FprEN 15101-1

(Main)Thermal insulation products for buildings - In-situ formed loose fill cellulose (LFCI) products - Part 1: Specification for the products before installation

Thermal insulation products for buildings - In-situ formed loose fill cellulose (LFCI) products - Part 1: Specification for the products before installation

This European Standard specifies requirements for loose-fill cellulose insulation (LFCI) products for the thermal and/or sound insulation of buildings when installed into walls, floors, galleries, roofs and ceilings.

This Part 1 of the standard is a specification for the loose-fill cellulose insulation (LFCI) products before installation.

Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity.

Products covered by this standard may also be used in prefabricated thermal insulation systems and composite panels; the structural performance of systems incorporating these products is not covered.

Products with a declared thermal conductivity at 10 °C greater than 0,060 W/(m x K) or a declared thermal resistance lower than 0,25 m2 x K/W are not covered by this standard.

This European Standard does not specify the required level of all properties to be achieved by a product to demonstrate fitness for purpose in a particular application. The required levels are to be found in local regulations or non-conflicting standards.

This European Standard does not cover factory made cellulose products placed on the market as bats, mats or boards intended to be used for the insulation of buildings or loose-fill cellulose products for the insulation of building equipment and industrial installations.

Wärmedämmstoffe für Gebäude - An der Verwendungsstelle hergestellte Wärmedämmung aus Zellulosefüllstoff - Teil 1: Spezifikation für die Produkte vor dem Einbau

Diese Europäische Norm legt Anforderungen für Produkte aus loser Zellulosedämmung (LFCI, en: Loose-Fill

Cellulose Insulation) fest, die als Wärme- und/oder Schalldämmung von Gebäuden in Wände, Fußböden,

Galerien, Dächer und Decken eingebaut werden.

Teil 1 dieser Norm ist eine Spezifikation für Produkte aus loser Zellulosedämmung (LFCI) vor dem Einbau.

Teil 1 dieser Europäischen Norm beschreibt die Produkteigenschaften und enthält Verfahren für die Prüfung,

Kennzeichnung und Etikettierung sowie Vorschriften für die Konformitätsbewertung.

Die von dieser Norm abgedeckten Produkte dürfen auch in vorgefertigten Wärmedämmsystemen und Mehrschicht-

Verbundplatten verwendet werden; das Tragverhalten von Systemen, in die diese Produkte eingebaut

sind, wird jedoch nicht behandelt.

Produkte mit einem Nennwert der Wärmeleitfähigkeit bei 10 °C von mehr als 0,060 W/(m ⋅ K) oder einem

Nennwert des Wärmedurchlasswiderstandes von weniger als 0,25 m2 ⋅ K/W sind nicht Gegenstand dieser

Norm.

Diese Europäische Norm legt keine erforderlichen Leistungsstufen für alle Eigenschaften fest, die ein Produkt

erreichen sollte, um die Gebrauchstauglichkeit für eine bestimmte Anwendung nachzuweisen. Die

erforderlichen Stufen können Regelwerken oder nicht entgegenstehenden Normen entnommen werden.

Diese Europäische Norm gilt weder für werkseitig hergestellte Zelluloseprodukte für die Wärmedämmung von

Gebäuden, die in Form von Matten oder Platten verkauft werden, noch für lose Zelluloseprodukte für die

Wärmedämmung von haus- und betriebstechnischen Anlagen.

Produits isolants thermiques destinés aux applications du bâtiment - Isolation thermique formée en place à base de cellulose (LFCI) - Partie 1: Spécification des produits en vrac avant la mise en place

La présente Norme européenne spécifie les exigences relatives aux produits d’isolation cellulosiques en vrac

(LFCI) destinés à servir d’isolation thermique et/ou acoustique lorsqu'ils sont installés dans des parois,

planchers, galeries, toitures et plafonds.

La présente partie 1 de la norme est une spécification des produits d'isolation cellulosiques en vrac (LFCI)

avant la mise en place.

La partie 1 de la présente Norme européenne décrit les caractéristiques des produits et inclut les modes

opératoires pour les essais, le marquage et l'étiquetage, ainsi que les règles à respecter pour l'évaluation de

la conformité.

Les produits concernés par la présente norme peuvent également être utilisés en systèmes préfabriqués

d’isolation thermique et panneaux composites ; la performance structurelle des systèmes incorporant ces

produits n’est pas couverte.

Les produits dont la conductivité thermique déclarée à 10 °C est supérieure à 0,060 W/(m × K) ou dont la

résistance thermique déclarée est inférieure à 0,25 m2 × K/W ne sont pas couverts par la présente norme.

La présente Norme européenne ne spécifie pas le niveau requis de toutes les propriétés que doit acquérir un

produit pour démontrer son aptitude à l’emploi pour une application particulière. Les niveaux requis figurent

dans les réglementations locales ou les normes qui ne sont pas en contradiction.

La présente Norme européenne ne couvre pas les produits cellulosiques fabriqués en usine et mis sur le

marché sous forme de nattes, de matelas ou de panneaux destinés à être utilisés pour l’isolation de bâtiments

ou les produits cellulosiques en vrac destinés à l’isolation des équipements du bâtiment et des installations

industrielles.

