prEN 13055

(Main)Lightweight aggregates for construction works - Characteristics

Lightweight aggregates for construction works - Characteristics

This document specifies the characteristics of lightweight aggregates (LWA) and LWA fillers and mixtures of them intended to be used in concrete, mortar and grout, bituminous mixtures, surface treatments and for unbound and hydraulically bound applications in construction works.

This document covers LWA and LWA fillers from mineral materials having particle densities less or equal to 2000 kg/m3 (2,000 Mg/m3) or loose bulk densities less or equal to 1200 kg/m3 (1,200 Mg/m3).

With regard to the aggregate size, this document covers LWA: fine lightweight aggregate (see 3.1.7), coarse lightweight aggregate (hereafter called coarse LWA) (see 3.1.8), all-in lightweight aggregate (hereafter called all-in LWA) (see 3.1.9) and LWA fillers (see 3.1.10).

With regard to the material source and production technique, this document covers LWA and LWA fillers:

a) of natural origin (see 3.1.2),

b) manufactured from natural materials (see 3.1.3),

c) manufactured from by-products of industrial processes (see 3.1.4) or from recycled source materials (see 3.1.5), and

d) as by-products of industrial processes (see 3.1.4).

Limits given to densities are related to some test methods which might not be applicable to some lightweight aggregates and lightweight aggregate fillers. This limitation is purely based on technical reasons and not to exclude any products from the market.

This document also specifies procedures for assessment and verification of constancy (AVCP) of performance of characteristics of LWA and LWA fillers.

This document does not cover LWA and LWA fillers of recycled aggregates from construction and demolition waste and Municipal Solid Waste Incinerator Bottom Ash (MIBA) (covered by prEN 17555-1:2021).

Leichte Gesteinskörnungen

Dieses Dokument legt die Eigenschaften von leichten Gesteinskörnungen (LWA, en: lightweight aggregates) und leichten Füllern sowie Mischungen davon fest, die für Beton, Mörtel und Einpressmörtel, bituminöse Gemische, Oberflächenbehandlungen sowie für ungebundene und hydraulisch gebundene Anwendungen in Bauwerken verwendet werden.

Dieses Dokument erfasst leichte Gesteinskörnungen und leichte Füller aus mineralischem Material mit einer Rohdichte von höchstens 2 000 kg/m3 (2,000 Mg/m3) oder einer Schüttdichte von höchstens 1 200 kg/m3 (1,200 Mg/m3).

Im Hinblick auf die Korngruppe erfasst dieses Dokument folgende leichte Gesteinskörnungen: feine leichte Gesteinskörnungen (siehe 3.1.7), grobe leichte Gesteinskörnungen (nachfolgend grobe LWA genannt) (siehe 3.1.8), kombinierte leichte Gesteinskörnungen (nachfolgend kombinierte LWA genannt) (siehe 3.1.9) und leichte Füller (siehe 3.1.10).

Im Hinblick auf den Ursprung des Materials und das Herstellungsverfahren erfasst dieses Dokument leichte Gesteinskörnungen und leichte Füller

a) natürlichen Ursprungs (siehe 3.1.2);

b) hergestellt aus natürlichem Material (siehe 3.1.3);

c) hergestellt aus Nebenprodukten aus industriellen Prozessen (siehe 3.1.4) oder aus Recycling Ausgangsmaterialien (siehe 3.1.5); und

d) als Nebenprodukte aus industriellen Prozessen (siehe 3.1.4).

Die Grenzwerte der Dichten stehen in Zusammenhang mit einigen Prüfverfahren, die auf einige leichte Gesteinskörnungen und leichte Füller nicht anwendbar sein könnten. Diese Begrenzung ist rein technisch bedingt und beabsichtigt nicht, Produkte vom Markt auszuschließen.

Dieses Dokument legt darüber hinaus Verfahren zur Bewertung und Überprüfung der Leistungsbeständigkeit (AVCP) der Eigenschaften leichter Gesteinskörnungen und leichter Füller fest.

Dieses Dokument erfasst keine leichten Gesteinskörnungen und leichten Füller aus rezyklierten Gesteinskörnungen aus Bau und Rückbauabfällen sowie aus Hausmüllverbrennungsasche (HMV Asche) (erfasst von prEN 17555-1:2021).

Granulats légers

Le présent document spécifie les caractéristiques relatives aux granulats légers (GL), aux fillers légers et aux mélanges de ces produits pour les applications béton, mortier, coulis, mélanges hydrocarbonés et traitements de surface et pour les matériaux traités et non traités aux liants hydrauliques pour les travaux de construction

Ce document couvre les granulats légers et les fillers légers élaborés à partir de matériaux minéraux dont les particules solides présentent une masse volumique réelle n’excédant pas 2000 kg/m3 (2,00 Mg/m3) ou une masse volumique en vrac n’excédant pas 1200 kg/m3 (1,20 Mg/m3).

En ce qui concerne la classe granulaire, ce document couvre les granulats légers suivants : les sables légers fins (voir 3.1.7), les gravillons légers (voir 3.1.8), les graves légères (voir 3.1.9) et les fillers légers (voir 3.1.10).

