EN 12942:2023

(Main)Respiratory protective devices - Powered filtering devices incorporating full face masks, half masks or quarter masks - Requirements, testing, marking

Respiratory protective devices - Powered filtering devices incorporating full face masks, half masks or quarter masks - Requirements, testing, marking

This document specifies minimum requirements for powered Respiratory Protective Devices (RPD) incorporating a tight-fitting respiratory interface. It does not cover devices designed for use in circumstances where there is or might be an oxygen deficiency.

Escape RPD and filters for use against CO are not covered by this document.

Laboratory tests and practical performance tests are included for the assessment of compliance with the requirements.

Atemschutzgeräte - Gebläsefiltergeräte mit Vollmaske, Halbmaske oder Viertelmaske - Anforderungen, Prüfung, Kennzeichnung

Dieses Dokument legt Mindestanforderungen an Atemschutzgeräte (ASG) mit Gebläse und einem Atem¬anschluss mit Dichtsitz fest. Es ist nicht anwendbar für Geräte, die für die Verwendung bei möglichem Sauerstoff-Mangel vorgesehen sind.

Fluchtgeräte (ASG zu Fluchtzwecken) und Filter zur Verwendung gegen CO werden von diesem Dokument nicht abgedeckt.

Laborprüfungen und praktische Leistungsprüfungen sind enthalten, um die Übereinstimmung mit den Anforderungen feststellen zu können.

Appareils de protection respiratoire - Appareils filtrants à ventilation assistée avec masques complets, demi-masques ou quarts de masques - Exigences, essais, marquage

Le présent document spécifie des exigences minimales applicables aux appareils de protection respiratoire (APR) intégrant une interface respiratoire à ajustement serré. Il ne traite pas des appareils conçus pour être utilisés dans des circonstances présentant ou susceptibles de présenter un défaut (manque) d’oxygène.

Les APR d’évacuation et les filtres spécifiques contre le monoxyde de carbone ne sont pas couverts par le présent document.

Il comporte des essais de laboratoire et des essais pratiques de performance pour évaluer la conformité aux exigences.

Oprema za varovanje dihal - Zaščitna obrazna, polobrazna ali četrtinska maska s tlačno filtracijo zraka - Zahteve, preskušanje, označevanje

Dokument določa minimalne zahteve za opremo za varovanje dihal (RPD) s tesno prilegajočim se vmesnikom za dihanje. Ne zajema naprav, ki so zasnovane za uporabo v okoliščinah, kjer obstaja ali se lahko pojavi pomanjkanje kisika.

Ta dokument ne zajema opreme za varovanje dihal za izhod v sili in filtrov za zaščito pred ogljikovimi oksidi.

Vključeni so tudi laboratorijski in praktični preskusi učinkovitosti za ocenjevanje skladnosti z zahtevami.

General Information

- Status

- Published

- Publication Date

- 19-Dec-2023

- Withdrawal Date

- 10-Apr-2022

- Technical Committee

- CEN/TC 79 - Respiratory protective devices

- Drafting Committee

- CEN/TC 79/WG 4 - Filters and absorption devices

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 20-Dec-2023

- Due Date

- 26-Dec-2018

- Completion Date

- 20-Dec-2023

- Directive

- Not Harmonized2016/425 - Regulation (EU) 2016/425 of the European Parliament and of the Council of 9 March 2016 on personal protective equipment and repealing Council Directive 89/686/EEC

Not Harmonized89/686/EEC - Personal protective equipment (PPE)

Relations

- Effective Date

- 27-Dec-2023

- Effective Date

- 27-Dec-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 136:1998 - Respiratory protective devices - Full face masks - Requirements, testing, marking - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12942:2023 is the CEN European standard specifying minimum requirements, testing and marking for powered filtering Respiratory Protective Devices (RPD) that incorporate a tight‑fitting respiratory interface (full face masks, half masks or quarter masks). The standard covers design, performance and practical performance tests for powered filtering devices (blower‑assisted units) and defines how manufacturers and conformity assessors demonstrate compliance.

Important exclusions: devices intended for oxygen‑deficient atmospheres, escape RPD, and filters for use against carbon monoxide (CO) are not covered.

Key Topics

EN 12942:2023 sets out technical requirements and test methods including:

- Classification and designation of powered filtering RPD by performance class.

- Design and ergonomics: human factors, compatibility with other PPE and construction requirements.

- Materials and mechanical strength: suitability, durability and optional mechanical strength tests.

- Respiratory interface (RI): requirements for tight‑fitting full, half and quarter masks.

- Inward leakage and breathing resistance: laboratory and practical performance tests to assess contaminant ingress and breathing effort.

- Air supply and blower performance: minimum airflows, battery/energy supply, interactive flow testing and manufacturer’s minimum design condition.

- Warning facilities and electrical components: low‑energy/low‑flow warnings and electrical safety requirements.

- Filters and filter testing: filter performance, types (including Hg and NO classifications where applicable) and marking.

- Noise level, carbon dioxide content of inhalation air, flammability, mass and wearer load.

- Testing schedule and conditioning: sample preparation, inspection, and required laboratory and practical tests following referenced methods (e.g., particle penetration, noise measurement).