Toplotnoizolacijski proizvodi za stavbe - Razsuti celulozni proizvodi (LFCI) za oblikovanje na mestu vgradnje - 1. del: Specifikacija za proizvode pred vgradnjo

General Information

- Status

- Not Published

- Publication Date

- 01-Feb-2011

- Withdrawal Date

- 01-Aug-2011

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88/WG 15 - In situ formed insulation products

- Current Stage

- 5098 - Decision to abandon - Formal Approval

- Start Date

- 15-Dec-2011

- Completion Date

- 15-Dec-2011

- Directive

- 89/106/EEC - Construction products

Overview

FprEN 15101-1 - "Thermal insulation products for buildings - In-situ formed loose‑fill cellulose (LFCI) products - Part 1: Specification for the products before installation" (CEN) specifies product characteristics, test procedures, marking and labelling, and rules for evaluation of conformity for loose‑fill cellulose insulation before it is installed. This Part 1 covers LFCI used for thermal and/or sound insulation in walls, floors, roofs, ceilings and lofts, and for use in prefabricated insulation systems (structural performance of systems is not covered).

Key topics and technical requirements

- Scope and exclusions

- Applies to in‑situ formed loose‑fill cellulose insulation (LFCI) installed by dry blowing, dry injection or wet spray.

- Products with declared thermal conductivity at 10 °C > 0.060 W/(m·K) or declared thermal resistance < 0.25 m2·K/W are excluded.

- Does not cover factory‑made bats, mats or boards or LFCI for industrial/building equipment insulation.

- Thermal performance

- Thermal conductivity and resistance measured per EN 12667; reference mean temperature 10 °C.

- Declared thermal values are 90/90 limit values (at least 90 % of production with 90 % confidence).

- Rounding/declared steps: λ in 0.001 W/(m·K) steps; R in 0.05 m2·K/W steps.

- Durability and behaviour

- Requirements and test methods for settlement, short‑term water absorption, airflow resistance, resistance to biological agents, corrosion and reaction to fire.

- Settlement classes and performance charts (loft, masonry cavity/floor, frame construction) are provided; different applications may require different settlement classes.

- Conformity, marking and labelling

- Procedures for Initial Type Testing (ITT), factory production control and evaluation of conformity (see EN 13172).

- Obligations for marking and labelling product characteristics and declared values.

- Annexes

- Normative test procedures for thermal conductivity, settlement, water absorption, corrosion, biological resistance, airflow resistance and factory production control.

Applications

- Specification and pre‑installation product control for:

- Loft insulation, masonry cavity walls, floor insulation and framed constructions.

- Manufacturers preparing product data sheets, test labs performing ITT, and product certification bodies.

- Useful for producers and specifiers ensuring declared thermal performance and conformity with European CEN practices before site installation.

Who should use this standard

- Manufacturers of loose‑fill cellulose insulation (LFCI) preparing declarations and labels.

- Test laboratories conducting thermal, durability and safety testing.

- Architects, specifiers and consultants requiring verified product data for building designs.

- Certification bodies and regulators assessing conformity and marking.

Related standards

- EN 12667 (thermal testing), EN 13172 (evaluation of conformity), EN 13501‑1 / EN 13823 / EN ISO 11925‑2 (reaction to fire), EN 12086 / EN 1609 (moisture tests), EN 29053 (airflow resistance), ISO 12491 and prEN 15101‑2 (installed product).

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

FprEN 15101-1 is a draft published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products for buildings - In-situ formed loose fill cellulose (LFCI) products - Part 1: Specification for the products before installation". This standard covers: This European Standard specifies requirements for loose-fill cellulose insulation (LFCI) products for the thermal and/or sound insulation of buildings when installed into walls, floors, galleries, roofs and ceilings. This Part 1 of the standard is a specification for the loose-fill cellulose insulation (LFCI) products before installation. Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity. Products covered by this standard may also be used in prefabricated thermal insulation systems and composite panels; the structural performance of systems incorporating these products is not covered. Products with a declared thermal conductivity at 10 °C greater than 0,060 W/(m x K) or a declared thermal resistance lower than 0,25 m2 x K/W are not covered by this standard. This European Standard does not specify the required level of all properties to be achieved by a product to demonstrate fitness for purpose in a particular application. The required levels are to be found in local regulations or non-conflicting standards. This European Standard does not cover factory made cellulose products placed on the market as bats, mats or boards intended to be used for the insulation of buildings or loose-fill cellulose products for the insulation of building equipment and industrial installations.

This European Standard specifies requirements for loose-fill cellulose insulation (LFCI) products for the thermal and/or sound insulation of buildings when installed into walls, floors, galleries, roofs and ceilings. This Part 1 of the standard is a specification for the loose-fill cellulose insulation (LFCI) products before installation. Part 1 of this European Standard describes the product characteristics and includes procedures for testing, marking and labelling and the rules for evaluation of conformity. Products covered by this standard may also be used in prefabricated thermal insulation systems and composite panels; the structural performance of systems incorporating these products is not covered. Products with a declared thermal conductivity at 10 °C greater than 0,060 W/(m x K) or a declared thermal resistance lower than 0,25 m2 x K/W are not covered by this standard. This European Standard does not specify the required level of all properties to be achieved by a product to demonstrate fitness for purpose in a particular application. The required levels are to be found in local regulations or non-conflicting standards. This European Standard does not cover factory made cellulose products placed on the market as bats, mats or boards intended to be used for the insulation of buildings or loose-fill cellulose products for the insulation of building equipment and industrial installations.

