EN 12259-14:2020+A2:2024

(Main)Fixed firefighting systems - Components for sprinkler and water spray systems - Part 14: Sprinklers for residential applications

Fixed firefighting systems - Components for sprinkler and water spray systems - Part 14: Sprinklers for residential applications

This document specifies requirements for the construction and performance of residential sprinklers as well as test methods for their type approval, which are operated by a change of state of an element or bursting of a glass bulb under the influence of heat and incorporating the following types of water seals:

— conical metal spring with a PTFE gasket or coating;

— metal cap or disc with PTFE gasket or coating;

— copper gasket, with or without a PTFE coating.

Sprinklers in accordance with this document are only used in automatic sprinkler systems for domestic and residential applications as defined in EN 16925.

Ortsfeste Brandbekämpfungsanlagen - Bauteile für Sprinkler- und Sprühwasseranlagen - Teil 14: Sprinkler für die Anwendung im Wohnbereich

Dieses Dokument legt Anforderungen an die Konstruktion und Leistung von Wohnraumsprinklern, die dadurch öffnen, dass sich bei Erwärmung der Zustand eines Elements ändert oder ein Glasfass zerspringt, sowie Prüfverfahren zu deren Bauartzulassung fest. Wohnraumsprinkler nach diesem Dokument enthalten außerdem folgende Arten von Wasserdichtungen:

— konische Metallfeder mit PTFE-Dichtung oder -Beschichtung;

— Metallkappe oder –scheibe mit PTFE-Dichtung oder -Beschichtung;

— Kupferdichtung, mit oder ohne PTFE-Beschichtung.

Sprinkler nach diesem Dokument werden ausschließlich in automatischen Sprinkleranlagen für den Wohn- und Hausgebrauch, wie nach EN 16925 festgelegt, verwendet.

Installations fixes de lutte contre l'incendie - Composants des systèmes d'extinction du type sprinkleur et à pulvérisation d'eau - Partie 14: Sprinkleurs pour applications résidentielles

Le présent document spécifie les exigences relatives à la conception et aux performances des sprinkleurs résidentiels, ainsi que les méthodes d’essai en vue de leur homologation de type, ces sprinkleurs étant déclenchés par un changement d’état d’un élément ou l’éclatement d’une ampoule de verre sous l’effet de la chaleur et comportant les types de joints hydrauliques suivants :

— ressort métallique conique avec un joint ou un revêtement en PTFE ;

— bouchon ou disque métallique avec un joint ou un revêtement PTFE ;

— joint en cuivre avec ou sans revêtement PTFE.

Les sprinkleurs conformes au présent document sont utilisés uniquement dans les systèmes d’extinction automatique de type sprinkleurs à usage domestique et résidentiel, tels que définis dans l’EN 16925.

Vgrajene naprave za gašenje - Sestavni deli sprinklerskih sistemov in sistemov s pršečo vodo - 14. del: Sprinklerji za uporabo v stanovanjih (vključno z dopolnilom A2)

Ta dokument določa zahteve za izdelavo in delovanje ter preskusne metode za tipsko odobritev stanovanjskih sprinklerjev, ki delujejo po načelu spremembe stanja elementa oziroma razbitja steklenega mehurčka pod vplivom toplote in vključujejo naslednje vrste vodnih zapor:

– stožčasto kovinsko vzmet s tesnilom ali prevleko PTFE;

– kovinski pokrovček ali kolut s tesnilom ali prevleko PTFE;

– bakreno tesnilo s prevleko PTFE ali brez nje.

Sprinklerji v skladu s tem dokumentom se uporabljajo samo v avtomatskih sprinklerskih sistemih za bivalne površine, kot je opredeljeno v standardu EN 16925.

General Information

- Status

- Published

- Publication Date

- 13-Aug-2024

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/WG 5 - Sprinkler systems

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 03-Sep-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 26-Jun-2024

- Effective Date

- 26-Jun-2024

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TS 14972:2011 - Fixed firefighting systems - Watermist systems - Design and installation - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12259-14:2020+A2:2024 is the European (CEN) standard specifying construction, performance and type‑approval test methods for residential sprinklers used exclusively in automatic sprinkler systems for domestic and residential applications (as defined in EN 16925). The standard covers sprinklers that operate by a heat‑sensitive element (change of state) or by bursting of a glass bulb and that incorporate specific water seal types: conical metal spring with PTFE gasket/coating, metal cap/disc with PTFE gasket/coating, or copper gasket (with or without PTFE).

Key technical topics and requirements

- Scope and intended use: Residential occupancy sprinklers only (domestic applications per EN 16925).

- Seal types covered: conical metal spring + PTFE, metal cap/disc + PTFE, copper gasket ± PTFE.

- Construction & performance: dimensional and pressure rating requirements, nominal operating and operating temperatures, K‑factor (discharge coefficient), and thermal response (RTI).

- Functional tests: water flow and distribution, activation/function tests, and fire tests for type approval.

- Mechanical and environmental tests: body/deflector strength, release element strength, leak resistance, hydrostatic strength, water hammer, corrosion/exposure, vibration, impact, low/high temperature resistance and glass bulb thermal shock.

