EN 13108-31:2019

(Main)Bituminous mixtures - Material specifications - Part 31: Asphalt Concrete with Bituminous Emulsion

Bituminous mixtures - Material specifications - Part 31: Asphalt Concrete with Bituminous Emulsion

This European Standard specifies requirements for plant mixtures of the mix group Asphalt concrete with bituminous emulsion for use on roads, and other trafficked areas. Asphalt concrete with bituminous emulsion is used for surface courses, binder courses, regulating courses, and bases. It is a mixture in which mechanical properties evolve over time following installation. This is not just in terms of cooling, as other asphalts, but also includes curing effects.

NOTE Asphalt concrete with bituminous emulsion is a mixture in which mechanical properties evolve over time following installation because of curing.

Mixtures utilizing bituminous emulsion based on in situ recycling are not covered by this standard.

This European Standard includes requirements for the selection of the constituent materials. It is designed to be read in conjunction with:

- Annex A Product Type Assessment (Normative);

- Annex B Performance characteristic assessment (Informative);

- Annex C Factory Production Control (Normative).

Asphaltmischgut - Mischgutanforderungen - Teil 31: Asphaltbeton mit Bitumenemulsion

Dieses Dokument legt Anforderungen an Werksmischungen der Mischgutart Asphaltbeton mit Bitumen-emulsion fest, die für die Verwendung beim Bau von Straßen und sonstigen Verkehrsflächen bestimmt sind. Asphaltbeton mit Bitumenemulsion wird für Deckschichten, Binderschichten, Ausgleichsschichten und Tragschichten verwendet. Asphaltbeton mit Bitumenemulsion ist ein Mischgut, bei dem sich die mechanischen Eigenschaften nach dem Einbau im Laufe der Zeit ändern. Das betrifft nicht nur die Abkühlung, wie bei anderen Asphalten, sondern auch die Reifung.

ANMERKUNG Asphaltbeton mit Bitumenemulsion ist ein Mischgut, bei dem sich die mechanischen Eigenschaften nach dem Einbau im Laufe der Zeit durch Reifung ändern.

Mischgüter, die Bitumenemulsionen auf der Basis der Wiederverwertung vor Ort enthalten, werden durch dieses Dokument nicht abgedeckt.

Dieses Dokument enthält Anforderungen an die Auswahl der Baustoffe. Es ist anzuwenden in Verbindung mit:

— Anhang A, Bewertung des Produkttyps (normativ);

— Anhang B, Werkseigene Produktionskontrolle (normativ);

— Anhang C, Bewertung der Leistungsmerkmale (informativ).

Mélanges bitumineux - Spécifications pour le matériau - Partie 31 : Enrobés bitumineux à l’émulsion de bitume

Ce document spécifie les exigences relatives aux mélanges appartenant à la famille des enrobés bitumineux à l’émulsion de bitume destinés aux routes et autres zones de circulation. Les enrobés bitumineux à l’émulsion de bitume sont utilisés pour les couches de roulement, de liaison, de reprofilage et d’assises. Il s’agit d’un mélange dans lequel les propriétés mécaniques évoluent dans le temps après la mise en œuvre. Cela n’est pas seulement en termes de refroidissement comme pour les autres enrobés mais inclut aussi des effets de mûrissement.

NOTE Un enrobé bitumineux à l’émulsion de bitume est un mélange dans lequel les propriétés mécaniques évoluent dans le temps après la mise en œuvre du fait du mûrissement.

Les mélanges utilisant des émulsions de bitume obtenus par recyclage en place ne sont pas couverts par ce document.

Ce document comporte des exigences pour la sélection des divers constituants. Il est destiné à être utilisée conjointement avec :

- L’Annexe A Évaluation des types de produit (normative) ;

- L’Annexe B Contrôle de la production en usine (informative) ;

- L’Annexe C Évaluation des caractéristiques de performance (normative).

Bitumenske zmesi - Specifikacije materialov - 31. del: Bitumenski beton z bitumensko emulzijo

Ta evropski standard določa zahteve za skupino proizvodnih zmesi bitumenskih betonov z bitumensko emulzijo za uporabo na cestah in drugih prometnih površinah. Bitumenski beton z bitumensko emulzijo se uporablja za obrabne plasti, vezne plasti, izravnalne plasti in nosilne plasti. Je zmes, katere mehanske lastnosti se razvijejo sčasoma po namestitvi. To ne zajema samo hlajenja, kot pri drugih asfaltih, ampak vključuje tudi učinke strjevanja.

OPOMBA: Bitumenski beton z bitumensko emulzijo je zmes, pri kateri se mehanske lastnosti razvijejo sčasoma po namestitvi zaradi strjevanja.

Zmesi, ki uporabljajo bitumenske emulzije, ki temeljijo na ponovni uporabi materialov na kraju samem, niso zajete v tem standardu.