FprEN 15101-1 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 15101-1 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 15101-1 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI oSIST prEN 15101-1:2005

PREDSTANDARD

maj 2005

Toplotnoizolacijski proizvodi za stavbe – Razsuti celulozni proizvodi za

oblikovanje na mestu vgradnje – 1. del: Specifikacija za proizvode pred

vgradnjo

Thermal insulation products for buildings - In-situ formed loose-fill cellulose

products - Part 1: Specification for the products before installation

ICS 91.120.10 Referenčna številka

oSIST prEN 15101-1:2005(en)

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

DRAFT

prEN 15101-1

NORME EUROPÉENNE

EUROPÄISCHE NORM

March 2005

ICS

English version

Thermal insulation products for buildings - In-situ formed loose-

fill cellulose products - Part 1: Specification for the products

before installation

Produits d'isolation thermique pour les bâtiments - Produits Wärmedämmstoffe für das Bauwesen - An der

isolants cellulosiques en vrac mis en forme sur place - Anwendungsstelle hergestelte Wärmedämmung aus

Partie 1 : Spécification des produits avant la mise en place Zellulosefasern (LFCI) - Teil 1: Spezifikation für die

Produkte vor dem Einbau

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 88.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15101-1:2005: E

worldwide for CEN national Members.

prEN 15101-1:2005 (E)

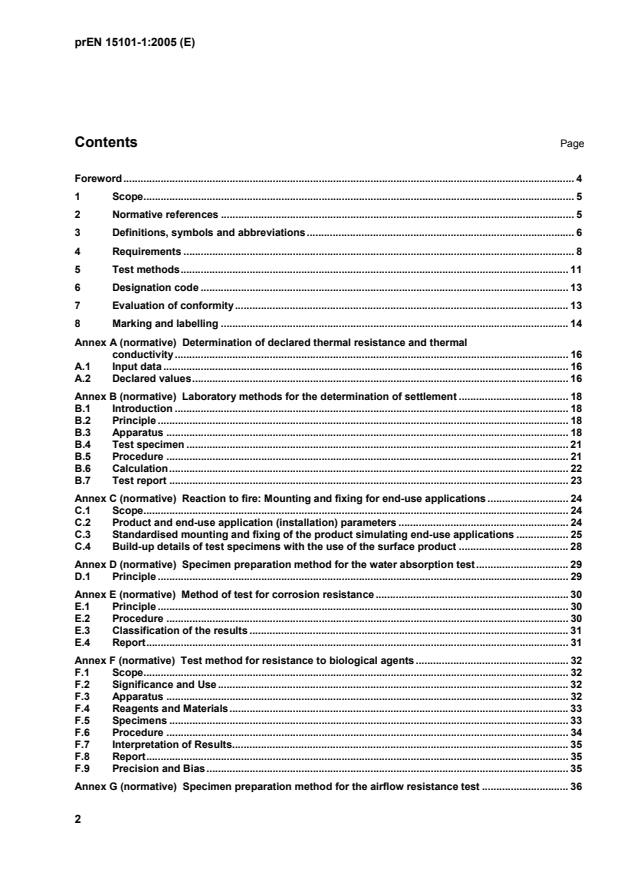

Contents Page

Foreword. 4

1 Scope. 5

2 Normative references . 5

3 Definitions, symbols and abbreviations. 6

4 Requirements . 8

5 Test methods. 11

6 Designation code . 13

7 Evaluation of conformity. 13

8 Marking and labelling . 14

Annex A (normative) Determination of declared thermal resistance and thermal

conductivity . 16

A.1 Input data . 16

A.2 Declared values. 16

Annex B (normative) Laboratory methods for the determination of settlement . 18

B.1 Introduction . 18

B.2 Principle . 18

B.3 Apparatus . 18

B.4 Test specimen . 21

B.5 Procedure . 21

B.6 Calculation. 22

B.7 Test report . 23

Annex C (normative) Reaction to fire: Mounting and fixing for end-use applications . 24

C.1 Scope. 24

C.2 Product and end-use application (installation) parameters . 24

C.3 Standardised mounting and fixing of the product simulating end-use applications . 25

C.4 Build-up details of test specimens with the use of the surface product . 28

Annex D (normative) Specimen preparation method for the water absorption test. 29

D.1 Principle . 29

Annex E (normative) Method of test for corrosion resistance. 30

E.1 Principle . 30

E.2 Procedure . 30

E.3 Classification of the results . 31

E.4 Report. 31

Annex F (normative) Test method for resistance to biological agents . 32

F.1 Scope. 32

F.2 Significance and Use. 32

F.3 Apparatus . 32

F.4 Reagents and Materials. 33

F.5 Specimens . 33

F.6 Procedure . 34

F.7 Interpretation of Results. 35

F.8 Report. 35

F.9 Precision and Bias. 35

Annex G (normative) Specimen preparation method for the airflow resistance test . 36

prEN 15101-1:2005 (E)

G.1 Principle . 36

G.2 Procedure . 36

Annex H (normative) Specimen preparation method for thermal conductivity test . 37

H.1 Principle . 37

H.2 Procedure . 37

Annex I (normative) fcb cf. 38

Annex J (normative) Factory production control . 39

Annex K (informative) Guidance for creating performance charts for loose-fill insulation

and examples of performance charts . 41

Annex ZA (informative) Clauses of this European Standard addressing the provisions of

the EU Construction Products Directive. 43

prEN 15101-1:2005 (E)

Foreword

This document (prEN 15101-1) has been prepared by Technical Committee CEN/TC 88 “Thermal

insulating materials and products”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and

the European Free Trade Association, and supports essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA, B, C or D, which is an integral part of

this document.