- Marking and user information: required label and documentation content for RPD, blower units and filters.

Applications and Who Uses It

EN 12942:2023 is used by:

- Manufacturers and designers of powered filtering RPD to design devices that meet EU requirements and to prepare technical files.

- Test houses and laboratories performing conformity and type testing (inward leakage, filter performance, blower flow, noise).

- Certification bodies and notified bodies assessing compliance with PPE Regulation (see Annex ZA / EU Regulation 2016/425).

- Safety professionals, procurement teams and end‑users selecting powered RPD for industrial hygiene, maintenance, laboratories, painting and other tasks requiring powered filtered air supply.

- Regulators and national standards bodies implementing harmonized requirements.

Related Standards (if applicable)

Normative references integrated with EN 12942:2023 include: EN 136, EN 140, EN 13274 series (test methods), EN ISO 16972:2020 (terminology), and ISO 16900‑14:2020 (sound pressure level). These standards provide complementary requirements and test procedures for facepieces, filters and test methods.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12942:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Respiratory protective devices - Powered filtering devices incorporating full face masks, half masks or quarter masks - Requirements, testing, marking". This standard covers: This document specifies minimum requirements for powered Respiratory Protective Devices (RPD) incorporating a tight-fitting respiratory interface. It does not cover devices designed for use in circumstances where there is or might be an oxygen deficiency. Escape RPD and filters for use against CO are not covered by this document. Laboratory tests and practical performance tests are included for the assessment of compliance with the requirements.

This document specifies minimum requirements for powered Respiratory Protective Devices (RPD) incorporating a tight-fitting respiratory interface. It does not cover devices designed for use in circumstances where there is or might be an oxygen deficiency. Escape RPD and filters for use against CO are not covered by this document. Laboratory tests and practical performance tests are included for the assessment of compliance with the requirements.

EN 12942:2023 is classified under the following ICS (International Classification for Standards) categories: 13.340.30 - Respiratory protective devices. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12942:2023 has the following relationships with other standards: It is inter standard links to EN 12942:1998/A2:2008, EN 12942:1998/A1:2002, EN 12942:1998, EN ISO 16972:2020, EN 148-3:1999, EN 136:1998, EN ISO 16321-3:2022, EN ISO 10256-1:2024, EN 175:1997, EN 13274-7:2019, EN 140:1998, EN 148-1:2018, EN 148-2:1999, EN 13274-2:2019, EN ISO 16321-1:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12942:2023 is associated with the following European legislation: EU Directives/Regulations: 2016/425, 89/686/EEC; Standardization Mandates: M/031, M/571, M/571 AMD 1. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12942:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2024

Nadomešča:

SIST EN 12942:1999

SIST EN 12942:1999/A1:2003

SIST EN 12942:1999/A2:2009

Oprema za varovanje dihal - Zaščitna obrazna, polobrazna ali četrtinska maska s

tlačno filtracijo zraka - Zahteve, preskušanje, označevanje

Respiratory protective devices - Powered filtering devices incorporating full face masks,

half masks or quarter masks - Requirements, testing, marking

Atemschutzgeräte - Gebläsefiltergeräte mit Vollmaske, Halbmaske oder Viertelmaske -

Anforderungen, Prüfung, Kennzeichnung

Appareils de protection respiratoire - Appareils filtrants à ventilation assistée avec

masques complets, demi-masques ou quarts de masques - Exigences, essais,

marquage

Ta slovenski standard je istoveten z: EN 12942:2023

ICS:

13.340.30 Varovalne dihalne naprave Respiratory protective

devices

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12942

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2023

EUROPÄISCHE NORM

ICS 13.340.30 Supersedes EN 12942:1998

English Version

Respiratory protective devices - Powered filtering devices

incorporating full face masks, half masks or quarter masks

- Requirements, testing, marking

Appareils de protection respiratoire - Appareils Atemschutzgeräte - Gebläsefiltergeräte mit Vollmaske,

filtrants à ventilation assistée avec masques complets, Halbmaske oder Viertelmaske - Anforderungen,

demi-masques ou quarts de masques - Exigences, Prüfung, Kennzeichnung

essais, marquage

This European Standard was approved by CEN on 9 August 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12942:2023 E

worldwide for CEN national Members.