- Marking & documentation: identification number, manufacturing data, operating temperature, heat‑sensitive element supplier, protective cover instructions and installation charts.

- Type approval framework: normative test conditions and annexes (A–Q) detail test procedures and acceptance criteria for certification.

Practical applications

- Product design and development: Manufacturers use the standard to design residential sprinklers that meet European type‑approval and market access requirements.

- Type testing and certification: Test laboratories and certification bodies apply the annexed test methods when assessing sprinkler performance and compliance.

- Specification and procurement: Architects, fire safety engineers, building owners, and procurement teams reference the standard when specifying and buying sprinklers for residential projects.

- Installation & maintenance guidance: Installers and maintenance contractors rely on the marking and instruction requirements to ensure correct installation and long‑term reliability.

- Regulatory compliance & insurance: Authorities having jurisdiction (AHJs) and insurers use conformity to this standard as evidence of appropriate fire protection measures in domestic occupancies.

Who should use this standard

- Sprinkler manufacturers and R&D teams

- Third‑party test laboratories and certification bodies

- Fire protection designers and consulting engineers

- Installers, maintenance providers and building owners

- Standards committees, regulators and insurers

Related standards

- EN 16925 (automatic residential sprinkler systems - design, installation, maintenance)

- EN 12259‑1 (general sprinklers) and other parts of EN 12259 series

- Relevant ISO standards referenced for threads and materials

Keywords: EN 12259-14:2020+A2:2024, residential sprinklers, automatic sprinkler systems, type approval, PTFE gasket, glass bulb, K‑factor, RTI, EN 16925, sprinkler testing.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12259-14:2020+A2:2024 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fixed firefighting systems - Components for sprinkler and water spray systems - Part 14: Sprinklers for residential applications". This standard covers: This document specifies requirements for the construction and performance of residential sprinklers as well as test methods for their type approval, which are operated by a change of state of an element or bursting of a glass bulb under the influence of heat and incorporating the following types of water seals: — conical metal spring with a PTFE gasket or coating; — metal cap or disc with PTFE gasket or coating; — copper gasket, with or without a PTFE coating. Sprinklers in accordance with this document are only used in automatic sprinkler systems for domestic and residential applications as defined in EN 16925.

This document specifies requirements for the construction and performance of residential sprinklers as well as test methods for their type approval, which are operated by a change of state of an element or bursting of a glass bulb under the influence of heat and incorporating the following types of water seals: — conical metal spring with a PTFE gasket or coating; — metal cap or disc with PTFE gasket or coating; — copper gasket, with or without a PTFE coating. Sprinklers in accordance with this document are only used in automatic sprinkler systems for domestic and residential applications as defined in EN 16925.

EN 12259-14:2020+A2:2024 is classified under the following ICS (International Classification for Standards) categories: 13.220.20 - Fire protection. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12259-14:2020+A2:2024 has the following relationships with other standards: It is inter standard links to EN 12259-14:2020+A1:2022/FprA2, EN 12259-14:2020+A1:2022, ISO 5660-1:2015, EN 12259-1:1999 + A1:2001/A2:2004, prEN 15116, EN 14770:2012, EN 12259-1:1999 + A1:2001/A3:2006, EN 12259-1:1999 + A1:2001, EN 12510:2001, EN 13501-1:2018, CEN/TS 12101-11:2022, EN 12259-15:2025, CEN/TS 14972:2011, EN 16925:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12259-14:2020+A2:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-oktober-2024

Nadomešča:

SIST EN 12259-14:2020+A1:2022

Vgrajene naprave za gašenje - Sestavni deli sprinklerskih sistemov in sistemov s

pršečo vodo - 14. del: Sprinklerji za uporabo v stanovanjih (vključno z dopolnilom

A2)

Fixed firefighting systems - Components for sprinkler and water spray systems - Part 14:

Sprinklers for residential applications

Ortsfeste Brandbekämpfungsanlagen - Bauteile für Sprinkler- und Sprühwasseranlagen -

Teil 14: Sprinkler für die Anwendung im Wohnbereich

Installations fixes de lutte contre l'incendie - Composants des systèmes d'extinction du

type sprinkleur et à pulvérisation d'eau - Partie 14: Sprinkleurs pour applications

résidentielles

Ta slovenski standard je istoveten z: EN 12259-14:2020+A2:2024

ICS:

13.220.10 Gašenje požara Fire-fighting

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12259-14:2020+A2

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2024

EUROPÄISCHE NORM

ICS 13.220.20 Supersedes EN 12259-14:2020+A1:2022

English Version

Fixed firefighting systems - Components for sprinkler and

water spray systems - Part 14: Sprinklers for residential

applications

Installations fixes de lutte contre l'incendie - Ortsfeste Brandbekämpfungsanlagen - Bauteile für

Composants des systèmes d'extinction du type Sprinkler- und Sprühwasseranlagen - Teil 14: Sprinkler

sprinkleur et à pulvérisation d'eau - Partie 14: für die Anwendung im Wohnbereich

Sprinkleurs pour applications résidentielles

This European Standard was approved by CEN on 4 November 2019 and includes Amendment 1 approved by CEN on 13 March

2022 and Amendment 2 approved by CEN on 14 July 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12259-14:2020+A2:2024 E

worldwide for CEN national Members.

