EN ISO 4126-4:2004

(Main)Safety devices for protection against excessive pressure - Part 4: Pilot operated safety valves (ISO 4126-4:2004)

Safety devices for protection against excessive pressure - Part 4: Pilot operated safety valves (ISO 4126-4:2004)

ISO 4126-4:2003 specifies general requirements for pilot operated safety valves, other than those covered in ISO 4126-1, irrespective of the fluid for which they are designed. In all cases, the operation is carried out by the fluid in the system to be protected.

ISO 4126-4:2003 is applicable to pilot operated safety valves having a valve flow diameter of 6 mm and above which are for use at set pressures of 0,1 bar gauge and above. No limitation is placed on temperature.

This is a product standard and it is not concerned with applications for pilot operated safety valves.

Sicherheitseinrichtungen gegen unzulässigen Überdruck - Teil 4: Pilotgesteuerte Sicherheitsventile (ISO 4126-4:2004)

Dieser teil der Europäischen Norm legt allgemeine Anforderungen an andere pilotgesteuerte Sicherheitsventile als im Teil 1 behandelte fest, unabhängig von dem Medium, für das diese Ventile vorgesehen sind. Die Funktion wird in allen Fällen durch das Medium in dem zu schützenden System ausgelöst. Die Norm gilt für pilotgesteuerte Sicherheitsventile mit einem engsten Strömungsdurchmesser von mindestens 6 mm und für Ansprechdrücke von 0,1 bar und höher. Hinsichtlich der Temperatur bestehen keine Einschränkungen.

Dispositifs de sécurité pour protection contre les pressions excessives - Partie 4: Soupapes de sûreté pilotées (ISO 4126-4:2004)

L'ISO 4126-4:2003 spécifie les prescriptions générales des soupapes de sûreté pilotées, autres que celles couvertes par l'ISO 4126-1, quel que soit le fluide pour lequel elles sont conçues. Dans tous les cas le fonctionnement est assuré par le fluide contenu dans le système à protéger.

L'ISO 4126-4:2003 est applicable aux soupapes de sûreté pilotées présentant un orifice d'écoulement de diamètre supérieur ou égal à 6 mm qui sont utilisables à des pressions de début d'ouverture de 0,1 bar effectif et au-dessus. Aucune limitation en température n'est fixée.

Il s'agit d'une norme de produit et elle ne s'adresse pas aux applications de soupapes de sûreté pilotées.

Naprave za varovanje pred visokim tlakom - 4. del: Predkrmiljeni varnostni ventili (ISO 4126-4:2004)

General Information

- Status

- Withdrawn

- Publication Date

- 14-Feb-2004

- Withdrawal Date

- 16-Jul-2013

- Technical Committee

- CEN/TC 69 - Industrial valves

- Drafting Committee

- CEN/TC 69/WG 10 - Safety devices against excessive pressure

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-Jul-2013

- Completion Date

- 17-Jul-2013

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN ISO 4126-4:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety devices for protection against excessive pressure - Part 4: Pilot operated safety valves (ISO 4126-4:2004)". This standard covers: ISO 4126-4:2003 specifies general requirements for pilot operated safety valves, other than those covered in ISO 4126-1, irrespective of the fluid for which they are designed. In all cases, the operation is carried out by the fluid in the system to be protected. ISO 4126-4:2003 is applicable to pilot operated safety valves having a valve flow diameter of 6 mm and above which are for use at set pressures of 0,1 bar gauge and above. No limitation is placed on temperature. This is a product standard and it is not concerned with applications for pilot operated safety valves.

ISO 4126-4:2003 specifies general requirements for pilot operated safety valves, other than those covered in ISO 4126-1, irrespective of the fluid for which they are designed. In all cases, the operation is carried out by the fluid in the system to be protected. ISO 4126-4:2003 is applicable to pilot operated safety valves having a valve flow diameter of 6 mm and above which are for use at set pressures of 0,1 bar gauge and above. No limitation is placed on temperature. This is a product standard and it is not concerned with applications for pilot operated safety valves.

