EN 16900:2017

(Main)Fast pyrolysis bio-oils for industrial boilers - Requirements and test methods

Fast pyrolysis bio-oils for industrial boilers - Requirements and test methods

This European Standard specifies requirements and test methods for fast pyrolysis bio-oils for boiler use at industrial scale (>1 MW thermal capacity), not for domestic use. Two different grades are specified.

It is recommended to draw attention to differences especially in those properties, which can have an effect on the required flue gas treatment system, such as ash, nitrogen, and sulfur content. National and local regulations determine the requirements for flue gas treatment system.

In addition to the quality requirements and test methods for fast pyrolysis bio-oils, further instructions on storage (Annex A), sampling, and materials compatibility (Annex B) are given.

NOTE For the purposes of this European Standard, the term "% (m/m)" is used to represent respectively the mass fraction.

Schnellpyrolyse-Bioöle für industrielle Kesselanlagen - Anforderungen und Prüfverfahren

Diese Europäische Norm legt Anforderungen und Prüfverfahren für Schnellpyrolyse-Bioöle für industrielle Kesselanlagen (> 1 MW Wärmekapazität), nicht jedoch für den häuslichen Gebrauch fest. Es werden zwei verschiedene Klassen bestimmt.

Es wird empfohlen die Unterschiede insbesondere derjenigen Eigenschaften zu beachten, die einen Einfluss auf das erforderliche Abgasbehandlungssystem haben können, wie Asche-, Stickstoff- und Schwefelgehalt. Nationale und lokale Regelungen bestimmen die Anforderungen an das Abgasbehandlungssystem.

Zusätzlich zu den Qualitätsanforderungen und Prüfverfahren für Schnellpyrolyse-Bioöle sind weitere Hinweise zur Lagerung (Anhang A), Probenahme und Kompatibilität der Materialien (Anhang B) angegeben.

ANMERKUNG Für die Zwecke dieser Europäischen Norm wird der Ausdruck "% (m/m)" zur Darstellung des jeweiligen Massenanteils genutzt.

Huiles de pyrolyse rapide pour application chaudières - Spécifications et méthodes d’analyses

La présente Norme européenne spécifie les exigences et méthodes d'essai applicables aux bio-huiles de pyrolyse rapide destinées à être utilisées dans des chaudières à usage industriel (> 1 MW de capacité thermique), et non dans des chaudières à usage domestique. Elle spécifie deux niveaux de qualité différents.

Il est recommandé de souligner les différences existantes, notamment au niveau des propriétés pouvant avoir un impact sur le système de traitement des gaz de combustion requis, telles que les teneurs en cendres, en azote et en soufre. Les réglementations locales et nationales fixent les exigences applicables en termes de système de traitement des gaz de combustion.

Outre les exigences de qualité et les méthodes d'essai applicables aux bio-huiles de pyrolyse rapide, des instructions relatives au stockage (Annexe A), à l'échantillonnage et à la compatibilité du matériel (Annexe B) sont données.

NOTE Pour les besoins de la présente Norme européenne, l’expression «% (m/m)» est utilisée pour désigner les fractions massiques.

Bioolja, pridobljena s hitro pirolizo, za industrijske kotle - Zahteve in preskusne metode

Ta evropski standard določa zahteve in preskusne metode za trženo in dobavljeno gorivo, pridobljeno s postopki hitre pirolize olja. Uporablja se za olja, pridobljena s hitro pirolizo, za uporabo v industrijskih kotlih in povezani opremi, ki proizvaja toploto ali elektriko. Predstavlja alternativo ali komponento za mešanje v težkem ali lahkem kurilnem olju, ki se uporablja za podobne namene.

