EN 16834:2019

(Main)Railway applications - Braking - Brake performance

Railway applications - Braking - Brake performance

This document defines a harmonized way to assess the braking performance by test of locomotives, passenger coaches, freight wagons and self-propelled passenger trains (EMU/DMU).

The document sets out the standardized method for undertaking brake performance tests and the correction factors to be applied to the data obtained for all types of rolling stock.

This document also defines the methods to assess the brake performance in terms of stopping distance, and from this the process to determine vehicle(s) deceleration and braked weight.

It then deals with conversion of the braked weight to the braked weight percentage of a vehicle or train for operating purposes. It also sets out additional factors when determining the braked weight percentage of a train calculated from specified braked weight, depending on the formation of the train.

In Annex D there is a method for determining brake performance of freight wagons fitted with P10 cast iron or LL-blocks using limited testing (force measurement).

Bahnanwendungen - Bremse - Bremsvermögen

Dieses Dokument legt eine harmonisierte Verfahrensweise zur Bewertung des Bremsvermögens durch Prüfung von Lokomotiven, Reisezugwagen, Güterwagen und Elektro- und Dieseltriebwagen und triebzügen fest.

Dieses Dokument legt das Normverfahren für die Durchführung von Prüfungen des Bremsvermögens und die Korrektur¬faktoren dar, die auf die für alle Arten von Schienenfahrzeugen gewonnenen Daten anzuwenden sind.

Dieses Dokument legt auch die Verfahren zur Bewertung des Bremsvermögens in Bezug auf den Anhalteweg und, davon ausgehend, den Prozess zur Bestimmung der Fahrzeugverzögerung und des Bremsgewichts fest.

Es befasst sich mit der Umwandlung des Bremsgewichts eines Fahrzeugs oder Zuges in Bremsgewichtshundertstel für betriebliche Zwecke. Es legt auch die zusätzlichen Faktoren bei der Bestimmung des Bremsgewichtshundertstel eines Zuges fest, das in Abhängigkeit von der Zugbildung aus dem festgelegten Bremsgewicht berechnet wird.

Anhang D enthält ein Verfahren (Kraftmessung) zur Bestimmung des Bremsvermögens von Güterwagen, die mit Bremsklötzen aus Grauguss P10 oder LL-Bremsklötzen ausgestattet sind.

Applications ferroviaires - Freins - Performance de freinage

Le présent document définit une méthode harmonisée pour évaluer la performance de freinage par essai des locomotives, des voitures voyageurs, des wagons et des rames automotrices (électriques et diesel).

Le présent document décrit la méthode normalisée pour réaliser les essais de performance de freinage, ainsi que les facteurs de correction à appliquer aux données obtenues pour tous les types de matériels roulants.

Le présent document définit également les méthodes d'évaluation de la performance de freinage en termes de distance d'arrêt et, à partir de celle-ci, le processus pour déterminer la décélération et la masse freinée du ou des véhicules.

Il traite ensuite de la conversion de la masse freinée en pourcentage de masse freinée d'un véhicule ou d'un train pour l'utilisation en service. Il présente également des facteurs supplémentaires pour la détermination du pourcentage de masse freinée d'un train calculé à partir d'une masse freinée spécifiée, selon la composition du train.

L'Annexe D spécifie une méthode pour déterminer la performance de freinage des wagons équipés de semelles en fonte P10 ou de semelles LL en utilisant des essais limités (mesurage de l'effort).

Železniške naprave - Zavore - Značilnosti zavore

Ta evropski standard določa usklajen način ocenjevanja značilnosti zavor s preskusom lokomotiv, potniških vagonov, tovornih vagonov in potniških vlakov na lastni pogon (EMU/DMU).

Evropski standard določa standardizirano metodo za preskušanje značilnosti zavor in korekcijske faktorje, ki se uporabljajo za podatke, pridobljene za vse tipe tirnih vozil.

Ta evropski standard prav tako opredeljuje metode za ocenjevanje značilnosti zavor v smislu zavorne razdalje in pri tem postopek za določanje pojemanja vozila in zavorne teže.

Vsebuje tudi pretvorbo zavorne mase v odstotek zavorne mase vozila ali vlaka za namene obratovanja. Prav tako določa dodatne faktorje za določanje odstotka zavorne mase vlaka, izračunanega iz specifične zavorne mase v odvisnosti od formacije vlaka.

V dodatku D je na voljo metoda za določanje značilnosti zavor tovornih vagonov, opremljenih z železovo litino P10, z uporabo omejenega preskušanja (merjenje sile).

