EN 861:2007+A1:2009

(Main)Safety of woodworking machines - Surface planing and thicknessing machines

Safety of woodworking machines - Surface planing and thicknessing machines

This document deals with all the significant hazards, hazardous situation and events as listed in Clause 4 relevant to stationary and displaceable surface planing and thicknessing machines with an integrated feed in thicknessing mode, (with or without demountable power feed unit in planning mode) and with manual loading and unloading of the work-piece, hereinafter referred to as "machines". The cutterblock is fixed in position and for thicknessing an integrated feed is provided. The machines are designed to cut solid wood, chipboard, fibreboard and plywood when they are used as intended and under the conditions foreseen by the manufacturer.

This document does not deal with any hazards which result from the attachment of an optional mortising unit. These hazards are covered by prEN 940:2007.

This document does not apply to:

a) machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand;

NOTE 1 Transportable motor-operated electric tools are covered by the requirements of EN 61029-1:2000 together with prEN 61029-2-3:2004.

b) surface planing and thicknessing machines where the cutterblock is adjustable for depth of cut setting in thicknessing mode;

c) machines where the conversion from planing to thicknessing mode or vice versa is achieved by mounting or demounting parts/units;

d) machines where surfacing and thicknessing can be performed at the same time.

This document is not applicable to surface planing and thicknessing machines which are manufactured before the date of its publication as EN.

NOTE 2 Machines covered by this document are listed under A.5 of Annex IV of the Machinery Directive.

Sicherheit von Holzbearbeitungsmaschinen - Kombinierte Abricht- und Dickenhobelmaschinen

Dieses Dokument detailliert alle in Abschnitt 4 aufgeführten signifikanten Gefährdungen, Gefährdungs¬situationen und Gefährdungsereignisse, die auf stationäre und verschiebbare kombinierte Abricht- und Dickenhobelmaschinen mit mechanischem Vorschub in der Betriebsart Dickenhobeln (mit oder ohne abnehm¬baren Vorschubapparat in der Betriebsart Abrichthobeln) und mit Werkstückaufgabe und Werkstück¬abnahme von Hand, im folgenden als „Maschinen“ bezeichnet, zutreffen. Die Messerwelle ist in fester Lage und für das Dickenhobeln ist ein mechanischer Vorschub vorhanden. Die Maschinen sind konstruiert zum Hobeln von Massivholz, Spanplatten, Faserplatten und Sperrholz, wenn sie bestimmungsgemäß und entsprechend den vorhersehbaren Bedingungen des Herstellers verwendet werden.

Dieses Dokument behandelt nicht irgendwelche Gefährdungen, die sich aus dem Anbau einer optionalen Langlochbohreinheit ergeben. Diese Gefährdungen sind in prEN 940:2007 behandelt.

Dieses Dokument gilt nicht für:

a) Maschinen, die auf ein Gestell oder auf einen Tisch, der einem Gestell ähnlich ist, aufgesetzt sind und die vorgesehen sind, während des Betriebs stationär verwendet zu werden und die von einer Person von Hand angehoben werden können;

ANMERKUNG 1 Transportable elektrisch angetriebene Werkzeuge sind in EN 61029-1:2000 zusammen mit prEN 61029-2-3:2004 behandelt.

b) kombinierte Abricht- und Dickenhobelmaschinen, bei denen die Messerwelle für die Spanabnahme verstellt werden kann;

c) Maschinen, bei denen die Umrüstung vom Abrichthobeln zum Dickenhobeln und umgekehrt durch An- oder Abbau von Teilen/Einheiten erfolgt;

d) Maschinen, bei denen Abrichthobeln und Dickenhobeln gleichzeitig durchgeführt werden können.

Dieses Dokument gilt nicht für kombinierte Abricht- und Dickenhobelmaschinen, die vor dem Datum seiner Veröffentlichung als EN hergestellt wurden.

ANMERKUNG 2 Die in diesem Dokument behandelten Maschinen sind unter A.5 des Anhangs IV der Maschinen¬richtlinie genannt.