Ta evropski standard vključuje zahteve za izbiro sestavnih materialov. Zasnovan je tako, da se uporablja skupaj z naslednjim:

– dodatek A: Ocena vrste izdelka (normativni);

– dodatek B: Ocena lastnosti (informativni);

– dodatek C: Kontrola proizvodnje v obratu (normativni).

General Information

- Status

- Published

- Publication Date

- 24-Sep-2019

- Withdrawal Date

- 30-Mar-2020

- Technical Committee

- CEN/TC 227 - Road materials

- Drafting Committee

- CEN/TC 227/WG 1 - Bituminous mixtures

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 18-Jun-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13108-31:2019 - Bituminous mixtures: Asphalt Concrete with Bituminous Emulsion is a CEN standard that specifies material and mixture requirements for plant-produced asphalt concrete made with bituminous emulsion. It covers mixtures intended for roads and other trafficked areas - including surface courses, binder courses, regulating courses and bases - and recognizes that mechanical properties of these mixes evolve over time because of curing as well as cooling. Mixtures based on in situ recycling with bituminous emulsion are explicitly excluded.

Keywords: EN 13108-31:2019, Asphalt Concrete with Bituminous Emulsion, bituminous mixtures, CEN standard, road construction materials

Key Topics

The standard sets out technical requirements and test methods for:

- Constituent materials: selection criteria for binders (bituminous emulsions), aggregates, filler, additives, water and reclaimed asphalt.

- Mixture composition: grading, binder content and mix formulation principles.

- Performance properties: void content, water sensitivity, indirect tensile strength, compressive strength, stiffness and temperature-related behavior.

- Specimen preparation & compaction: reference density, compaction energy and methods used for laboratory and production validation.

- Factory Production Control (FPC) and Assessment & Verification of Constancy of Performance (AVCP) to ensure consistent quality.

- Identification and documentation requirements for product traceability.

- Health, safety and environment: reaction to fire and regulated dangerous substances considerations.

- Annexes: Product Type Assessment (normative), Factory Production Control (normative) and Performance Characteristic Assessment (informative) provide supplementary procedures and validation guidance.

Keywords: grading, binder content, void content, water sensitivity, stiffness, factory production control

Applications

EN 13108-31:2019 is applied when specifying, producing or validating asphalt concretes bound with bituminous emulsion for pavements and trafficked surfaces where long-term curing contributes to performance. Typical uses:

- Road surface layers and binder courses

- Regulating and base courses for new construction or overlays (excluding in situ emulsion recycling)

- Airport pavements and other heavy-trafficked areas (subject to special requirements)

Keywords: surface courses, binder courses, regulating courses, road pavements

Who uses this standard

- Highway authorities and road specification writers

- Pavement engineers and materials laboratories

- Asphalt producers and plant quality managers

- Contractors performing placing and compaction of emulsion-bound mixes

- Certification bodies and testing organizations

Related Standards

EN 13108 series (other parts for different mix types) and referenced test methods (EN 12697 series for laboratory testing) should be consulted alongside EN 13108-31:2019 for a full specification and test suite.

Keywords: EN 13108 series, EN 12697, road materials, pavement specification

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 13108-31:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Bituminous mixtures - Material specifications - Part 31: Asphalt Concrete with Bituminous Emulsion". This standard covers: This European Standard specifies requirements for plant mixtures of the mix group Asphalt concrete with bituminous emulsion for use on roads, and other trafficked areas. Asphalt concrete with bituminous emulsion is used for surface courses, binder courses, regulating courses, and bases. It is a mixture in which mechanical properties evolve over time following installation. This is not just in terms of cooling, as other asphalts, but also includes curing effects. NOTE Asphalt concrete with bituminous emulsion is a mixture in which mechanical properties evolve over time following installation because of curing. Mixtures utilizing bituminous emulsion based on in situ recycling are not covered by this standard. This European Standard includes requirements for the selection of the constituent materials. It is designed to be read in conjunction with: - Annex A Product Type Assessment (Normative); - Annex B Performance characteristic assessment (Informative); - Annex C Factory Production Control (Normative).

This European Standard specifies requirements for plant mixtures of the mix group Asphalt concrete with bituminous emulsion for use on roads, and other trafficked areas. Asphalt concrete with bituminous emulsion is used for surface courses, binder courses, regulating courses, and bases. It is a mixture in which mechanical properties evolve over time following installation. This is not just in terms of cooling, as other asphalts, but also includes curing effects. NOTE Asphalt concrete with bituminous emulsion is a mixture in which mechanical properties evolve over time following installation because of curing. Mixtures utilizing bituminous emulsion based on in situ recycling are not covered by this standard. This European Standard includes requirements for the selection of the constituent materials. It is designed to be read in conjunction with: - Annex A Product Type Assessment (Normative); - Annex B Performance characteristic assessment (Informative); - Annex C Factory Production Control (Normative).