EN ISO 4126-4:2004 is classified under the following ICS (International Classification for Standards) categories: 13.240 - Protection against excessive pressure. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 4126-4:2004 has the following relationships with other standards: It is inter standard links to EN ISO 4126-4:2013, EN ISO 6708:1995, prEN 15116, EN 12627:2017, EN 1092-3:2003, EN 1759-1:2004, EN 12516-3:2002, EN 12760:2016, EN 1092-1:2018, EN 1092-2:2023, EN 13648-1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 4126-4:2004 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN ISO 4126-4:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2004

Naprave za varovanje pred visokim tlakom - 4. del: Predkrmiljeni varnostni ventili

(ISO 4126-4:2004)

Safety devices for protection against excessive pressure - Part 4: Pilot operated safety

valves (ISO 4126-4:2004)

Sicherheitseinrichtungen gegen unzulässigen Überdruck - Teil 4: Pilotgesteuerte

Sicherheitsventile (ISO 4126-4:2004)

Dispositifs de sécurité pour protection contre les pressions excessives - Partie 4:

Soupapes de sureté pilotées (ISO 4126-4:2004)

Ta slovenski standard je istoveten z: EN ISO 4126-4:2004

ICS:

13.240

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN ISO 4126-4

NORME EUROPÉENNE

EUROPÄISCHE NORM

February 2004

ICS 13.240

English version

Safety devices for protection against excessive pressure - Part

4: Pilot operated safety valves (ISO 4126-4:2004)

Dispositifs de sécurité pour protection contre les pressions Sicherheitseinrichtungen gegen unzulässigen Überdruck -

excessives - Partie 4: Soupapes de sûreté pilotées (ISO Teil 4: Pilotgesteuerte Sicherheitsventile (ISO 4126-4:2004)

4126-4:2004)

This European Standard was approved by CEN on 16 May 2003.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2004 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 4126-4:2004: E

worldwide for CEN national Members.

