FprEN 15501

(Main)Thermal insulation products for building equipment and industrial installations - Factory made expanded perlite (EP) and exfoliated vermiculite (EV) products - Specification

Thermal insulation products for building equipment and industrial installations - Factory made expanded perlite (EP) and exfoliated vermiculite (EV) products - Specification

This European Standard specifies the requirements for factory made expanded perlite and exfoliated vermiculite products which are used for the thermal insulation of building equipment and industrial installations with an operating temperature in the range of approximately 0°C to + 1 300°C.

NOTE Products covered by this standard can be used below 0°C but special tests regarding the suitability of the product in the intended application are advised and manufacturers advice should be heeded in all cases.

The products are manufactured in the form of boards, pipe sections, segment, prefabricated ware and special ware.

This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling.

Products covered by this standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered.

This standard does not specify the required level of a given property that shall be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application can be found in regulations and invitations to tender.

This standard does not cover products for in-situ insulation (blowing or pouring) or products for the insulation of the building structure.

The standard does not cover the following acoustical aspects: direct airborne sound insulation and impact transmission noise index.

Wärmedämmstoffe für die Haustechnik und für betriebstechnische Anlagen - Werkmäßig hergestellte Produkte aus Blähperlit (EP) und expandiertem Vermiculit (EV) - Spezifikation

Diese Europäische Norm legt die Anforderungen für werkmäßig hergestellte Produkte aus Blähperlit

(expandiertem Perlit) und expandiertem Vermiculit fest, die als Wärmedämmstoffe für die Haustechnik und

betriebstechnische Anlagen im Temperaturbereich von etwa 0 °C bis 1 300 °C benutzt werden.

ANMERKUNG Die von dieser Norm abgedeckten Produkte können unterhalb von 0 °C verwendet werden. Unterhalb

dieser Temperatur sind jedoch besondere Prüfungen bezüglich der Eignung der Produkte für den beabsichtigten

Anwendungsfall ratsam. In jedem Fall sollten die Empfehlungen des Herstellers beachtet werden.

Die Produkte werden in der Form von Platten, Rohrschalen, Segmenten, vorgefertigten Produkten und

Formprodukten hergestellt.

Diese Norm beschreibt die Stoffeigenschaften und enthält die Prüfverfahren und Festlegungen für die

Konformitätsbewertung, die Kennzeichnung und die Etikettierung.

In dieser Norm beschriebene Produkte werden auch in vorgefertigten Wärmedämmsystemen und Mehrschicht-

Verbundplatten angewendet; die Eigenschaften von Systemen, in die diese Produkte integriert sind, werden

nicht behandelt.

Diese Norm legt keine Leistungsstufen für eine vorgegebene Eigenschaft fest, die ein Produkt erreichen muss,

um für einen bestimmten Anwendungsfall tauglich zu sein. Für bestimmte Anwendungen benötigte Stufen

können Regelwerken oder Ausschreibungen entnommen werden.

Diese Europäische Norm gilt nicht für Produkte für an der Verwendungsstelle hergestellte Wärmedämmung

(eingeblasen oder geschüttet) oder Produkte, die zur Dämmung des Bauwerks bestimmt sind.

Diese Norm gilt nicht für die folgenden akustischen Zwecke: Luftschalldämmung und Trittschallübertragung.

Produits isolants thermiques pour l'équipement du bâtiment et les installations industrielles - Produits manufacturés en perlite expansée (EP) et à base de vermiculite exfoliée (EV) - Spécification

La présente Norme européenne spécifie les exigences relatives aux produits manufacturés en perlite expansée et

à base de vermiculite exfoliée qui sont utilisés pour l'isolation thermique de l'équipement du bâtiment et des

installations industrielles et dont la température de service se situe entre 0 °C et + 1 300 °C environ.

NOTE Les produits couverts par la présente norme peuvent être utilisés à des températures inférieures à 0 °C, mais des

essais spéciaux sont recommandés pour s'assurer de l'aptitude du produit à l'utilisation dans l'application prévue ; dans tous les

cas, il convient de tenir compte de l'avis des fabricants.