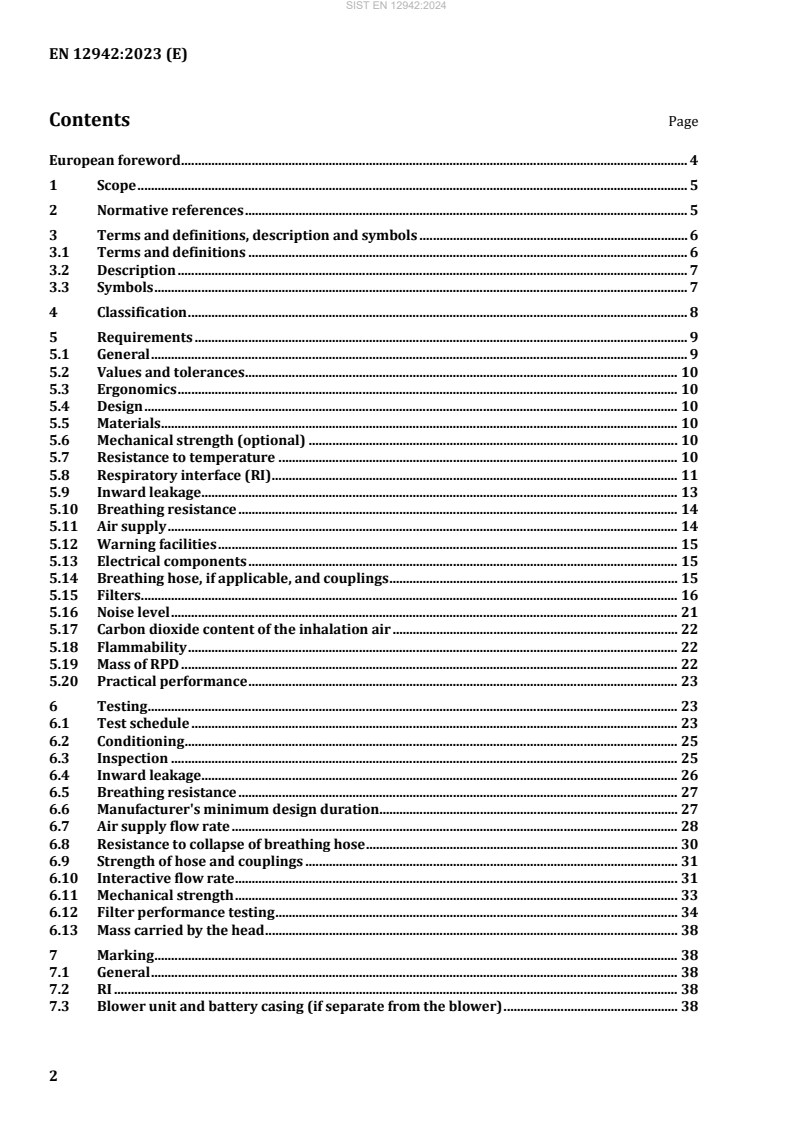

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions, description and symbols . 6

3.1 Terms and definitions . 6

3.2 Description . 7

3.3 Symbols . 7

4 Classification . 8

5 Requirements . 9

5.1 General . 9

5.2 Values and tolerances . 10

5.3 Ergonomics . 10

5.4 Design . 10

5.5 Materials . 10

5.6 Mechanical strength (optional) . 10

5.7 Resistance to temperature . 10

5.8 Respiratory interface (RI) . 11

5.9 Inward leakage . 13

5.10 Breathing resistance . 14

5.11 Air supply . 14

5.12 Warning facilities . 15

5.13 Electrical components . 15

5.14 Breathing hose, if applicable, and couplings . 15

5.15 Filters . 16

5.16 Noise level . 21

5.17 Carbon dioxide content of the inhalation air . 22

5.18 Flammability . 22

5.19 Mass of RPD . 22

5.20 Practical performance . 23

6 Testing . 23

6.1 Test schedule . 23

6.2 Conditioning . 25

6.3 Inspection . 25

6.4 Inward leakage . 26

6.5 Breathing resistance . 27

6.6 Manufacturer's minimum design duration. 27

6.7 Air supply flow rate . 28

6.8 Resistance to collapse of breathing hose . 30

6.9 Strength of hose and couplings . 31

6.10 Interactive flow rate . 31

6.11 Mechanical strength . 33

6.12 Filter performance testing . 34

6.13 Mass carried by the head . 38

7 Marking . 38

7.1 General . 38

7.2 RI . 38

7.3 Blower unit and battery casing (if separate from the blower) . 38

7.4 Filters . 39

7.5 Filter package . 40

7.6 RPD packages . 40

8 Information supplied by the manufacturer . 40

8.1 Complete RPD . 40

8.2 Filters . 41

Annex ZA (informative) Relationship between this European Standard and the essential

health and safety requirements of Regulation 2016/425/EU [2016 OJ L81] aimed to

be covered . 42

Bibliography . 44

European foreword

This document (EN 12942:2023) has been prepared by Technical Committee CEN/TC 79 “Respiratory

protective devices”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2024 and conflicting national standards shall be

withdrawn at the latest by June 2024.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12942:1998.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

The following main technical changes have been made compared to EN 12942:1998:

a) Clause 4 Designation was deleted;

b) number of test samples was added to the requirements, where necessary;

c) classification table was amended to cover Hg and NO filter for all classes (TM1, TM2 and TM3);

d) nominal values and tolerances were added;

e) clogging was deleted;

f) warning facilities were amended to cover low energy and low flow warning;

g) visual inspection was changed to inspection and detailed list inserted;

h) test substances and number of test subjects for inward leakage test was changed;

i) test for noise level was adapted to the test procedure specified in ISO 16900-14:2020;

j) Annex A was deleted;

k) figures were adapted to the changes made in the test procedures, where appropriate.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies minimum requirements for powered Respiratory Protective Devices (RPD)

incorporating a tight-fitting respiratory interface. It does not cover devices designed for use in

circumstances where there is or might be an oxygen deficiency.

Escape RPD and filters for use against CO are not covered by this document.