This European Standard is one of a series for mineral wool, expanded clay, expanded perlite, exfoliated

vermiculite, polyurethane/polyisocyanurate, cellulose and urea formaldehyde in-situ formed insulation

products used in buildings, but this standard may be used in other areas where appropriate.

prEN 15101-1:2005 (E)

1 Scope

This document specifies requirements for in-situ formed loose-fill cellulose thermal insulation products

when installed in internal walls, external walls, floors, galleries, roofs and ceilings.

This Part 1 of the document is a specification for the loose-fill cellulose products before installation.

Part 1 of this document describes the product characteristics and includes procedures for testing,

marking and labelling and the rules for evaluation of conformity.

This document does not specify the required level of all properties that should be achieved by a

product to demonstrate fitness for purpose in a particular application. The required levels are to be

found in regulations or non-conflicting standards.

Products covered by this document may also be used in pre-fabricated thermal insulation systems

and composite panels; the structural performance of systems incorporating these products is not

covered.

Products with a declared thermal conductivity at 10 °C greater than 0,060 W/(m·K) or a declared

thermal resistance lower than 0,25 m /k/W are not covered by this standard.

This document does not cover factory made cellulose products intended to be used for the insulation of

buildings or in-situ cellulose products for the insulation of building equipment and industrial installations.

This Standard does not specify performance requirements for loadbearing, direct airborne sound and

acoustic absorption applications.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 1609:1997, Thermal insulating products for building application — Determination of short term

water absorption by partial immersion

EN 12086:2001, Thermal insulating products for building application — Determination of water vapour

transmission properties

EN 12667, Building materials — Determination of thermal resistance by means of guarded hot plate

and heat flow meter method — Products of high and medium thermal resistance

EN 13172:2001, Thermal insulating products for building applications — Evaluation of conformity

EN 13238, Reaction to fire tests for building products. Conditioning procedures and general rules for

selection of substrates

EN 13501-1, Fire classification of construction products and building elements — Part 1

EN 13823, Reaction to fire tests for building products — Building products excluding floorings

exposed to the thermal attack by a single burning item

EN 29053:1993, Acoustics — Materials for acoustical applications — Determination of airflow

resistance

prEN 15101-1:2005 (E)

EN ISO 11925-2, Reaction to fire tests. Ignitability of building products subjected to direct

impingement of flame — Single-flame source test

ISO 12491, Statistical methods for quality control of building materials and components

prEN ISO 9229, Thermal insulation — Definitions of terms

prEN 15101-2, Thermal insulation products for buildings — In-situ formed loose-fill cellulose products —

Part 2 Specification for the installed product

3 Definitions, symbols and abbreviations

3.1 Definitions

For the purposes of this standard, the following definitions apply.

3.1.1 Definitions as given in prEN ISO 9229

3.1.1.1

installed insulation thickness

insulation thickness as installed by the installer

3.1.1.2

frame construction

walls with wood or metal studs, sloping roof with insulation between rafters

3.1.1.3

settlement

the decrease of installed insulation thickness in lofts or height in cavities and frame constructions with

time, expressed as a percentage of the initial installed thickness (after compaction if prescribed)

3.1.1.4

coverage

mass of insulation per unit area

3.1.1.5

performance chart

a table giving thickness and coverage requirements for different values of declared thermal resistance

3.1.2 Additional definitions

3.1.2.1

level

the given value, which is the upper or lower limit of a requirement. The level is given by the declared

value of the characteristic concerned

3.1.2.2

class

a combination of two levels of the same property between which the performance shall fall, where the

levels are given by the declared value of the characteristic concerned

3.1.2.3

loose fill cellulose insulation product

a fibrous or granulated natural cellulose product with or without additives, installed either by dry

blowing, dry injection or by wet spray, either on- site or in a factory

prEN 15101-1:2005 (E)

3.2 Symbols and abbreviations

Symbols used in this standard:

λ is the 90 % fractile with a confidence level of 90 % for the thermal conductivity W/(m·K)

90/90

λ is the declared thermal conductivity W/(m·K)

D

λ is one test result of thermal conductivity W/(m·K)

i

λ is the mean thermal conductivity W/(m·K)

mean

µ is the water vapour diffusion resistance factor -

n is the number of test results -

R is the 90% fractile with a confidence level of 90% for the thermal resistance m K/W

90/90

R is the declared thermal resistance m K/W

D

R is the mean thermal resistance m K/W

mean

ρ is the bulk density before settlement test kg/m

s is the estimate of the standard deviation of the thermal conductivity W/(m·K)

λ

W is the short term water absorption kg/m

p

s is the initial height in the settlement tests mm

i

s is the final height in the settlement tests mm

a

s is the mean declared settlement value mm

D

R is the level of airflow resistivity kPas/m

a

P is the settled density after testing kg/m

s

S is the symbol of the declared class for settlement

WS is the symbol of the declared level for short-term water absorption

CR is the symbol for the declared class for corrosion

BA is the symbol for the declared class for resistance to biological agents

AF is the symbol for airflow resistivity

Abbreviations used in this standard:

ITT is Initial Type Test

LFCI is Loose-Fill Cellulose Insulation

prEN 15101-1:2005 (E)

4 Requirements

4.1 General

Product properties shall be assessed in accordance with clause 5. To comply with this standard,

products shall meet the requirements of 4.2, and the requirements of 4.3 as appropriate.

This standard gives performance charts for three different applications:

loft insulation

masonry cavity wall, and floor insulation

frame construction

NOTE The three applications may require different classes for settlement.

One test result on a product property is the average of the measured values on the number of test

specimens given in Table 6.

4.2 For all applications

4.2.1 Thermal conductivity and thermal resistance

Thermal conductivity and thermal resistance shall be based upon measurements carried out in

accordance with EN 12667.

