EN 15624:2021

(Main)Railway applications - Braking - Empty-loaded changeover devices

Railway applications - Braking - Empty-loaded changeover devices

This document is applicable to empty-loaded changeover devices. The purpose of such devices is the generation of a load-related signal which causes the brake performance to be adjusted to the current vehicle mass.

The manually operated empty-loaded changeover devices change their output signal according to the position of the handles which together with the associated changeover plates serve as interfaces. The changeover plates read the required information for the operation of the empty-loaded changeover devices, i.e. brake weights for each position and the relevant changeover mass of the vehicle.

Automatic empty-loaded changeover devices sense a certain load threshold of the vehicle to automatically adjust the output signal when the mass of a vehicle reaches a defined value. This threshold is the changeover mass. Below this mass the vehicle’s brake system provides a reduced brake force. For the changeover mass or more the high brake force applies.

This document specifies the requirements for the design, testing and quality assurance of empty-loaded changeover devices.

Bahnanwendungen - Bremse - Leer-Beladen-Umstellvorrichtungen

Dieses Dokument ist für Leer-Beladen-Umstellvorrichtungen anzuwenden. Der Zweck solcher Vorrichtungen ist die Erzeugung eines lastabhängigen Signals, das die Anpassung des Bremsvermögens an die jeweilige Fahrzeugmasse bewirkt.

Die handbetätigten Leer-Beladen-Umstellvorrichtungen ändern ihr Ausgangssignal je nach Stellung der Handgriffe, die zusammen mit den zugehörigen Schildlagern als Schnittstellen dienen. Die Schildlager lesen die für die Betätigung der Leer-Beladen-Umstellvorrichtungen erforderlichen Informationen, d. h. Bremsgewichte für jede Stellung und die entsprechende Umstellmasse des Fahrzeugs.

Automatische Leer-Beladen-Umstellvorrichtungen tasten einen bestimmten Schwellenwert der Fahrzeuglast ab, um das Ausgangssignal automatisch anzupassen, wenn die Fahrzeugmasse einen festgelegten Wert erreicht. Dieser Schwellenwert ist die Umstellmasse. Unterhalb dieser Masse stellt das Bremssystem des Fahrzeugs eine reduzierte Bremskraft bereit. Bei der Umstellmasse oder höheren Massen wird die hohe Bremskraft angewendet.

Dieses Dokument legt die Anforderungen an die Konstruktion, die Prüfung und die Qualitätssicherung von Leer-Beladen-Umstellvorrichtungen fest.

Applications ferroviaires - Freinage - Dispositifs de changement de régime vide-chargé

Le présent document s’applique aux dispositifs de changement de régime « Vide-Chargé ». La finalité de ces dispositifs est la production d’un signal dépendant de la charge qui permet l’ajustement des performances de freinage à la masse effective du véhicule.

Les dispositifs de changement de régime « Vide-Chargé » à commande manuelle modifient leur signal de sortie selon la position des poignées qui, avec les plaques de commutation associées, servent d’interfaces. Les plaques de commutation indiquent les valeurs nécessaires lors de l’exploitation des dispositifs de changement de régime « Vide-Chargé », c’est-à-dire les masses freinées pour chaque position et la masse de changement de régime correspondante du véhicule.

Les dispositifs de changement de régime Vide-Chargé automatiques détectent un certain seuil de charge du véhicule afin d’ajuster automatiquement le signal de sortie lorsque la masse du véhicule atteint une valeur déterminée. Ce seuil est la masse de changement de régime. En dessous de cette masse, le système de freinage du véhicule fournit un effort de freinage réduit. Pour la masse de changement de régime ou pour une masse supérieure, l’effort de freinage élevé est appliqué.

Le présent document spécifie les exigences relatives à la conception, aux essais et à l’assurance qualité des dispositifs de changement de régime « Vide-Chargé ».

Železniške naprave - Zavore - Avtomatsko menjalo "naloženo-prazno"

General Information

- Status

- Withdrawn

- Publication Date

- 09-Feb-2021

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 25-Sep-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 17-Feb-2021

- Effective Date

- 09-Jul-2024

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 01-Dec-2021

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 15624:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking - Empty-loaded changeover devices". This standard covers: This document is applicable to empty-loaded changeover devices. The purpose of such devices is the generation of a load-related signal which causes the brake performance to be adjusted to the current vehicle mass. The manually operated empty-loaded changeover devices change their output signal according to the position of the handles which together with the associated changeover plates serve as interfaces. The changeover plates read the required information for the operation of the empty-loaded changeover devices, i.e. brake weights for each position and the relevant changeover mass of the vehicle. Automatic empty-loaded changeover devices sense a certain load threshold of the vehicle to automatically adjust the output signal when the mass of a vehicle reaches a defined value. This threshold is the changeover mass. Below this mass the vehicle’s brake system provides a reduced brake force. For the changeover mass or more the high brake force applies. This document specifies the requirements for the design, testing and quality assurance of empty-loaded changeover devices.