General Information

- Status

- Published

- Publication Date

- 14-Mar-2017

- Withdrawal Date

- 29-Sep-2017

- Technical Committee

- CEN/TC 19 - Petroleum products, lubricants and related products

- Drafting Committee

- CEN/TC 19/WG 41 - Pyrolysis oil

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 19-Sep-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Refers

EN ISO 2719:2025 - Determination of flash point - Pensky-Martens closed cup method (ISO 2719:2025) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16900:2017 (CEN) specifies requirements and test methods for fast pyrolysis bio‑oils (FPBO) intended for use in industrial boilers (>1 MW thermal capacity). It is not intended for domestic heating. The standard defines two product grades, includes quality limits, sampling and handling rules, and gives guidance on storage and materials compatibility to support safe, reliable combustion and emissions control.

Key topics and technical requirements

Scope and grades

- Applies to FPBO for industrial boiler applications and distinguishes Grade 1 (stricter) and Grade 2 (less stringent) to reflect different burner/emission requirements.

- Emphasises differences in properties that affect flue gas treatment (ash, nitrogen, sulfur).

Quality limits and test methods

- Specifies properties and analytical methods (examples from the standard):

- Net calorific value (wet basis) ≈ 14.0 MJ/kg

- Water content ≤ 30% (m/m) (ASTM E203)

- pH ≈ 2.0 (acidic) (ASTM E70)

- Density at 15 °C up to 1 300 kg/m³ (EN ISO 12185)

- Pour point around -9 °C (ISO 3016)

- Emission/burner dependent limits (examples):

- Kinematic viscosity at 40 °C: Grade 1 ≤ 125 mm²/s, Grade 2 ≤ 50 mm²/s

- Sulfur (dry basis): Grade 1 ≤ 0.10%, Grade 2 ≤ 0.05%

- Solids and ash specified with stricter limits for Grade 2

- Test methods referenced include EN and ISO methods plus ASTM procedures for specific FPBO analyses.

- Specifies properties and analytical methods (examples from the standard):

Sampling and sample handling

- Follow EN ISO 3170 and national rules; special FPBO advice:

- Homogenise before sampling, analyse ASAP or freeze samples

- Minimum recommended sample ~0.1 L; viscosity reproducibility ±5% at 40 °C

- Avoid preheating above 40 °C for >30 min

- Follow EN ISO 3170 and national rules; special FPBO advice:

Storage and materials compatibility

- Annex A: recommended storage 15–20 °C, maximum ~6 months; avoid prolonged high temperatures that accelerate ageing

- Annex B: material compatibility guidance for tanks, pumps, seals and sampling equipment

Applications and users

- Who uses EN 16900:2017:

- Boiler manufacturers and burner designers adapting equipment for FPBO

- Fuel producers and suppliers (quality specification & conformity)

- Industrial plant operators using FPBO as a renewable fuel

- Testing laboratories performing FPBO analysis and dispute resolution

- Regulators and consultants advising on emissions and flue gas treatment

- Practical value:

- Provides harmonised quality criteria, test methods and storage/handling rules to enable safe combustion, consistent fuel supply, and manageable emissions control for industrial-scale FPBO use.

Related standards

EN 16900:2017 references relevant test and transport standards (examples):

- EN ISO 2719 (flash point), EN ISO 3104 (viscosity), EN ISO 12185 (density)

- ASTM E203 (water by Karl Fischer), ASTM D5291 (C/H/N), ASTM D7579 (pyrolysis solids)

- EN ISO 6245 (ash), EN ISO 20846 (sulfur by UV fluorescence)

Keywords: EN 16900:2017, fast pyrolysis bio‑oil, FPBO, industrial boilers, test methods, ash content, sulfur content, nitrogen content, storage, sampling, materials compatibility.

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 16900:2017 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fast pyrolysis bio-oils for industrial boilers - Requirements and test methods". This standard covers: This European Standard specifies requirements and test methods for fast pyrolysis bio-oils for boiler use at industrial scale (>1 MW thermal capacity), not for domestic use. Two different grades are specified. It is recommended to draw attention to differences especially in those properties, which can have an effect on the required flue gas treatment system, such as ash, nitrogen, and sulfur content. National and local regulations determine the requirements for flue gas treatment system. In addition to the quality requirements and test methods for fast pyrolysis bio-oils, further instructions on storage (Annex A), sampling, and materials compatibility (Annex B) are given. NOTE For the purposes of this European Standard, the term "% (m/m)" is used to represent respectively the mass fraction.