Laboratory tests and practical performance tests are included for the assessment of compliance with the

requirements.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 136:1998, Respiratory protective devices — Full face masks — Requirements, testing, marking

EN 140:1998, Respiratory protective devices — Half masks and quarter masks — Requirements, testing,

marking

EN 148-1:2018, Respiratory protective devices — Threads for facepieces — Part 1: Standard thread

connection

EN 148-2:1999, Respiratory protective devices — Threads for facepieces — Part 2: Centre thread

connection

EN 148-3:1999, Respiratory protective devices — Threads for facepieces — Part 3: Thread

connection M 45 × 3

EN 175:1997, Personal protection — Equipment for eye and face protection during welding and allied

processes

EN 13274-2:2019, Respiratory protective devices — Methods of test — Part 2: Practical performance tests

EN 13274-4:2020, Respiratory protective devices — Methods of test — Part 4: Flame test

EN 13274-7:2019, Respiratory protective devices — Methods of test — Part 7: Determination of particle

filter penetration

EN ISO 16321-1:2022, Eye and face protection for occupational use — Part 1: General requirements (ISO

16321-1:2021)

EN ISO 16321-3:2022, Eye and face protection for occupational use — Part 3: Additional requirements for

mesh protectors (ISO 16321-3:2021)

EN ISO 16972:2020, Respiratory protective devices — Vocabulary and graphical symbols (ISO 16972:2020)

ISO 16900-14:2020, Respiratory protective devices — Methods of test and test equipment — Part 14:

Measurement of sound pressure level

3 Terms and definitions, description and symbols

For the purposes of this document, the terms and definitions given in EN ISO 16972:2020 and the

following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp/

3.1 Terms and definitions

3.1.1

as received

not pre-conditioned or modified to carry out a test

[SOURCE: EN ISO 16972:2020, definition 3.16]

3.1.2

ready for assembly state

component with seals, plugs or other environmental protective means, if applicable, still in place

[SOURCE: EN ISO 16972:2020, definition 3.195]

3.1.3

respiratory interface

RI

part of a respiratory protective device (RPD) that forms the protective barrier between the wearer's

respiratory tract and the ambient atmosphere

Note 1 to entry: The RI is connected to the filtering part of the RPD or the part managing the supply of breathable

gas.

[SOURCE: EN ISO 16972:2020, definition 3.202]

3.1.4

tight-fitting respiratory interface

RI that forms a protective barrier between the wearers respiratory tract and the ambient atmosphere by

forming a seal to the wearer’s skin

[SOURCE: EN ISO 16972:2020, definition 3.241]

3.1.5

powered filtering RPD

filtering RPD in which air is moved through the filter(s) by means of a blower to supply the wearer with

breathable air

[SOURCE: EN ISO 16972:2020, definition 3.180]

3.1.6

unencapsulated filter

filter that in itself is not contained in a rigid housing

[SOURCE: EN ISO 16972:2020, definition 3.247]

3.1.7

manufacturer's minimum design condition

lowest level of operating conditions of the device as stated by the manufacturer at which the complete

RPD will still meet the requirements for the designated class

[SOURCE: EN ISO 16972:2020, definition 3.137]

3.2 Description

Each device typically consists of:

— a tight-fitting respiratory interface, e.g. a full face mask, a half mask or a quarter mask which can be

combined with other types of PPE;

— a blower unit with an energy supply intended to be carried/worn by the wearer which supplies

filtered ambient air to the respiratory interface. The energy supply for the blower unit can or cannot

be carried on the person;

— a filter or filters through which all air supplied passes;

— one or more exhalation valves or other outlets through which exhaled air and air in excess of the

wearer's demand is discharged.

3.3 Symbols

3.3.1 "See information supplied by the manufacturer”

3.3.2 Crossed out 2: Symbol “for single shift use only”

During one shift multiple use is allowed.

3.3.3 Hour glass “end of shelf life”

YYYY-MM

Key: YYYY = year, MM = month

3.3.4 Maximum time of use of Hg filters

3.3.5 Temperature range of storage conditions

Key: -xx °C to +yy °C

3.3.6 Maximum humidity of storage conditions

Key:

4 Classification

The complete devices are classified and designated according to the maximum inward leakage and

maximum particle filter penetration as given in Table 1 and strength of hoses and couplings as given in

Table 2.

Table 1 — Classification

Maximum inward

Maximum particle

leakage

filter penetration

Classification of complete device

a

(TIL or IL)

%

%

Power

Gasfilter

type and

Particle filter Paraffin

Class class NaCl

(if applicable) oil

On Off

(if

applicable)

A1, A2 or A3

B1, B2 or B3

E1, E2 or E3

P 5 5

K1, K2 or K3

TM1 5 5

AX

SX

Hg P

0,05 0,05

NO P

A1, A2 or A3

B1, B2 or B3

E1, E2 or E3

P 0,5 0,5

K1, K2 or K3

TM2 0,5 1

AX

SX

Hg P

0,05 0,05

NO P

A1, A2 or A3

B1, B2 or B3

E1, E2 or E3

P

K1, K2 or K3

TM3 0,05 0,1 0,05 0,05

AX

SX

Hg P

NO P

EXAMPLE TM2A2P: a powered filtering device incorporating a tight-fitting RI (TM) fitted with a combined gas

filter and a particle filter (A2P) and where the inward leakage of the complete device is 0,5 % or

less.

a

TIL for combined and particle filter systems only. IL for gas filter systems.