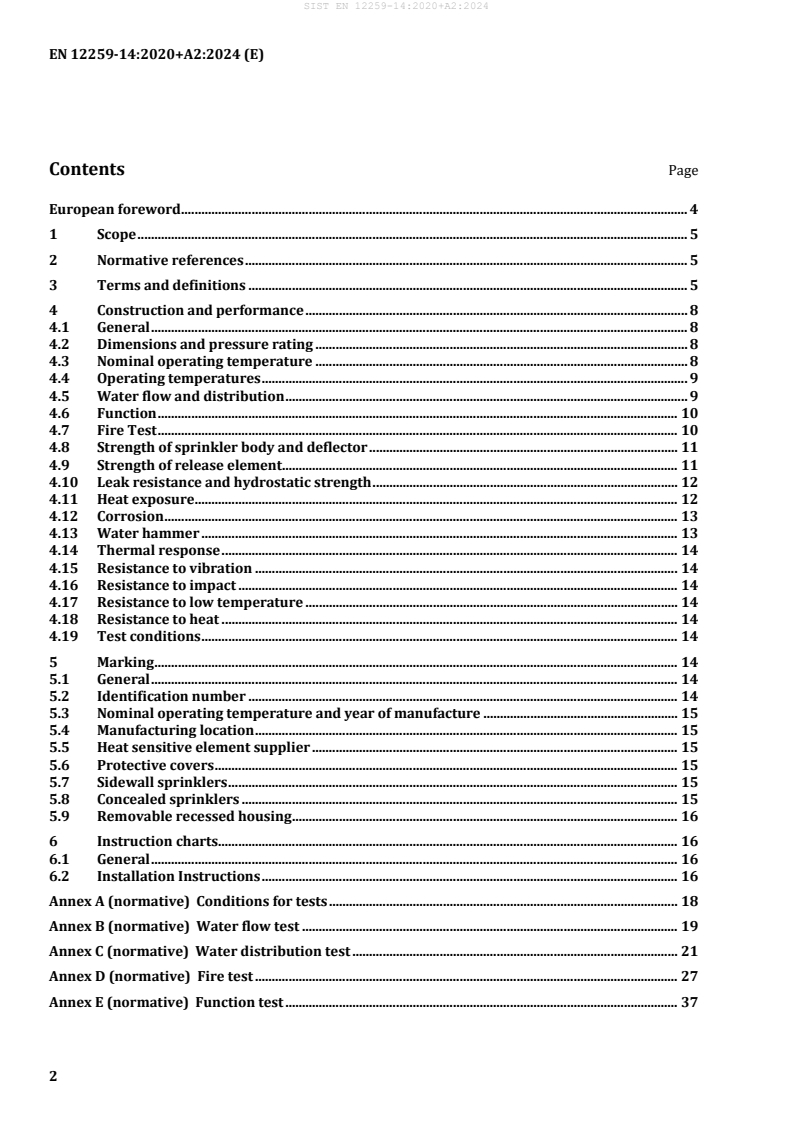

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Construction and performance . 8

4.1 General . 8

4.2 Dimensions and pressure rating . 8

4.3 Nominal operating temperature . 8

4.4 Operating temperatures . 9

4.5 Water flow and distribution . 9

4.6 Function . 10

4.7 Fire Test . 10

4.8 Strength of sprinkler body and deflector . 11

4.9 Strength of release element. 11

4.10 Leak resistance and hydrostatic strength . 12

4.11 Heat exposure . 12

4.12 Corrosion . 13

4.13 Water hammer . 13

4.14 Thermal response . 14

4.15 Resistance to vibration . 14

4.16 Resistance to impact . 14

4.17 Resistance to low temperature . 14

4.18 Resistance to heat . 14

4.19 Test conditions . 14

5 Marking . 14

5.1 General . 14

5.2 Identification number . 14

5.3 Nominal operating temperature and year of manufacture . 15

5.4 Manufacturing location . 15

5.5 Heat sensitive element supplier . 15

5.6 Protective covers . 15

5.7 Sidewall sprinklers . 15

5.8 Concealed sprinklers . 15

5.9 Removable recessed housing . 16

6 Instruction charts. 16

6.1 General . 16

6.2 Installation Instructions . 16

Annex A (normative) Conditions for tests . 18

Annex B (normative) Water flow test . 19

Annex C (normative) Water distribution test . 21

Annex D (normative) Fire test . 27

Annex E (normative) Function test . 37

Annex F (normative) Strength of sprinkler body and deflector . 39

Annex G (normative) Strength of release elements test . 41

Annex H (normative) Leak resistance tests . 44

Annex I (normative) Heat exposure . 45

Annex J (normative) Glass bulb sprinkler thermal shock test . 46

Annex K (normative) Exposure and corrosion tests . 47

Annex L (normative) Water hammer test . 51

Annex M (normative) Thermal response test. 52

Annex N (normative) Vibration test . 57

Annex O (normative) Impact test . 58

Annex P (normative) Resistance to low temperature test . 59

Annex Q (normative) Resistance to high temperature test . 60

Bibliography . 61

European foreword

This document (EN 12259-14:2020+A2:2024) has been prepared by Technical Committee CEN/TC 191

“Fixed firefighting systems”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2025, and conflicting national standards

shall be withdrawn at the latest by February 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document includes Amendment 1 approved by CEN on 13 March 2022 and Amendment 2

approved by CEN on 14 July 2024.