General Information

- Status

- Published

- Publication Date

- 16-Apr-2019

- Withdrawal Date

- 30-Oct-2019

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 3/WG 47 - Braking

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 17-Apr-2019

- Due Date

- 10-Jun-2016

- Completion Date

- 17-Apr-2019

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 15877-1:2024 - Railway applications - Markings of railway vehicles - Part 1: Freight wagons - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16834:2019 - Railway applications: Braking - Brake performance defines a harmonized, standardized method to assess braking performance of rolling stock by test. Published by SIST/CEN in 2019, the standard covers brake performance testing for locomotives, passenger coaches, freight wagons and self‑propelled passenger trains (EMU/DMU). It specifies test execution, correction factors, methods to determine stopping distance, vehicle deceleration, braked weight and the conversion of braked weight to braked weight percentage for operational use.

Key topics and technical requirements

- Scope and principles: Harmonized approach for brake assessment using stopping‑distance and deceleration methods.

- Test execution: Defined test methods for single vehicles and trains, load and speed conditions, number and validity of tests, and tests in degraded modes.

- Data correction and evaluation: Prescribed correction factors for environmental and test conditions and procedures to calculate mean and corrected stopping distances.

- Deceleration method: Procedures to derive decelerations and related parameters from measured data.

- Braked weight and braked weight percentage: Methods to determine braked weight, convert to percentage values and account for train formation effects and special equipment (e.g., accelerators, ep‑assist).

- Annexes (normative): Includes assessment sheets and formulae for trains and single vehicles (A–C), a limited testing method for freight wagons with P10 cast iron or LL‑blocks (Annex D), equivalent brake response time (Annex E), and an ETCS/ERTMS conversion model (Annex F).

- Special topics: Parking/holding brake assessment, maximum utilization of adhesion and procedures for verifying adhesion (Annex H), and rules for operation with ETCS.

Practical applications - who uses this standard

EN 16834:2019 is used by:

- Rolling stock manufacturers to demonstrate brake performance during type approval and design verification.

- Test laboratories and vehicle acceptance teams executing standardized brake performance tests.

- Rail operators and infrastructure managers for operational braking rules, stopping‑distance verification and train formation planning.

- Certification bodies and safety assessors for conformity assessment and regulatory compliance.

- Maintenance and upgrade teams when evaluating brake component changes (e.g., brake block materials) or retrofits.

Typical uses include establishing stopping distances for timetabling and safety cases, determining braked weight percentages for operational braking charts, and converting vehicle test data into ETCS braking parameters.

Related standards and keywords

This standard complements other railway braking and vehicle testing standards and is relevant when working with ETCS/ERTMS braking models, brake system design, adhesion testing and rolling‑stock certification. Key SEO terms: EN 16834:2019, brake performance, railway braking, stopping distance, braked weight, rolling stock testing, EMU/DMU, freight wagon P10, LL‑blocks, ETCS conversion model.

Get Certified

Connect with accredited certification bodies for this standard

Bureau Veritas Railway Certification

Railway and transportation certification.

Deutsch Quality Systems (India) Pvt. Ltd. (DQS India)

Subsidiary of DQS Holding GmbH, founding member of IQNet. CDSCO Notified Body.

Excellence Ireland Quality Association (EIQA)

Irish quality certification organization.

Sponsored listings

Frequently Asked Questions

EN 16834:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Braking - Brake performance". This standard covers: This document defines a harmonized way to assess the braking performance by test of locomotives, passenger coaches, freight wagons and self-propelled passenger trains (EMU/DMU). The document sets out the standardized method for undertaking brake performance tests and the correction factors to be applied to the data obtained for all types of rolling stock. This document also defines the methods to assess the brake performance in terms of stopping distance, and from this the process to determine vehicle(s) deceleration and braked weight. It then deals with conversion of the braked weight to the braked weight percentage of a vehicle or train for operating purposes. It also sets out additional factors when determining the braked weight percentage of a train calculated from specified braked weight, depending on the formation of the train. In Annex D there is a method for determining brake performance of freight wagons fitted with P10 cast iron or LL-blocks using limited testing (force measurement).

This document defines a harmonized way to assess the braking performance by test of locomotives, passenger coaches, freight wagons and self-propelled passenger trains (EMU/DMU). The document sets out the standardized method for undertaking brake performance tests and the correction factors to be applied to the data obtained for all types of rolling stock. This document also defines the methods to assess the brake performance in terms of stopping distance, and from this the process to determine vehicle(s) deceleration and braked weight. It then deals with conversion of the braked weight to the braked weight percentage of a vehicle or train for operating purposes. It also sets out additional factors when determining the braked weight percentage of a train calculated from specified braked weight, depending on the formation of the train. In Annex D there is a method for determining brake performance of freight wagons fitted with P10 cast iron or LL-blocks using limited testing (force measurement).