This document is applicable to empty-loaded changeover devices. The purpose of such devices is the generation of a load-related signal which causes the brake performance to be adjusted to the current vehicle mass. The manually operated empty-loaded changeover devices change their output signal according to the position of the handles which together with the associated changeover plates serve as interfaces. The changeover plates read the required information for the operation of the empty-loaded changeover devices, i.e. brake weights for each position and the relevant changeover mass of the vehicle. Automatic empty-loaded changeover devices sense a certain load threshold of the vehicle to automatically adjust the output signal when the mass of a vehicle reaches a defined value. This threshold is the changeover mass. Below this mass the vehicle’s brake system provides a reduced brake force. For the changeover mass or more the high brake force applies. This document specifies the requirements for the design, testing and quality assurance of empty-loaded changeover devices.

EN 15624:2021 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15624:2021 has the following relationships with other standards: It is inter standard links to EN 15624:2008+A1:2010, EN 15624:2021+A1:2024, EN 61373:2010, EN 60721-3-5:1997, ISO 8573-1:2010, EN ISO 228-1:2003, EN 15625:2021, EN 14478:2017, EN 45545-2:2020, EN 15877-1:2012+A1:2018, EN 15624:2021/FprA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15624:2021 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC, 2016/797/EU; Standardization Mandates: M/483, M/591. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15624:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2021

Nadomešča:

SIST EN 15624:2009+A1:2010

Železniške naprave - Zavore - Avtomatsko menjalo "naloženo-prazno"

Railway applications - Braking - Empty-loaded changeover devices

Bahnanwendungen- Bremse - Leer-Beladen-Umstellvorrichtungen

Applications ferroviaires - Freinage - Dispositifs de changement de régime Vide-Chargé

Ta slovenski standard je istoveten z: EN 15624:2021

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15624

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2021

EUROPÄISCHE NORM

ICS 45.040 Supersedes EN 15624:2008+A1:2010

English Version

Railway applications - Braking - Empty-loaded changeover

devices

Applications ferroviaires - Freinage - Dispositifs de Bahnanwendungen - Bremse - Leer-Beladen-

changement de régime vide-chargé Umstellvorrichtungen

This European Standard was approved by CEN on 20 December 2020.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15624:2021 E

worldwide for CEN national Members.