This document supersedes !EN 12259-14:2020+A1:2022".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !"

and #$.

#In comparison with EN 12259-14:2020, technical modifications have been made to clarify the types

of sprinkler seal that are covered by this document in Amendment 1. In Amendment 2 the pressure

values in C.1.1 and C.2.1 were corrected as well as the unit for the force increase in G.1.$

It is included in a series of European Standards planned to cover:

— automatic sprinkler systems (EN 12259 and EN 12845);

— gas extinguishing systems (EN 12094);

— powder systems (EN 12416);

— foam systems (EN 13565);

— hydrant and hose reel systems (EN 671);

— smoke and heat control systems (EN 12101).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

!This document specifies requirements for the construction and performance of residential

sprinklers as well as test methods for their type approval, which are operated by a change of state of an

element or bursting of a glass bulb under the influence of heat and incorporating the following types of

water seals:

— conical metal spring with a PTFE gasket or coating;

— metal cap or disc with PTFE gasket or coating;

— copper gasket, with or without a PTFE coating.

Sprinklers in accordance with this document are only used in automatic sprinkler systems for domestic

and residential applications as defined in EN 16925."

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

!EN 12259-1:1999+A1:2001 ", Fixed firefighting systems — Components for sprinkler and water

spray systems — Part 1: Sprinklers

EN 13501-1, Fire classification of construction products and building elements - Part 1: Classification

using data from reaction to fire tests

EN 16925, Fixed firefighting systems - Automatic residential sprinkler systems - Design, installation and

maintenance

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions,

tolerances and designation

ISO 49, Malleable cast iron fittings threaded to ISO 7-1

ISO 65, Carbon steel tubes suitable for screwing in accordance with ISO 7-1

ISO 5658-2:2006, Reaction to fire tests — Spread of flame — Part 2: Lateral spread on building and

transport products in vertical configuration

ISO 5660-1:2015, Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 1:

Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement)

UL 723, Standard for test for surface burning characteristics of building materials

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at https://www.electropedia.org/

!As impacted by EN 12259-1:1999+A1:2001/A2:2004 and EN 12259-1:1999+A1:2001/A3:2006."

— ISO Online browsing platform: available at https://www.iso.org/obp

3.1

concealed sprinkler

unit (pre-assembled or assembled on site) consisting of a nozzle with a thermally sensitive sealing

device, a housing and a cover plate, that ensures that the sprinkler will be installed with all or part of

the thermally sensitive element behind the plane of the ceiling

3.2

recessed sprinkler

unit (pre-assembled or assembled on site) consisting of a nozzle with a thermally sensitive sealing

device and a housing, that ensures that the sprinkler will be installed with all or part of the thermally

sensitive element above the plane of the ceiling

3.3

discharge coefficient

known as K-factor

coefficient of discharge in the formula,

Q = K √ p (1)

where

Q is the flow in litres per minute, and

p is the pressure in bar

3.4

dry-type sprinkler

nozzle with a thermally sensitive sealing device secured in an extension nipple that has a seal at the

inlet end to prevent water from entering the nipple until the sprinkler operates

3.5

flush sprinkler

unit consisting of a nozzle with a thermally sensitive sealing device and housing, that ensures that the

sprinkler will be installed partly behind, but with the temperature sensitive element before, the finished

plane of the ceiling or wall

3.6

heat responsive element

portion of a sprinkler that breaks, melts, or otherwise functions to initiate the automatic operation of

the sprinkler when exposed to sufficient heat

3.7

heptane

commercial grade heptane having the following characteristics:

a) minimum Initial Boiling Point of 88 °C;

b) maximum Dry Point of 100 °C; and

c) specific Gravity (15,6 °C/15,6 °C) of 0,68 - 0,73.

3.8

orifice

opening that controls the amount of water discharged from a sprinkler at a given pressure

3.9

pendent sprinkler

nozzle with a thermally sensitive sealing device intended to be installed so that its deflector is located

below the orifice and the water flows downward through the orifice

3.10

residential sprinkler

nozzle with a thermally sensitive sealing device intended to be installed only in residential occupancies

as defined in EN 16925

3.11

sidewall sprinkler

nozzle with a thermally sensitive sealing device intended for installation on or near the wall

3.12

upright sprinkler

nozzle with a thermally sensitive sealing device intended to be installed so that its deflector is located

above the orifice

3.13

response time index

RTI

½ ½

measure of the thermal sensitivity of the sprinkler expressed in (meters.seconds) (m×s)

Note 1 to entry: Unlike in EN12259–1, the RTI value is calculated without considering the conductivity factor

3.14

design lower tolerance limit

DLTL

glass bulb supplier’s specified and assured lowest lower tolerance limit

3.15

design upper tolerance limit

DUTL

sprinkler supplier’s specified and assured highest upper tolerance limit

3.16

fusible link sprinkler

nozzle with a thermally sensitive sealing device which opens when an element provided for that

purpose melts

3.17

glass bulb sprinkler

nozzle with a thermally sensitive sealing device which opens when a liquid-filled glass bulb bursts