EN 13108-31:2019 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13108-31:2019 has the following relationships with other standards: It is inter standard links to EN ISO 11925-2:2026, EN 13043:2013, EN 12697-54:2019, EN 1008:2002, EN 12697-22:2020+A1:2023, EN 1097-6:2013, EN 1097-7:2022, EN 12697-3:2013+A1:2018, EN ISO 11925-2:2020, EN 932-3:2022, EN 1426:2024, EN 1428:2012, EN 13108-8:2016, EN 12697-12:2018, EN 12697-27:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13108-31:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2019

Bitumenske zmesi - Specifikacije materialov - 31. del: Bitumenski beton z

bitumensko emulzijo

Bituminous mixtures - Material specifications - Part 31: Asphalt Concrete with Bituminous

Emulsion

Asphaltmischgut - Mischgutanforderungen - Teil 31: Emulsionsgebundene

Asphaltbetone

Mélanges bitumineux - Spécifications sur le matériau - Partie 31: Enrobés bitumineux à

l’émulsion de bitume

Ta slovenski standard je istoveten z: EN 13108-31:2019

ICS:

93.080.20 Materiali za gradnjo cest Road construction materials

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 13108-31

EUROPEAN STANDARD

NORME EUROPÉENNE

September 2019

EUROPÄISCHE NORM

ICS 93.080.20

English Version

Bituminous mixtures - Material specifications - Part 31:

Asphalt Concrete with Bituminous Emulsion

Mélanges bitumineux - Spécifications sur le matériau - Asphaltmischgut - Mischgutanforderungen - Teil 31:

Partie 31: Enrobés bitumineux à l'émulsion de bitume Emulsionsgebundene Asphaltbetone

This European Standard was approved by CEN on 5 August 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 13108-31:2019 E

worldwide for CEN national Members.