En ce qui concerne la matière première et la technique de production, le présent document couvre les granulats légers et fillers légers :

a) d’origine naturelle (voir 3.1.2),

b) artificiels issus de matériaux naturels (voir 3.1.3),

c) artificiels issus de résidus de processus industriels (voir 3.1.4) ou de matériaux recyclés (voir 3.1.5), et

d) comme résidus de processus industriels (voir 3.1.4).

Les limites indiquées pour les masses volumiques sont liées à certaines méthodes d’essai qui ne sont pas nécessairement applicables à certains granulats légers et à certains fillers légers. Cette limitation est purement basée sur des raisons techniques et ne vise pas à exclure des produits du marché.

Le présent document spécifie également les procédures d’Évaluation et de vérification de la constance des performances (EVCP) des caractéristiques des granulats légers et des fillers légers.

Ce document ne couvre pas les granulats légers et fillers légers fabriqués à partir de granulats recyclés issus des débris de construction, de démolition et des Mâchefers d’incinération des déchets non dangereux (MIDND) (couverts par la prEN 17555-1:2021).

Lahki agregati

General Information

- Status

- Not Published

- Technical Committee

- CEN/TC 154 - Aggregates

- Drafting Committee

- CEN/TC 154/SC 5 - Lightweight aggregates

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Due Date

- 02-Aug-2021

- Completion Date

- 26-Aug-2021

Overview

prEN 13055 - published by CEN - defines the characteristics and conformity procedures for lightweight aggregates (LWA) and LWA fillers used in construction. The standard applies to mineral LWAs with particle density ≤ 2000 kg/m³ or loose bulk density ≤ 1200 kg/m³ and covers aggregate types by size (fine, coarse, all‑in, fillers) and by origin (natural, manufactured from natural materials, from industrial by‑products or recycled source materials, and by‑products of industrial processes). It specifies sampling, test methods and Assessment and Verification of Constancy of Performance (AVCP) including factory production control (FPC), inspections and surveillance.

Key topics and technical requirements

The document addresses practical properties and test procedures relevant to design, production and quality control:

- Physical characteristics: particle density, loose bulk density, aggregate size, grading, particle shape, fineness.

- Hygro‑mechanical properties: water absorption, water content, water suction, porosity and volume of voids.

- Mechanical performance: bulk crushing resistance, resistance to fragmentation, compressibility, confined compressive strength, cyclic load shear strength.

- Durability and wear: freeze–thaw durability of coarse LWA, resistance to polishing, abrasion, wear from studded tyres, thermal shock.

- Chemical and compositional limits: chloride, acid‑soluble sulphate, total sulphur, loss on ignition, water solubility.

- Testing, sampling and reporting: specified sampling, sample reduction, and detailed test methods (e.g., bulk crushing procedure in Annex B).

- Conformity & AVCP: procedures for testing, FPC requirements, initial inspection and continuous surveillance to verify constancy of performance.

- Product designation, marking and labelling: guidance for clear product identification and information to users.

Note: some density limits relate to applicability of specific test methods and are technical limitations - not intended to exclude products from the market. Recycled aggregates from construction/demolition waste and MIBA are excluded (see prEN 17555‑1:2021).

Applications and users

prEN 13055 is essential for professionals specifying, producing, testing or approving LWA for:

- Structural and lightweight concrete, mortar and grout manufacturers

- Road and pavement designers (bituminous mixtures, surface treatments)

- Contractors and specifiers for unbound and hydraulically bound applications (e.g., geotechnical fill, lightweight fill)

- Aggregate producers and QA managers implementing FPC

- Testing laboratories, certification bodies and regulators ensuring compliance with EU construction product requirements

Using prEN 13055 helps ensure consistent performance, durability and safe application of LWA across civil, building and highway projects.

Related standards

- prEN 17555‑1:2021 - covers recycled aggregates from construction/demolition waste and MIBA (exclusion in prEN 13055).

- Historical: EN 13055‑1:2002 and EN 13055‑2:2004 (to be superseded).

- Annex ZA links prEN 13055 to Regulation (EU) No 305/2011 (Construction Products Regulation).

For detailed test procedures, limits and AVCP assignment consult the full prEN 13055 text.

Frequently Asked Questions

prEN 13055 is a draft published by the European Committee for Standardization (CEN). Its full title is "Lightweight aggregates for construction works - Characteristics". This standard covers: This document specifies the characteristics of lightweight aggregates (LWA) and LWA fillers and mixtures of them intended to be used in concrete, mortar and grout, bituminous mixtures, surface treatments and for unbound and hydraulically bound applications in construction works. This document covers LWA and LWA fillers from mineral materials having particle densities less or equal to 2000 kg/m3 (2,000 Mg/m3) or loose bulk densities less or equal to 1200 kg/m3 (1,200 Mg/m3). With regard to the aggregate size, this document covers LWA: fine lightweight aggregate (see 3.1.7), coarse lightweight aggregate (hereafter called coarse LWA) (see 3.1.8), all-in lightweight aggregate (hereafter called all-in LWA) (see 3.1.9) and LWA fillers (see 3.1.10). With regard to the material source and production technique, this document covers LWA and LWA fillers: a) of natural origin (see 3.1.2), b) manufactured from natural materials (see 3.1.3), c) manufactured from by-products of industrial processes (see 3.1.4) or from recycled source materials (see 3.1.5), and d) as by-products of industrial processes (see 3.1.4). Limits given to densities are related to some test methods which might not be applicable to some lightweight aggregates and lightweight aggregate fillers. This limitation is purely based on technical reasons and not to exclude any products from the market. This document also specifies procedures for assessment and verification of constancy (AVCP) of performance of characteristics of LWA and LWA fillers. This document does not cover LWA and LWA fillers of recycled aggregates from construction and demolition waste and Municipal Solid Waste Incinerator Bottom Ash (MIBA) (covered by prEN 17555-1:2021).