3.18

mean design service load

sprinkler supplier’s specified and assured highest mean service load for any batch of 10 or more

sprinklers

3.19

mean design strength

glass bulb supplier’s specified and assured lowest mean bulb strength for any batch of 55 or more bulbs

3.20

horizontal sprinkler

nozzle with a thermally sensitive sealing device in which the nozzle directs the water horizontally

3.21

lower tolerance limit

LTL

glass bulb lowest strength determined by test and statistical analysis of a batch of 55 or more bulbs

3.22

supplier

company responsible for the design, manufacture and quality assurance of a product

3.23

upper tolerance limit

UTL

highest service load determined by test and statistical analysis of a batch of 20 or more sprinklers

3.24

frame arms

part of a sprinkler that maintains the thermally sensitive element in load bearing contact with the

sprinkler head valve

4 Construction and performance

4.1 General

Sprinklers shall only be assembled in such a way that adjustment or dismantling will result in

destruction of an element of construction.

It shall be possible to remove the cover of a concealed sprinkler without having to use special tools, e.g.

for visual inspections.

4.2 Dimensions and pressure rating

4.2.1 Dimensions

Nominal thread sizes shall be suitable for fittings threaded in accordance with ISO 7-1.

It shall be possible for a sphere of (5,0 +0,01/-0) mm diameter to pass through the orifice of the

sprinkler.

4.2.2 Pressure ratings

A residential sprinkler shall have a maximum operating pressure of at least 12 bar.

4.3 Nominal operating temperature

When tested in accordance with “Test to determine operating temperatures of fusible link sprinklers

and glass bulb sprinklers” of !EN 12259-1:1999+A1:2001", sprinklers shall operate at a

temperature within the range:

o

T = [t ± (0,035 t +0,62)] C

test

where

t is the nominal operating temperature.

When cover plates are tested in accordance with the “Test to determine operating temperatures of

fusible link sprinklers and glass bulb sprinklers” of !EN 12259-1:1999+A1:2001", cover plates

shall operate at a temperature within the range:

o

T = [t ± (0,035 t +0,62)] C

test cover

where

t is the nominal operating temperature of the cover.

cover

This temperature t shall be 8 °C to 20 °C lower than the nominal operating temperature of its

cover

sprinkler head.

4.4 Operating temperatures

The temperature classification, temperature rating, and colour coding of a residential sprinkler shall be

as specified in Table 1.

Table 1 — Nominal operating temperatures and colour codes

Glass bulb sprinklers Fusible link sprinklers

Nominal operating Liquid Nominal operating Frame arms

temperature colour code temperature within colour code

°C range

°C

57 Orange 57 to 77 uncoloured

68 Red 80 to 107 white

79 Yellow

93 Green

100 Green

4.5 Water flow and distribution

4.5.1 K-factor

The nominal K-factor shall be specified by the supplier. The K-factor of the sprinklers shall be within the

nominal value ± 5 % for other than dry sprinklers and ± 8 % for dry sprinklers, when determined in

accordance with Annex B.

4.5.2 Water distribution

4.5.2.1 Water distribution test – Horizontal surface

When installed in accordance with the installation instructions and tested as described in C.1 a

residential sprinkler shall distribute water over a horizontal surface so that the discharge density for

any pan within the design area (the maximum area the sprinkler is intended to protect) shall be at least

0,8 mm/min except that:

a) no more than 2 pans (0,5 m × 0,5 m) or not more than 4 pans (0,3m × 0,3m) for each quadrant shall

be allowed to be at least 0,6 mm/min for upright and pendant sprinklers; and

b) no more than 8 pans (0,3 m × 0,3 m) or 3 pans (0,5 m × 0,5 m) shall be allowed to be at least

0,6 mm/min for each half (split along the sprinkler centreline) of the maximum area a sidewall

sprinkler is intended to protect

4.5.2.2 Water distribution test – Vertical surface

When installed in accordance with the installation instructions and tested as described in C.2, a

residential sprinkler shall distribute water in a uniform manner over vertical surfaces as follows:

a) walls within the coverage area shall be completely wetted to at least within 711 mm of the ceiling

with one sprinkler discharging water at the specified design flow rate;

b) for square coverage areas, each wall within the coverage area shall be wetted with at least 5 % of

the sprinkler flow; for rectangular coverage areas, each wall within the coverage area shall be

wetted with a proportional water amount based on 20 % of the total sprinkler discharge in

accordance with the following formula

WW – 20 % (D / P) (2)

where

WW is required amount of water collected on a wall, in %;

D is wall length, in m;

P is total perimeter of coverage area, in m.

4.5.3 Water Impingement Test

When tested in accordance with Annex C and while discharging water at a service pressure of 5,2 bar

less than the maximum operating pressure, a residential sprinkler shall not prevent the operation of an

adjacent residential sprinkler.