EN 16834:2019 is classified under the following ICS (International Classification for Standards) categories: 45.040 - Materials and components for railway engineering. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16834:2019 has the following relationships with other standards: It is inter standard links to EN 15663:2017+A2:2024, EN 15877-2:2013, EN 14531-2:2015, EN 15595:2018+A1:2023, EN 15877-1:2024, EN 15355:2019+A1:2023, EN 14531-1:2015+A1:2018, EN ISO 24478:2024, EN 16452:2015+A1:2019, EN 16207:2014+A1:2019, CEN/TS 15427-1-3:2023, EN 14198:2016, EN 16207:2024, EN 17997:2025, CEN/TS 15427-1-3:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16834:2019 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/334, M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16834:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2019

Železniške naprave - Zavore - Značilnosti zavore

Railway applications - Braking - Brake performance

Bahnanwendung - Bremse - Bremsleistung

Applications ferroviaires - Freins - Performance de freinage

Ta slovenski standard je istoveten z: EN 16834:2019

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 16834

EUROPEAN STANDARD

NORME EUROPÉENNE

April 2019

EUROPÄISCHE NORM

ICS 45.040

English Version

Railway applications - Braking - Brake performance

Applications ferroviaires - Freins - Performance de Bahnanwendungen - Bremse - Bremsvermögen

freinage

This European Standard was approved by CEN on 12 November 2018.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland,

Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 16834:2019 E

worldwide for CEN national Members.

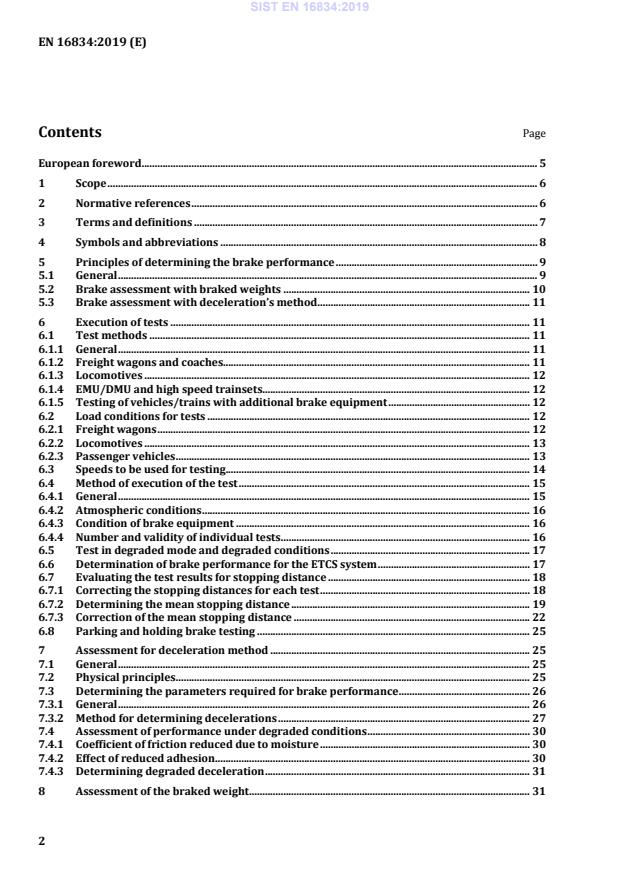

Contents Page

European foreword . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Symbols and abbreviations . 8