Les produits sont fabriqués sous la forme de panneaux, de coquilles, de segments, d'articles préfabriqués et de

pièces spéciales.

La présente norme décrit les caractéristiques de ces produits et comporte des modes opératoires d'essai,

d'évaluation de conformité, de marquage et d'étiquetage.

Les produits couverts par la présente norme sont également utilisés dans les systèmes d'isolation thermique

préfabriqués et les panneaux composites ; les performances des systèmes incorporant ces produits ne sont pas

traitées.

La présente norme ne spécifie pas le niveau requis pour une propriété donnée que doit posséder un produit pour

démontrer son aptitude à l'emploi dans une application particulière. Les niveaux requis pour une application

donnée peuvent être trouvés dans les réglementations et les appels d'offres.

La présente norme ne couvre ni les produits pour l'isolation in situ (soufflage ou déversement) ni les produits pour

l'isolation des structures de bâtiments.

La présente norme ne couvre pas les aspects acoustiques suivants : l'isolation contre le bruit aérien direct et

l'indice de transmission du bruit d'impact.

Toplotnoizolacijski proizvodi za opremo stavb in industrijske inštalacije - Proizvodi iz ekspandiranega perlita (EPB) in vermikulita (EV) - Specifikacije

General Information

- Status

- Not Published

- Publication Date

- 22-Sep-2009

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88/WG 10 - Building equipment and industrial installations

- Current Stage

- 5098 - Decision to abandon - Formal Approval

- Start Date

- 09-Jul-2010

- Completion Date

- 09-Jul-2010

- Directive

- 89/106/EEC - Construction products

Overview

FprEN 15501 (CEN) specifies requirements for factory-made expanded perlite (EP) and exfoliated vermiculite (EV) thermal insulation products used on building equipment and industrial installations. The standard covers products manufactured as boards, pipe sections, segments, prefabricated ware and special ware and is intended for service temperatures approximately 0 °C to +1 300 °C. It defines product characteristics and procedures for testing, evaluation of conformity, marking and labelling. Products may be used below 0 °C but require special suitability testing and manufacturer guidance.

Key Topics

- Material scope: Expanded perlite (EP) and exfoliated vermiculite (EV) factory-made products.

- Temperature range: Designed for applications roughly 0 °C to +1 300 °C (special testing advised for sub‑0 °C use).

- Product forms: Boards, slabs, pipe sections (including split pipe), segments, blocks and prefabricated items.

- Product characteristics and tests: Dimensional tolerances, thermal conductivity, apparent density, compressive and bending strength, dimensional stability, water vapour transmission, reaction to fire (see Annex B) and trace ion content. Test standards referenced include EN series and ISO methods (for example EN 1604, EN 13467, EN 13823, EN ISO 1716).

- Conformity and factory control: Requirements for Initial Type Testing (ITT), Factory Production Control (FPC) and designation coding are included; Annex A addresses FPC procedures.

- Marking and labelling: Rules for labelling products and CE marking information (Annex ZA) in relation to the EU Construction Products Directive.

- Limitations: Does not set performance levels for specific applications (those are determined by regulations or tender documents). It does not cover in-situ (blown or poured) insulation, insulation of building structural elements or acoustical performance (airborne sound, impact noise index).

Applications

- Insulation of mechanical building services (HVAC ducts, boilers, vessels) and industrial installations operating at low to very high temperatures.

- Use by manufacturers to develop and declare product performance and by testing laboratories to perform standardized assessments.

- Reference for specifiers, M&E engineers, architects and procurement teams when selecting EP/EV insulation for high‑temperature or corrosive environments where lightweight, refractory insulating materials are required.

- Useful for conformity bodies and contract authorities during tendering and CE-marking assessments.