Check in accordance with 7.3.

5 Requirements

5.1 General

All test samples specified in the related test clauses shall meet the relevant requirements.

Where it is required in a specific clause the manufacturer shall declare that a risk assessment, e.g. a

Failure Modes and Effect Analysis (FMEA) concerning these specific requirements has been conducted.

NOTE Further information is given in EN IEC 60812 [1].

If the manufacturer claims that the RPD may be used in potentially explosive atmospheres it shall comply

with the appropriate requirements.

If the RPD is intended to provide additional protection, e.g. head protection, eye protection, face

protection, or including protective clothing it shall additionally comply with the relevant requirements

of the standards covering those related PPE.

Check in accordance with 6.3.

It shall not be possible to connect any part of the RPD to a thread conforming to EN 148-2:1999 or

EN 148-3:1999.

Check in accordance with 6.3.

When the RPD manufacturer states that an accessory is intended for use with the RPD, the RPD including

the accessory shall be tested.

Check in accordance with 6.3 and test in accordance with the appropriate test method.

Depending on the design of the RPD all air flow rates can be influenced by:

— possible flow settings of the RPD,

— service life,

— the charging status of the battery,

— different filter types,

— alarm settings,

— use of accessories,

— hose length, and

— other factors, if applicable.

All results of measured air flow rates are deemed to be volumetric flow rates and shall be corrected to

20 °C, 1 013 hPa according to Formula (1).

P

m

(1)

Q Qk⋅⋅

cor m

T

m

where

Q is the corrected air flow;

cor

Q is the measured air flow;

m

k is a constant 0,289 [K/hPa], i.e. 293 K divided by 1 013 hPa (20°C);

P is the pressure during measurement in hPa;

m

T is the temperature during measurement in K.

m

=

5.2 Values and tolerances

Temperature limits, values which describe test conditions and that are not stated as maxima or minima

shall be subject to a tolerance of ± 5 %. Unless otherwise specified, the ambient conditions for testing

shall be between 16 °C and 32 °C and (50 ± 30) % relative humidity.

Any temperature limits specified shall be subject to an accuracy of ± 1 °C.

5.3 Ergonomics

The requirements of this document are intended to take account of the interaction between the wearer,

the RPD, and where possible the working environment in which the RPD is likely to be used. The RPD

shall satisfy 5.5, 5.11 and 5.12.

Testing shall be performed in accordance with EN 13274-2:2019.

5.4 Design

The finish of any part of the device likely to be in contact with the wearer shall be free from sharp edges

and burrs.

Check in accordance with 6.3 and test in accordance with EN 13274-2:2019.

5.5 Materials

5.5.1 General

Materials used shall be suitable to withstand the intended use and conditions (e.g. temperatures,

humidity and corrosive environments) as stated by the manufacturer, unless otherwise specified in this

document.

The manufacturer shall supply a declaration that this was addressed by a risk assessment, e.g. a FMEA.

Check in accordance with 6.3.

5.5.2 Skin compatibility

Materials that may come into direct contact with the wearer's skin or that can affect the quality of the

breathing air shall not be known to be likely to cause skin irritation or any other adverse effects to health.

The manufacturer shall supply a declaration that this was addressed by a risk assessment, e.g. a FMEA.

Check in accordance with 6.3.

5.6 Mechanical strength (optional)

After conditioning in accordance with 6.2.1, blower units and battery casings (if separate from the blower

unit) shall show no significant deformation of major components, nor shall these components separate

from each other.

The requirements of 5.7, 5.9 to 5.14 and 5.16 to 5.20 shall be met and the RPD shall be marked in

accordance with 7.3 d).

5.7 Resistance to temperature

After conditioning at the extremes of temperature and humidity in accordance with 6.2.2, the RPD

components including filters in their ready for assembly state shall show no significant deformation of

major components, nor shall these components separate from each other or from the complete RPD. The

requirements of 5.8 to 5.14 and 5.16 to 5.20 shall be met.

5.8 Respiratory interface (RI)

5.8.1 General

Where the RI is fitted with the standard thread connection as defined in EN 148-1:2018 it shall comply

with the requirements of EN 136:1998 or EN 140:1998 as appropriate.

Full face masks shall meet the requirements specified in 5.8.2 or EN 136:1998, as appropriate.

Half masks and quarter masks shall meet the requirements specified in 5.8.3 or EN 140:1998, as

appropriate.

5.8.2 Full face masks (other than those complying with EN 136:1998)

5.8.2.1 Connection to full face mask

RI shall not be equipped with a standard thread connection according to EN 148-1:2018.

The connection to the full face mask shall be leaktight.

When tested in accordance with EN 136:1998, 8.8, it shall withstand an axial force of (500 ± 50) N applied

for (10 ± 1) s whilst the RI is held by the facepiece.

All demountable connections shall be easily connected and secured, where possible by hand. Any means

of sealing used shall be retained in position when the connection is disconnected during normal

maintenance.