5 Principles of determining the brake performance . 9

5.1 General . 9

5.2 Brake assessment with braked weights . 10

5.3 Brake assessment with deceleration’s method . 11

6 Execution of tests . 11

6.1 Test methods . 11

6.1.1 General . 11

6.1.2 Freight wagons and coaches. 11

6.1.3 Locomotives . 12

6.1.4 EMU/DMU and high speed trainsets. 12

6.1.5 Testing of vehicles/trains with additional brake equipment . 12

6.2 Load conditions for tests . 12

6.2.1 Freight wagons . 12

6.2.2 Locomotives . 13

6.2.3 Passenger vehicles . 13

6.3 Speeds to be used for testing. 14

6.4 Method of execution of the test . 15

6.4.1 General . 15

6.4.2 Atmospheric conditions . 16

6.4.3 Condition of brake equipment . 16

6.4.4 Number and validity of individual tests . 16

6.5 Test in degraded mode and degraded conditions . 17

6.6 Determination of brake performance for the ETCS system . 17

6.7 Evaluating the test results for stopping distance . 18

6.7.1 Correcting the stopping distances for each test . 18

6.7.2 Determining the mean stopping distance . 19

6.7.3 Correction of the mean stopping distance . 22

6.8 Parking and holding brake testing . 25

7 Assessment for deceleration method . 25

7.1 General . 25

7.2 Physical principles . 25

7.3 Determining the parameters required for brake performance . 26

7.3.1 General . 26

7.3.2 Method for determining decelerations . 27

7.4 Assessment of performance under degraded conditions . 30

7.4.1 Coefficient of friction reduced due to moisture . 30

7.4.2 Effect of reduced adhesion . 30

7.4.3 Determining degraded deceleration . 31

8 Assessment of the braked weight . 31

8.1 General . 31

8.1.1 Determining braked weight percentage . 31

8.1.2 Determining braked weight . 32

8.2 Coaches and EMU/DMU's . 33

8.3 Additional assessment for Coaches operating with a speed above 160 km/h from

vehicles test . 33

8.4 Freight wagons in P . 34

8.5 Freight wagons in G . 34

8.6 Locomotives . 34

8.7 Magnetic track brake and eddy current brake . 35

8.7.1 General . 35

8.7.2 Assessment using train test . 35

8.7.3 Assessment using single vehicle test . 35

8.8 ep brake (ep-direct and ep-assist) . 35

8.9 Brake pipe accelerators valves . 35

9 Recommendations for the use of braked weight percentage in operation . 36

9.1 General . 36

9.2 Principles of use for trains operating in P mode . 36

9.3 Adjustment for trains comprising a locomotive and coaches . 37

9.3.1 Variation in braked weight taking into account the length of the train . 37

9.3.2 Braked weight of trains fitted with brake accelerators . 37

9.3.3 Rules of use for train operation: Braked weight of trains fitted with ep assist . 38

9.3.4 Variation in braked weight taking into account supplementary dynamic brake . 38

9.4 Adjustments for Freight trains braked in the P mode . 38

9.4.1 Variation in braked weight taking into account the length of the train . 38

9.4.2 Reduction in the braked weight of a G-braked vehicle in a P-braked train . 39

9.4.3 Variation in braked weight taking into account Brake accelerators and ep assist . 39

9.5 Principles of use for trains operating in G mode . 39

9.5.1 General . 39

9.5.2 Freight trains . 39

10 Operation with the ETCS system . 40

11 Assessment of maximum utilization of adhesion. 40

12 Assessment of gradient capability of parking/holding brake . 41

Annex A (normative) Brake assessment for trains . 42

A.1 Assessment sheet for trains using brake positions P, R, R+Mg . 42

A.2 Overview of the mathematical formulae for the assessment curves for trains using

brake positions P, R, R+Mg . 44

Annex B (normative) Brake assessment for single vehicles . 45

B.1 Assessment sheet for single vehicles . 45

B.2 Overview of the mathematical formulae for the assessment curves for single vehicles . 47

Annex C (normative) Checking of the friction pairing of disc-braked single vehicles . 48

C.1 Diagram for checking the friction pairing of disc-braked single vehicles . 48

C.2 Overview of the mathematical formulae for the assessment curves for checking the

friction pairing of disc-braked single vehicles . 50

Annex D (normative) Determining the brake performance of freight wagons fitted with cast

iron brake blocks (P10) or fully certified and exchangeable LL-blocks . 51

Annex E (normative) Determining the equivalent brake response time . 54

E.1 General . 54

E.2 Determining the equivalent brake response time based on train deceleration . 54

E.3 Determining the equivalent brake response time based on brake cylinder filling

times . 55

E.3.1 General . 55

E.3.2 Assessment . 55

Annex F (normative) Conversion model for ERTMS/ETCS . 57

F.1 Introduction . 57

F.2 Symbols for this Annex . 57

F.3 Scope of validity of model . 59

F.4 Brake model . 60

F.4.1 General principles . 60

F.4.2 Calculating the equivalent emergency brake development time . 62

F.4.3 Calculating the equivalent full brake development time . 63

F.4.4 Calculating the basic decelerations . 64

F.4.5 Calculating the decelerations during emergency braking . 66

F.5 Example of calculation of the stopping or slowing distance . 67

Annex G (normative) Assessment sheet for individual vehicles running at speeds of less

than 100 km/h using brake positions P and R . 68

G.1 Assessment sheet for individual vehicles fitted with cast iron blocks (P10) at speeds

below 100 km/h . 68

G.2 Overview of the mathematical formulae used in assessment curves for individual

vehicles fitted with cast iron blocks (P10) at speeds below 100 km/h . 70

G.3 Assessment sheet for individual vehicles fitted with EN-UIC brake system and disc

brakes or K blocks at speeds below 100 km/h. 71

G.4 Overview of the mathematical formulae used in assessment curves for individual

vehicles fitted with EN-UIC disc brakes or composite brake blocks at speeds below