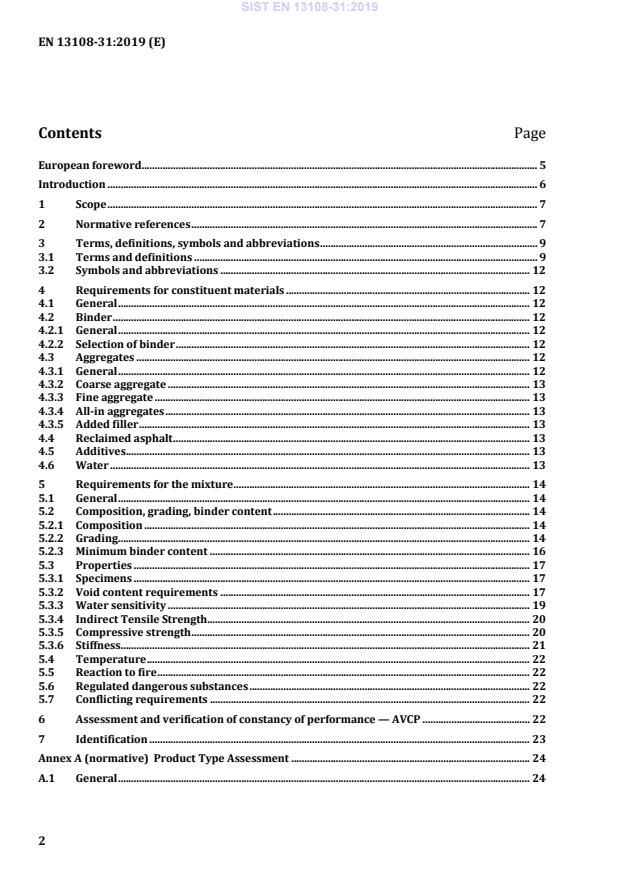

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviations . 9

3.1 Terms and definitions . 9

3.2 Symbols and abbreviations . 12

4 Requirements for constituent materials . 12

4.1 General . 12

4.2 Binder . 12

4.2.1 General . 12

4.2.2 Selection of binder . 12

4.3 Aggregates . 12

4.3.1 General . 12

4.3.2 Coarse aggregate . 13

4.3.3 Fine aggregate . 13

4.3.4 All-in aggregates . 13

4.3.5 Added filler . 13

4.4 Reclaimed asphalt . 13

4.5 Additives . 13

4.6 Water . 13

5 Requirements for the mixture . 14

5.1 General . 14

5.2 Composition, grading, binder content . 14

5.2.1 Composition . 14

5.2.2 Grading . 14

5.2.3 Minimum binder content . 16

5.3 Properties . 17

5.3.1 Specimens . 17

5.3.2 Void content requirements . 17

5.3.3 Water sensitivity . 19

5.3.4 Indirect Tensile Strength. 20

5.3.5 Compressive strength . 20

5.3.6 Stiffness . 21

5.4 Temperature . 22

5.5 Reaction to fire . 22

5.6 Regulated dangerous substances . 22

5.7 Conflicting requirements . 22

6 Assessment and verification of constancy of performance — AVCP . 22

7 Identification . 23

Annex A (normative) Product Type Assessment . 24

A.1 General . 24

A.2 Validity . 24

A.2.1 Period of validity . 24

A.2.2 Changes in aggregate . 24

A.2.3 Change in bituminous emulsion . 24

A.2.4 Change in Reclaimed Asphalt . 25

A.2.5 Change in additive . 25

A.3 Constituent materials . 25

A.4 Bituminous Emulsion Mixtures . 25

A.4.1 General . 25

A.4.2 Application . 25

A.4.3 Sampling and testing . 26

A.4.4 Composition . 26

A.4.5 Specimen preparation . 26

A.4.5.1 General . 26

A.4.5.2 Laboratory validation . 26

A.4.5.3 Production validation . 26

A.5 Product type assessment Report . 27

A.5.1 General . 27

A.5.2 Constituents . 27

A.5.3 Mix formulation . 27

A.5.4 Temperatures . 27

A.5.5 Test results . 28

A.6 Properties and test methods for constituent materials . 28

A.7 Methods of specimen preparation. 29

A.7.1 General . 29

A.7.2 Compaction energy . 29

A.7.3 Reference density . 29

A.7.4 Compaction degree . 30

A.7.5 Void content . 30

A.7.6 Water sensitivity . 31

A.7.6.1 Water sensitivity according to EN 12697-12:2018, Method A . 31

A.7.6.2 Water sensitivity according to EN 12697-12:2018, Method B . 32

A.8 Test procedures and conditions . 33

A.8.1 General . 33

A.8.2 Stiffness . 33

A.9 Special requirements for airfields . 34

Annex B (normative) Factory Production Control . 35

B.1 General . 35

B.2 Testing, tolerances and conformity assessment . 35

Annex C (informative) Performance characteristic assessment . 37

C.1 General . 37

C.2 Resistance to permanent deformation . 37

C.2.1 Wheel-tracking test . 37

C.3 Fracture toughness . 40

C.4 Spreadability . 41

C.5 Coating and homogeneity . 41

Bibliography . 42

European foreword

This document (EN 13108-31:2019) has been prepared by Technical Committee CEN/TC 227 “Road

materials”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by March 2019, and conflicting national standards shall

be withdrawn at the latest by March 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

A list of all parts of the EN 13108 series can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

Introduction

The aim of this document is to enable specification of asphalt concrete mixtures with bituminous

emulsion on a performance basis. In general, however, there are currently more empirical tests

available to describe the mixtures.

This document covers a large variety of materials for different applications, traffic and climate

conditions. The standard gives properties and listings of possible categories. It has to accommodate the

road industry for all of Europe. For this reason, the menu approach for properties has been chosen. The

tables represent categories that are required all over Europe. For this reason, numerical values in tables

do not always obey statistical rules. Based on conditions of use, specific properties and categories may

be defined, in documents related to the application of the product. The categories defined in those

documents take into account the reproducibility of the test when this is given in the appropriate test

method.

Care is to be taken to only select those tests which are applicable to the application of the asphalt and

the use of the pavement and to avoid a combination of potentially conflicting requirements.

1 Scope

This document specifies requirements for plant mixtures of the mix group Asphalt concrete with

bituminous emulsion for use on roads, and other trafficked areas. Asphalt concrete with bituminous

emulsion is used for surface courses, binder courses, regulating courses, and bases. It is a mixture in

which mechanical properties evolve over time following installation. This is not just in terms of cooling,

as other asphalts but also includes curing effects.

NOTE Asphalt concrete with bituminous emulsion is a mixture in which mechanical properties evolve over

time following installation because of curing.

Mixtures utilizing bituminous emulsion based on in situ recycling are not covered by this document.

This document includes requirements for the selection of the constituent materials. It is designed to be

read in conjunction with:

— Annex A Product Type Assessment (Normative);

— Annex B Factory Production Control (Normative);

— Annex C Performance characteristic assessment (Informative).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 932-3, Tests for general properties of aggregates — Part 3: Procedure and terminology for simplified

petrographic description

EN 933-1, Tests for geometrical properties of aggregates — Part 1: Determination of particle size

distribution — Sieving method

EN 933-10, Tests for geometrical properties of aggregates — Part 10: Assessment of fines — Grading of

filler aggregates (air jet sieving)

EN 1008, Mixing water for concrete — Specification for sampling, testing and assessing the suitability of

water, including water recovered from processes in the concrete industry, as mixing water for concrete