Check in accordance with 6.3.

5.8.2.2 Exhalation means

5.8.2.2.1 A full face mask shall have a means of allowing the escape of exhaled air and excess air

delivered by the air supply.

Check in accordance with 6.3.

5.8.2.2.2 Exhalation means shall be easily to maintain and correctly replaced.

Check in accordance with 6.3.

5.8.2.2.3 If tested in accordance with 6.5.3 the exhalation means shall function correctly.

5.8.2.2.4 Exhalation means shall be protected against or shall be resistant to dirt and mechanical

damage.

Check in accordance with 6.3.

5.8.2.2.5 Exhalation means shall operate correctly when tested in accordance with 6.4 and 6.5 and after

an exposure of a continuous exhalation flow of (300 ± 15) l/min for a period of (60 ± 6) s.

Check in accordance with 6.3.

5.8.2.2.6 When the housing of the exhalation means is attached to the RI it shall withstand an axial

force of (150 ± 15) N for a period of (10 ± 1) s.

The test shall be repeated 9 times.

5.8.2.3 Head harness

The head harness shall be designed so that the RI can be donned and removed easily.

The head harness shall be adjustable and shall hold the RI firmly and comfortably in position.

Check in accordance with 6.3 and test in accordance with 6.4 and EN 13274-2:2019.

Each strap shall withstand a tensile force of (150 ± 10) N for (10 ± 1) s in the direction of pull when the

full face mask is donned.

5.8.2.4 Eyepieces and visor(s)

5.8.2.4.1 Visors shall not distort vision nor shall any misting occur which significantly affects vision

when determined in accordance with EN 13274-2:2019.

Where anti-misting compounds are used or specified by the manufacturer they shall not be known to be

likely to cause irritation or any other adverse effect to health.

The manufacturer shall supply a declaration that this was addressed by a risk assessment, e.g. a FMEA.

5.8.2.4.2 When tested in accordance with EN 136:1998, 8.17, the field of vision of the complete device

shall meet the following requirements:

— the effective field of vision of a full face mask fitted with a single visor shall be not less than 70 %

related to the natural field of vision, and the overlapped field of vision related to the natural

overlapped field of vision shall be not less than 80 %;

— a full face mask with two eyepieces shall be designed so that the effective field of vision shall be not

less than 70 % related to the natural field of vision, and the overlapped field of vision related to the

natural overlapped field of vision shall be not less than 20 %.

5.8.2.4.3 If it is intended to provide additionally protection against certain types of non-ionizing

radiation then the protection shall comply with the relevant clauses of EN 175:1997,

EN ISO 16321-1:2022 or EN ISO 16321-3:2022, as appropriate.

If the means of protection against non-ionizing radiation is integral with the equipment covered by this

document then the field of vision shall be measured as specified in EN 136:1998, 8.17, and reported for

information only and the device shall comply with the relevant clauses of EN 175:1997,

EN ISO 16321-1:2022 or EN ISO 16321-3:2022, as appropriate.

5.8.2.4.4 When tested in accordance with EN 136:1998, 8.11 (excluding leaktightness), but using two

samples only, the eyepieces or visor shall not be damaged so that the RI fails to meet the requirements

specified in 5.9.

5.8.2.5 Speech diaphragm

Where the RI includes a speech diaphragm it shall be protected against mechanical damage and shall

withstand a positive pressure of 15 mbar and a negative pressure of 80 mbar (static pressure).

When a speech diaphragm can be subjected to an external force it shall withstand an axial force of

(150 ± 10) N for (10 ± 1) s. The test shall be repeated 9 times.

5.8.3 Half masks and quarter masks (other than those complying with EN 140:1998)

5.8.3.1 RI connector

RI shall not be equipped with a standard thread connection according to EN 148-1:2018.

All demountable connections shall be easily connected and secured, where possible by hand. Any means

of sealing used shall be retained in position when the connection is disconnected during normal

maintenance.

Check in accordance with 6.3.

The connection to the half mask or quarter mask shall be leaktight. It shall withstand an axial tensile force

of (50 ± 5) N applied for (10 ± 1) s whilst the RI shall be held by the faceblank.

Testing shall be performed in accordance with EN 140:1998, 7.8.

5.8.3.2 Exhalation means

5.8.3.2.1 A half mask or quarter mask shall have a means of allowing the escape of exhaled air and

excess air delivered by the air supply.

5.8.3.2.2 Any exhalation means shall be easily to maintain and correctly replaced.

Check in accordance with 6.3.

5.8.3.2.3 If tested in accordance with 6.5.3 the exhalation means shall function correctly.

5.8.3.2.4 Exhalation means shall be protected against or be resistant to dirt and mechanical damage.

Check in accordance with 6.3.

5.8.3.2.5 Exhalation means shall operate correctly when tested in accordance with 6.4 and 6.5 and after

an exposure of a continuous exhalation flow of (300 ± 15) l/min for a period of (60 ± 6) s.

Check in accordance with 6.3.

5.8.3.2.6 When the housing of the exhalation means is attached to the RI it shall withstand an axial

force of (50 ± 5) N for a period of (10 ± 1) s.