This European Standard specifies requirements and test methods for fast pyrolysis bio-oils for boiler use at industrial scale (>1 MW thermal capacity), not for domestic use. Two different grades are specified. It is recommended to draw attention to differences especially in those properties, which can have an effect on the required flue gas treatment system, such as ash, nitrogen, and sulfur content. National and local regulations determine the requirements for flue gas treatment system. In addition to the quality requirements and test methods for fast pyrolysis bio-oils, further instructions on storage (Annex A), sampling, and materials compatibility (Annex B) are given. NOTE For the purposes of this European Standard, the term "% (m/m)" is used to represent respectively the mass fraction.

EN 16900:2017 is classified under the following ICS (International Classification for Standards) categories: 75.160.20 - Liquid fuels; 75.160.40 - Biofuels. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16900:2017 has the following relationships with other standards: It is inter standard links to EN ISO 3170:2004, EN ISO 2719:2025, EN ISO 4259-1:2017, EN ISO 9038:2025, EN ISO 6245:2002, EN ISO 12185:2024, EN ISO 4259-2:2017, EN 16476:2014, EN ISO 20846:2019, EN ISO 3104:2023, CEN/TR 17103:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16900:2017 is associated with the following European legislation: Standardization Mandates: M/525. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16900:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Bioolja, pridobljena s hitro pirolizo, za industrijske kotle - Zahteve in preskusne metodeFast Pyrolyse-Öle für die stationäre Wärmeerzeugung - Anforderungen und PrüfverfahrenHuiles de pyrolyse rapide pour application chaudières - Spécifications et méthodes d’analysesFast pyrolysis bio-oils for industrial boilers - Requirements and test methods75.160.40BiogorivaBiofuelsICS:Ta slovenski standard je istoveten z:EN 16900:2017SIST EN 16900:2017en,fr,de01-junij-2017SIST EN 16900:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16900

March

t r s y ICS

y wä s x rä v r English Version

Fast pyrolysis bioæoils for industrial boilers æ Requirements and test methods Huiles de pyrolyse rapide pour application chaudières æSpécifications et méthodes d 5analyses

SchnellpyrolyseæBioöle für industrielle Kesselanlagen æAnforderungen und Prüfverfahren This European Standard was approved by CEN on

s x January

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s y CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x { r rã t r s y ESIST EN 16900:2017