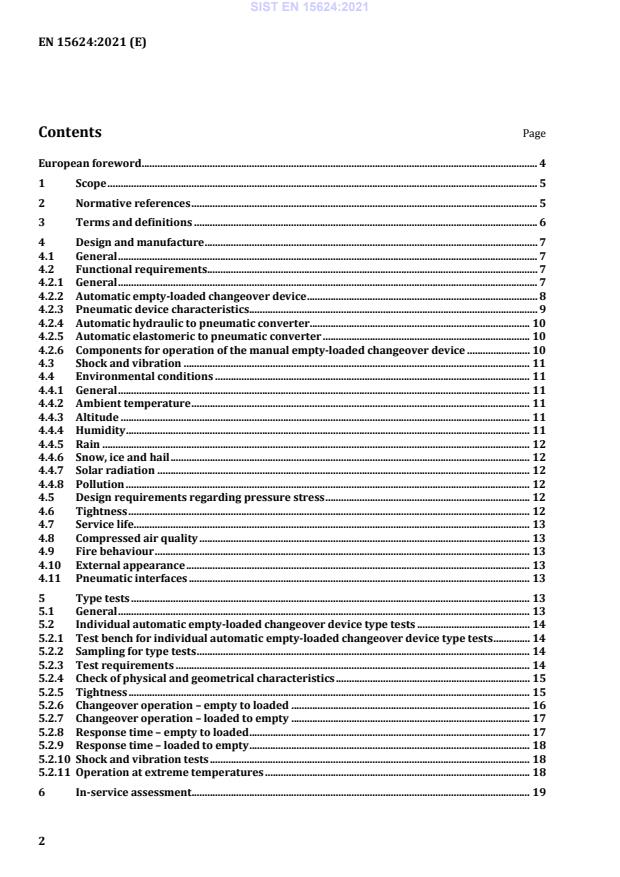

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Design and manufacture . 7

4.1 General . 7

4.2 Functional requirements. 7

4.2.1 General . 7

4.2.2 Automatic empty-loaded changeover device . 8

4.2.3 Pneumatic device characteristics. 9

4.2.4 Automatic hydraulic to pneumatic converter. 10

4.2.5 Automatic elastomeric to pneumatic converter . 10

4.2.6 Components for operation of the manual empty-loaded changeover device . 10

4.3 Shock and vibration . 11

4.4 Environmental conditions . 11

4.4.1 General . 11

4.4.2 Ambient temperature . 11

4.4.3 Altitude . 11

4.4.4 Humidity . 11

4.4.5 Rain . 12

4.4.6 Snow, ice and hail . 12

4.4.7 Solar radiation . 12

4.4.8 Pollution . 12

4.5 Design requirements regarding pressure stress . 12

4.6 Tightness . 12

4.7 Service life . 13

4.8 Compressed air quality . 13

4.9 Fire behaviour . 13

4.10 External appearance . 13

4.11 Pneumatic interfaces . 13

5 Type tests . 13

5.1 General . 13

5.2 Individual automatic empty-loaded changeover device type tests . 14

5.2.1 Test bench for individual automatic empty-loaded changeover device type tests . 14

5.2.2 Sampling for type tests . 14

5.2.3 Test requirements . 14

5.2.4 Check of physical and geometrical characteristics . 15

5.2.5 Tightness . 15

5.2.6 Changeover operation – empty to loaded . 16

5.2.7 Changeover operation – loaded to empty . 17

5.2.8 Response time – empty to loaded . 17

5.2.9 Response time – loaded to empty . 18

5.2.10 Shock and vibration tests . 18

5.2.11 Operation at extreme temperatures . 18

6 In-service assessment. 19

7 Designation . 20

8 Identification and marking . 20

8.1 Identification . 20

8.2 Changeover plate for the manual empty-loaded changeover device . 20

Annex A (informative) Assessment of an empty-loaded changeover device when fitted to a

vehicle . 21

A.1 General . 21

A.2 Design acceptance testing set-up . 21

A.3 Static testing . 21

A.3.1 Vehicle requirements . 21

A.3.2 Test procedures . 21

A.3.2.1 Changeover setting of automatic empty-loaded changeover devices . 21

A.3.2.1.1 Procedure . 21

A.3.2.1.2 Pass/fail criteria . 21

A.3.2.2 Effects on brake characteristics . 22

A.3.2.2.1 General . 22

A.3.2.2.2 Procedure . 22

A.3.2.2.3 Pass/fail criteria . 22

A.4 Running tests . 22

A.4.1 General . 22

A.4.2 Pneumatic empty-loaded changeover device – Air consumption . 22

A.4.2.1 Procedure . 22

A.4.2.2 Pass/fail criteria . 22

A.4.3 Pneumatic empty-loaded changeover device – Impact of vibrations on the output

signal . 23

A.4.3.1 Procedure . 23

A.4.3.2 Pass/fail criteria . 23

Annex B (informative) Examples of manual empty-loaded changeover device handles and

changeover plates . 24

Annex C (informative) Test bench diagram . 26

Annex D (normative) In-service assessment . 27

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 2016/797/EU aimed to be covered. 28

Bibliography . 30

European foreword

This document (EN 15624:2021) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2021, and conflicting national standards shall be

withdrawn at the latest by August 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15624:2008+A1:2010.

The main changes compared to EN 15624:2008+A1:2010 are:

a) normative references have been updated;

b) terms and definitions have been revised;

c) requirements on design and manufacture have been revised;

d) requirements on materials have been removed;

e) requirements on type tests have been revised;

f) requirements on routine test and inspection have been removed;

g) requirements on type validation have been removed;

h) requirements on in-service assessment have been added;

i) requirements on installation validation and on documentation have been removed;

j) requirements on designation, identification and marking have been revised;

k) Annex ZA has been updated.

This document has been prepared under a standardization request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive 2016/797/EU.

For relationship with EU Directive 2016/797/EU, see informative Annex ZA, which is an integral part of

this document.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

1 Scope

This document is applicable to empty-loaded changeover devices. The purpose of such devices is the

generation of a load-related signal which causes the brake performance to be adjusted to the current

vehicle mass.