Sécurité des machines pour le travail du bois - Machines combinées à raboter et à dégauchir

Varnost lesnoobdelovalnih strojev - Kombinirani in debelinski skobeljniki

General Information

- Status

- Withdrawn

- Publication Date

- 11-Aug-2009

- Withdrawal Date

- 26-Jun-2012

- Technical Committee

- CEN/TC 142 - Woodworking machines - Safety

- Drafting Committee

- CEN/TC 142/WG 2 - Planing and thickness machines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Jun-2012

- Completion Date

- 27-Jun-2012

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Merged Into

EN 861:2007+A2:2012 - Safety of woodworking machines - Surface planing and thicknessing machines - Effective Date

- 02-May-2012

- Effective Date

- 20-Jun-2009

- Merged From

EN 861:2007/prA1 - Safety of woodworking machines - Surface planing and thicknessing machines - Effective Date

- 20-Jun-2009

- Effective Date

- 17-Jul-2010

Get Certified

Connect with accredited certification bodies for this standard

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 861:2007+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of woodworking machines - Surface planing and thicknessing machines". This standard covers: This document deals with all the significant hazards, hazardous situation and events as listed in Clause 4 relevant to stationary and displaceable surface planing and thicknessing machines with an integrated feed in thicknessing mode, (with or without demountable power feed unit in planning mode) and with manual loading and unloading of the work-piece, hereinafter referred to as "machines". The cutterblock is fixed in position and for thicknessing an integrated feed is provided. The machines are designed to cut solid wood, chipboard, fibreboard and plywood when they are used as intended and under the conditions foreseen by the manufacturer. This document does not deal with any hazards which result from the attachment of an optional mortising unit. These hazards are covered by prEN 940:2007. This document does not apply to: a) machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand; NOTE 1 Transportable motor-operated electric tools are covered by the requirements of EN 61029-1:2000 together with prEN 61029-2-3:2004. b) surface planing and thicknessing machines where the cutterblock is adjustable for depth of cut setting in thicknessing mode; c) machines where the conversion from planing to thicknessing mode or vice versa is achieved by mounting or demounting parts/units; d) machines where surfacing and thicknessing can be performed at the same time. This document is not applicable to surface planing and thicknessing machines which are manufactured before the date of its publication as EN. NOTE 2 Machines covered by this document are listed under A.5 of Annex IV of the Machinery Directive.

This document deals with all the significant hazards, hazardous situation and events as listed in Clause 4 relevant to stationary and displaceable surface planing and thicknessing machines with an integrated feed in thicknessing mode, (with or without demountable power feed unit in planning mode) and with manual loading and unloading of the work-piece, hereinafter referred to as "machines". The cutterblock is fixed in position and for thicknessing an integrated feed is provided. The machines are designed to cut solid wood, chipboard, fibreboard and plywood when they are used as intended and under the conditions foreseen by the manufacturer. This document does not deal with any hazards which result from the attachment of an optional mortising unit. These hazards are covered by prEN 940:2007. This document does not apply to: a) machines set up on a bench or a table similar to a bench, which are intended to carry out work in a stationary position, capable of being lifted by one person by hand; NOTE 1 Transportable motor-operated electric tools are covered by the requirements of EN 61029-1:2000 together with prEN 61029-2-3:2004. b) surface planing and thicknessing machines where the cutterblock is adjustable for depth of cut setting in thicknessing mode; c) machines where the conversion from planing to thicknessing mode or vice versa is achieved by mounting or demounting parts/units; d) machines where surfacing and thicknessing can be performed at the same time. This document is not applicable to surface planing and thicknessing machines which are manufactured before the date of its publication as EN. NOTE 2 Machines covered by this document are listed under A.5 of Annex IV of the Machinery Directive.

EN 861:2007+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 79.120.10 - Woodworking machines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 861:2007+A1:2009 has the following relationships with other standards: It is inter standard links to EN 861:2007+A2:2012, EN 861:2007, EN 861:2007/prA1, EN 861:2007+A1:2009/FprA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 861:2007+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 861:2007+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost lesnoobdelovalnih strojev - Kombinirani in debelinski skobeljnikiSicherheit von Holzbearbeitungsmaschinen - Kombinierte Abricht- und DickenhobelmaschinenSécurité des machines pour le travail du bois - Machines combinées à raboter et à dégauchirSafety of woodworking machines - Surface planing and thicknessing machines79.120.10Lesnoobdelovalni strojiWoodworking machines25.080.25Planing machinesICS:Ta slovenski standard je istoveten z:EN 861:2007+A1:2009SIST EN 861:2008+A1:2009en01-oktober-2009SIST EN 861:2008+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 861:2007+A1

August 2009 ICS 79.120.10 Supersedes EN 861:2007English Version

Safety of woodworking machines - Surface planing and thicknessing machines

Sécurité des machines pour le travail du bois - Machines combinées à raboter et à dégauchir