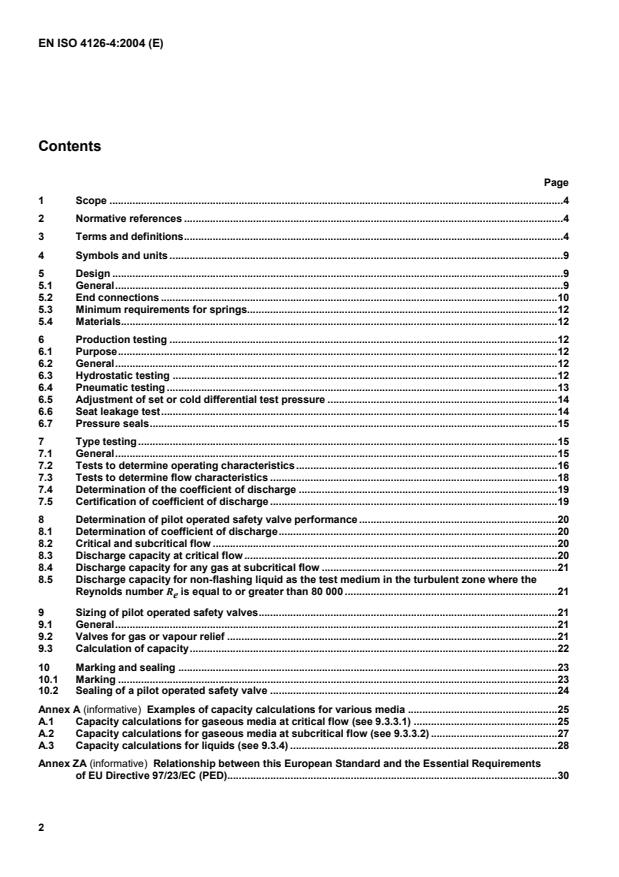

Contents

Page

1 Scope .4

2 Normative references .4

3 Terms and definitions.4

4 Symbols and units .9

5 Design .9

5.1 General.9

5.2 End connections .10

5.3 Minimum requirements for springs.12

5.4 Materials.12

6 Production testing .12

6.1 Purpose.12

6.2 General.12

6.3 Hydrostatic testing .12

6.4 Pneumatic testing .13

6.5 Adjustment of set or cold differential test pressure .14

6.6 Seat leakage test.14

6.7 Pressure seals.15

7 Type testing.15

7.1 General.15

7.2 Tests to determine operating characteristics.16

7.3 Tests to determine flow characteristics .18

7.4 Determination of the coefficient of discharge .19

7.5 Certification of coefficient of discharge .19

8 Determination of pilot operated safety valve performance .20

8.1 Determination of coefficient of discharge.20

8.2 Critical and subcritical flow .20

8.3 Discharge capacity at critical flow .20

8.4 Discharge capacity for any gas at subcritical flow .21

8.5 Discharge capacity for non-flashing liquid as the test medium in the turbulent zone where the

Reynolds number R is equal to or greater than 80 000 .21

e

9 Sizing of pilot operated safety valves.21

9.1 General.21

9.2 Valves for gas or vapour relief .21

9.3 Calculation of capacity.22

10 Marking and sealing .23

10.1 Marking .23

10.2 Sealing of a pilot operated safety valve .24

Annex A (informative) Examples of capacity calculations for various media .25

A.1 Capacity calculations for gaseous media at critical flow (see 9.3.3.1) .25

A.2 Capacity calculations for gaseous media at subcritical flow (see 9.3.3.2) .27

A.3 Capacity calculations for liquids (see 9.3.4) .28

Annex ZA (informative) Relationship between this European Standard and the Essential Requirements

of EU Directive 97/23/EC (PED).30

Foreword

This document (EN ISO 4126-4:2004) has been prepared by Technical Committee CEN/TC 69 “Industrial valves”,

the secretariat of which is held by AFNOR, in collaboration with Technical Committee ISO/TC 185 “Safety devices

for protection against excessive pressure”.

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by August 2004, and conflicting national standards shall be withdrawn at the latest by

August 2004.

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Directive.

For relationship with EU Directive, see informative annex ZA, which is an integral part of this document.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

This standard for safety devices for protection against excessive pressure consists of seven parts of which this is

Part 4. The various parts are:

Part 1 : Safety valves

Part 2 : Bursting disc safety devices

Part 3 : Safety valves and bursting disc safety devices in combination

Part 4 : Pilot operated safety valves

Part 5 : Controlled safety pressure relief systems (CSPRS)

Part 6 : Application, selection and installation of bursting disc safety devices

Part 7 : Common data

Part 7 contains data that is common to more than one of the parts of this standard to avoid unnecessary repetition.

Annex A is informative.

1 Scope

This part of this European Standard specifies general requirements for pilot operated safety valves, other than

those covered in Part 1, irrespective of the fluid for which they are designed. In all cases, the operation is carried

out by the fluid in the system to be protected.

It is applicable to pilot operated safety valves having a valve flow diameter of 6 mm and above which are for use at

set pressures of 0,1 bar gauge and above. No limitation is placed on temperature.

This is a product standard and it is not concerned with applications for pilot operated safety valves.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

EN 1092-1, Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories PN designated –

Part 1: Steel flanges.

EN 1092-2, Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories PN designated –

Part 2: Cast iron flanges.

EN 1092-3 , Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories PN designated –

Part 3: Copper alloy and composite flanges.

prEN 1759-1, Flanges and their joints – Circular flanges for pipes, valves, fittings and accessories, Class

designated – Part 1: Steel flanges NPS1/2 to 24.

EN 12516-3, Valves – Shell design strength – Part 3: Experimental method.

EN 12627, Industrial Valves – Butt welding ends for steel valves.

EN 12760, Valves – Socket welding ends for steel valves.

EN ISO 6708, Pipework components – Definition and selection of DN (nominal size) (ISO 6708:1995).

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances and

designation.

ASME B1.20.1, NPT threads.

3 Terms and definitions

For the purposes of this European Standard, the following terms and definitions apply.

3.1

pilot operated safety valve

self actuated device comprising a valve and an attached pilot

NOTE The pilot responds to the pressure of the fluid without any other energy than the fluid itself and controls the

operation of the valve. The valve opens when the fluid pressure that keeps it closed is removed or reduced. The valve re-closes

when the pressure is re-applied.