The manually operated empty-loaded changeover devices change their output signal according to the

position of the handles which together with the associated changeover plates serve as interfaces. The

changeover plates read the required information for the operation of the empty-loaded changeover

devices, i.e. brake weights for each position and the relevant changeover mass of the vehicle.

Automatic empty-loaded changeover devices sense a certain load threshold of the vehicle to

automatically adjust the output signal when the mass of a vehicle reaches a defined value. This threshold

is the changeover mass. Below this mass the vehicle’s brake system provides a reduced brake force. For

the changeover mass or more the high brake force applies.

This document specifies the requirements for the design, testing and quality assurance of empty-loaded

changeover devices.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14478:2017, Railway applications — Braking — Generic vocabulary

EN 15625:2021, Railway applications — Braking — Automatic variable load sensing devices

EN 15877-1:2012+A1:2018, Railway applications — Marking on railway vehicles — Part 1: Freight

wagons

EN 45545-2:2020, Railway applications — Fire protection on railway vehicles — Part 2: Requirements for

fire behavior of materials and components

EN 60721-3-5:1997, Classification of environmental conditions — Part 3: Classification of groups of

environmental parameters and their severities — Section 5: Ground vehicle installations

(IEC 60721-3-5:1997)

EN 61373:2010, Railway applications — Rolling stock equipment — Shock and vibration tests

(IEC 61373:2010)

EN ISO 228-1:2003, Pipe threads where pressure-tight joints are not made on the threads — Part 1:

Dimensions, tolerances and designation (ISO 228-1:2000)

ISO 8573-1:2010, Compressed air — Part 1: Contaminants and purity classes

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 14478:2017, EN 15625:2021

and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http://www.electropedia.org/

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

empty-loaded changeover device

device connected to the vehicle, which is either manually operated or responds automatically to a change

of vehicle load, thereby providing a load-related signal which changes at a certain vehicle mass threshold

(changeover mass) when the load is increased or when the load is decreased

3.2

positive load signal pressure device

empty-loaded changeover device that provides a positive output pressure in the loaded state

3.3

zero load signal pressure device

empty-loaded changeover device that exhausts the output pressure to nominally 0 bar in the loaded state

3.4

changeover mass

lowest value of vehicle mass at which it is deemed to be in the loaded state, thereby requiring the

adjustment of brake force to achieve the required brake performance

3.5

automatic variable load sensing device

weighing valve

device connected to the vehicle, which responds to the loading of that vehicle to provide a continuous

load proportional signal to the brake control device

Note 1 to entry: The load input is normally a share of the wagon’s mass because of the devices position in the

vehicle suspension system. The result is a pneumatic output signal pressure that can be any value between a

minimum at tare mass and a maximum at maximum mass. Most of the existing self-adjusting load-dependant brakes

generate the load signal using a weighing valve.

[SOURCE: EN 15625:2021, 3.1]

3.6

mechanically operated pneumatic device

device or mechanism which responds to a mechanical input by a change of the output pressure

[SOURCE: EN 15625:2021, 3.2]

3.7

hydraulic to pneumatic converter

device or mechanism which transforms a hydraulic pressure into a pneumatic pressure with a defined

transmission ratio

[SOURCE: EN 15625:2021, 3.3]

3.8

elastomeric to pneumatic converter

device or mechanism having both elastomeric and pneumatic components which transforms a pressure

in the elastomer into a pneumatic pressure with a defined transmission ratio

[SOURCE: EN 15625:2021, 3.4]

3.9

output signal pressure

load signal pressure

LSP

output pressure delivered by the empty-loaded changeover device, which signals the load state (either

empty or loaded) of the vehicle to the brake control device

3.10

supply pressure

input pressure to a pneumatic empty-loaded changeover device

3.11

normal litre

Nl

unit of amount of a gas equal to the amount of 1 l at a pressure of 1,0 bar and at a standard temperature,

at 20 °C

Note 1 to entry: Air flow is often stated in normal litres per minute (Nl/min).

4 Design and manufacture

4.1 General

The design and manufacture of the empty-loaded changeover device shall take the requirements of this

clause into account for all intended operating conditions.

4.2 Functional requirements

4.2.1 General

4.2.1.1 The empty-loaded changeover device shall supply a signal indicating the variation in vehicle

load (empty or loaded) to the braking control system; this shall be mechanical or pneumatic. The method

of producing the pneumatic signal shall be a mechanically operated pneumatic device, hydraulic to

pneumatic converter device or an elastomeric to pneumatic converter device.