Sicherheit von Holzbearbeitungsmaschinen - Kombinierte Abricht- und Dickenhobelmaschinen This European Standard was approved by CEN on 10 May 2007 and includes Corrigendum 1 issued by CEN on 29 October 2008 and Amendment 1 approved by CEN on 16 July 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 861:2007+A1:2009: ESIST EN 861:2008+A1:2009

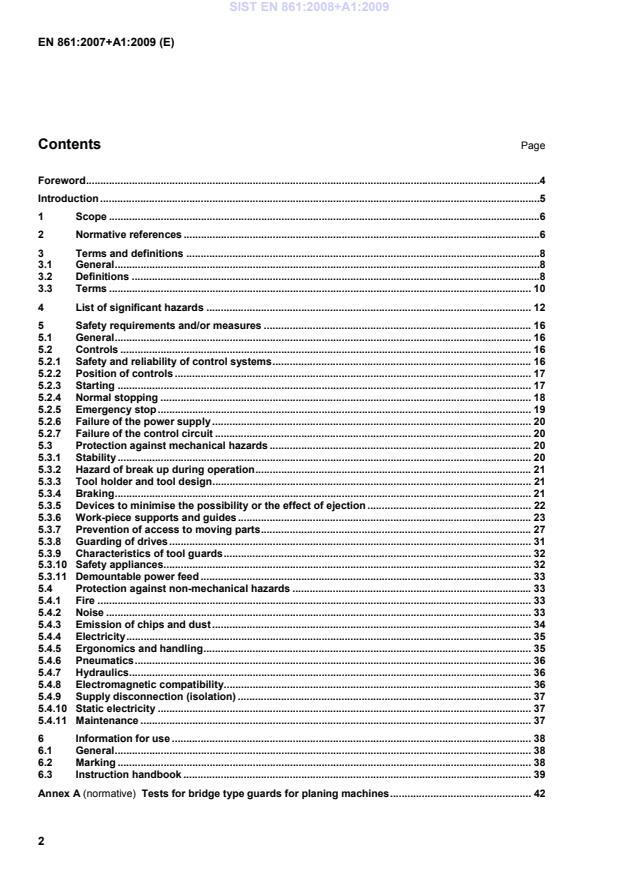

Tests for bridge type guards for planing machines . 42SIST EN 861:2008+A1:2009

Table lip resistance test . 44B.1 General . 44B.2 Work-piece . 44B.3 Measurements . 46B.4 Test . 47B.5 Result . 47Annex C (normative)

Kickback test . 49Annex D (normative)

Stability test for displaceable machines . 50D.1 Stability test in the surfacing mode . 50D.2 Stability test in the thicknessing mode . 50Annex E (normative)

Impact test method for guards . 52E.1 General . 52E.2 Test method . 52E.2.1 Preliminary remarks . 52E.2.2 Testing equipment . 52E.2.3 Projectile for guards . 52E.2.4 Sampling. 52E.2.5 Test procedure . 52E.3 Results . 53E.4 Assessment . 53E.5 Test report . 53E.6 Test equipment for impact test . 53Annex F (informative)

Use of well-tried components . 55Annex G (normative)

Use of electronic components . 56G.1 General . 56G.2 SRECS design . 56G.2.1 Components, hardware . 56G.2.2 Safety related software . 57Annex H (normative)

Braking tests . 59H.1 Conditions for all tests . 59H.2 Unbraked run-down time . 59H.3 Braked run-down time . 59Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 60Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 63Bibliography . 67 SIST EN 861:2008+A1:2009

(IEC 60204-1:2005, modified) EN 60439-1:1999, Low-voltage switchgear and controlgear assemblies — Part 1: Type-tested and partially type-tested assemblies (IEC 60439-1:1999) EN 60529:1991, Degree of protection provided by enclosures (IP code) (IEC 60529:1989) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) EN 61508-3:2001, Functional safety of electrical/electronic/programmable electronic safety-related systems — Part 3: Software requirements (IEC 61508-3:1998 + Corrigendum 1999) EN 62061:2005, Safety of machinery — Functional safety of safety-related electrical, electronic and programmable electronic control systems (IEC 62061:2005) EN ISO 3743-1:1995, Acoustics — Determination of sound power levels of noise sources — Engineering methods for small, movable sources in reverberant fields — Part 1: Comparison method for hard-walled test rooms (ISO 3743-1:1994) EN ISO 3743-2:1996, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering methods for small, movable sources in reverberant fields — Part 2: Methods for special reverberant test rooms (ISO 3743-2:1994) EN ISO 3744:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Engineering method in an essentially free field over a reflecting plane (ISO 3744:1994) EN ISO 3745:2003, Acoustics — Determination of sound power levels of noise sources using sound pressure — Precision methods for anechoic and semi-anechoic rooms (ISO 3745:2003) EN ISO 3746:1995, Acoustics — Determination of sound power levels of noise sources using sound pressure — Survey method using an enveloping measurement surface over a reflecting plane (ISO 3746:1995) EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equipment (ISO 4871:1996) EN ISO 9614-1:1995, Acoustics — Determination of sound power levels of noise sources using sound intensity — Part 1: Measurement at discrete points (ISO 9614-1:1993) EN ISO 11202:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Survey method in situ