100 km/h . 73

Annex H (normative) Procedure for verifying the maximum utilization of adhesion between

wheel and rail . 74

H.1 Symbols and abbreviations for this Annex . 74

H.2 General . 74

H.3 Prerequisites . 74

H.4 Determination of the maximum equivalent mean deceleration based on distance

relevant for adhesion ā . 75

max,τ

H.5 Calculation of the mean friction coefficient for the friction brake µm of the test . 75

H.6 Calculation of the maximum utilization of adhesion between wheel and rail τ . 75

max

Annex I (informative) Example for verifying the maximum utilization of adhesion between

wheel and rail for non-homogenous friction brake equipment . 77

I.1 Non-homogenous friction brake equipment . 77

I.2 Variation of brake cylinder pressure during brake application . 77

Annex J (informative) Example for correction and validation of test results exceeding

mandatory test conditions — Treatment of curve radii lower than 1 000 m . 80

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2008/57/EC aimed to be covered . 82

Bibliography . 84

European foreword

This document (EN 16834:2019) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by October 2019, and conflicting national standards shall

be withdrawn at the latest by October 2019.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of EU Directive 2008/57/EC.

For relationship with EU Directive 2008/57/EC, see informative Annex ZA, which is an integral part of

this document.

According to the CEN-CENELEC Internal Regulations, the national standards organizations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands,

Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

the United Kingdom.

1 Scope

This document defines a harmonized way to assess the braking performance by test of locomotives,

passenger coaches, freight wagons and self-propelled passenger trains (EMU/DMU).

The document sets out the standardized method for undertaking brake performance tests and the

correction factors to be applied to the data obtained for all types of rolling stock.

This document also defines the methods to assess the brake performance in terms of stopping distance,

and from this the process to determine vehicle(s) deceleration and braked weight.

It then deals with conversion of the braked weight to the braked weight percentage of a vehicle or train

for operating purposes. It also sets out additional factors when determining the braked weight

percentage of a train calculated from specified braked weight, depending on the formation of the train.

In Annex D there is a method for determining brake performance of freight wagons fitted with P10 cast

iron or LL-blocks using limited testing (force measurement).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 14198, Railway applications — Braking — Requirements for the brake system of trains hauled by

locomotives

EN 14478, Railway applications — Braking — Generic vocabulary

EN 14531-1, Railway applications — Methods for calculation of stopping and slowing distances and

immobilization braking — Part 1: General algorithms utilizing mean value calculation for train sets or

single vehicles

EN 14531-2:2015, Railway applications — Methods for calculation of stopping and slowing distances and

immobilization braking — Part 2: Step by step calculations for train sets or single vehicles

EN 15355, Railway applications — Braking — Distributor valves and distributor-isolating devices

EN 15595, Railway applications — Braking — Wheel slide protection

EN 15663, Railway applications — Vehicle reference masses

EN 15877-1, Railway applications — Marking on railway vehicles — Part 1: Freight wagons

EN 15877-2, Railway applications — Markings of railway vehicles — Part 2: External markings on coaches,

motive power units, locomotives and on track machines

EN 16207, Railway applications — Braking — Functional and performance criteria of Magnetic Track

Brake systems for use in railway rolling stock

EN 16452, Railway applications — Braking — Brake blocks

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 14478, EN 14198 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

brake assessment speed

brake initiation speed which is decisive for determination of brake performance

Note 1 to entry: In general the initiation speed leading to the lowest braked weight.

3.2

braked weight

representative quantity for the mean braking capacity of the vehicle or train, expressed in tons, which is

always expressed as a whole number

Note 1 to entry: It is displayed on the vehicle (in accordance with EN 15877-1 and EN 15877-2). Braked weight

corresponds to the retardation effort and is currently expressed and designated as “B”.

3.3

braked weight percentage

quotient of braked weight and vehicle mass × 100

Note 1 to entry: Also known as λ (lambda).

3.4

maximum braking load

load condition lower or equal to “design mass under exceptional payload” as defined in EN 15663 in

accordance with the related vehicle standard (e.g. EN 16185-1, EN 14198)

3.5

minimum load

load condition “design mass in working order” (as defined in EN 15663)

3.6

normal load

load condition “design mass under normal payload” (as defined in EN 15663)

3.7

fully certified and exchangeable LL-block

LL-block, which fulfils all UIC requirements including exchangeability with P10 (as listed in

ERA document ERA/TD/2009-02/INT)

3.8

K-block

brake block with “K”-friction materials as defined in EN 16452

3.9

EN-UIC brake

brake system as defined in EN 14198

4 Symbols and abbreviations

For the purposes of this document, the following symbols and abbreviations in Table 1 apply.