This document specifies the characteristics of lightweight aggregates (LWA) and LWA fillers and mixtures of them intended to be used in concrete, mortar and grout, bituminous mixtures, surface treatments and for unbound and hydraulically bound applications in construction works. This document covers LWA and LWA fillers from mineral materials having particle densities less or equal to 2000 kg/m3 (2,000 Mg/m3) or loose bulk densities less or equal to 1200 kg/m3 (1,200 Mg/m3). With regard to the aggregate size, this document covers LWA: fine lightweight aggregate (see 3.1.7), coarse lightweight aggregate (hereafter called coarse LWA) (see 3.1.8), all-in lightweight aggregate (hereafter called all-in LWA) (see 3.1.9) and LWA fillers (see 3.1.10). With regard to the material source and production technique, this document covers LWA and LWA fillers: a) of natural origin (see 3.1.2), b) manufactured from natural materials (see 3.1.3), c) manufactured from by-products of industrial processes (see 3.1.4) or from recycled source materials (see 3.1.5), and d) as by-products of industrial processes (see 3.1.4). Limits given to densities are related to some test methods which might not be applicable to some lightweight aggregates and lightweight aggregate fillers. This limitation is purely based on technical reasons and not to exclude any products from the market. This document also specifies procedures for assessment and verification of constancy (AVCP) of performance of characteristics of LWA and LWA fillers. This document does not cover LWA and LWA fillers of recycled aggregates from construction and demolition waste and Municipal Solid Waste Incinerator Bottom Ash (MIBA) (covered by prEN 17555-1:2021).

prEN 13055 is classified under the following ICS (International Classification for Standards) categories: 91.100.15 - Mineral materials and products. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 13055 is associated with the following European legislation: Standardization Mandates: M/125. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 13055 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2021

Lahki agregati

Lightweight aggregates

Leichte Gesteinskörnungen

Granulats légers

Ta slovenski standard je istoveten z: prEN 13055

ICS:

91.100.15 Mineralni materiali in izdelki Mineral materials and

products

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2021

ICS 91.100.15 Will supersede EN 13055:2016

English Version

Lightweight aggregates

Granulats légers Leichte Gesteinskörnungen

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 154.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13055:2021 E

worldwide for CEN national Members.