ISO 11202:1995) SIST EN 861:2008+A1:2009

3 Terms and definitions 3.1 General For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following apply: 3.2 Definitions 3.2.1 surface planing and thicknessing machine combined machine designed to plane a surface of a work-piece and to give it in a following operation a set thickness by means of a horizontally rotating cutterblock, a cylindrical shaped complex tool equipped with blades with horizontal straight cutting line that cuts while rotating (see for a description of the complex tool also EN 847-1:2005) NOTE The work-piece is fed into the machine against the direction of the cut. When surfacing, the work-piece is passed over the cutterblock located between two tables which are used to position and support the work-piece and the lower surface is planed. The infeed table of the surface planing unit is adjustable in height. When thicknessing, both of the surfacing tables are raised. The work-piece rests on the thicknessing table the distance between it and the cutting circle diameter is adjustable. The upper surface of the work-piece is planed

1) !EN ISO 13849-1:2006 superseded EN 954-1:1996." SIST EN 861:2008+A1:2009

!EN ISO 13849-1:2008"). 3.3 Terms The names of the main parts of the machine are shown in Figures 1 a) and 1 b). SIST EN 861:2008+A1:2009

Figure 1 a) — Example of surface planing and thicknessing machine (set up for planing)

Figure 1 b) — Example of surface planing and thicknessing machine (set up for thicknessing) Key 1 infeed table

6 controls 2 outfeed table

7 infeed table height adjustment 3 tiltable fence

8 bridge guard adjustment 4 bridge guard

9 thicknessing table 5 guard rear the fence

10 guard for thicknessing mode Figure 1 — Example of surface planing and thicknessing machine SIST EN 861:2008+A1:2009

Key 1 anti kickback fingers 2

stop for the rotation of the finger 3 infeed roller 4

outfeed roller 5 cutterblock 6

direction of feed

Figure 2 — Example of internal of a one side planing and thicknessing machine

The most usual working operations when using the machine in the surface planing mode are shown in

Figure 3.

Figure 3 — Planing (left) and edging (right)

4 List of significant hazards This clause contains !all significant" hazards, hazardous situations and events (see EN 1050:1996), as far as they are dealt with in this document, identified by risk assessment as significant for the machines as defined in the scope and which require action to eliminate or reduce the risk. This document deals with these significant hazards by defining safety requirements and / or measures or by reference to relevant standards. These hazards are listed in Table 1 in accordance with Annex A of EN 1050:1996. SIST EN 861:2008+A1:2009

No Hazards, hazardous situations and hazardous events EN ISO 12100

Relevant clause of this document

Part 1: 2003

Part 2: 2003

1 Mechanical hazards related to: - machine parts or work-pieces due to:

a) shape; 4.2 4.2.1, 4.2.2, 5

5.3.3, 5.3.5, 5.3.6, 5.3.7

b) relative location; 5.2.2, 5.2.5, 5.3.5, 5.3.6, 5.3.7

c) mass and stability (potential energy of elements which may move under the effect of gravity); 5.3.1, 5.3.6, 5.3.7

d) mass and velocity (kinetic energy of elements in controlled or uncontrolled motion); 5.2.3, 5.3.7

e)

mechanical strength; 5.3.2, 5.3.3, 5.3.5, 5.3.6, 5.3.7, 5.3.8, 5.3.9,

Annex A, Annex B, Annex E

- accumulation of energy inside the machinery by:

f) elastic elements (springs); 4.2 4.10, 5.5.4

5.3.6, 5.3.7, 5.4.5

g) liquids and gases under pressure; 5.4.6, 5.4.7 1.1 Crushing hazard 4.2.1

5.3.7 1.2 Shearing hazard

5.3.7 1.3 Cutting or severing hazard

5.3.3, 5.3.7, 6.3 1.4 Entanglement hazard

5.3.7 1.5 Drawing-in or trapping hazard

5.3.7 to be continued SIST EN 861:2008+A1:2009

No Hazards, hazardous situations and hazardous events

EN ISO 12100

Relevant clause of this document Part 1: 2003

Part 2: 2003

1.6 Impact hazard

5.3.6 1.9 High pressure fluid injection or ejection hazard 4.2.1 4.10

5.4.7 2 Electrical hazards due to: 2.1 Contact of persons with live parts (direct contact) 4.3 4.9, 5.5.4