EN 1097-6:2013, Tests for mechanical and physical properties of aggregates — Part 6: Determination of

particle density and water absorption

EN 1097-7, Tests for mechanical and physical properties of aggregates — Part 7: Determination of the

particle density of filler — Pyknometer method

EN 1426, Bitumen and bituminous binders — Determination of needle penetration

EN 1427, Bitumen and bituminous binders — Determination of the softening point — Ring and Ball

method

EN 1428, Bitumen and bituminous binders — Determination of water content in bituminous emulsions —

Azeotropic distillation method

EN 1431, Bitumen and bituminous binders — Determination of residual binder and oil distillate from

bitumen emulsions by distillation

EN 12595, Bitumen and bituminous binders — Determination of kinematic viscosity

EN 12596, Bitumen and bituminous binders — Determination of dynamic viscosity by vacuum capillary

EN 12697-1, Bituminous mixtures — Test methods for hot mix asphalt — Part 1: Soluble binder content

EN 12697-2, Bituminous mixtures — Test methods — Part 2: Determination of particle size distribution

EN 12697-3, Bituminous mixtures — Test methods — Part 3: Bitumen recovery: Rotary evaporator

EN 12697-4, Bituminous mixtures — Test methods — Part 4: Bitumen recovery: Fractionating column

EN 12697-5, Bituminous mixtures — Test methods— Part 5: Determination of the maximum density

EN 12697-6, Bituminous mixtures — Test methods for hot mix asphalt — Part 6: Determination of bulk

density of bituminous specimens

EN 12697-8, Bituminous mixtures — Test methods — Part 8: Determination of void characteristics of

bituminous specimens

EN 12697-12, Bituminous mixtures — Test methods— Part 12: Determination of the water sensitivity of

bituminous specimens

EN 12697-22, Bituminous mixtures — Test methods for hot mix asphalt — Part 22: Wheel tracking

EN 12697-23, Bituminous mixtures — Test methods— Part 23: Determination of the indirect tensile

strength of bituminous specimens

EN 12697-26, Bituminous mixtures — Test methods— Part 26: Stiffness

EN 12697-27, Bituminous mixtures — Test methods — Part 27: Sampling

EN 12697-28, Bituminous mixtures — Test methods for hot mix asphalt — Part 28: Preparation of

samples for determining binder content, water content and grading

EN 12697-29, Bituminous mixtures — Test method for hot mix asphalt — Part 29: Determination of the

dimensions of a bituminous specimen

EN 12697-31, Bituminous mixtures — Test methods — Part 31: Specimen preparation by gyratory

compactor

EN 12697-32, Bituminous mixtures — Test methods — Part 32: Specimen preparation by vibratory

compactor

EN 12697-33, Bituminous mixtures — Test method — Part 33: Specimen prepared by roller compactor

EN 12697-35, Bituminous mixtures — Test methods — Part 35: Laboratory mixing

EN 12697-44, Bituminous mixtures — Test methods — Part 44: Crack propagation by semi-circular

bending test

EN 12697-53, Bituminous mixtures — Test methods — Part 53: Cohesion increase by spreadability-meter

method

EN 12697-54, Bituminous mixtures — Test methods — Part 54: Curing of specimen for test of mixtures

with bitumen emulsion

EN 12697-55, Bituminous mixtures — Test methods — Part 55: Organoleptic assessment of mixtures with

bitumen emulsion

EN 12697-56, Bituminous mixtures — Test methods — Part 56: Specimen preparation by static

compaction

EN 13043, Aggregates for bituminous mixtures and surface treatments for roads, airfields and other

trafficked areas

EN 13075-1, Bitumen and bituminous binders — Determination of breaking behaviour — Part 1:

Determination of breaking value of cationic bituminous emulsions, mineral filler method

EN 13075-2, Bitumen and bituminous binders — Determination of breaking behaviour — Part 2:

Determination of fines mixing time of cationic bituminous emulsions

EN 13108-8, Bituminous mixtures — Material specifications — Part 8: Reclaimed asphalt

EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification

using data from reaction to fire tests

EN 13808, Bitumen and bituminous binders — Framework for specifying cationic bituminous emulsions

EN ISO 11925-2, Reaction to fire tests — Ignitability of products subjected to direct impingement of

flame — Part 2: Single-flame source test (ISO 11925-2)

3 Terms, definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at http://www.iso.org/obp

3.1.1

pavement

structure, composed of one or more courses, to assist the passage of traffic over terrain

3.1.2

layer

element of a pavement laid in a single operation

3.1.3

course

element of a pavement constructed with a single asphalt mixture which may be laid in one or more

layers

3.1.4

surface course

upper course of the pavement, which is in contact with the traffic

3.1.5

binder course

structural course of the pavement between the surface course and the base

3.1.6

regulating course

course of variable thickness applied to an existing course or surface to provide the necessary profile for

a further course of consistent thickness

3.1.7

base

main structural element of a pavement, which may be laid in one or more courses, described as “upper”

base “lower” base

3.1.8

asphalt

homogenous mixture typically of coarse and fine aggregates, filler aggregate and bituminous binder

which is used in the construction of a pavement

Note 1 to entry: The asphalt may include one or more additives to enhance the laying characteristics,

performance or appearance of the mixture.