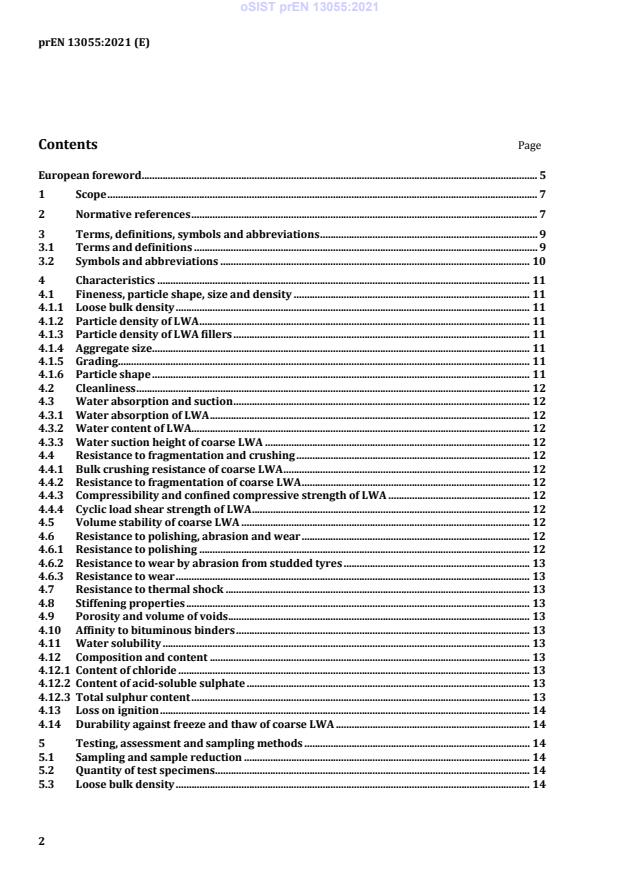

Contents Page

European foreword . 5

1 Scope . 7

2 Normative references . 7

3 Terms, definitions, symbols and abbreviations . 9

3.1 Terms and definitions . 9

3.2 Symbols and abbreviations . 10

4 Characteristics . 11

4.1 Fineness, particle shape, size and density . 11

4.1.1 Loose bulk density . 11

4.1.2 Particle density of LWA . 11

4.1.3 Particle density of LWA fillers . 11

4.1.4 Aggregate size . 11

4.1.5 Grading . 11

4.1.6 Particle shape . 11

4.2 Cleanliness . 12

4.3 Water absorption and suction . 12

4.3.1 Water absorption of LWA . 12

4.3.2 Water content of LWA . 12

4.3.3 Water suction height of coarse LWA . 12

4.4 Resistance to fragmentation and crushing . 12

4.4.1 Bulk crushing resistance of coarse LWA . 12

4.4.2 Resistance to fragmentation of coarse LWA . 12

4.4.3 Compressibility and confined compressive strength of LWA . 12

4.4.4 Cyclic load shear strength of LWA . 12

4.5 Volume stability of coarse LWA . 12

4.6 Resistance to polishing, abrasion and wear . 12

4.6.1 Resistance to polishing . 12

4.6.2 Resistance to wear by abrasion from studded tyres . 13

4.6.3 Resistance to wear . 13

4.7 Resistance to thermal shock . 13

4.8 Stiffening properties . 13

4.9 Porosity and volume of voids . 13

4.10 Affinity to bituminous binders . 13

4.11 Water solubility . 13

4.12 Composition and content . 13

4.12.1 Content of chloride . 13

4.12.2 Content of acid-soluble sulphate . 13

4.12.3 Total sulphur content . 13

4.13 Loss on ignition . 14

4.14 Durability against freeze and thaw of coarse LWA . 14

5 Testing, assessment and sampling methods . 14

5.1 Sampling and sample reduction . 14

5.2 Quantity of test specimens . 14

5.3 Loose bulk density . 14

5.4 Particle density of LWA . 14

5.5 Particle density of LWA fillers . 14

5.6 Aggregate size . 14

5.7 Grading of LWA . 14

5.8 Grading of LWA fillers . 14

5.9 Particle shape . 15

5.10 Cleanliness . 15

5.11 Water absorption of LWA . 15

5.12 Water content of LWA . 15

5.13 Water suction height of coarse LWA . 15

5.14 Bulk crushing resistance of coarse LWA . 15

5.15 Resistance to fragmentation of coarse LWA . 15

5.16 Compressibility and confined compressive strength of LWA . 15

5.17 Cyclic load shear strength of LWA . 15

5.18 Resistance to disintegration of coarse LWA . 15

5.19 Resistance to polishing . 15

5.20 Resistance to wear by abrasion from studded tyres . 15

5.21 Resistance to wear . 16

5.22 Resistance to thermal shock . 16

5.23 Stiffening properties . 16

5.24 Porosity and volume of voids . 16

5.25 Affinity to bituminous binders. 16

5.26 Water solubility . 16

5.27 Content of chloride . 16

5.28 Content of acid-soluble sulphate . 16

5.29 Total sulphur content . 16

5.30 Loss on ignition . 16

5.31 Durability against freeze and thaw of coarse LWA . 16

6 Assessment and verification of constancy of performance - AVCP . 17

6.1 General . 17

6.2 Assessment of performance . 17

6.2.1 General . 17

6.2.2 Test samples, testing and assessment criteria . 18

6.3 Verification of constancy of performance . 19

6.3.1 Factory production control (FPC) . 19

6.3.2 Initial inspection of factory and of FPC . 23

6.3.3 Continuous surveillance of FPC . 23

7 Product designation. 23

7.1 Lightweight aggregates codes, sources and products . 23

7.2 Designation . 25

8 Marking, labelling and packaging . 25

Annex A (normative) Standards covering other applications of LWA . 26

Annex B (normative) Determination of bulk crushing resistance . 27

B.1 Principle . 27

B.2 Apparatus . 27

B.3 Preparation of test specimens . 28

B.4 Procedure . 28

B.4.1 Procedure 1. 28

B.4.2 Procedure 2 . 28

B.4.3 Procedure 3 . 28

B.5 Calculation and expression of results . 29

B.6 Test report . 29

Annex C (normative) Mass conversion . 33

C.1 Background . 33

C.2 Calculation . 33

Annex ZA (informative) Relationship of this European Standard with Regulation (EU)

No 305/2011 . 34

ZA.1 Scope and relevant characteristics . 34

ZA.2 System of Assessment and Verification of Constancy of Performance (AVCP) . 41

ZA.3 Assignment of AVCP tasks . 41

Bibliography . 44

European foreword

This document prEN 13055 has been prepared by Technical Committee CEN/TC 154 “Aggregates”, the

secretariat of which is held by BSI.

This document is currently submitted to the CEN Enquiry.

This document will supersede the withdrawn harmonized standards:

EN 13055-1:2002, Lightweight aggregates — Part 1: Lightweight aggregates for concrete, mortar and

grout;

EN 13055-2:2004, Lightweight aggregates — Part 2: Lightweight aggregates for bituminous mixtures and

surface treatments and for unbound and bound applications.

This document will also supersede the non-harmonized standard:

— EN 13055:2016, Lightweight aggregates.

For information, EN 13055:2016 was published, but this version has failed to be cited in the OJEU.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Regulation(s).

For relationship with Regulation (EU) No 305/2011 on construction products (CPR), see informative

Annex ZA, which is an integral part of this document.