4.2.1.2 The empty-loaded changeover device shall, in all cases, supply an output signal, which is a

function of the load.

4.2.1.3 The empty-loaded changeover device shall not alter any of the characteristics of the

distributor and/or any associated relay device, when fitted to a vehicle, thereby not altering the

characteristics of the brake system, other than to signal the load change and thereby cause the brake

cylinder pressure to change from one state to another.

4.2.1.4 The design of the empty-loaded changeover device shall either provide a positive output

pressure (positive load signal pressure device) or exhaust the output pressure to nominally 0 bar (zero

load signal pressure device) in the loaded state dependant on the applicable design requirements.

4.2.1.5 The air consumption of a pneumatic empty-loaded changeover device shall, during running

of the vehicle, be minimal and shall not interfere with the normal braking performance of that vehicle. A

test which can be used to confirm this is described in A.4.2.

4.2.2 Automatic empty-loaded changeover device

4.2.2.1 General

4.2.2.1.1 An automatic empty-loaded changeover device shall change from the empty to a loaded state

or vice versa, when the vehicle mass exceeds or falls below the changeover mass.

4.2.2.1.2 The automatic empty-loaded changeover device shall comply with the changeover values

specified in its technical specification.

Once fitted on the vehicle the changeover shall take place within ± 5 % of the defined changeover mass

of the vehicle.

For vehicles that operate only in empty or fully loaded states, this tolerance is in the range of ± 20 %.

NOTE A test which can be used to confirm this is described in A.3.2.1.

4.2.2.1.3 An automatic empty-loaded changeover device may have a damping facility within its

mechanism to prevent the effects of transient suspension movement from causing a change of the load

signal.

4.2.2.1.4 An automatic empty-loaded changeover device shall be designed to fit to a vehicle in a

position to sense the load change of that vehicle, causing a change of state/output signal of the changeover

device.

4.2.2.2 Changeover response

Where the empty-loaded changeover device does not include integral damping the response of the output

pressure shall be immediate, i.e. the pressure shall fall or increase dependent on the particular design of

the device, as soon as the device is moved from one state to another. Where the empty-loaded changeover

device has integral damping a delay in the LSP response shall be apparent.

4.2.2.3 Empty to loaded changeover

4.2.2.3.1 Integrally damped device supplied with air from the distributor auxiliary reservoir or

main reservoir pipe

Not earlier than 3 s after the operating mechanism was moved to the loaded position and remains there

the output pressure shall change to the loaded state for the particular design of the device as defined in

4.2.3. This shall be tested in accordance with 5.2.8.2.

When the operating mechanism is moved to the loaded position and kept there for less than 3 s the output

pressure shall not reach a value that causes a changeover to occur.

4.2.2.3.2 Device supplied with air from the distributor output pressure

When the operating mechanism is in the loaded position the output pressure shall remain in or change

to the loaded state during braking for the particular design of the device as defined in 4.2.3. This shall be

tested in accordance with 5.2.8.

When the brake is released there is no output pressure provided by the empty-loaded changeover device

regardless the position of the operating mechanism.

4.2.2.4 Loaded to empty changeover

4.2.2.4.1 Integrally damped device supplied with air from the auxiliary reservoir or main

reservoir pipe

Not earlier than 3 s after the operating mechanism was moved to the empty position and remains there

the output pressure shall change to the empty state for the particular design of the device as defined in

4.2.3. This shall be tested in accordance with 5.2.9.2.

When the operating mechanism is moved to the empty position and kept there for less than 3 s the output

pressure shall not reach a value that causes a changeover to occur.

4.2.2.4.2 Device supplied with air from the distributor output pressure

When the operating mechanism is in the empty position the output pressure shall remain in or change to

the empty state during braking for the particular design of the device as defined in 4.2.3. This shall be

tested in accordance with 5.2.9.

When the brake is released there is no output pressure provided by the empty-loaded changeover device

regardless the position of the operating mechanism.

4.2.3 Pneumatic device characteristics

4.2.3.1 The device shall be designed to accept a supply pressure directly from the vehicle’s auxiliary

reservoir or from the distributor output/brake cylinder pressure.

4.2.3.2 When the load signal is pneumatically transmitted to the brake control device, the changeover

device shall produce a step in LSP at a defined value of input signal representing the changeover mass

between the empty and loaded states.