3.1.9

asphalt concrete with bituminous emulsion

asphalt in which the aggregate particles are continuously graded or gap-graded to form an interlocking

structure in which all or part of the binder is added in the form of a bituminous emulsion

3.1.10

curing

process whereby mechanical properties of the bituminous mixture with emulsion evolve over time

Note 1 to entry: Depending on the emulsion, the aggregate, the type of mixture, the temperature of application,

the thickness, the local condition, climate, rain, frost, drainage of water etc., the curing takes place over few days

and few years.

3.1.11

mix formulation

composition of a single mixture expressed as a target composition

Note 1 to entry: A target composition is expressed in two ways (see 3.1.12 and 3.1.13).

3.1.12

input target composition

expression of the mix formulation in terms of the constituent materials, the grading curve and the

percentage of bitumen emulsion added to the mixture

Note 1 to entry: This will usually be the result of a laboratory mix design and validation.

3.1.13

output target composition

expression of the mix formulation in terms of the constituent materials and the mid point grading and

soluble binder content to be found on analysis

Note 1 to entry: This will usually be the result of a production validation.

3.1.14

additive

constituent material that can be added in small quantities to influence specific properties of the mixture

Note 1 to entry: For example, additives are used to influence the affinity of binder to aggregate, and the

mechanical properties when using inorganic and organic fibres and polymers. They are also used to influence the

colour of the mixture.

3.1.15

conflicting requirements

combination of requirements or properties which are impracticable to fulfil in their entirety

Note 1 to entry: This can occur by combining specific requirements for the composition and constituent

materials together with more performance related tests. These are also relevant when two or more performance

or test parameters are selected which measure similar properties using conflicting test methods resulting in a lack

of clarity and consistency in the characteristics of the mixture.

3.1.16

category

defined level of a property of an asphalt mixture; the designation of a category of which may be a

symbol and a numerical value representing the level

Note 1 to entry: The tables in this document list the defined categories for each property.

3.1.17

class

range of levels delimited by a minimum and a maximum value

3.1.18

added water

amount of water eventually added to the mixture

3.1.19

total water content

amount of water added in the mixture, water brought by the emulsion in the mixture and water brought

by the aggregates expressed in percentage by mass of the dry aggregate and the conventional residual

anhydrous binder

3.2 Symbols and abbreviations

ACBE general designation of Asphalt Concrete with Bituminous Emulsion

ACBE D designation of Asphalt Concrete with Bituminous Emulsion followed by an indication of D,

the upper sieve size of the aggregate in the mixture, in millimetres (mm)

EXAMPLE ACBE 16 Asphalt Concrete with Bituminous Emulsion with an upper sieve size of the aggregate of

16 mm.

4 Requirements for constituent materials

4.1 General

Only constituent materials with established suitability shall be used. For all constituent materials the

properties relevant to the performance of the mixture shall be made available.

The establishment of suitability shall result from one or more of the following:

— European Standard;

— European Technical Assessment;

— Specifications for materials based on a demonstrable history of satisfactory use in asphalt. Evidence

shall be based on research and/or the evidence of satisfactory practical use.

In documents relating to the application of the product details for the assessment of this proof may be

defined.

There can be technical limitations regarding the future recycling possibilities. Also traceability of the

nature of constituent materials can affect the potential for future recycling.

4.2 Binder

4.2.1 General

All or part of the binder shall be a bituminous emulsion, according to EN 13808.

4.2.2 Selection of binder

Depending on the conditions of use, the bituminous emulsion type may be defined in documents related

to the application of the product.

The bituminous emulsion product designation shall be declared in the Product Type Assessment report

according to Annex A.

4.3 Aggregates

4.3.1 General

NOTE The expression “appropriate to the intended use” in 4.3.1 to 4.3.4 means that the selection of the

requirements and the particular category depends on a number of conditions. These conditions include traffic

density, climatic conditions, the construction of the course in which the mixture will be used, and economic

considerations.

4.3.2 Coarse aggregate

Coarse aggregate shall conform to EN 13043 as appropriate for the intended use.

4.3.3 Fine aggregate

Fine aggregate shall conform to EN 13043 as appropriate for the intended use.

4.3.4 All-in aggregates

All-in aggregates shall conform to EN 13043 as appropriate for the intended use.

4.3.5 Added filler

Added filler shall conform to EN 13043 as appropriate for the intended use and may include materials

such as cement, limestone and hydrated lime. Based on the experience in the place of use the type and

amount of added filler may be defined in documents related to the application of the product.