In comparison with the previous editions (2002, 2004 and 2016), the following technical modifications

have been made:

a) Merging of the former two parts, changing the title and clarifying the scope of the standard;

b) Reorganization, alignment and revision of terminology and text according to the Construction

Product Regulation, templates for harmonized standards, AVCP clauses and Annex ZA and in line

with the CEN/TC 154 approach for all aggregate product standards;

c) All normative references are made dated references;

d) Common terms and definitions are in accordance with prEN 17555-1:2021 Aggregates for

construction works — Part 1: Characteristics;

e) Previous Table 1 with sieve sized for specifying aggregate size replaced by a normative reference to

EN 933-2:2020;

f) Percentage of crushed particles is deleted as a characteristic and shall no longer be determined. (This

is in accordance with the revised answer to the mandate);

g) Deleting the clauses related to thermal conductivity;

h) Essential characteristics without a European test method have no longer been considered;

i) Replacement of 3 former test method annexes with normative references to separate EN test method

standards;

j) Information from the previous annex on test frequencies for factory production control are now

included in new Clause 6 on AVCP;

k) The previous annex on source material is deleted, see Bibliography;

l) The previous annex on chemical constituents and organic components is deleted. Text on chlorides

(because it is a concrete matter), alkali aggregate reaction and sulphates is deleted.

m) Referring certain LWA for specific applications to other aggregate standards in a normative Annex A

Standards covering other applications of LWA;

n) Annex B Determination of bulk crushing resistance includes a new procedure 3 for factory production

control of material up to 63 mm;

o) New normative Annex C on mass conversion;

p) Deleting previous annex on Determination of water absorption for fine LWA as a result of the ongoing

revision of prEN 1097-6:2020;

Characteristics for other aggregates are specified in the following European Standards:

— prEN 13383-1:2021, Armourstone — Part 1: Characteristics;

— prEN 13450-1:2021, Aggregates for railway ballast — Part 1: Characteristics;

— prEN 17555-1:2021, Aggregates for construction works — Part 1: Characteristics.

Some LWA for specific applications are covered in separate European product Standards, see normative

Annex A.

1 Scope

This document specifies the characteristics of lightweight aggregates (LWA) and LWA fillers and mixtures

of them intended to be used in concrete, mortar and grout, bituminous mixtures, surface treatments and

for unbound and hydraulically bound applications in construction works.

This document covers LWA and LWA fillers from mineral materials having particle densities less or equal

3 3 3 3

to 2000 kg/m (2,000 Mg/m ) or loose bulk densities less or equal to 1200 kg/m (1,200 Mg/m ).

With regard to the aggregate size, this document covers LWA: fine lightweight aggregate (see 3.1.7),

coarse lightweight aggregate (hereafter called coarse LWA) (see 3.1.8), all-in lightweight aggregate

(hereafter called all-in LWA) (see 3.1.9) and LWA fillers (see 3.1.10).

With regard to the material source and production technique, this document covers LWA and LWA fillers:

a) of natural origin (see 3.1.2),

b) manufactured from natural materials (see 3.1.3),

c) manufactured from by-products of industrial processes (see 3.1.4) or from recycled source materials

(see 3.1.5), and

d) as by-products of industrial processes (see 3.1.4).

Limits given to densities are related to some test methods which might not be applicable to some

lightweight aggregates and lightweight aggregate fillers. This limitation is purely based on technical

reasons and not to exclude any products from the market.

This document also specifies procedures for assessment and verification of constancy (AVCP) of

performance of characteristics of LWA and LWA fillers.

This document does not cover LWA and LWA fillers of recycled aggregates from construction and

demolition waste and Municipal Solid Waste Incinerator Bottom Ash (MIBA) (covered by

prEN 17555-1:2021).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 932-1:1996, Tests for general properties of aggregates — Part 1: Methods for sampling

EN 932-2:1999, Tests for general properties of aggregates — Part 2: Methods for reducing laboratory

samples

EN 932-5:2012 , Tests for general properties of aggregates — Part 5: Common equipment and calibration

EN 933-1:2012, Tests for geometrical properties of aggregates — Part 1: Determination of particle size

distribution — Sieving method

EN 933-2:2020, Tests for geometrical properties of aggregates — Part 2: Determination of particle size

distribution — Test sieves, nominal size of apertures

As impacted by corrigendum EN 932-5:2012/AC:2014.

EN 933-10:2009, Tests for geometrical properties of aggregates — Part 10: Assessment of fines — Grading

of filler aggregates (air jet sieving)

EN 1097-1:2011, Tests for mechanical and physical properties of aggregates — Part 1: Determination of

the resistance to wear (micro-Deval)

EN 1097-2:2020, Tests for mechanical and physical properties of aggregates — Part 2: Methods for the

determination of resistance to fragmentation

EN 1097-3:1998, Tests for mechanical and physical properties of aggregates — Part 3: Determination of

loose bulk density and voids

EN 1097-4:2008, Tests for mechanical and physical properties of aggregates — Part 4: Determination of

the voids of dry compacted filler

EN 1097-5:2008, Tests for mechanical and physical properties of aggregates — Part 5: Determination of

the water content by drying in a ventilated oven

prEN 1097-6:2020, Tests for mechanical and physical properties of aggregates — Part 6: Determination of

particle density and water absorption

prEN 1097-7:2020, Tests for mechanical and physical properties of aggregates — Part 7: Determination of

the particle density of filler — Pyknometer method

EN 1097-8:2020, Tests for mechanical and physical properties of aggregates — Part 8: Determination of

the polished stone value

EN 1097-9:2014, Tests for mechanical and physical properties of aggregates — Part 9: Determination of