4.2.3.3 Where the supply pressure to the empty-loaded changeover device is supplied from the

auxiliary reservoir the following shall apply.

a) For a positive load signal pressure device:

1) all values of the LSP of ≤ 0,5 bar shall indicate a vehicle load that is less than the changeover mass

with the purpose of causing the brake control device to output its lower ratio,

2) all values of the LSP of ≥ 3,0 bar shall indicate a vehicle load greater than the changeover mass

with the purpose of causing the brake control device to output its higher ratio. An LSP lower than

3,0 bar is acceptable to signal a vehicle load greater than the changeover mass, when an

automatic variable load sensing device is used as an automatic empty-loaded changeover device.

b) For a zero load signal pressure device:

1) all values of the LSP of ≥ 3,0 bar shall indicate a vehicle load that is less than the changeover mass

with the purpose of causing the brake control device to output its lower ratio,

2) all values of the LSP of ≤ 0,5 bar shall indicate a vehicle load greater than the changeover mass

with the purpose of causing the brake control device to output its higher ratio.

4.2.3.4 Where the supply pressure is supplied from the distributor output/brake cylinder pressure

system the following shall apply.

a) For a positive load signal pressure device:

1) the value of the LSP indicating a vehicle mass greater than the changeover mass, shall be

equivalent to the distributor output/brake cylinder pressure,

2) the value of the LSP indicating a vehicle mass lower than the changeover mass, shall be 0 bar.

b) For a zero load signal pressure device:

1) the value of the LSP indicating a vehicle mass greater than the changeover mass, shall be 0 bar,

2) the value of the LSP indicating a vehicle mass lower than the changeover mass, shall be

equivalent to the distributor output/brake cylinder pressure.

4.2.4 Automatic hydraulic to pneumatic converter

4.2.4.1 The load from the vehicle suspension applied mechanically to the empty-loaded changeover

device shall result in a change in state of the device as a consequence of a change in hydraulic pressure

within the device. This change of state shall occur at a value to be defined by the technical specification

of the component considered and result in a step change in the pneumatic LSP as in 4.2.3.

4.2.4.2 The design shall incorporate a method of ensuring that normal transient movements of the

vehicle suspension do not affect the state of the empty-loaded changeover device. This may be for

example achieved by incorporating a damping restriction in the hydraulic circuit of the device.

4.2.5 Automatic elastomeric to pneumatic converter

4.2.5.1 The load from the vehicle suspension applied mechanically to the empty-loaded changeover

device shall result in a change in state of the device as a consequence of a change in load on the

elastomeric element within the device. This change of state shall occur at a value to be defined by the

technical specification of the component considered and result in a step change in the pneumatic LSP as

in 4.2.3.2.

4.2.5.2 The design shall incorporate a method of ensuring that normal transient movements of the

vehicle suspension do not affect the state of the empty-loaded changeover device. This can be for example

achieved by a special elastomeric characteristic of the device.

4.2.6 Components for operation of the manual empty-loaded changeover device

4.2.6.1 When a vehicle is fitted with a brake system with one “empty” state and one or several

“loaded” states, changeover from one state to another shall be made by means of a cranked lever actuated

from both sides of the vehicle. See Figure B.1 for an example.

4.2.6.2 Operation of the manual empty-loaded changeover lever shall either cause a change of the

rigging’s lever ratio, or provide a signal which then causes a changeover of brake cylinder output

pressure.

4.2.6.3 For the “loaded” brake state corresponding to the maximum vehicle mass the lever shall be

inclined towards the top on the right, making an angle of 90 ° ± 10 ° with the “empty” position.

4.2.6.4 For the “empty” brake state, the changeover lever shall be inclined towards the top on the left

and occupy its extreme position on the left.

4.2.6.5 The lever positions corresponding to defined intermediate states between “empty” and

“loaded” shall be between those positions and increasing in brake power as moved to the right.

4.2.6.6 When the vehicle is fitted with one empty-loaded changeover device only, it shall have a

simple cranked lever only. See Figure B.1 a) for an example of the cranked lever form.

4.2.6.7 When the vehicle is fitted with two or more separate empty-loaded changeover devices, the

levers shall be cranked and feature an oblong hole in the handle. See Figure B.1 b) for the shape of this

cranked lever.

4.3 Shock and vibration

The design of the empty-loaded changeover device shall consider outside influences, e.g. impacts and

vibrations, and protect the device appropriately.

The empty-loaded changeover device shall be able to operate without restriction under shock and

vibration conditions as specified in EN 61373:2010. The class and category of test severity shall be

declared by design documentation. These requirements shall be tested in accordance with 5.2.10.