4.4 Reclaimed asphalt

The use and the amount of reclaimed asphalt, and the mix group and/or the courses from which the

reclaimed asphalt has been or will be derived may be defined in documents related to the application of

the product.

The properties of reclaimed asphalt declared in accordance with EN 13108-8 shall conform to

requirements that may be selected appropriate to the intended use.

The upper sieve size D of the aggregate in the reclaimed asphalt shall not exceed the upper sieve size D

of the mixture. The aggregate properties of the reclaimed asphalt or of the mixed aggregates from the

reclaimed asphalt with the virgin aggregates shall fulfil the requirements for aggregate defined in

documents relating to the application of the mixture.

When defined in documents relating to the application of the product, the amount of reclaimed asphalt,

the mix group and/or the courses from which the reclaimed asphalt has been or will be derived shall be

declared in the Product Type Assessment report.

4.5 Additives

The nature and properties of all additives shall be declared and they shall conform to the requirements

referred to in 4.1. For specific applications and based on the experience in the place of use the amount

of additives may be defined in documents related to the application of the product.

4.6 Water

Only potable water according to EN 1008 shall be used.

5 Requirements for the mixture

5.1 General

At the target composition, the mixture shall conform to the appropriate requirements in accordance

with this document.

The mix formulation shall be declared in the Product Type assessment report according to Annex A.,

including:

— Target percentages passing the specified sieves. The target grading shall be declared for the sieve

1,4 D and the sieves as called up in Table 3;

— Target emulsion content;

— Percentage of additive(s);

— Total water content: water from emulsion, where relevant added water and water from aggregate;

— Total binder content expressed as:

— For input target composition,

— Binder content from emulsion,

— And where relevant the binder content derived from reclaimed asphalt,

— For output target composition;

— Target soluble binder content.

The test results in accordance with Annex A, shall be made available.

5.2 Composition, grading, binder content

5.2.1 Composition

The target grading shall be expressed in percentages by mass of total aggregate. The target binder,

additive and total water content shall be expressed in percentages by mass of the total dry mixture. The

percentages passing the sieves, with the exception of the sieve 0,063 mm shall be expressed to 1 %, the

binder content, the water content, the percentage passing sieve 0,063 mm and any additive content

shall be expressed to 0,1 %. Where appropriate the additive content shall be expressed to 0,01 %.

5.2.2 Grading

5.2.2.1 General grading requirements

The requirements for the overall grading limits of the target composition are given in Tables 1 and 2 for

the sieves 1,4 D, D, 2 mm and 0,063 mm. The target composition shall be within this grading envelope

(maximum and minimum values included).

The sieves to be used shall be either basic sieve set plus set 1 or basic sieve set plus set 2, according to

EN 13043. A combination of sieve sizes from set 1 and set 2 shall not be permissible.

Table 1 — General grading requirements of target composition — basic sieve set plus set 1

D 4 5 (5,6) 8 11 (11,2) 16 22 (22,4) 32 (31,5)

Sieve

Percentage passing by mass

mm

a

100 100 100 100 100 100 100

1,4 D

D 90 to 100 90 to 100 90 to 100 90 to 100 90 to 100 90 to 100 90 to 100

b b

2 50 to 85 15 to 72 10 to 72 10 to 60 10 to 65

10 to 50 10 to 50

0,063 5,0 to 17,0 2,0 to 15,0 2,0 to 13,0 2,0 to 12,0 0 to 12,0 0 to 11,0 0 to 11,0

a

Where the sieve calculated as 1,4 D is not an exact number in the basic set plus set 1 series then the next

nearest sieve in the set shall be adopted.

b

For application on airfields the maximum percentage passing 2 mm may be increased to 60 %.

Table 2 — General grading requirements of target composition — basic sieve set plus set 2

12 32

D 4 6 (6,3) 8 10 14 16 20

(12,5) (31,5)

Sieve

Percentage passing by mass

mm

a

100 100 100 100 100 100 100 100 100

1,4 D

90 to 90 to 90 to 90 to 90 to 90 to

D 90 to 100 90 to 100 90 to 100

100 100 100 100 100 100

10 to 10 to 10 to

50 to 15 to

2 10 to 72 10 to 60 10 to 55 10 to 65

b b b

85 72

50 50 50

5,0 to 2,0 to 2,0 to 2,0 to 2,0 to 0 to 0 to

0,063 0 to 11,0 0 to 11,0

17,0 15,0 13,0 12,0 12,0 12,0 12,0

a

Where the sieve calculated as 1,4 D is not an exact number in the basic set plus set 2 series then the next

nearest sieve in the set shall be adopted.

b

For application on airfields the maximum percentage passing 2 mm may be increased to 60 %.