5.4.4 2.2 Contact of persons with parts which have become live under faulty conditions (indirect contact) 4.3 4.9

5.4.4 4 Hazards generated by noise, resulting in: 4.1 Hearing loss (deafness), other physiological disorders (loss of balance, loss of awareness) 4.5 4.2.2, 5

5.4.2 4.2 Interference with speech communication, acoustic signals

5.4.2 7 Hazards generated by materials and substances (and their constituent elements) processed or used by the machinery 7.1 Hazards from contact with or inhalation of harmful fluids and dusts 4.8 4.3b, 4.4

5.4.3 7.2 Fire

4.8 4.4

5.4.1 8 Hazards generated by neglecting ergonomic principles in machinery design: 8.1 Unhealthy postures or excessive effort 4.9 4.7, 4.8.2, 4.11.12, 5.5.5, 5.5.6

5.2.2, 5.4.5, 6.3 8.2 Hand-arm or foot-leg anatomy 4.9 4.8.3

5.2.2, 5.3.7, 5.4.5 8.4 Local lighting

4.8.6

6.3 8.6 Human error, human behaviour 4.9 4.8, 4.11.8, 4.11.10, 5.5.2, 6

6.3 8.7 Design, location or identification of manual controls

4.8.7, 4.11.8

5.2.2 8.8 Design or location of visual display units

4.8.8, 6.2

5.4.5, 5.4.9, 6.1, 6.2 to be continued

No Hazards, hazardous situations and hazardous events EN ISO 12100

Relevant clause of this document Part 1: 2003

Part 2: 2003

9 Combination of hazards 4.11

5.2.3, 5.2.5, 5.2.6, 5.2.7, 5.3.5, 5.4.9, 5.4.10 10 Unexpected start-up, unexpected overrun/overspeed (or any similar malfunction) from: 10.1 Failure/disorder of the control system

4.11, 5.5.4

5.2.1, 5.2.2, 5.2.3, 5.2.4, 5.2.5, 5.2.6, 5.2.7 10.2 Restoration of energy supply after an interruption

4.11.4

5.2.6 10.3 External influences on electrical equipment

4.11.11

5.4.8, Annex G 10.5 Errors in the software

4.11.7 Annex G 10.6 Errors made by the operator (due to mismatch of machinery with human characteristics and abilities, see 8.6) 4.9 4.8, 4.11.8, 4.11.10, 5.5.2, 6

5.4.5, 5.4.10, 6.3 11 Impossibility of stopping the machine in the best possible conditions

4.11.1, 4.11.3, 5.5.2

5.2.4, 5.2.5, 5.3.4 13 Failure of the power supply

4.11.1, 4.11.4

5.2.6 14 Failure of the control circuit

4.11, 5.5.4

5.2.1, 5.2.7, 5.3.4 15 Errors of fitting 4.9

4.7, 6.5

6.2 16 Break-up during operation 4.2.2 4.3

5.3.2, 5.3.8, 5.3.9, Annex A, Annex B, Annex C 17 Falling or ejected objects or fluids 4.2.2 4.3, 4.10

5.3.2, 5.3.3, 5.3.6 18 Loss of stability / overturning of machinery 4.2.2 5.2.6

5.3.1

!EN ISO 13849-1:2008". At the end of programmed adjustment the power shall be cut to the adjustment actuator. A new initiation shall be necessary to perform additional adjustment. The category of the control circuits (also see 5.2.1) for start and restart of the machine and for the integrated feed motor shall be in accordance with the requirements of !EN ISO 13849-1:2008" and at least: a) category 1 if the control circuits are hardwired; b) category 3 if the control circuits include electronic components. The category of the control circuit (also see 5.2.1) for hold-to-run control shall be in accordance with the requirements in !EN ISO 13849-1:2008" and at least: 1) category 1 if the control circuits are hardwired; 2) category 3 if the control circuits include electronic components. Verification: By checking the relevant drawings and/or circuit diagrams, inspection of the machine and !relevant functional" testing of the machine. 5.2.4 Normal stopping The machine shall be fitted with a stop control system, where by the machine and – if fitted – a demountable power feed unit-can be brought safely to a complete stop. The stopping action shall include disconnection from energy supply of all machine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...