4.6 Function

When tested in accordance with Annex E each of the residential sprinklers shall operate at service

pressures of 0,5 bar to the maximum operating pressure. The sprinkler shall open and within 5 s of

release of the thermally sensitive element shall operate satisfactorily. Any lodgement of released parts

shall be cleared within 60 s of the release of the thermally sensitive element. After testing in accordance

with Annex E the sprinkler shall conform to the requirements of 4.5.2.

NOTE In most instances visual examination of the equipment will be sufficient to establish conformity with the

requirements of 4.5.2.

4.7 Fire Test

When fire tested as described in Annex D a residential sprinkler shall limit temperatures as specified

below when tested at each spacing referenced in the installation instructions. Additionally, a maximum

of two residential sprinklers shall operate and the third sprinkler, located near the 1 000 mm wide

doorway, shall not operate. The sprinklers shall limit temperatures as follows:

a) The maximum temperature measured 76 mm below the ceiling at locations 4 and 5 as illustrated in

Figure D.1, Figure D.2 and Figure D.3 shall not exceed 316 °C.

b) The maximum temperature measured 1,6 m above the floor at location 4 shall not exceed 93 °C.

c) The temperature at the location described in (b) shall not exceed 54 °C for more than any

continuous 2 min period.

d) The maximum ceiling material temperature measured 6 mm behind the finished ceiling surface

shall not exceed 260 °C.

NOTE The thermocouple 76 mm below the ceiling, located above the fire source, is for reference purposes

only.

See Figure D.1, (pendant, upright, flush, recessed pendant, and concealed sprinklers) or Figure D.2 and

Figure D.3 (sidewall sprinklers) for temperature measuring locations.

4.8 Strength of sprinkler body and deflector

4.8.1 Strength of frame

The sprinkler body shall not show permanent elongation of more than 0,2 % between the load-bearing

parts when subjected to twice the average service load when tested in accordance with F.1.

4.8.2 Flow endurance

A residential sprinkler shall withstand for 30 min, without evidence of cracking, deformation, or

separation of any part when tested in accordance with F.2.

4.8.3 Strength of deflector

The sprinkler deflector and its supporting parts shall withstand an applied force of 70 N without

permanent deformation when tested in accordance with F.3.

4.9 Strength of release element

4.9.1 Glass bulb sprinklers

When evaluated and tested in accordance with Annex G, glass bulb sprinklers shall have:

a) a mean design bulb strength of at least six times the mean design service load;

b) a mean bulb strength not less than the mean design bulb strength;

c) a mean service load not more than the mean design service load;

d) a design lower tolerance limit (DLTL) on the distribution curve of at least two times the design

upper tolerance limit (DUTL) of the service load distribution curve;

e) an upper tolerance limit (UTL) less than or equal to the design upper tolerance limit (DUTL);

f) a lower tolerance limit (LTL) greater than or equal to the design lower tolerance limit (DLTL) see

Figure 1.

Key

1 service load distribution curve

2 bulb strength distribution curve

3 mean service load

4 mean bulb strength

5 upper tolerance limit (UTL)

6 lower tolerance limit (LTL)

A number of samples

B strength (N)

Figure 1 — Graph of service load and bulb strength distribution curves

4.9.2 Fusible link sprinklers

It shall be determined that:

a) the temperature sensitive elements withstand a load of 15 times the maximum design load for a

period of 100 h, without failure; or

b) the estimated time to failure of temperature sensitive elements is not less than 876 600 h at the

design load, when tested in accordance with Annex G.

4.10 Leak resistance and hydrostatic strength

Twenty residential sprinklers shall be tested and not leak when tested in accordance with H.1 and,

subsequently, shall not rupture, operate or release, when tested in accordance with H.2.

4.11 Heat exposure

4.11.1 General

A residential sprinkler shall withstand for 90 days, without evidence of weakness or malfunction, an

exposure to the high-ambient temperature in accordance with I.1.

After the exposure period four sprinklers shall be tested in accordance with E.2; the sprinklers shall

operate such that the waterway is cleared. Any lodgements shall be disregarded. Four sprinklers shall

be leak tested in accordance with H.1. Four sprinklers shall be tested in accordance with “Test to

determine operating temperatures of fusible link sprinklers and glass bulb sprinklers” of

!EN 12259-1:1999+A1:2001".

Additionally, after the exposure period four recessed, concealed and flush sprinklers shall be tested in

accordance with M.2. Their mean operating time shall be equal to or less than a 1,30 multiple of the

mean operating time of the sprinkler tested in accordance with M.2 for compliance with 4.14.2.

4.11.2 Additional heat exposure of glass bulb sprinklers

There shall be no damage to the glass bulb when sprinklers are tested in accordance with I.2.

!deleted text"

4.11.3 Thermal shock

When glass bulb sprinklers are tested in accordance with Annex J, the glass bulbs shall either:

— break correctly on cooling such that the waterway is cleared; or

— remain intact. After immersion when subjected to a function test in accordance with E.2, the

sprinkler shall operate in such way that the waterway is cleared; any lodgements shall be

disregarded.

4.12 Corrosion

4.12.1 Stress corrosion

After being subjected for 10 days to a moist ammonia exposure as described in K.1 a residential

sprinkler having copper alloy parts shall:

a) show no evidence of cracking, delamination, or degradation; and

b) perform as intended when tested as described in K.1.