The thermal values shall be determined in accordance with Annex A, 5.1.1 and 5.3.2 and declared by

the manufacturer, according to the following:

the reference mean temperature shall be 10 °C;

the measured values shall be expressed with three significant values;

the declared thermal values, shall be given as limit values representing at least 90 % of the

production determined with a confidence level of 90 %;

the declared thermal resistance, R , shall be calculated from the insulation thickness and the

D

declared thermal conductivity, λ (See note);

D

the value of thermal conductivity λ shall be rounded upwards to the nearest 0,001 W/(m·K) and

D

declared in levels with steps of 0,001 W/(m·K);

the value of thermal resistance, R , shall be rounded upward to the nearest 0,05 m K/W and

D

declared in levels with steps of 0,05 rn K/W.

NOTE The declaration of thermal resistance for installed loose-fill cellulose is described in Part 2 of this

standard (prEN 15101-2).

4.2.2 Settlement

4.2.2.1 Horizontal applications, loft and floors

Settlement shall be classified and declared in accordance with Table 1. The classification shall be

based on the long-term settlement experience after installation or measurements made in accordance

with the laboratory method A given in Annex B.

prEN 15101-1:2005 (E)

Table 1 — Classes for settlement for horizontal applications, lofts and floors

Class Requirement

SH1 No measurable settlement

SH2

≤ 5 %

SH3

≤ 10 %

SH4

≤ 15 %

SH5

≤ 20 %

SH6

≤ 25 %

SH7 > 25 %

4.2.2.2 Cavity insulation, frame constructions and cavity walls

Settlement shall be classified and declared in accordance with Table 2. The classification shall be

based on the long-term settlement experience after installation or measurements made in accordance

with the laboratory method B given in Annex B.

Table 2 — Classes for settlement for cavity insulation, frame constructions and cavity walls

Class Requirement

SCO No settlement

4.2.3 Reaction to fire

Reaction to fire classifications (Euroclasses) shall be determined in their end-use applications and if

required as placed on the market in accordance with EN 13501-1. Mounting and fixing details are specified

according to end-use in Annex C.

4.2.4 Durability characteristics

4.2.4.1 General

The appropriate durability characteristics have been considered and are covered in 4.2.4.2,

4.2.4.3,4.2.4.4 and 4.2.4.5.

4.2.4.2 Durability of reaction to fire against ageing/degradation

There is no change in reaction to fire for LFCI products with time as the contents of additives do not

change with time.

4.2.4.3 Durability of reaction to fire against biological agents

There is no change with time of the reaction to fire as a result of biological action.

4.2.4.4 Durability of thermal resistance against biological agents

There is no change with time of the thermal performance as a result of biological action.

4.2.4.5 Durability of thermal resistance against ageing/degradation

The thermal conductivity (4.2.1) of LCFI products does not change with time. Account is taken of

settlement (4.2.2) (classes given in Table 1) in stating the declared thermal resistance values.

prEN 15101-1:2005 (E)

4.3 For specific applications

4.3.1 General

If there is no intended requirement for a property, described in 4.3, for a product in its end-use

application, then the property need not be determined and declared by the manufacturer

4.3.2 Short-term water absorption

Short-term water absorption, W , shall be determined in accordance with EN 1609: 1997, method A

p

with specimen preparation in accordance with Annex D. Test results shall be classified according to

Table 3:

Table 3 — Classes of short-term water absorption

Class Requirements

WS1 No requirements

WS2

≤ 1,0 kg/m

WS3 > 1,0 kg/m

4.3.3 Water vapour diffusion resistance factor

Loose-fill products have a structure that is highly permeable to water vapour. The water vapour

resistance factor, µ, may be assumed to be 1 if no measurements are available. If measurements are

undertaken the product shall be tested in accordance with EN 12086.

4.3.4 Release of dangerous substances

NOTE See Annex ZA.

4.3.5 Corrosion resistance

Corrosion resistance shall be classified and declared in accordance with Table 4 after testing in

accordance with Annex E.

Table 4 — Classes of corrosion resistance

Class Requirements

CR0 No requirement or no performance

determined

CR1 Test passed

4.3.6 Resistance to biological agents

Resistance to biological agents shall be classified and declared in accordance with Table 5 after testing

in accordance with the procedure given in Annex F.

prEN 15101-1:2005 (E)

Table 5 — Classes for resistance to biological agents

Class Requirements

BA0 No requirement or no performance

determined

BA1 Test passed

4.3.7 Airflow resistivity

Airflow resistivity, R , shall be determined in accordance with EN 29053:1993, method A using a

a

specimen prepared in accordance with Annex G. The value of airflow resistance shall be declared in

levels with steps of 1 kPa·s/m . No test result shall be lower than the declared value.

NOTE Airflow resistivity can be used when estimating the risk for reduced thermal resistance caused by

convection.

5 Test methods

5.1 Sampling

5.1.1 Sampling for measuring thermal conductivity

For information on sampling, preparation and conditioning of the samples for measuring thermal

conductivity see Annex H.

5.2 Conditioning

No special conditioning of the test specimens is needed unless otherwise specified in the Annexes to

this standard or other test standards. In case of dispute, the test specimens shall be stored at

(23 ± 2) °C and (50 ± 5) % relative humidity for at least 24 hours prior to testing.