4.4 Environmental conditions

4.4.1 General

All the environmental requirements listed shall be taken into account within the design concept of the

components. However only the assessment tests listed in Clause 5 shall be performed. The remaining

proofs shall be presented in the declarations of conformity.

4.4.2 Ambient temperature

The empty-loaded changeover device covered by this document shall be able to operate from −40 °C to

+70 °C in accordance with the requirements of this document.

4.4.3 Altitude

The empty-loaded changeover device shall be able to operate without restrictions up to an altitude of

2 000 m above sea level.

4.4.4 Humidity

The following external humidity levels shall be considered:

— yearly average: ≤ 75 % relative humidity;

— on 30 days in the year continuously: between 75 % and 95 % relative humidity;

— on the other days occasionally: between 95 % and 100 % relative humidity;

— maximum absolute humidity: 30 g/m occurring in tunnels.

An operationally caused infrequent and slight moisture condensation shall not lead to any malfunction

or failure.

At cooled surfaces, 100 % relative humidity may occur, causing condensation on parts of equipment; this

shall not lead to any malfunction or failure.

Sudden lowering of the air temperature local to the vehicle may cause condensation of water on parts of

equipment with rate of 3 K/s and maximum fall in temperature of 40 K.

These conditions particularly occurring when entering or leaving a tunnel shall not lead to any

malfunction or failure of the equipment.

4.4.5 Rain

Rain rate of 6 mm/min shall be taken into account. The effect of rain shall be considered depending on

the possible equipment installation together with wind and vehicle movement.

4.4.6 Snow, ice and hail

Consideration shall be given to the effect of all kinds of snow, ice and/or hail. The maximum diameter of

hailstones shall be taken as 15 mm, exceptionally, larger diameters can occur.

The effect of snow, ice and hail shall be considered depending on the equipment installation together with

wind and vehicle movement.

4.4.7 Solar radiation

Equipment design shall allow for direct exposure to solar radiation at the rate of 1 120 W/m for a

maximum duration of 8 h.

4.4.8 Pollution

The effects of pollution shall be considered in the design of equipment and components. The severity of

pollution will depend upon the location of the equipment. Means may be provided to reduce the effect of

pollution. The effects of the following kinds of pollution shall be considered as given in Table 1.

Table 1 — Pollution requirements

Pollution Requirements

Chemically active substances Class 5C2 of EN 60721-3-5:1997

Class 5F2 (electrical engine) of EN 60721-3-5:1997

Contaminating fluids

Class 5F3 (thermal engine) of EN 60721-3-5:1997

Biologically active substances Class 5B2 of EN 60721-3-5:1997

Dust Class 5S2 of EN 60721-3-5:1997

Stone and other objects Objects of max. 15 mm diameter and ballast

Sand Class 5S2 of EN 60721-3-5:1997

Sea spray Class 5C2 of EN 60721-3-5:1997

4.5 Design requirements regarding pressure stress

The empty-loaded changeover device shall be able to withstand a supply pressure of (10,00 ± 0,50) bar

where applicable.

4.6 Tightness

Where applicable tightness of the empty-loaded changeover device shall be such that technical

performance as specified by this European Standard is met without restrictions.

This requirement is tested in accordance with 5.2.11.2.

4.7 Service life

No specific requirements for the empty-loaded changeover device to attain a particular service life are

contained in this document.

Any testing to estimate the service life of an empty-loaded changeover device should be conducted as

part of the product development.

NOTE The service life of the empty-loaded changeover device is a function of the environment/operating

conditions in which the device will function, and the requirements for the device to achieve a serviceable life in

accordance with the maintenance requirements of the vehicle to which it is fitted.

4.8 Compressed air quality

It shall be possible to operate the empty-loaded changeover device without restrictions with at least the

compressed air quality in accordance with the following classes defined in ISO 8573-1:2010:

— class 3 — for the maximum particle size and the maximum concentration of solid contaminants;

— class 4 — for the water dewpoint;

— class 4 — for the maximum total (droplets, aerosols and vapours) oil concentration.

4.9 Fire behaviour

The fire behaviour of the empty-loaded changeover device shall correspond to the requirements of

EN 45545-2:2020.

4.10 External appearance

The dimensions and the coordinates and threads of the ports and fixing points of the empty-loaded

changeover device shall comply with the details given by the relevant drawing.