5.8.3.3 Head harness

The head harness shall be so designed that the half mask or quarter mask can be donned and removed

easily.

The head harness shall be adjustable and shall hold the half mask or quarter mask firmly and comfortably

in position.

Check in accordance with 6.3 and test in accordance with 6.4 and EN 13274-2:2019.

Each strap shall withstand an axial force of (50 ± 5) N for (10 ± 1) s in the direction of pulling when the

half mask or quarter mask is donned.

5.8.3.4 Field of vision

The field of vision shall be assessed for acceptability.

Testing shall be performed in accordance with EN 13274-2:2019.

5.9 Inward leakage

5.9.1 General

Two samples, or more if disposable, shall be temperature conditioned in accordance with 6.2.2 and, if

applicable, mechanical strength conditioned in accordance with 6.2.1

The manufacturers' minimum design conditions shall be determined in accordance with 5.11.

If the RPD is for

— particles only, the inward leakage test shall be performed with ten subjects using NaCl aerosol;

— gases only, the inward leakage test shall be performed with ten test subjects using SF ;

— particles and gases, the inward leakage test shall be performed with five test subjects, using SF and

five subjects using NaCl aerosol. See Table 7.

Testing shall be performed in accordance with 6.4.

5.9.2 Power-on mode

When tested at the manufacturer's minimum design condition the inward leakage of the test substance

for each of the exercises shall not exceed the levels given in the appropriate class from Table 1, for each

of the 10 test subjects.

Testing shall be performed in accordance with 6.4.

5.9.3 Power-off mode

For 3 of the 10 test subjects and after the test in power-on mode, without removing the device, the inward

leakage shall be tested in the power off mode during which the inward leakage shall be not greater than

the levels given in the appropriate class from column 5 of Table 1, for each of the 3 test subjects.

Testing shall be performed in accordance with 6.4.

5.10 Breathing resistance

5.10.1 General

One sample shall be temperature preconditioned in accordance with 6.2.2 and, if applicable, mechanical

preconditioned in accordance with 6.2.1.

5.10.2 Inhalation resistance

When tested in accordance with 6.5.1, the peak inhalation resistance shall not exceed 11 mbar. When

tested in accordance with 6.5.2 and 6.5.3, the peak inhalation resistance shall not exceed 3,5 mbar.

5.10.3 Exhalation resistance

The peak exhalation resistance shall not exceed 7 mbar.

Testing shall be performed in accordance with 6.5.3.

5.11 Air supply

One sample shall be temperature conditioned in accordance with 6.2.2 and if applicable mechanical

preconditioned in accordance with 6.2.1.

The performance of the complete RPD shall equal or exceed the performance of the manufacturer's

minimum design condition for the manufacturer's stated design duration, when tested at a setting of the

breathing machine of 50 l/min (20 x 1,5 l/min) with a tolerance of ± 5 %.

Testing shall be performed in accordance with 6.6.

Where the manufacturer's minimum design condition is a manufacturer's minimum flow rate the

determination of the air supply flow rate shall be as specified in 6.7.

The flow rate and distribution of the air under the RI shall not cause distress to the wearer (for example

by excessive local cooling of the head and face or by causing eye irritation).

Check in accordance with 6.3 and test in accordance with EN 13274-2:2019.

It shall not be possible to switch off the air supply inadvertently.

Testing shall be performed in accordance with EN 13274-2:2019.

If a means is provided to adjust the air supply to give a RPD classification, it shall not be possible to change

the classification during use. The RPD shall be so designed that it is not possible to inadvertently change

the air flow.

A means for adjusting the airflow during use within a classification can be provided.

Check in accordance with 6.3 and test in accordance with EN 13274-2:2019.

5.12 Warning facilities

5.12.1 General

Two samples shall be mechanical preconditioned in accordance with 6.2.1, if applicable, and temperature

preconditioned in accordance with 6.2.2.

All warnings shall draw the attention of the wearer within 15 s once activated at or above the

manufacturer’s minimum design condition.

All warnings, except for low energy, shall continue to function while the cause of the warning remains.

After activation of the warning, it shall not be possible to turn off the warning device by the wearer while

the cause of the alarm remains.

Test in accordance with EN 13274-2:2019.

5.12.2 Low energy warning

All classes of the RPD shall be equipped with at least one low energy warning facility. Information about

the remaining service time to leave the hazardous environment, which shall be at least 5 min, shall be

given in the information supplied by the manufacturer.

Check in accordance with 6.3 and test in accordance with 6.7.5 and EN 13274-2:2019.

5.12.3 Manufacturer's minimum design condition warning

All classes of the RPD shall be equipped with at least one warning facility which indicates to the wearer

that the manufacturer's minimum design conditions are not met.

Check in accordance with 6.3 and test in accordance with 6.7.5 and EN 13274-2:2019.

5.13 Electrical components

One sample as received shall be checked .

Electrical components shall be so designed that it is not possible to inadvertently reduce or reverse the

air flow.

Check in accordance with 6.3 and EN 13274-2:2019.

If the device is claimed to be intrinsically safe for use in potentially explosive atmospheres it shall comply

with the appropriate requirements.

5.14 Breathing hose, if applicable, and couplings

5.14.1 General

Two samples shall be temperature preconditioned in accordance with 6.2.2.