If the application of a 12 bar water pressure to the inlet of the sprinkler increases the assembly load by

more than 10 %, the additional load is to be applied during the moist ammonia-air mixture exposure

specified in K.1.

4.12.2 Sulphur dioxide corrosion

Residential sprinklers shall be subjected to a sulphur dioxide corrosion test in accordance with K.2.

After exposure, when subjected to a function test in accordance with E.2 the sprinkler shall operate

such that the waterway is cleared; any lodgements shall be disregarded.

4.12.3 Salt mist corrosion

Residential sprinklers shall be subjected to a salt mist corrosion test in accordance with K.3. After

exposure, when subjected to a function test in accordance with E.2, the sprinkler shall operate such that

the waterway is cleared; any lodgements shall be disregarded.

4.12.4 Moist air

Residential sprinklers shall withstand an exposure to moist air atmospheres when tested in accordance

with K.4.

4.13 Water hammer

Sprinklers shall not leak when subjected to pressure surges in accordance with Annex L. After the test,

when subjected to a function test in accordance with E.2, the sprinkler shall operate such that the

waterway is cleared; any lodgements shall be disregarded.

4.14 Thermal response

4.14.1 Oven test

When tested in accordance with M.1, upright, pendent and horizontal sprinklers, other than flush,

recessed and concealed sprinklers, shall release within a maximum time which is to be calculated from

the formula in M.1, based on a response time index (RTI) 50.

4.14.2 Room response test

When tested in accordance with M.2, flush, recessed and concealed sprinklers shall release within 75 s.

4.15 Resistance to vibration

A residential sprinkler shall withstand the effects of vibration without deterioration of its performance

characteristics when tested in accordance with Annex N.

4.16 Resistance to impact

A residential sprinkler, except for dry-type sprinklers, shall be tested as described in Annex O and shall

not be damaged or leak.

4.17 Resistance to low temperature

The sprinkler shall not operate before the function test, when tested in accordance with Annex P. After

the low temperature exposure it shall show no visible evidence of damage. Following examination,

when subjected to a function test in accordance with E.2, the sprinkler shall operate such that the

waterway is cleared; any lodgements shall be disregarded.

4.18 Resistance to heat

When tested in accordance with Annex Q, the sprinkler body, deflector and its supporting parts shall

show no significant deformation or breakage.

4.19 Test conditions

For sprinkler testing conditions, see Annex A.

5 Marking

5.1 General

Sprinklers shall be marked with the name or trade mark of the supplier.

An identification number as defined in 5.2 is considered to satisfy this requirement.

5.2 Identification number

A four- to six-character identification number, with no intervening spaces, should be used to identify

the supplier and sprinkler operating characteristics. The number, if used, shall be cast or die-stamped

on the sprinkler deflector or on a visible non-operating part, which is not used to install the sprinkler.

The identification number is permitted to be located behind the cover plate which is removable with

common tools, provided the number will be visible after the sprinkler is installed and the cover plate is

removed.

The identification number, if used, shall consist of one or two characters which identify the supplier,

followed by three or four digits to identify a unique sprinkler identification for orifice size or shape,

deflector characteristic, pressure rating and thermal sensitivity classification.

5.3 Nominal operating temperature and year of manufacture

A residential sprinkler shall be permanently marked on a visible non-operating part with the

temperature rating and year of manufacture.

Exception: The nominal operating temperature may be marked on a visible operating part instead of being

marked on a visible non-operating part.

A sprinkler produced in the last 3 months of a calendar year may be marked with the following year as

the date of manufacture, and one produced in the first 6 months of a calendar year may be marked with

the preceding year as the date of manufacture.

The frame arms of residential sprinklers of the various nominal operating temperatures shall be

coloured in accordance with the colour code designated in Table 1.

Exception No. 1: Frame arm colour identification is not required for painted sprinklers, flush sprinklers, or

similar decorative types.

Exception No. 2: Frame arm colour identification is not required for sprinklers having frangible bulb heat

responsive elements colour coded in accordance with Table 1.

5.4 Manufacturing location

If a supplier produces sprinklers at more than one factory, each sprinkler shall have a distinctive

marking to identify it as the product of a particular factory.

5.5 Heat sensitive element supplier

When sprinklers are made with more than one supplier of the heat sensitive element, i.e. the glass bulb

or the fusible link, each sprinkler shall have a distinctive marking to identify the heat sensitive element

supplier.

5.6 Protective covers

Protective covers, if used, shall be shall be marked to indicate that the cover shall be removed before

the sprinkler system is placed in service. The marking shall be placed on the protective cover so that it

is visible after sprinkler installation.

5.7 Sidewall sprinklers

5.7.1 General

The deflector of a sidewall sprinkler shall clearly show its intended orientation with regard to the

direction of flow. If an arrow is employed, it shall indicate the direction of flow and be accompanied by

the word “FLOW.”

5.7.2 Horizontal sidewall sprinklers

A residential sprinkler intended for horizontal sidewall installation shall be marked with the word

“TOP.”

5.8 Concealed sprinklers

The cover plate for a concealed sprinkler shall be marked with the words: “Do not paint” on the exterior

surface.