Related Standards

- EN 1604 - Dimensional stability

- EN 13467 - Preformed pipe insulation dimensions

- EN 13823 / EN ISO 1716 - Reaction to fire test methods

- EN 13501-1 - Fire classification of construction products

Keywords: EN 15501, FprEN 15501, expanded perlite, exfoliated vermiculite, thermal insulation, building equipment, industrial installations, high-temperature insulation, CEN.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

FprEN 15501 is a draft published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products for building equipment and industrial installations - Factory made expanded perlite (EP) and exfoliated vermiculite (EV) products - Specification". This standard covers: This European Standard specifies the requirements for factory made expanded perlite and exfoliated vermiculite products which are used for the thermal insulation of building equipment and industrial installations with an operating temperature in the range of approximately 0°C to + 1 300°C. NOTE Products covered by this standard can be used below 0°C but special tests regarding the suitability of the product in the intended application are advised and manufacturers advice should be heeded in all cases. The products are manufactured in the form of boards, pipe sections, segment, prefabricated ware and special ware. This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling. Products covered by this standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This standard does not specify the required level of a given property that shall be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application can be found in regulations and invitations to tender. This standard does not cover products for in-situ insulation (blowing or pouring) or products for the insulation of the building structure. The standard does not cover the following acoustical aspects: direct airborne sound insulation and impact transmission noise index.

This European Standard specifies the requirements for factory made expanded perlite and exfoliated vermiculite products which are used for the thermal insulation of building equipment and industrial installations with an operating temperature in the range of approximately 0°C to + 1 300°C. NOTE Products covered by this standard can be used below 0°C but special tests regarding the suitability of the product in the intended application are advised and manufacturers advice should be heeded in all cases. The products are manufactured in the form of boards, pipe sections, segment, prefabricated ware and special ware. This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling. Products covered by this standard are also used in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This standard does not specify the required level of a given property that shall be achieved by a product to demonstrate fitness for purpose in a particular application. The levels required for a given application can be found in regulations and invitations to tender. This standard does not cover products for in-situ insulation (blowing or pouring) or products for the insulation of the building structure. The standard does not cover the following acoustical aspects: direct airborne sound insulation and impact transmission noise index.

FprEN 15501 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

FprEN 15501 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

FprEN 15501 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI oSIST prEN 15501:2006

PREDSTANDARD

may 2006

Toplotnoizolacijski proizvodi za opremo stavb in industrijske inštalacije -

Proizvodi iz ekspandiranega perlita (EPB) in vermikulita (EV) - Specifikacije

Thermal insulation products for building equipment and industrial installations -

Factory made expanded perlite (EP) and exfoliated vermiculite (EV) products -

Specification

ICS 91.120.10 Referenčna številka

oSIST prEN 15501:2006(en)

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

DRAFT

prEN 15501

NORME EUROPÉENNE

EUROPÄISCHE NORM

March 2006

ICS

English Version

Thermal insulation products for building equipment and industrial

installations - Factory made expanded perlite (EP) and

exfoliated vermiculite (EV) products - Specification

Produits isolants thermiques pour l'équipement du bâtiment Wärmedämmstoffe für die Haustechnik und für

et les installations industrielles - Produits manufacturés en betriebstechnische Anlagen - Werkmäßig hergestellte

perlite expansée (EP) et à base de vermiculite exfoliée (EV) Produkte aus Blähperlit (EP) und expandiertem Vermiculite

- Spécification (EV) - Spezifikation

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 88.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2006 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15501:2006: E

worldwide for CEN national Members.

prEN 15501:2006 (E)