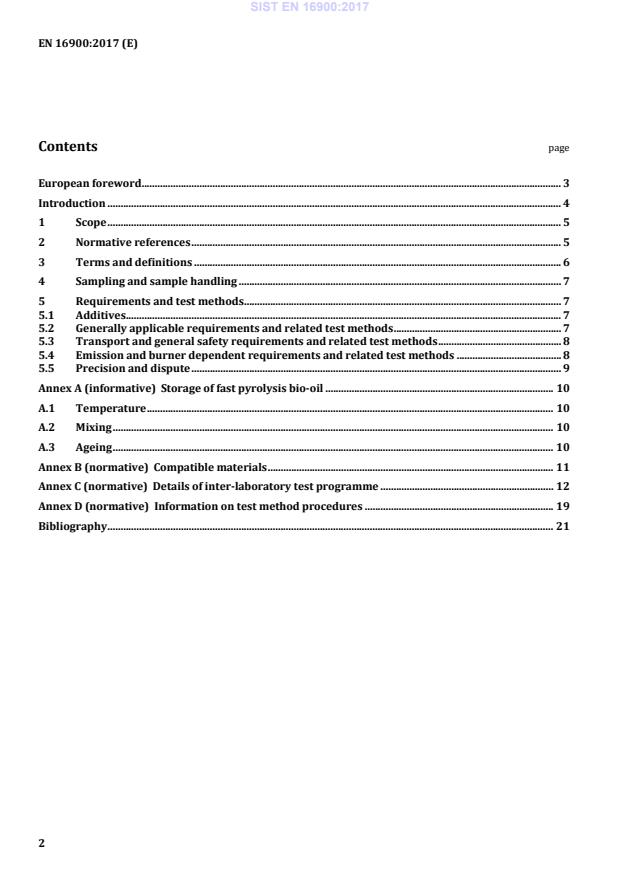

page European foreword . 3 Introduction . 4 1 Scope . 5 2 Normative references . 5 3 Terms and definitions . 6 4 Sampling and sample handling . 7 5 Requirements and test methods . 7 5.1 Additives . 7 5.2 Generally applicable requirements and related test methods . 7 5.3 Transport and general safety requirements and related test methods . 8 5.4 Emission and burner dependent requirements and related test methods . 8 5.5 Precision and dispute . 9 Annex A (informative)

Storage of fast pyrolysis bio-oil . 10 A.1 Temperature . 10 A.2 Mixing . 10 A.3 Ageing . 10 Annex B (normative)

Compatible materials . 11 Annex C (normative)

Details of inter-laboratory test programme . 12 Annex D (normative)

Information on test method procedures . 19 Bibliography . 21

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

14,0 Water content, on wet basis %(m/m) ASTM E203

30 pH

ASTM E70

2,0 Density at 15 °C kg/m3 EN ISO 12185

1 300 Pour point °C ISO 3016

- 9 Nitrogen content, (d.b.b). % (m/m) ASTM D5291 report a Net calorific value on wet basis is calculated from the gross calorific value according to DIN 51900–1. b d.b. is on dry basis. 5.3 Transport and general safety requirements and related test methods The UN transport of goods regulation [16] considers liquids with a flash point of more than 35 °C which do not sustain combustion as flammable liquids. Due to their consistency and water content (see Table 1 and Annex C) FPBO are in general non-flammable liquids and would not sustain combustion at a test temperature above 60,5 °C (as prescribed in EN ISO 9038 [17]). In line with the above FPBO that fulfils the following requirements are considered to be able to sustain combustion: — Flash point as measured by Procedure B of EN ISO 2719 is higher than 35 °C; and — Sustained combustibility passes the test procedure as in EN ISO 9038. NOTE Results of ILS analysis (Annex C) show that flash point is not suitable analysis method for FPBO. Also, according other research results [17] FPBO is non-flammable liquid. 5.4 Emission and burner dependent requirements and related test methods For emission and burner dependent requirements [6], options are given to allow grades to be set locally or chosen by the user. The options are two grades, of which Grade 1 requires more flue gas treatment than Grade 2. When tested by the methods indicated in Table 2, fast pyrolysis bio-oils shall be in accordance with the maximum limit specified in the Table 2 for the Grade applicable. The test methods listed in Table 2 have been assessed for application in boiler use. SIST EN 16900:2017

Storage of fast pyrolysis bio-oil A.1 Temperature Recommended storage conditions for large batches of bio-oil are 15 °C to 20 °C and maximum of six months. Storage at a minimum temperature of 15 °C is recommended to maintain adequate fluidity, but not higher than 20 °C for long-term storage. Long time at relatively high storage temperatures accelerate viscosity increase of the fuel [3, 6]. A.2 Mixing There are always some solids in FPBO but they are not considered as a separate phase in FPBO. After mixing solids are evenly distributed in the bio-oil. An extractive-rich phase may be gradually separated to top layer of the liquid. The stratification to top and bottom phase is slow and can be avoided by constant mixing. Similar type of phenomena is observed also with some agro-biomass. If moderate mixing is provided the fast pyrolysis bio-oil is a homogenous liquid [3, 14]. A.3 Ageing Ageing can lead to phase separation. All fast pyrolysis bi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...