Table 1 — Symbols and abbreviations

Symbol Description Unit

a deceleration m/s

B braked weight t

C constant for calculating the λ values —

D constant for calculating the λ values —

d diameter mm

F force kN

g acceleration due to gravity 9,81 m/s

i gradient ‰

k assessment factor for determining the braked weight —

m mass of the test train or test vehicle t

r radius mm

s total stopping distance (up to v = 0) m

t time s

v speed km/h

λ braked weight percentage %

ρ coefficient of inertia of rotating masses —

standard deviation of test result m

σ

n

τ adhesion —

μ coefficient of friction —

η efficiency of brake rigging —

ATP Automatic Train Protection

Bg brake block type Bg (single block)

Bgu brake block type Bgu (double brake block)

DMU Diesel Multiple Unit

ep-brake electropneumatic brake

EMU Electric Multiple Unit

ETCS European Train Control System

Symbol Description Unit

G brake mode of the slow-acting brake (freight train)

K brake block material in accordance with EN 16452

L brake block material in accordance with EN 16452

LL brake block material in accordance with EN 16452

Mg magnetic track brake

P brake position of quick-acting brake (passenger train)

P+E brake position P + electrodynamic brake

P+H brake position P + hydrodynamic brake

P+Mg brake position P + magnetic track brake

P10 material designation of the cast-iron block with a 1 % phosphorus

content

brake position in accordance with EN 14198

R brake position in accordance with EN 14198

R+E brake position R + electrodynamic brake

R+H brake position R + hydrodynamic brake

R+Mg brake position R + magnetic track brake

S train related brake performance category in accordance with

EN 14198

SS train related brake performance category in accordance with

EN 14198

Sbb brake accelerator

Wb eddy current brake

5 Principles of determining the brake performance

5.1 General

The object of defining the brake performance of railway brakes is to characterize the braking capabilities

of railway vehicles.

To determine the brake performance three methods of brake assessment can be used: stopping distance,

braked weights, and deceleration. All three will determine the brake performance.

From vehicle testing, braked weight is derived from stopping distance. For freight wagons (fitted with

cast iron blocks or fully certified and exchangeable LL-blocks) the braked weight may be calculated as set

out in Annex D, if applicable.

Brake performance assessment is defined based on a number of standardized conditions (e.g. level track,

dry rail and mean in-service vehicle condition). Brake assessment thus does not assume the worst

possible vehicle condition, which can be the result of e.g. braking force tolerances, friction coefficient

scatter, downgraded efficiency, or the failure of brake system components etc.

These brake performances do not contain safety margins.

For vehicle having different brake positions as described in EN 14198, there shall be an assessment for

each brake position.

The brake performance marked on vehicles (EN 15877-1 and EN 15877-2) shall be derived from the

performance determined by tests and/or calculation according to this document.

Links between calculation of brake performance and test are given in Table 2.

Table 2 — Links between calculation of brake performance and test

Vehicle type Calculation Brake performance Validation by test

All vehicles EN 14531-1 and/or Decelerations + response mandatory

excluding freight EN 14531-2 time / stopping distance

wagons

↑↓

Braked weights

freight wagons EN 14531-1 and/or Stopping distance mandatory

EN 14531-2 or Annex D,

↑↓ (with exception of

if applicable (cast iron /

freight wagons, where

Braked weights

certified LL-blocks)

the requirements of

Annex D are met)

5.2 Brake assessment with braked weights

This method originated after the introduction of the compressed air brake. For this purpose a huge

number of test runs on level track had been performed with a given passenger train with 60 wheelsets,

defined brake equipment and given mass from various initial speeds.

The brake performance of this train has been ever since equivalent to λ = 100 % and serves as reference

standard deceleration so that per definition the braked weight is equivalent to the mass of the train. The

results of further tests with different brake settings set up brake assessment charts providing the

relations:

λ= f vs, (1)

( )

where

s stopping distance, expressed in m;

v initial speed, expressed in km/h;

λ brake weight percentage, expressed in %.

The reference train was equipped with block brakes with low-phosphorus cast-iron blocks.

A brake assessment diagram is used as a basis of reference for determining the brake performance of

new vehicles using the passenger brake mode.

The assessment diagrams (see Figure A.1 and B.1) are applicable for an initial braking speed of up to

200 km/h.

The braked weight is expressed in tons. The quotient obtained from the sum of all the braked weights

and the mass of the train multiplied by 100 gives the braked weight percentage λ of the train and relates

to the stopping distance in the event of an emergency brake application.

The braked weights assigned to the individual vehicles or vehicle segments are normally to be marked

on the outside of the vehicles in accordance with EN 15877-1 and EN 15877-2 when they are obtained

from brake application by brake pipe only. Braked weights shall be indicated in whole numbers of tons,

with values < 0,5 to be rounded down and values ≥ 0,5 to be rounded up. If the results come from tests

on a train, the figures are initially rounded up or down for the smallest unit (wagon) on which a braked

weight is indicated.