5.2.2.2 Grading envelope

The grading requirements may be defined in documents related to the application of the product

(see 5.7 for conflicting requirements). When required, the grading requirements for the target

composition shall be expressed in terms of a grading envelope by selection of maximum and minimum

values for the percentages passing the sieves 1,4 D; D; a characteristic sieve between D and 2 mm,

2 mm, a characteristic sieve between 2mm and 0,063mm and 0,063 mm.

D and the sieves between D and 2 mm shall be selected from the following sieves:

— basic sieve set plus set 1: 4 mm; 5,6 mm; 8 mm; 11,2 mm; 16 mm; 22,4 mm, 31,5 mm;

— basic sieve set plus set 2: 4 mm; 6,3 mm; 8 mm; 10 mm; 12,5 mm; 14 mm; 16 mm; 20 mm, 31,5 mm.

In addition, the requirements for the grading envelope, when required, may include the percentages

passing one or two optional sieves between D and 2 mm and one or two optional sieves between 2 mm

and 0,063 mm. The optional sieves may be defined in documents related to the application of the

product.

The sieves between 2 mm and 0,063 mm shall be selected from the following sieves: 1 mm; 0,5 mm;

0,25 mm and 0,125 mm.

The target composition of the mixture shall be within this grading envelope (maximum and minimum

values included). The ranges between the maximum and minimum values for the grading envelope shall

be selected as a single value within the given limits (both included) from Table 3. The percentage

passing the sieves D,2 mm and 0,063 mm, of the selected grading envelope shall not exceed the

maximum and minimum values in Table 1 or Table 2.

Table 3 — Ranges between maximum and minimum percentage values for the selected grading

envelope

Sieve Ranges for grading envelope

mm

D 10

Characteristic sieve between D and 2 a

10 to 30

Any additional characteristic sieves between D a

10 to 30

and 2

2 a

5 to 25

Characteristic sieve between 2 and 0,063 a

4 to 25

Any additional characteristic sieves between 2 and a

4 to 25

0,063

0,063 a

2 to 12

a

Value to be selected within the given minimum and maximum value (both included).

In the case of a fixed target grading meeting the requirements of Table 1 or Table 2, the use of the

minimum range values in Table 3 is not required.

5.2.3 Minimum binder content

The minimum binder content may be defined in documents related to the application of the product and

shall be selected to the nearest 0,1 %, between values of 3,0 % till 8,0 % for a mixture in which the

aggregate density is assumed to be equal to 2,65 Mg/m .

The selected minimum binder content shall be expressed as B where x is the minimum soluble

minx

binder content in percentage.

The minimum binder content of the mixture shall be corrected by multiplying by the factor

2,650

α =

ρ

where

ρ is the weighted mean of the particle density of the aggregates at the target grading, in megagram

per cubic metre (Mg/m ), determined according to the appropriate clause or annex of EN 1097-6.

The appropriate particle density according to EN 1097-6 shall be declared in the product type

assessment report as defined in Annex A.

NOTE 1 For normal weight aggregates with water absorption less than about 1,5 %, the pre-dried particle

density method as defined in EN 1097-6:2013, Annex A is applicable for aggregates passing the 63 mm test sieve

and retained on the 0,063 mm test sieve. EN 1097-6:2013, Annex G is applicable to aggregates passing the

31,5 mm test sieve including the 0/0,063 mm size fraction.

Based on experience in the place of use for certain specific aggregates with particular granulometric

characteristics, the corrected minimum binder content may be adjusted appropriately. The adjustment

shall be defined in documents related to the application of the product.

For mixtures including reclaimed asphalt, the soluble binder content is the addition of the soluble

added binder content and the soluble binder content of the reclaimed asphalt.

The minimum added binder content may be defined in documents related to the application of the

product and shall be selected to the nearest 0,1 %.

Depending on the characteristics of the recovered binder, the type and the amount of reclaimed asphalt,

the type of emulsion, the contribution of the recovered binder may be defined in documents related to

the application of the product.

NOTE 2 The binder of the reclaimed asphalt can be considered as active, partially active or inactive in the

contribution to the properties of the mixture.

5.3 Properties

5.3.1 Specimens

For application of this document specimens shall be in accordance with A.7.

5.3.2 Void content requirements

5.3.2.1 Void content

The range of categories of minimum and maximum void contents is defined in Table 4.

The void content shall be determined in accordance with EN 12697-8 using the conditions defined in

Annex A.

The compaction of test specimens shall be selected from Annex A.

In documents related to the application of the product, categories or classes for the voids content may

be defined when appropriate as maximum and minimum categories selected from Table 4.

Table 4 — Void content, V and/or V

min max

Void content Class

%

V V

min max

V

6,0

min 6,0

V

7,0

min 7,0

V

8,0

min 8,0

V V

9,0

min 9,0 max 9,0

V V

10,0

min 10,0 max 10,0

V

11,0

max 11,0

V

12,0

max 12,0

V

13,0

max 13,0

V

14,0

max 14,0

V

15,0

max 15,0

V

16,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...