3.1.1

types of pilot

3.1.1.1

flowing pilot

pilot which discharges the fluid throughout the relieving cycle of the pilot operated safety valve

3.1.1.2

non-flowing pilot

pilot in which the fluid flows only during the opening and/or closing of the pilot operated safety valve

3.1.2

types of action of the pilot operated safety valve

3.1.2.1

ON/OFF

action characterised by stable operation resulting in fully open or fully closed main valve position

3.1.2.2

modulating

action characterised by a gradual opening and closing of the disc of the main valve which is a function of the

pressure, proportional but not necessarily linear

3.2

list of main components

see Figure 1

Key

1 Equipment to be protected 9 Disc

2 Main valve 10 Seat

3 Pilot valve 11 Body

4 Sensing line 12 Inlet

5 Loading/unloading line 13 Outlet

6 Pressure chamber 14 Pilot outlet

7 Cover 15 Connection of the sensing line : see the following note

8 Guide

NOTE The sensing line from the pilot can be either connected to the main valve inlet or connected directly to the

equipment to be protected. In cases where the sensing line is not connected to the main valve inlet, considerations should be

given to the length and to the protection from damage of the sensing line.

Figure 1 — Nomenclature of main components of a pilot operated safety valve

3.3

pressure

3.3.1

set pressure

predetermined pressure at which the valve of a pilot operated safety valve under operating conditions commences

to open

NOTE It is the gauge pressure measured at the valve inlet at which the pressure forces tending to open the valve for the

specific service conditions are in equilibrium with the forces retaining the valve disc on its seat.

3.3.2

maximum allowable pressure, PS

maximum pressure for which the equipment is designed as specified by the manufacturer

3.3.3

opening sensing pressure

pressure at which the pilot commences to open in order to achieve the set pressure

3.3.4

overpressure (of a pilot operated safety valve)

pressure increase over the set pressure, at which the main valve attains the lift specified by the manufacturer,

usually expressed as a percentage of the set pressure

NOTE This is the overpressure used to certify the pilot operated safety valve.

3.3.5

reseating pressure (of a pilot operated safety valve)

value of the inlet static pressure at which the disc re-establishes contact with the seat or at which the lift becomes

zero

3.3.6

cold differential test pressure

inlet static pressure at which a pilot operated safety valve is set to commence to open on the test bench

NOTE This test pressure includes corrections for service conditions, e.g., back pressure and/or temperature.

3.3.7

relieving pressure

pressure used for the sizing of a pilot operated safety valve which is greater than or equal to the set pressure plus

overpressure

3.3.8

built-up back pressure

pressure existing at the outlet of the main valve caused by flow through the main valve and the discharge system

3.3.9

superimposed back pressure

pressure existing at the outlet of the main valve at the time when the device is required to operate

NOTE It is the result of pressure in the discharge system from other sources.

3.3.10

blowdown (of a pilot operated safety valve)

difference between set and reseating pressures, normally stated as a percentage of set pressure except for

pressures of less than 3 bar when the blowdown is expressed in bar

3.4

lift

actual travel of the main valve disc away from the closed position

3.5

flow area

minimum cross-sectional flow area (but not the curtain area) between inlet and seat which is used to calculate the

theoretical flowing capacity of the main valve, with no deduction for any obstruction

NOTE The symbol is A.

3.6

flow diameter

diameter corresponding to the flow area

3.7

discharge capacity

3.7.1

theoretical discharge capacity

calculated capacity expressed in mass or volumetric units of a theoretically perfect nozzle having a cross-sectional

flow area equal to the flow area of a main valve

3.7.2

coefficient of discharge

value of actual flowing capacity (from tests) divided by the theoretical flowing capacity (from calculation)

3.7.3

certified (discharge) capacity

that portion of the measured capacity permitted to be used as a basis for the application of a pilot operated safety

valve

NOTE It may, for example, equal the :

a) measured flow rate times the derating factor ; or

b) theoretical flow rate times the coefficient of discharge times the derating factor ; or

c) theoretical flow rate times the certified derated coefficient of discharge.