the resistance to wear by abrasion from studded tyres — Nordic test

EN 1097-10:2014, Tests for mechanical and physical properties of aggregates — Part 10: Determination of

water suction height

EN 1097-11:2013, Tests for mechanical and physical properties of aggregates — Part 11: Determination of

compressibility and confined compressive strength of lightweight aggregates

EN 1367-5:2011, Tests for thermal and weathering properties of aggregates — Part 5: Determination of

resistance to thermal shock

EN 1367-7:2014, Tests for thermal and weathering properties of aggregates — Part 7: Determination of

resistance to freezing and thawing of Lightweight aggregates

EN 1367-8:2014, Tests for thermal and weathering properties of aggregates — Part 8: Determination of

resistance to disintegration of Lightweight Aggregates

EN 1744-1:2009+A1:2012, Tests for chemical properties of aggregates — Part 1: Chemical analysis

EN 12697-11:2020, Bituminous mixtures — Test methods — Part 11: Determination of the affinity between

aggregate and bitumen

EN 13179-1:2013, Tests for filler aggregate used in bituminous mixtures — Part 1: Delta ring and ball test

EN 13286-7:2004, Unbound and hydraulically bound mixtures — Part 7: Cyclic load triaxial test for

unbound mixtures

3 Terms, definitions, symbols and abbreviations

3.1 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1.1

lightweight aggregate

granular material of mineral origin having a particle density less or equal to (≤) 2000 kg/m (2,000

3 3 3

Mg/m ) or a loose bulk density less or equal to (≤) 1200 kg/m (1,200 Mg/m )

3.1.2

natural lightweight aggregate

aggregate from mineral sources which has been subjected to nothing more than mechanical processing

and sometimes washing

[SOURCE: prEN 17555-1:2021, 3.1.2]

3.1.3

manufactured lightweight aggregate

aggregate of mineral origin resulting from an industrial process involving thermal or other modification

[SOURCE: prEN 17555-1:2021, 3.1.3, modified — Note to entry has been deleted.]

3.1.4

by-product lightweight aggregate

aggregate of mineral origin from an industrial process which subsequently has been subjected to nothing

more than mechanical processing

3.1.5

recycled source material

raw material of inorganic or mineral origin from waste sources for use in manufactured LWA

3.1.6

recycled aggregate

aggregate resulting from processing of inorganic or mineral material previously used in construction

3.1.7

fine lightweight aggregate

designation given to the smaller aggregate sizes with D less than or equal to 4 mm and d greater than or

equal to 0 mm

[SOURCE: prEN 17555-1:2021, 3.1.12]

3.1.8

coarse lightweight aggregate

designation given to the larger aggregate sizes with D greater than 4 mm and less than 90 mm and d

greater than or equal to 1 mm

[SOURCE: prEN 17555-1:2021, 3.1.8]

3.1.9

all-in lightweight aggregate

processed aggregate consisting of a mixture of coarse and fine aggregates with D greater than 4 mm and

d equal to 0 mm

Note 1 to entry: It can be produced without separating into coarse and fine fractions or it can be produced by

combining coarse and fine aggregates.

[SOURCE: prEN 17555-1:2021, 3.1.13]

3.1.10

lightweight aggregate filler

fine lightweight aggregate, most of which passes a 0,063 mm sieve

3.1.11

grading

particle size distribution expressed as the percentage by mass passing a specified set of sieves

[SOURCE: prEN 17555-1:2021, 3.1.6, modified — Note to entry has been deleted.]

3.1.12

aggregate size

designation of aggregate in terms of lower (d) and upper (D) sieve sizes expressed as d/D, where d/D is

less than 0,72

Note 1 to entry: Sieve sizes are selected from those in EN 933-2:2020.

Note 2 to entry: The designation accepts the presence of some particles which are retained on the upper sieve

(oversize) and some particles which pass the lower sieve (undersize).

[SOURCE: prEN 17555-1:2021, 3.1.5]

3.1.13

constant mass

successive weighings after drying and conditioning at least 1 h apart not differing by more than 0,1 %

3.2 Symbols and abbreviations

For the purposes of this document, the following symbols and abbreviations apply.

AVCP Assessment and Verification of Constancy of Performance

d Lower sieve size designation in mm

D Upper sieve size designation in mm

DoP Declaration of Performance

FPC Factory production control

LWA Lightweight aggregate(s)

PSV Polished stone value

4 Characteristics

4.1 Fineness, particle shape, size and density

4.1.1 Loose bulk density

Loose bulk density of LWA and LWA fillers shall be determined according to 5.3. Measured values shall

3 3

be in the range of ± 15 % with a maximum of ± 100 kg/m (0,100 Mg/m ) of the declared value. The

3 3

performance shall be expressed as a level in kg/m (Mg/m ).

4.1.2 Particle density of LWA

Particle density of LWA shall be determined according to 5.4. Measured values shall be in the range

3 3

of ± 15 % with a maximum of ± 150 kg/m (0,150 Mg/m ) of the declared value. The performance shall

3 3

be expressed as a level in kg/m (Mg/m ).

4.1.3 Particle density of LWA fillers

Particle density of LWA fillers shall be determined according to 5.5. Measured values shall be in the range

3 3

of ± 15 % with a maximum of ± 150 kg/m (0,150 Mg/m ) of the declared value. The performance shall

3 3

be expressed as a level in kg/m (Mg/m ).