Any breathing hose shall permit free head movement without danger of being caught up, as assessed by

the test subjects.

Testing shall be performed in accordance with EN 13274-2:2019.

When the breathing hose is compressed, the peak inhalation resistance shall not be changed by more

than 0,5 mbar and shall not exceed 3,5 mbar.

Testing shall be performed in accordance with 6.8.

Table 2 — Strength of hose and couplings

Classification Strength

N

TM1 (50 ± 2,5)

TM2 (100 ± 5)

TM3 (250 ± 10)

5.14.2 Strength of couplings to RI

Hoses and couplings shall meet the requirements given in Table 2 and shall not become disconnected or

visibly damaged. Where multiple hoses are fitted to the device each hose shall meet the requirements

given in Table 2. Each connection shall withstand the force as defined by its classification.

Testing shall be performed in accordance with 6.9.

5.15 Filters

5.15.1 Particle filters

5.15.1.1 Classification and designation

Powered particle filtering RPD shall be classified according to the maximum particle filter penetration

given in Table 1 when tested in accordance with 6.12 at a flow rate that corresponds to the peak value of

the interactive flow rate measured in 6.10.

Powered particle filtering RPD can be classified at three levels and shall be designated as follows:

TMyP

where

y is the inward leakage class 1, 2 or 3.

5.15.2 Gas filters

5.15.2.1 Classification and designation

Powered gas filtering RPD shall be classified according to their application and protection capacity when

tested in accordance with 6.12 at a flow rate that corresponds to the average value of the interactive flow

measured in 6.10 and shall be designated as follows:

TMy Gas z

where

y is the inward leakage class 1, 2 or 3 and

z is the capacity of the gas filter 1, 2 or 3 and

'Gas' means one or more of the types listed in (5.15.2.2.2), (5.15.2.2.3) or (5.15.2.2.4).

5.15.2.2 Types of filters

5.15.2.2.1 General

Gas filters are classified in the following types or combinations of them. If a filter is a combination of types,

it shall meet the requirements of each type separately.

5.15.2.2.2 Types A, B, E and K

a) Type A

For use against certain organic gases and vapours of organic substances with a boiling point higher

than 65 °C as specified by the manufacturer.

b) Type B

For use against certain inorganic gases and vapours as specified by the manufacturer (excluding

carbon monoxide).

c) Type E

For use against sulfur dioxide and other acidic gases and vapours as specified by the manufacturer.

d) Type K

For use against ammonia and organic ammonia derivatives as specified by the manufacturer.

5.15.2.2.3 Special filters

Special filters shall include a particle filter on the inlet side.

a) Type NO P

For use against oxides of nitrogen, e.g. NO, NO and/or NO .

2 x

Type NO P filters are for single shift use only up to the intended use time specified by the

manufacturer and shall be marked with the symbol given in 3.3.2.

b) Type Hg P

For use against mercury.

All Hg P filters are for a maximum accumulated use time of 50 h and shall be marked with the symbol

given in 3.3.4.

5.15.2.2.4 AX and SX filters

a) Type AX

For use against certain organic gases and vapours with a boiling point ≤ 65 °C as specified by the

manufacturer.

Type AX filters are for single shift use only and shall be marked with the symbol given in 3.3.2.

b) Type SX

For use against specific named gases and vapours as specified by the manufacturer.

5.15.2.3 Classes of filters

5.15.2.3.1 Types A, B, E, and K

Type A, B, E and K filters are classified as follows:

— Class 1: Low capacity;

— Class 2: Medium capacity;

— Class 3: High capacity.

Special filter shall only be specified for one class.

5.15.2.3.2 Combined filters

Combined filters shall be classified as separate entities in accordance with 5.15.1 and 5.15.2 and shall be

designated as follows:

TM y Gas z P

where

y is 1, 2 or 3

z is 1, 2 or 3 and

Gas means one or more of the types listed in (5.15.2.2.2), (5.15.2.2.3) or (5.15.2.2.4).

5.15.3 Filter requirements

5.15.3.1 General

The connection between filter(s) and the mating part of the device shall be robust and leaktight.

The connection between the filter and the mating part may be achieved by a special type of a connection,

a thread conforming to EN 148-1:2018 or other screw threads.

Filters other than prefilters shall be designed to be irreversible and shall be easily replaceable without

use of special tools.

Filters in their ready for assembly state shall be subjected to temperature conditioning as specified in 6.2

followed by the mechanical strength for filter as specified in 5.15.3.3.

For particle filter efficiency three filters for each test aerosol shall be tested in accordance with 6.12.2.

For gas capacity three filters for each test gas shall be tested in accordance with 6.12.3.

The particle filter of a combination filter shall be on the influent side of the filter.

Check in accordance with 6.3 and test in accordance with 6.4 and 6.12.

5.15.3.2 Materials

The inside of the filter shall be resistant to corrosion by the filter media.

Material from the filter media released by the air flow through the filter shall not pose a hazard or an

adverse effect for the wearer.

The manufacturer shall supply a declaration that both requirements were addressed by a risk

assessment, e.g. a FMEA.

Check in accordance with 6.3.

-----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...