5.3 Brake assessment with deceleration’s method

The brake performance of trains can be expressed by decelerations. This method may be applied for all

speed ranges. For speeds over 200 km/h, it is mandatory.

The real train deceleration profile is approximated by a function with equivalent brake response time

and one or more speed intervals of constant decelerations.

The deceleration method set out in this document is intended to describe the train deceleration in a

simplified set of values and not by the individual braking functions.

6 Execution of tests

6.1 Test methods

6.1.1 General

The tests shall be performed by a competent authority.

NOTE As an example, a test institute in accordance with EN ISO/IEC 17025.

Train testing is the original method, which gives more accurate results and is always applicable. In the

following cases, the train test can be replaced by single vehicle test, which leads to more restrictive

results:

— for coaches with maximum speed ≤ 160 km/h;

— for coaches with only one stage of braking effort and maximum speed up to 200 km/h (special

evaluations rules: see braked weight assessment 8.3);

— for freight wagons;

— for locomotives;

— for single EMU/DMUs (as defined in EN 16185-2).

6.1.2 Freight wagons and coaches

If the braked weight of freight wagons/coaches is determined by testing with a train, the following special

conditions apply:

— coaches: For the purpose of the tests a 400 m long hauled train should be used comprising identical

coaches with the same brake equipment;

— freight wagons: For the purpose of the tests a 500 m long hauled train should be used comprising

identical freight wagons with the same brake equipment;

— in both cases the locomotive brake shall be isolated and all brake pipe accelerators and the EP assist

shall be deactivated.

6.1.3 Locomotives

When determining the braked weight of the locomotive in position G, tests from 100 km/h in position P

shall be undertaken with the locomotive operating on its own. For all other brake positions, the testing

shall be done as set out in 6.3.

Locomotives with multiple brake control architecture shall be tested in all operating modes (e.g.:

UIC brake pipe, direct ep-brake, rescue- or towing-mode, etc.).

6.1.4 EMU/DMU and high speed trainsets

The brake performance of a multiple unit is determined by dynamic tests for all existing brake positions

with all brakes active. To determine the brake performance in degraded modes dynamic tests shall be

performed for all relevant cases (e.g. isolated parts of air brake, ep assist, dynamic brake, magnetic track

brake).

For trainsets which can be coupled together to operate in multiple units, the tests shall be conducted in

the most unfavourable train configuration (considering the equivalent brake response time in Annex E)

determined by the static test (i.e. generally the longest planned formation).

EMU/DMU and highspeed trainsets with multiple brake control architecture shall be tested in all

operating modes (e.g.: UIC brake pipe, direct ep-brake, rescue- or towing-mode, etc.).

6.1.5 Testing of vehicles/trains with additional brake equipment

Typically additional brake equipments for service and/or emergency brake applications include:

dynamic brake, eddy current brake, EP assist, magnetic track brake, brake pipe accelerators.

The testing defined in 6.1.4 shall be undertaken with all brake equipment operational.

If additional brake equipment is used in emergency brake or service brake, additional testing should be

performed to determine brake performance with this equipment isolated.

If more than one additional equipment is fitted, there should be further testing to determine the

contribution of each equipment.

6.2 Load conditions for tests

6.2.1 Freight wagons

For freight wagons with empty/load devices, slip tests shall be conducted:

— with minimum load (empty freight wagons), in the “empty” position;

— in the “empty” position with a load at the changeover mass. When an automatic “empty-loaded”

changeover device is being used, the tests shall be carried out in the “empty” position with a load

close to the changeover mass, but far enough below it to ensure that the automatic changeover device

remains stable in the “empty” position;

— with normal load in the “loaded” position (EN 15663: Design mass under normal payload).

For freight wagons with self-adjusting load-proportional braking, the slip tests shall be conducted:

— with minimum load (empty freight wagons);

— in the lowest load status under which the maximum braked weight is achieved;

— at the condition at which the maximum energy is dissipated (combination of speed and load).

For S and SS freight wagons, as defined in EN 14198, the load definition leads to Table 3.

Table 3 — Load conditions for slip tests with S and SS freight wagons

Freight wagon

Freight wagon for S- for S-regime

regime with empty- with self-

Freight wagon

Vehicle mass loaded changeover adjusting load-

for SS-regime

device proportional

(S1 in EN 14198) (S2 in

EN 14198)

Minimum load x x x

Changeover mass x

14,5 t / wheelset x

18 t / wheelset x

20 t / wheelset x

22,5 t / wheelset x x

x mandatory tests

NOTE The values of the vehicle weight are typical values for UIC S-Regime or SS-Regime for tread-

braked wheels.