Any housing intended for installation with concealed sprinkler assemblies and not attached by the

supplier shall be marked as follows: “FOR USE WITH [SPRINKLER IDENTIFICATION description].”

5.9 Removable recessed housing

An escutcheon intended for installation with recessed and concealed type sprinkler assemblies and not

attached by the supplier shall be marked as follows: “FOR USE WITH [SPRINKLER IDENTIFICATION

NUMBER(S) AND SPRINKLER TEMPERATURE RATING(S)].”

6 Instruction charts

6.1 General

An instruction chart, giving the recommended method of installation and instructions on care and

replacement, shall be available with each type of sprinkler.

6.2 Installation Instructions

Each package of residential sprinklers shall be provided with installation instructions that shall include

the following:

a) coverage area dimensions;

b) minimum water flow rate in accordance with Table 2;

c) K-factor;

d) minimum distance between sprinklers;

e) installation position;

f) distance of sprinkler deflector from ceiling and / or wall;

g) minimum operating pressure;

h) distance between the sprinkler and obstructions;

i) indication as to whether a recessed or concealed sprinkler is vented or unvented;

j) indication whether concealed sprinklers are allowed to be installed in concrete or other solid

materials;

k) a reference to EN 16925 for design and installation; and

l) a statement that the minimum flow for each sprinkler shall be such that both the associated length

and width spacings given in the supplier’s table shall be equal to or greater than the sprinkler’s

length and width spacings in the actual installation.

If the installation instructions do not only refer to EN 16925, it shall be clearly indicated which clauses,

parts and values relate to EN 16925.

Guidance for locating sprinklers away from obstructions shall be provided.

For dry-type sprinklers intended to be installed in dry systems, information shall be provided on the

appropriate sprinkler-fitting compatibility, to minimize the potential to accumulate water, scale, and

sediment of the sprinkler inlet and provide for an unobstructed flow path upon operation.

The minimum water flow rates shall not be less than those given in Table 2 for typical spacings. The

minimum flow rate for a sprinkler shall be the same for single and multiple operating sprinklers.

Table 2 — Minimum sprinkler flow rates for typical spacings

Upright, pendant, recessed pendant, flush, and Sidewall sprinklers

concealed sprinklers

Typical spacing Minimum flow Typical spacing Minimum flow

m l/min m l/min

3,7 × 3,7 28 3,7 × 3,7 28

4,3 × 4,3 38 4,3 × 4,3 38

4,9 × 4,9 49 4,9 × 4,9 49

5,5 × 5,5 62 5,5 × 5,5 62

6,1 × 6,1 76 6,1 × 6,1 76

4,9 × 5,5 55

4,9 × 6,1 61

5,5 × 6,1 69

!deleted text" The maximum spacing shall not be more than 37,2 m . If another spacing as stated

above is used, the minimum flow shall not be less than that required to provide a minimum design

discharge density of 2,1 mm/min.

Annex A

(normative)

Conditions for tests

See 4.19 for the corresponding requirement.

Except where specified otherwise, carry out tests at (20 ± 10) °C. Examine sprinklers for visually

obvious defects before testing.

Annex B

(normative)

Water flow test

See 4.5.1 for the corresponding requirement. Mount the sprinkler on a supply pipe together with a

means of pressure measurement (see Figure B.1). Bleed the air from the pipe assembly using the bleed

valve. Measure the flow rate, by direct measurement of flow rate or by collecting and measuring the

weight or volume of water discharged, for water pressures of 0,5 bar to 6,5 bar at the sprinkler head at

intervals of (1 ± 2 %) bar. The maximum permissible error of the flow measuring device shall be ± 2 %

of the value measured. Calculate the K-factor for each pressure interval from Formula (1):

K = Q / √ P

where

P is the pressure in bar (bar)

Q is the flow rate in litres per minute (l/min)

During the test, pressures should be corrected for difference in height between the gauge and the outlet

orifice of the sprinkler.

Dimensions in millimetres

Key

1 deburred orifice

2 steel tube nominal internal diameter 40 mm, medium weight (in accordance with ISO 65)

3 fitting 10 mm, 15 mm, 20 mm, 25 mm or 32 mm (in accordance with ISO 49)

4 pressure gauge

5 air bleed valve

6 plug or cap

NOTE Tolerances: Pressure gauge ± 2 % or 0,04 bar whichever is the greater, weighing machine ± 1 %.

Figure B.1— Water flow test apparatus

Annex C

(normative)

Water distribution test

C.1 Water distribution test – Horizontal surface

C.1.1 General

See 4.5.1.2 for the corresponding requirement.

Tests are to be conducted on an individual sprinkler using minimum flow rates specified in the

installation instructions. #In addition, for sprinklers having a pressure rating greater than 12 bar,

tests shall be conducted at the maximum spacing specified in the installation instructions using a flow

corresponding to a pressure of 5 bar less than the maximum operating pressure.$ The water

distribution test is to be conducted for 20 min at each flow rate, except a shorter duration can be used if

a pan within the collected area has reached its capacity.

Dry-type sprinklers are to be tested using the shortest available length and the longest available length,

if the K-factor for the longest length deviates by more than 5 % from the shortest available length.

An open horizontal sidewall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...