is recommended to refer to 4.7. 4.2.4 Loss of stability (of cleaning machine and cleaning machine parts) These hazards are related to, e. g. improper positioning of the cleaning machine; overload; overfilling. NOTE

The hazards under this sub-clause are of a mechanical nature but the aggravating effects of the nature of the cleaning liquid should be considered. It is recommended to refer to 4.7. 4.2.5 Personnel's slip, trip and fall hazards Such hazards may occur, for instance, on gangways, platforms, ladders, stairs, gratings and excavations equipping the cleaning machines. 4.3 Electrical hazards These hazards are related to electrical shock (direct or indirect contact); external influences on electrical equipment (electromagnetic influences). 4.4 Thermal hazards These hazards resulting in burns and scalds are related to by e.g.: contact of skin with hot surfaces; radiation and/or convection of heat; overheating of the cleaning liquid. 4.5 Hazards generated by noise

Emission of airborne noise can cause hearing impairment, accidents due to interferences with verbal communication and acoustical danger signals, extra-auditory effects, shock-reactions. Such noise emissions can be generated by e. g.:

ultrasonic transducers; fans;

4.6.2 Hazards resulting from contact with/or inhalation of dangerous liquids, gases, vapours, aerosol, fumes and dusts caused by e.g. :

preparation of the cleaning liquid; cleaning liquid used in the cleaning machine during normal operation and maintenance; fumes and emissions generated by the surface cleaning and pre-treatment process; spillage of cleaning liquid generated by dripping off parts processed, condensation of cleaning liquids,

fault or breakdown and fumes and emissions arising from such spillage; fumes and emissions generated by chemical reaction; fumes and emissions generated by chemical decomposition. NOTE

See also 4.9. 4.6.3 Fire and explosion hazard 4.6.3.1 Fire hazard Fire hazards can be generated by, e. g.: ignition of flammable solvents inside the cleaning machine or in exhaust ducts; when the cleaning machine is in operation a misuse or mechanical or electrical defects can cause ignition of flammable solvents; in maintenance operations requiring use of cutting or welding tools, energy released can also initiate a combustion. The fast propagation of fire induces a risk for the neighbouring areas; ignition of cleaning rags containing solvents; SIST EN 12921-1:2005

Examples of ignition sources are: hot surfaces e. g. of heating systems and electrical equipment; sparks created by mechanically induced energy e. g. fans, conveyors, etc.; electrostatic discharges; electrical sparks; welding and other sources of thermal energy used during maintenance and cleaning. 4.6.3.2 Explosion hazard Explosion hazards can occur inside the cleaning machine when the concentration of the flammable substances in air exceeds the lower explosion limit (LEL) and if an effective ignition source is present. NOTE 1

Examples of sources of flammable substances which increase concentration above the normal: solvent vapours from the cleaning process inside the cleaning machine; solvent vapours from the flash off process;

gases released from deposits; products of chemical reaction or decomposition of the cleaning liquid; combustible heating gases; solvent vapours from any leakage from broken pipes or fittings; solvent vapours from recirculating process; cleaning liquid is contaminated by a liquid with a low flash point (e. g. when cleaning carburettors). NOTE 2

For examples of sources of ignition see Note of 4.6.3.1. 4.7 Hazards combinations Some individual hazards which seem to be minor may, when combined with each other lead to a risk which should be dealt with. A risk assessment shall be done in relation to the nature of the process, the cleaning liquid used and the material of items. 4.8 Hazards caused by failure of energy supply A risk assessment shall be done in relation to the nature of the process, the cleaning liquid used and/or the items material for instance against: failure of forced ventilation; unexpected ejection of cleaning machine parts or cleaning liquids; failure, malfunction of control system (unexpected start up, unexpected overrun, cooling system failure); items remaining in the cleaning machine. 4.9 Hazards related to failure of control systems These hazards may lead to: SIST EN 12921-1:2005

NOTE

Guards and doors are removed for "setting-up" purposes, for example: to supply items to be processed, to supply the cleaning liquid, for make-ready. Automatic travel of movable guards shall not create danger points. 5.2.1.4 Moving parts of the cleaning machine Access to power driven turntables, rotating baskets or container shall be prevented by fence-type enclosure or ESPD or be safeguarded in a way resulting in the same level of safety.

Access doors and openings for feeding items which are accessible by persons shall be interlocked with the dangerous movement. The travel when opening automatic powered doors if installed shall be guarded in such a way that the hazard from crushing between the door leaf and fixed adjacent machinery parts or walls is prevented. 5.2.1.5 Location of controls Safety, measuring and regulating devices shall be arranged such that easy access and replacement is possible and shall be protected against damage and contamination. Preferably the main control panel shall be located in such a way that all doors and openings which give access to the cleaning machine can be observed. Where a one-hand operated hold-to-run control is provided to prevent the operator from reaching dangerous moving parts, it shall be located in a way that it is not possible for the operator to reach hazardous moving parts. Provisions shall be made that hazardous movements can only be started from a control located in such a way that it is not reachable from the inside of a guarded area. An emergency stop control shall at least be located at the main control panel and at every designated control position. 5.2.1.6 Prevention against the hazard from close or fall of covers, lids and doors Guards, that can be opened (e. g. covers, lids and doors) shall be safeguarded against gravity falls or unintended or/and unexpected close if this creates a risk of injury.

This requirement can be achieved, e. g. by devices for balancing the weight, pneumatic spring, SIST EN 12921-1:2005

Hold-to-run control devices shall have a displacement limited to a maximum of 75 mm or with a maximum operating speed of 5 m/min. For the application of hold-to-run devices designed as two-hand control device, the same limitations of displacement and operating speed shall apply. The movement shall come to a stop in a time that, taking into consideration the hand approach speed, ensures there is no danger for the operator. The hand approach speeds specified in EN 999 shall be taken as a basis.

Where hold-to-run controls are being used to allow safe control of hazardous movements, starting the cleaning machine in the hold-to-run mode, after opening the interlocking guard, shall only be possible when other interlocking guards outside the area that can be observed by the operator are closed. 5.2.2 Safety measures against high pressure fluid ejection 5.2.2.1 General Cleaning machines and their parts shall be designed and constructed in such a way that ejection of a cleaning liquid at a pressure which can cause harm cannot occur in normal operation and maintenance. Hydraulic power systems and components shall comply with EN 982. Pneumatic power systems and components shall comply with EN 983. These requirements shall be fulfilled by: Adequate design of all parts under pressure; Guards and protection according to EN 953; A means of isolating parts under pressure if the rest of the cleaning machine is depressurised (see 5.2.2.2). SIST EN 12921-1:2005

5.2.4 Safety measures regarding mass and stability and inadequacy of mechanical strength 5.2.4.1 General The design shall take into consideration the mass and volume of the stored cleaning liquid and prevent any leakage of dangerous cleaning liquids. Cleaning machines and their parts shall be designed, constructed and installed so that their stability shall be ensured. NOTE

Permanent excessive deformation can lead to leakage. 5.2.4.2 Positioning of the cleaning machine Cleaning machines shall be designed and equipped in such a way that they are stable. The requirements of EN ISO 12100-2 shall be satisfied. SIST EN 12921-1:2005

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...