6.2.2 Locomotives

For locomotives only minimum load shall be tested.

6.2.3 Passenger vehicles

Load condition for passenger vehicles is specified in Table 4.

Table 4 — Load condition for testing

Vehicle type Load status

Minimum load Normal load Maximum braking

load

Coach, passenger trains, multiple

unit and high speed train a

X X

(x)

without load-proportional braking

Coach, passenger trains, multiple

unit and high speed train a

X X

X

with load-proportional braking

(x) Recommendation

X Requirement

a

If difference between normal load and maximum braking load is more than 10 % of the normal load.

In cases where loading is not possible, alternative methods are permitted, such as simulation by isolating

other brake units, as long as this introduces no significant errors into the procedure. In particular, it shall

be observed on vehicles with self-adjusting load-proportional braking that the correct brake cylinder

pressures (corresponding to the load) are simulated.

Simulation is performed as follows:

The number of isolated brakes is determined such that the ratio of:

∑ the active brake forces Dynamic mass of test train

= (2)

∑ the installed braked forces Dynamic mass of laden train

is generally complied with.

The simulation is only allowed for long trains (400 m excluding the locomotive) not for single vehicles,

EMU/DMU and high speed train.

6.3 Speeds to be used for testing

The speed criteria specified in Table 5 shall be used for all types of brake applications to a stop, i.e. for

the emergency applications for brake assessment as well as for (e.g.) service brake applications or

degraded mode tests.

Combinations of speed and brake position, which are not applicable for operation, are not mandatory for

testing.

Table 5 — Brake position test

Emergency brake Service brake

TEST SPEED

(not necessary for

P P+E R R+E R+Mg R+Wb

braked weight

km/h

P+H R+H P+E+Mg P+E+Wb

assessment)

30 C, D, E D, E C, D, E D, E — — D, E

100 A, B, C, D, E A, C, D, D, E ─ ─ D, E

D, E E

120 A, B, C, D, E A, C, D, D, E ─ ─ D, E

D, E E

140 A, B, C, D, E A, C, D, D, E A, C, E C, E D, E

D, E E

160 A, B, C, D, E A, C, D, D, E A, C, E C, E D, E

D, E E

200 C, D, E D, E C, D, E D, E C, E C, E D, E

Maximum speed A, B, C, D, E A, C, D, D, E C, E C, E D, E

a D, E E

(<160)

Maximum speed B, C, D, D, E C, D, E D, E C, E C, E D, E

E

a b

(>160)

A = single vehicle – coach or wagon

B = freight train

C = passenger train

D = loco

E = EMU/DMU and High speed train sets

Freight vehicles/trains which have R brake position shall be assessed as passenger vehicles/trains.

a

Test shall be also performed from maximum speed if not included in the Table.

b

For speed > 250 km/h, other speeds in steps not greater than 40 km/h from 200 km/h to maximum design

speed shall be tested.

6.4 Method of execution of the test

6.4.1 General

The test train or test vehicle shall be accelerated up to the speed for the intended brake application. At

this speed, the traction is switched off and after that an emergency brake application is initiated on level

and straight track. If there are different possibilities to initiate an emergency braking (e.g. by driver brake

valve, push-button, ATP valves.) the possibility leading to the longest response time shall be chosen for

tests used for brake performance assessment. The choice shall be validated by suitable tests.

For single vehicle testing the method of slip test applies. The vehicle shall be uncoupled after reaching

the test speed and the emergency brake shall be applied at the same time or short time after uncoupling.

In every test the stopping distance is measured from the point at which the emergency brake application

was initiated (e.g. leaving running position of brake controller or emergency button depressed) until the

standstill.

The measured stopping distance includes the distance covered during the delay time and the build-up

time of brake equipment.

This test method can similarly be applied for other than emergency brake applications (e.g. maximum

service braking).

6.4.2 Atmospheric conditions

In order to prevent adverse atmospheric conditions from affecting the results the tests should be carried

out with minimum wind and dry rails.

No test in flying snow conditions is allowed.

6.4.3 Condition of brake equipment

6.4.3.1 Wheels

For block-braked vehicles with new or reprofiled wheels, these should have been run in for at least

1 200 km.

6.4.3.2 Friction components

Before the start of the tests the friction components (brake pads/blocks) shall be bedded-in to give at

least 85 % contact pattern. If the tests include brake applications in wet conditions, the leading edge of

the pad/block shall be bedded-in in the direction of rotation. The bedding-in status shall be documented

by means of photos of a useful selection of friction elements.

After the successful bedding-in of the brake pads the brake disc roughness is conside

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...