5.3 Testing

5.3.1 General

Table 6 gives the dimensions of the test specimens, the minimum number of measurements required

to get one test result and any other specific conditions which are necessary.

prEN 15101-1:2005 (E)

Table 6 — Test methods, test specimens and conditions

Dimensions in millimetres

Clause Title Test method Test specimen Specific conditions

Dimensions No. to get

one result

4.2.1 Thermal EN 12667 > (800 x 800 x 100) 1 Measuring area:

conductivity and > (500 x 500)

thermal resistance

> (500 x 500 x 100) 1 > (250 x 250)

4.2.2 Settlement

Lofts and floors Annex B

Method A 550 x 550 x 330 1

Frame Annex B,

construction and Method B 1000 x 625 x 160 1

cavity walls minimum

1)

4.2.3 Reaction to fire See EN13501-1 and Annex C

4.3.2 Short-term water EN 1609: 1997 200 x 200 x 50 4

absorption Method A

4.3.3 Water vapour EN 12086: Maximum 5

diffusion 2001:Annex B thickness 100

resistance factor

4.3.5 Corrosion Annex E 20 g test 4

resistance specimens

4.3.6 Resistance to Annex F Diameter 150 2

biological agents Thickness 20

4.3.7 Airflow resistivity EN 29053: 1993 500 x 500 x 100

Method A

5.3.2 Thermal conductivity

Thermal resistance and thermal conductivity shall be determined in accordance with EN 12667 and

under the following conditions:

at a mean temperature of (10 ± 0,30) °C;

after conditioning in accordance with 5.2;

after preparation in accordance with the procedure given in Annex H.

prEN 15101-1:2005 (E)

6 Designation code

The manufacturer shall give a designation code for a LFCI product. The following shall be included

except when there is no requirement for a property described in 4.3:

Loose-fill cellulose (LFCI)

This EN standard number

Declared settlement class for horizontal applications SHi

Declared settlement class for cavity insulation SCi

Declared water absorption class WSi

Declared corrosion resistance class CRi

Declared class for resistance to biological agents BAi

Declared airflow resistivity AFi

where ,,i” shall be used to indicate the relevant class or level.

The designation code for a loose-fill cellulose product declared for use as cavity insulation is

illustrated by the following example:

LFCI EN 15101—SC0 – WS2 – CR1 – BA1

7 Evaluation of conformity

The manufacturer or his authorized representative shall be responsible for the conformity of his

product with the requirements of this European Standard. The evaluation of conformity shall be

carried out in accordance with EN 13172 and shall be based on factory production control and tests

on samples taken at the factory.

Clause 7 of EN 13172: 2001 applies to LFCI-products with the following modifications:

Note 2 of clause 7 of EN 13172: 2001 does not apply.

The maximum acceptable failure of anyone measurement is 10 %.

In case of an up to 10 % failure of the first measurement, two other samples shall be taken and

measured.

The two additional measurements must meet the declared value, and the average of the three

measurements taken must also be on the positive side of the declared value.

If a manufacturer decides to group his products it shall be done in accordance with EN 13172.

The minimum frequencies of tests in the factory production control shall be in accordance with

Annex J of this standard. When indirect testing is used, the correlation to direct testing shall be

established in accordance with EN 13172.

NOTE 1 The system of attestation of conformity for the CE marking of the product is chosen in accordance

with Annex ZA of this standard (See ZA.2.2). For in-situ formed loose-fill cellulose insulation (LFCI) products the

footnote * of Table ZA.2.2 applies except when it can be demonstrated to the notified body for a particular

product that no stage in the production process will result in an improvement of the reaction to fire classification

(see Table ZA.2.2, footnote **).

prEN 15101-1:2005 (E)

The manufacturer or his authorised representative shall make available, in response to a request, a

certificate or declaration of conformity as appropriate.

NOTE 2 For the EC certificate and declaration of conformity, as appropriate, see ZA.2.3.

8 Marking and labelling

8.1 Marking and labelling

Products complying with this standard shall be clearly marked on the container and/or consignment

note with following information:

designation code as given in clause 6;

product name or other identifying characteristic;

name or identifying mark and address of the producer or his authorised representative

established in the EEA;

year of production (the last two digits);

shift or time or traceability code;

reaction to fire class;

quantity of material in the package (kg);

performance charts in the format of Tables 7,8 and 9 whichever is applicable.

NOTE For CE marking see Annex ZA.

Table 7 — Performance chart for loft applications

Loft insulation

Declared thermal Thickness after Minimum Minimum Minimum bag

resistance level settlement installed coverage usage rate

R thickness

D

2. 2 2

mK/W mm mm k/rn bags per 100m

R.

R.

R.

R.

R.

R.

R.

The values for minimum installed thickness refer to the thickness immediately following installation.

The values for declared thermal resistance level refer to the situation after settlement has occurred.

prEN 15101-1:2005 (E)

Table 8 — Performance chart for mason cavity wall and floor applications

Masonry cavity wall and floor insulation

Average cavity width Declared thermal Minimum bag usage rate

resistance level

2. 2

mm m K/W bags per 100 m

....

....

R.

R.

R.

R.

R.

R.

Table 9 — Performance chart for frame applications

Frame insulation

Frame width Declared thermal resistance level Minimum bag usage rate

2 2

mm M .K/W Bags per 100 m

R…

R…

R…

R…

R…

R…

R…

prEN 15101-1:2005 (E)

Annex A

(normative)

Determination of declared thermal resistance and thermal

conductivity

It is the responsibility of the manufacturer to determine the declared value of thermal resistance and

thermal conductivity. He will have to demonstrate conformity of the product to its declared value. The

declared value of thermal resistance and thermal conductivity of a product are the expected value of

the property during an economically reasonable working life under normal conditions, assessed

through measured data at reference conditions.