3.8

DN (nominal size)

see EN ISO 6708

4 Symbols and units

Table 1 — Symbols and their descriptions

Symbol Description Unit

A

Flow area of a safety valve (not curtain area)

mm

C Function of the isentropic exponent -

K Theoretical capacity correction factor for subcritical flow -

b

a

K

Coefficient of discharge -

d

a

K -

Certified derated coefficient of discharge (K · 0,9)

dr

d

K Viscosity correction factor -

v

k

Isentropic exponent -

M Molar mass kg/kmol

n Number of tests -

p Relieving pressure bar (abs.)

o

p Back pressure bar (abs.)

b

p

Critical pressure bar (abs.)

c

Q Mass flow rate kg/h

m

q Theoretical specific discharge capacity

kg/(h·mm )

m

q’

Specific discharge capacity determined by tests

kg/(h·mm )

m

R Universal gas constant -

T

Relieving temperature K

o

Tc Actual critical temperature K

mDynamic viscosity Pa·s

v Specific volume at actual relieving pressure and temperature

m /kg

o

x Dryness fraction of wet steam at the valve inlet at actual relieving pressure and -

o

b

temperature

Z

Compressibility factor at actual relieving pressure and temperature -

a

K and K are expressed as 0,xxx.

d dr

b

x is expressed as 0,xx.

5 Design

5.1 General

5.1.1 The design shall incorporate guiding arrangements necessary to ensure consistent operation and seat

tightness.

5.1.2 The seat of the main valve, other than when it is an integral part of the valve shell, shall be fastened

securely to prevent the seat becoming loose in service.

5.1.3 Means shall be provided to lock and/or to seal all external adjustments in such a manner so as to prevent

or reveal unauthorized adjustments of the pilot operated safety valve.

5.1.4 In the case of main valves with restricted lift, the lift restricting device shall limit the main valve lift but shall

not otherwise interfere with the operation of the main valve. The lift restricting device shall be designed so that, if

adjustable, the adjustable feature can be mechanically locked and sealed. The lift restricting device shall be

installed and sealed by the valve manufacturer.

Valve lift shall not be restricted to a value less than 1 mm.

5.1.5 Pilot operated safety valves for toxic or flammable fluids shall have the pilot vented to a safe place.

5.1.6 The main valve shall be provided with a drain connection at the lowest point where liquid can collect unless

other provisions for draining are provided.

5.1.7 The design stress of load carrying parts shall not exceed that specified in the appropriate European

Standard, e.g. EN 12516-3.

5.1.8 In the case of failure of any sealing elements, the pilot operated safety valve shall discharge its certified

capacity at not over 1,1 times the maximum allowable pressure of the equipment to be protected.

5.1.9 The materials for adjacent sliding surfaces such as guides and disc/disc holder/spindle shall be selected to

ensure corrosion resistance and to minimise wear and avoid galling.

5.1.10 In the case of reasonably foreseeable damage to connections between the various components the

resulting flow areas shall be such that the pilot operated safety valve will discharge its certified capacity at not more

than 1,1 times the maximum allowable pressure.

5.1.11 When the superimposed back pressure is higher than the inlet pressure, means shall be provided that the

main valve shall not open.

5.1.12 The fitting of any additional device to a pilot and valve combination shall not prevent the pressurized

system from being protected under any circumstances.

5.2 End connections

5.2.1 Types

The types of end connections for pilot operated safety valves shall be as follows:

Butt welding EN 12627 ;

Socket welding EN 12760 ;

Flanged EN 1092-1 ;

EN 1092-2 ;

EN 1092-3 ;

prEN 1759-1 ;

Threaded ISO 7-1 or ASME B1.20.1.

Other types of end connections are possible by agreement between the manufacturer and purchaser.

5.2.2 Design of valve end connections

The design of valve end connections, whatever their type, shall be such that the internal area of the external pipe

or stub connection at the safety valve inlet is at least equal to that of the valve inlet connection (see Figure 2a).

The internal area of the external pipe connection at the safety valve outlet shall be at least equal to that of the valve

outlet, except those valves with female threaded outlet connections (see Figure 2b).

NOTE See clause 7 regarding type testing.

Key

1Valve

2 Satisfactory

3 Unsatisfactory

4 Required internal diameter of the safety valve for the valve to function properly

Figure 2 a) — Inlet

Key

1Valve

2 The nominal diameter of the pipe to be equal to the nominal diameter of the valve outlet

With this construction at the valve outlet, a suitable pipe shall be fitted during testing as specified in 7.1.4.