4.1.4 Aggregate size

The performance of LWA related to its aggregate size (d/D) is the quantity of aggregate passing the lower

(undersize) sieve (d) and retained on the upper (oversize) sieve (D) and shall be determined respectively,

as:

— the lower sized aggregate (d), and

— the upper sized aggregate (D).

The quantity of the lower sized LWA shall be determined according to 5.6. The quantity obtained shall

not exceed 15 % by mass.

The quantity of the upper sized LWA shall be determined according to 5.6. The quantity obtained shall

not exceed 10 % by mass.

The performance shall be expressed as d/D in mm/mm. The ratio d/D shall not exceed 0,72.

4.1.5 Grading

4.1.5.1 Grading of LWA

Grading of LWA shall be determined according to 5.7. The performance shall be expressed as particle size

distribution.

4.1.5.2 Grading of LWA fillers

Grading of LWA fillers shall be determined according to 5.8. The performance shall be expressed as

particle size distribution.

4.1.6 Particle shape

Particle shape of LWA shall be determined according to 5.9. The particle shape shall be described.

4.2 Cleanliness

Cleanliness is expressed through the absence of organic components in natural LWA i.e. which alter the

rate of setting and hardening of concrete, mortar and grout shall be determined according to 5.10. The

cleanliness shall be described.

4.3 Water absorption and suction

4.3.1 Water absorption of LWA

Water absorption of LWA shall be determined according to 5.11. The performance shall be expressed as

a level in % by mass.

4.3.2 Water content of LWA

The water content of LWA shall be determined according to 5.12. The performance shall be expressed as

a level in % by mass.

4.3.3 Water suction height of coarse LWA

Water suction height of coarse LWA shall be determined according to 5.13. The performance shall be

expressed as a level in mm.

4.4 Resistance to fragmentation and crushing

4.4.1 Bulk crushing resistance of coarse LWA

Bulk crushing resistance of coarse LWA shall be determined according to 5.14. The performance shall be

expressed as a level in N/mm .

4.4.2 Resistance to fragmentation of coarse LWA

Resistance to fragmentation of coarse LWA shall be determined according to 5.15. The performance shall

be expressed as a level in % by mass.

4.4.3 Compressibility and confined compressive strength of LWA

The compressibility and confined compressive strength of LWA shall be determined according to 5.16.

The compressibility performance shall be expressed as a level in %. The confined compressive strength

performance shall be expressed as a level in MPa.

4.4.4 Cyclic load shear strength of LWA

The cyclic load shear strength is expressed through resilient modulus and shall be determined by cyclic

triaxial tests according to 5.17. The performance shall be expressed as a level in MPa.

4.5 Volume stability of coarse LWA

Volume stability is expressed through resistance to disintegration of coarse LWA and shall be determined

according to 5.18. The performance shall be expressed as a level in % by mass.

4.6 Resistance to polishing, abrasion and wear

4.6.1 Resistance to polishing

Resistance to polishing of coarse LWA shall be determined according to 5.19. The performance shall be

expressed as a level.

4.6.2 Resistance to wear by abrasion from studded tyres

Resistance to wear by abrasion from studded tyres of coarse LWA in surface treatments shall be

determined according to 5.20. The performance shall be expressed as a level.

4.6.3 Resistance to wear

Resistance to wear of coarse LWA shall be determined according to 5.21 The performance shall be

expressed as a level in % by mass.

4.7 Resistance to thermal shock

Resistance to thermal shock of coarse LWA shall be determined according to 5.22. The performance shall

be expressed as a level in % by mass.

4.8 Stiffening properties

Stiffening properties of LWA fillers shall be determined according to 5.23. The performance shall be

expressed as a level.

4.9 Porosity and volume of voids

Porosity and volume of voids are expressed through voids of dry compacted LWA fillers and shall be

determined according to 5.24. The performance shall be expressed as a level in % by volume.

4.10 Affinity to bituminous binders

Affinity between coarse LWA and bitumen shall be determined according to 5.25. The performance shall

be expressed as a level in %.

4.11 Water solubility

Water solubility of LWA fillers shall be determined according to 5.26. The performance shall be expressed

as a level in % by mass.

4.12 Composition and content

4.12.1 Content of chloride

The content of chloride shall be determined according to 5.27. The performance shall be expressed as a

level in % by mass.

For mass conversion, see Annex C.

4.12.2 Content of acid-soluble sulphate

The content of acid-soluble sulphate shall be determined according to 5.28. The performance shall be

expressed as a level in % by mass.

For mass conversion, see Annex C.

4.12.3 Total sulphur content

The total sulphur content shall be determined according to 5.29. The performance shall be expressed as

a level in % by mass.

For mass conversion, see Annex C.

4.13 Loss on ignition

Loss on ignition shall be determined according to 5.30. The performance shall be expressed as a level in

% by mass.

For mass conversion, see Annex C.

4.14 Durability against freeze and thaw of coarse LWA

Durability is expressed through freezing and thawing resistance of coarse LWA and shall be determined

according to 5.31. The performance shall be expressed as a level in % by mass.