A.1 Input data

The manufacturer shall have at least ten test results for thermal resistance and thermal conductivity,

obtained from external direct or from internal direct or indirect measurements In order to calculate the

declared value. The thermal resistance and thermal conductivity measurements shall be carried out at

regular intervals spread over a period of the last twelve months. If less than ten direct test results are

available, that period may be extended until ten test results are obtained, but with a maximum period

of three years, within which the product and production conditions have not changed significantly. If

still less than ten direct test results are available, results from indirect tests can be used.

The mean thermal conductivity derived from thirty indirect measurements equals one direct

measurement (see note 2 under A.3). Each of the values derived from indirect measurements shall be

the mean value of mm. 30 individual λ-values derived from indirect test results. The tests for one final

λ-value may be performed over one month or over a longer period. No result must be used more than

once and no result must be excluded. The resulting ten results shall include at least three direct test

results.

For new products the ten thermal resistance and thermal conductivity test results shall be carried out

spread over a minimum period of ten days. The results shall include at least three direct test results.

The declared value shall be calculated according to the method given in A.3 and shall be recalculated

at intervals not exceeding three months of production.

A.2 Declared values

The derivation of the declared values R and λ from the calculated values R and λ shall use

D D 90/90 90/90

the rules given in 4.2.1, which include the rounding conditions.

A.2.1 Case where thermal resistance and thermal conductivity are declared

The declared value R and λ shall be derived from the calculated value, R and λ , which are

D D 90/90 90/90

determined using the equations A.1, A.2 and A.3.

λ = λ + k.s (A.1)

90/90 mean λ

n

(λ − λ )

∑ mean

i=1

(A.2)

s =

λ

n −1

prEN 15101-1:2005 (E)

R = d/λ (A.3)

90/90 90/90

Table A.1 — Values for k for one sided 90 % tolerance interval with a confidence level of 90 %

Number of test results k

10 2,07

11 2,01

12 1,97

13 1,93

14 1,90

15 1,87

16 1,84

17 1,82

18 1,80

19 1,78

20 1,77

22 1,74

24 1,71

25 1,70

30 1,66

35 1,62

40 1,60

45 1,58

50 1,56

100 1,47

300 1,39

500 1,36

2000 1,32

For other numbers of test results use ISO 12491 or

linear interpolation

NOTE 1 Linear interpolation is acceptable.

NOTE 2 The number of test results in Table A.1 is results from direct measurements. If indirect tests are used

the number of test results in Table A. I equals the number of indirect tests divided by 30 (corresponding to the

proportion between the minimum frequencies stated in Annex B).

prEN 15101-1:2005 (E)

Annex B

(normative)

Laboratory methods for the determination of settlement

B.1 Introduction

The purpose of the test methods described in this Annex is to determine the settling (long-term

change in thickness) of attic loose-fill thermal insulation and cavity applications by impact excitation,

vibration and acclimatization. They are accelerated laboratory methods and can be used for type

approval certificate testing. They can also be used for development of loose-fill thermal insulation

products.

The results of these tests give information of settling value for the loose fill product after a certain time

period under service conditions. The settling value is one property required for establishing design

thermal performance and for determining life time energy requirements.

The present accelerated test methods are based on the fact that the settling of attic loose-till thermal

insulation shall be determined under the same conditions as in real attic situation. It means that the

loose-fill materials are affected by the same main factors as in reality. It also means that the material

is tested as it is positioned in the real attic structure. Settling is accelerated by means of

humidity changing more often than in reality,

vibrations applied constantly,

vibration shocks applied at regular intervals.

B.2 Principle

B.2.1 Settling of loose-fill insulation by impact excitation (method A)

An open-top box containing the loose-fill product is impacted to a rigid ground as a impact excitation.

The number of impacts and the height of drop is defined. The measured difference of the insulation

height before and after the impact excitation gives the settlement.

B.2.2 Settling of cavity insulation by vibration (method B)

A closed wooden box containing the cavity product is exposed to sinusoidal vibrations. The decrease

of the insulation height caused by the vibration is determined and the settlement calculated.

B.3 Apparatus

B.3.1 Apparatus for method A

B.3.1.1 General

The apparatus for method A shall consist elements indicated in B.3.1.2 to B.3.1.5.

prEN 15101-1:2005 (E)

B.3.1.2 Test box

The test box is an open top wooden box. It has a square cross section of 0,55 m 0,55 m. The height

of the box is 0,33 m.

B.3.1.3 Mass measuring equipment

For the determination of the mass use a scale with a dissolution of at least 50 g.

B.3.1.4 Insulation height measuring equipment

A measuring device comprising a tape measure and a square pressure plate. The tape measure shall

have an accuracy of at least 1 mm.

A pressure plate (200 ± 2) mm² which creates a total pressure on the test specimen of (20 ± 1,5) Pa.

Any test equipment, which provides the same results at least the same accuracy may be used.

B.3.1.5 Test equipment to produce the impact excitation

Stable steel-frame, on which a motor with a cam disk is assembled. A movable frame, which is led by

center bearings, so that it drops free of friction from the top point to the impact bed. The cam disk lifts

the movable frame by a ram stake to the top point. Behind the top point the movable frame drops

down to the impact beds. The drop height can be changed with adjusting-screws in the groundframe

with a top mounted rigid plastic bed. In order to automize the means, the motor should be controlled

by a counter. The test box is mounted on the movable frame. See Figure B.1.