Figure 2 b) — Outlet

Key

1Valve

With this construction at the valve outlet, no pipe is required during testing as specified in 7.1.4.

Figure 2 c) — Outlet

Figure 2 — Design of end connections

5.3 Minimum requirements for springs

Springs shall be in accordance with Part 7 of this standard.

5.4 Materials

The materials for pressure retaining shells shall be in accordance with Part 7 of this standard.

6 Production testing

6.1 Purpose

The purpose of these tests is to ensure that all pilot operated safety valves meet the requirements for which they

have been designed without exhibiting any form of leakage from pressure retaining components or joints.

6.2 General

All temporary pipes, connections and blanking devices shall be adequate to withstand the test pressure.

Any temporary welded-on attachments shall be carefully removed and the resulting weld scars shall be ground

flush with the parent material. After grinding, all such scars shall be inspected by using magnetic particle or liquid

penetrant techniques.

6.3 Hydrostatic testing

6.3.1 Application

The portion of the main valve from the inlet to the seat shall be tested to a pressure 1,5 times the manufacturer's

stated maximum pressure for which the pilot operated safety valve is designed.

The shell on the discharge side of the seat shall be tested to 1,5 times the manufacturer's stated maximum back

pressure for which the valve is designed. This pressure can be lower than that given by the outlet flange rating.

6.3.2 Duration

The test pressure shall be applied and maintained at the required magnitude for a sufficient length of time to permit

a visual examination to be made of all surfaces and joints, but in any case for not less than the times given in

Table 2. For tests on the discharge side of the seat, the testing time shall be based on the pressure specified

in 6.3.1 and the discharge size.

Table 2 — Minimum duration of hydrostatic test

Pressure rating

Nominal size

Up to 40 bar Greater than 40 bar (4 MPa) up Greater than 63 bar

(4 MPa) to 63 bar (6,3 MPa) (6,3 MPa)

DN

Minimum duration in minutes

22 3

DN £ 50

22 4

50 < DN £ 65

65 < DN £ 80 23 4

80 < DN £ 100 24 5

100 < DN £ 125 24 6

125 < DN £ 150 25 7

150 < DN £ 200 35 9

200 < DN £ 250 36 11

250 < DN £ 300 47 13

300 < DN £ 350 48 15

350 < DN £ 400 49 17

400 < DN £ 450 49 19

450 < DN £ 500 510 22

512 24

500 < DN £ 600

6.3.3 Acceptance criteria

No leakage from the tested parts as defined in 6.3.1 is accepted.

6.3.4 Safety requirements

Water of suitable purity shall normally be used as the test medium. Where other testing media are used, additional

precautions may be necessary. Valve bodies shall be properly vented to remove entrapped air.

If materials which are liable to failure by brittle fracture are incorporated in that part of the pilot operated safety

valve which is to be hydrostatically tested, then both the pilot operated safety valve, or part thereof, and the testing

medium shall be at a sufficient temperature to prevent the possibility of such failure.

No valve or part thereof undergoing pressure testing shall be subjected to any form of shock loading, for example

hammer testing.

6.4 Pneumatic testing

6.4.1 Application and duration of test

Pressure testing with air or other suitable gas should be avoided but may be carried out in place of the standard

body hydrostatic test with the agreement of all parties involved in the following cases :

a) valves of such design and construction that it is not practicable for them to be filled with liquid ; and/or

b) valves that are to be used in service where even small traces of water cannot be tolerated.

The test pressure, duration of application and acceptance criteria shall be as specified in 6.3.

6.4.2 Safety requirements

The hazards involved in pneumatic pressure testing shall be considered and adequate precautions taken.

Particular attention is drawn to some relevant factors as follows:

a) If a major rupture of the valve should occur at some stage during application of pressure, considerable energy

will be released ; hence no personnel should be in the immediate vicinity during pressure raising (for example

a given volume of air contains 200 times the amount of energy that a similar volume of water contains when

both are at the same pressure) ;

b) The risk of brittle failure under test conditions shall have been critically assessed at the design stage and the

choice of materials for valves which are to be pneumatically tested shall be such as to avoid the risk of brittle

failure during test. This necessitates provision of an adequate margin between the transition temperature of all

parts and the metal temperature during testing ;

c) Attention is d

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...