The design of the empty-loaded changeover device shall ensure that the exterior surfaces of the empty-

loaded changeover device are free of sharp edges and corners that could be dangerous to those people

handling the empty-loaded changeover device or, when installed on a vehicle, working on adjacent

equipment. This requirement shall be checked in accordance with 5.2.4.

4.11 Pneumatic interfaces

Where applicable the connection of the pneumatic supply input to the empty-loaded changeover device

and the LSP from the empty-loaded changeover device, to the vehicle pipework, shall be achieved using

a threaded connection of size G 1/4 or G 1/2 in accordance with EN ISO 228-1:2003.

5 Type tests

5.1 General

The tests shall be performed by a competent laboratory.

NOTE As an example, a test institute in accordance with EN ISO/IEC 17025.

The following type tests shall be carried out in order to assess the performance of the empty-loaded

changeover device against the requirements of this document.

The type tests shall be conducted and the records shall be kept as evidence of the compliance with this

document.

The type tests shall be conducted on individual empty-loaded changeover devices.

All the test requirements shall be achieved to obtain type test compliance.

For manual empty-loaded changeover devices the type test in 5.2.4 shall be carried out. Further

functional type testing of manually operated changeover devices is not required as these devices operate

on the associated vehicle installation and their operation is subject to that installation. The correct

operation of manually operated empty-loaded changeover devices shall be tested on the vehicle.

Annex A contains tests that can be conducted as part of the type certification of a new empty-loaded

changeover device type.

5.2 Individual automatic empty-loaded changeover device type tests

5.2.1 Test bench for individual automatic empty-loaded changeover device type tests

The type tests shall be performed on a test bench designed so that all the requirements given by this

document for the testing of an empty-loaded changeover device can be performed and to confirm

compliance with the requirements of 4.2.

The test bench arrangement shall include:

1) precision pressure reducing device;

2) supply pressure isolating cock;

3) supply pressure vent cock;

4) supply pressure test gauge;

5) automatic empty-loaded changeover device;

6) LSP isolating cock;

7) LSP vent cock;

8) LSP test gauge;

9) reservoir.

A diagram of a typical test bench arrangement consisting of the above constituent parts which should be

used is shown in Annex C.

The capability of the test bench arrangement to meet the requirements of the type test procedure shall

be verified by the manufacturer.

The pipe volumes of the test bench shall be known in order to allow calculation of the leakage rates.

A suitable air supply shall be provided with a maximum supply pressure of 10 bar.

The test bench leakage rate shall not be greater than 0,001 Nl/min.

5.2.2 Sampling for type tests

A sample of three (3) empty-loaded changeover devices shall be taken from the production (see Table 2).

5.2.3 Test requirements

All the type tests except the type tests of 5.2.11, shall be performed at ambient temperature (20 ± 5) °C.

All type tests shall be performed with a minimum air quality of the compressed air of class 3-4-4 specified

in ISO 8573-1:2010.

It is acceptable for the tests to be conducted with a varying force amplitude with a peak-to-peak value of

up to ± 15 % of the nominal value at a frequency of 3 Hz

The tests on the sample of three (3) automatic empty-loaded changeover devices shall be carried out in

the order shown in Table 2.

Table 2 — Sample testing

Tested empty-loaded

Corresponding

changeover device

Tests subclauses of this

number

document

1 2 3

Physical and geometrical characteristics 5.2.4 X X X

Tightness 5.2.5 X X X

Operation empty to loaded 5.2.6 X X X

Operation loaded to empty 5.2.7 X X X

Response empty to loaded 5.2.8 X X X

Response loaded to empty 5.2.9 X X X

Shock and vibration 5.2.10 X

Extreme temperatures 5.2.11 X X

5.2.4 Check of physical and geometrical characteristics

5.2.4.1 Procedure

In accordance with the particular technical documentation, dimensional accuracy shall be verified by

means of appropriate measuring instruments and form gauges e.g. threaded connections may be checked

using GO/NO GO gauges in accordance with EN ISO 228-2. The external surfaces shall be checked for

sharp edges and corners.

5.2.4.2 Pass/fail criteria

The results are satisfactory if all the specified characteristics are met and no sharp edges and corners are

present on the external surfaces.

5.2.5 Tightness

5.2.5.1 Positive load signal pressure devices

5.2.5.1.1 Procedure

Mount the empty-loaded changeover device to the test bench positioned to receive the supply pressure

and output an LSP to the reservoir volume. The empty-loaded changeover device shall be in its loaded

state.

With vent cocks and LSP isolating cock closed, open the supply pressure isolating cock and usin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...