Key

1 test box 6 ground frame

2 movable steel frame 7 shock absorber

3 ram stake 8 drop height

4 ball bearing 9 counter controlled motor

5 cam disk

Figure B.1 — Apparatus for method A

prEN 15101-1:2005 (E)

B.3.2 Apparatus for method B

B.3.2.1 General

The apparatus for method B shall consist of elements indicated in B.3.3.2 to B.3.3.5.

B.3.2.2 Test box

The test box is a pattern wall construction with a height of at least 1 m. The width of the pattern wall

shall be at least 0,625 m, the cavity depth should not less than 0,16 m. The frame of the construction

shall consist of at least 40 mm thick wood. On the side, there are any holes, closed by a punched

plate.

It is necessary to reduce the pressure inside the wall during installing the insulation. The top of the

frame should be a door to give the possibility to fill the insulation material by free-flowing.

The surface shall consist of minimum 16 mm thick multiplex sheets. Alternatively one surface can

consist of a 6 mm thick safety glass. In the wood surface, there is a blowing hole about 15 cm under

the top side in the middle of the surface. The diameter of the hole depends on the diameter of the

blowing tube. The front surface, for example the glass surface, should be a door to replace the

material after the tests and weight it.

B.3.2.3 Mass measuring equipment

For the determination of the mass use a scale with a dissolution of at least 50 g.

B.3.2.4 Insulation height measuring equipment

A measuring device comprising a tape measure and a square pressure plate. The tape measure

having a accuracy of at least 1 mm. A pressure plate (100 ± 2) mm², which experts a total pressure on

the test specimen of (50 ± 1,5) Pa . Any test equipment, which provides the same results at least the

same accuracy may be used.

B.3.2.5 Vibration exitation testing equipment

Stable frame construction with a motor with eccentricity weights. Inside this construction the test box

is assembled.

An example is given in Figure B.2.

Figure B.2 — Apparatus for method B

prEN 15101-1:2005 (E)

B.4 Test specimen

B.4.1 Dimension of the test specimen

The test specimens are inside the test box. The dimension are equal to the dimensions of the test box.

B.4.2 Number of test specimen

The number of the test specimens is given in the relevant product standard. If no specification is

available take at least

three specimens for the method A

one for method B .

B.4.3 Conditioning of test specimen

For preparing the test specimen taken from the sample of the material to be tested shall be stored for

a time specified by the relevant product standard but for at least 6 h at (23 ± 5) °C. In case of dispute

they shall be stored at (23 ± 2) °C and (50 ± 5) % relative humidity.

B.4.4 Preparation of test specimens

The test specimen shall be prepared as under working conditions. Either the material to be tested will

be filled into the boxes either manually or mechanically by special equipment. The surface of test

specimen will correspond with the surface of the test boxes.

When manually preparing the test specimen material should be carefully filled into the test box by

using a shovel. The quantity of the test material is selected in the way that the specimen is able to

achieve the required density.

When using a mechanical equipment, the test boxes should be filled using a tube of a diameter

similar to that used in working conditions. If its usual under working conditions to use a blowing nozzle,

the test specimen should also be prepared by means of a nozzle. The mechanical equipment shall be

adjusted in a way, so that the required density can be achieved in the test boxes.

B.5 Procedure

B.5.1 Test conditions

The test should be carried out at (23 ± 5) °C. In case of dispute it shall be carried out at (23 ± 2) °C

and (50 ± 5) % relative humidity.

B.5.2 Test procedure for method A

Measure the insulation height s using equipment in accordance with B.3.1.4. Place the test specimen

i

in the test equipment (B.3.1.5) to produce the impact excitation by using fixing accessories. The drop

height and the number of impacts if not indicated in the relevant product standard shall be at least

50 mm and 20 times or shall be in agreement between the parties. Measure the insulations height s

a

using equipment in accordance with B.3.1.4.

prEN 15101-1:2005 (E)

B.5.3 Test procedure for method B

Measure the insulation height s using equipment in accordance with B.3.3.4. Place the test specimen

A

in the test equipment to produce the impact excitation (B.3.3.5) by using fixing accessories. The

vibratory acceleration peak amplitude and the vibration time are given in the relevant product

standard or by agreement between the parties and shall be at least 15 m/s and 30 min. Measure the

insulations height s using equipment in accordance with B.3.3.4.

s

B.6 Calculation

B.6.1 Settlement

Settlement , s , expressed in percent, shall be calculated using equation (B.1).

D

SS

i a

s (%) = 100 (B.1)

D

S

a

where:

s is the mean value of measured initial insulation height in mm before the settling process;

i

s is the mean value of measured final insulation height in mm after the settling process.

a

s is the mean declared settlement value

D

B.6.2 Bulk density before settlement test

Bulk density, ρ expressed in kilogram per cubic metre, shall be calculated using equation (B.2).

m

ρ = (B.2)

V

Where:

m is the mean value of measured mass, in kilogram, of the thermal insulation material

V is the mean value of measured volume, in cubic metre, of the test box.

B.6.3 Settled density after testing

Settled density, p , expressed in kilogram per cubic metre, shall be calculated using equation (B.3)

s

m

ρ = (B.3)

a

A s

a

where

A is the base area of the test box

prEN 15101-1:2005 (E)

B.7 Test report

In the test report shall be indicated at least the following information:

a) all details necessary to identify the product tested;

b) a reference to this European Standard;

c) the method used (see B.2);

d) information about the preparation of test specimens (see B.4);

e) information about the procedure (see B.5);

f) results (see B.6);

g) date of the test.

prEN 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...