5 Testing, assessment and sampling methods

5.1 Sampling and sample reduction

Where sampling and sample reduction is not mentioned specifically in the test method, sampling shall be

carried out in accordance with EN 932-1:1996, and necessary sample reduction shall be carried out in

accordance with EN 932-2:1999.

To ensure a representative sample, segregation and degradation shall be minimized.

5.2 Quantity of test specimens

The test specimen quantity specified in any test method shall, if not taken into account for LWA, be

corrected on the basis of loose bulk density.

5.3 Loose bulk density

The loose bulk density of LWA and LWA fillers shall be determined in accordance with EN 1097-3:1998.

The container shall be filled using a standard scoop held centrally over the container and without

touching it.

5.4 Particle density of LWA

The particle density of LWA shall be determined in accordance with prEN 1097-6:2020.

3 3

NOTE This test method does not work for all LWA having a bulk density of less than 150 kg/m (0,150 Mg/m ).

5.5 Particle density of LWA fillers

The particle density of LWA fillers shall be determined in accordance with prEN 1097-7:2020.

5.6 Aggregate size

The lower and upper aggregate size shall be determined using sieving according to EN 933-1:2012 in

terms of d in mm as the lower limit designation sieve and D in mm as the upper limit designation sieve

between which most of the particle size distribution lies. Sieve sizes shall be selected from those given in

EN 933-2:2020.

5.7 Grading of LWA

The particle size distribution of LWA shall be determined together with the content of fines by dry sieving

in accordance with EN 933-1:2012.

5.8 Grading of LWA fillers

The particle size distribution of LWA fillers shall be determined in accordance with EN 933-10:2009.

5.9 Particle shape

The particle shape of LWA shall be described.

5.10 Cleanliness

The presence of harmful organic components in natural LWA i.e. which alter the rate of setting and

hardening of concrete, mortar and grout shall be determined in accordance with

EN 1744-1:2009+A1:2012.

5.11 Water absorption of LWA

The water absorption of LWA shall be determined in accordance with prEN 1097-6:2020.

5.12 Water content of LWA

The water content of LWA shall be determined in accordance with EN 1097-5:2008.

5.13 Water suction height of coarse LWA

The water suction height of coarse LWA shall be determined in accordance with EN 1097-10:2014.

5.14 Bulk crushing resistance of coarse LWA

The bulk crushing resistance of coarse LWA shall be determined in accordance with Annex B.

NOTE 1 The bulk crushing resistance is intended only for factory production control.

NOTE 2 There is no simple correlation between the results obtained by the three procedures in Annex B.

5.15 Resistance to fragmentation of coarse LWA

The resistance to fragmentation (Los Angeles) of coarse LWA shall be determined in accordance with

EN 1097-2:2020.

NOTE This test method does not work for all types of LWA.

5.16 Compressibility and confined compressive strength of LWA

The compressibility and confined compressive strength of LWA shall be determined in accordance with

EN 1097-11:2013.

5.17 Cyclic load shear strength of LWA

The resilient modulus shall be determined by cyclic triaxial test in accordance with EN 13286-7:2004.

5.18 Resistance to disintegration of coarse LWA

The resistance to disintegration of coarse LWA shall be determined in accordance with EN 1367-8:2014.

5.19 Resistance to polishing

The polished stone value (PSV) of coarse LWA shall be determined in accordance with EN 1097-8:2020.

5.20 Resistance to wear by abrasion from studded tyres

The resistance to abrasion from studded tyres of coarse LWA shall be determined in accordance with

EN 1097-9:2014.

NOTE The expression “Nordic abrasion value(s)” is used in the referred test standard.

5.21 Resistance to wear

The resistance to wear (micro-Deval) of coarse LWA shall be determined in accordance with

EN 1097-1:2011.

NOTE This test method does not work for all types of LWA.

5.22 Resistance to thermal shock

The resistance to thermal shock of coarse LWA shall be determined in accordance with EN 1367-5:2011.

5.23 Stiffening properties

The stiffening properties of LWA fillers in bituminous mixtures shall be determined in accordance with

EN 13179-1:2013.

5.24 Porosity and volume of voids

The voids of dry compacted LWA fillers shall be determined in accordance with EN 1097-4:2008.

5.25 Affinity to bituminous binders

The affinity between coarse LWA and bitumen shall be determined in accordance with

EN 12697-11:2020.

5.26 Water solubility

The water solubility of LWA fillers used in bituminous mixtures shall be determined in accordance with

EN 1744-1:2009+A1:2012.

5.27 Content of chloride

The water-soluble chloride ion content shall be determined in accordance with

EN 1744-1:2009+A1:2012.

5.28 Content of acid-soluble sulphate

The acid-soluble sulphate content shall be determined in accordance with EN 1744-1:2009+A1:2012.

5.29 Total sulphur content

The total sulphur content shall be determined in accordance with EN 1744-1:2009+A1:2012.

5.30 Loss on ignition

The loss on ignition of by-products of industrial processes shall be determined in accordance with

EN 1744-1:2009+A1:2012.

5.31 Durability against freeze and thaw of coarse LWA

The resistance to freezing and thawing of coarse LWA having a loose bulk density of not less than

3 3

150 kg/m (0,150 Mg/m ) shall be determined in accordance with EN 1367-7:2014.

Alternatively, aggregates can be assessed on the basis of satisfactory service record of performance.

6 As

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...