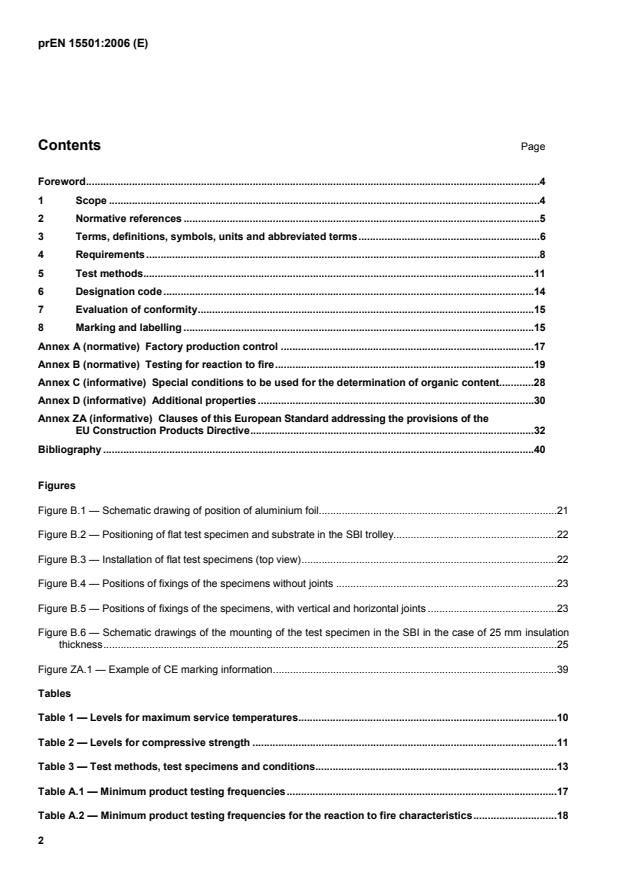

Contents Page

Foreword.4

1 Scope .4

2 Normative references .5

3 Terms, definitions, symbols, units and abbreviated terms.6

4 Requirements.8

5 Test methods.11

6 Designation code.14

7 Evaluation of conformity.15

8 Marking and labelling .15

Annex A (normative) Factory production control .17

Annex B (normative) Testing for reaction to fire.19

Annex C (informative) Special conditions to be used for the determination of organic content.28

Annex D (informative) Additional properties .30

Annex ZA (informative) Clauses of this European Standard addressing the provisions of the

EU Construction Products Directive.32

Bibliography .40

Figures

Figure B.1 — Schematic drawing of position of aluminium foil.21

Figure B.2 — Positioning of flat test specimen and substrate in the SBI trolley.22

Figure B.3 — Installation of flat test specimens (top view).22

Figure B.4 — Positions of fixings of the specimens without joints .23

Figure B.5 — Positions of fixings of the specimens, with vertical and horizontal joints .23

Figure B.6 — Schematic drawings of the mounting of the test specimen in the SBI in the case of 25 mm insulation

thickness.25

Figure ZA.1 — Example of CE marking information.39

Tables

Table 1 — Levels for maximum service temperatures.10

Table 2 — Levels for compressive strength .11

Table 3 — Test methods, test specimens and conditions.13

Table A.1 — Minimum product testing frequencies.17

Table A.2 — Minimum product testing frequencies for the reaction to fire characteristics.18

prEN 15501:2006 (E)

Table B.1 — Product parameters .19

Table B.2 — End use application parameters.20

Table D.1 — Test methods, test specimens, conditions and minimum testing frequencies .31

Table ZA.1 — Relevant clauses.33

Table ZA.2 - System(s) of attestation of conformity .34

Table ZA.3.1 — Assignment of evaluation of conformity tasks for products under system 1.35

Table ZA.3.2 — Assignment of evaluation of conformity tasks for products under system 3 or system 3

combined with system 4 for reaction to fire.36

prEN 15501:2006 (E)

Foreword

This document (prEN 15501:2006) has been prepared by Technical Committee CEN/TC 88 “Thermal insulating

materials and products”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This European Standard has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports the essential requirements of EU Directive(s).

For relationship with EU Directive(s), see informative Annex ZA which is an integral part of this standard.

Locally responsible authorities and contracting entities, who are bound by EU Directives to specify their

requirements using European harmonized product standards, shall be allowed to demand additional properties

outside the provisions of this standard if this is technically necessary due to prevailing operational conditions of the

building equipment or the industrial installation projected or due to safety regulations.

This European Standard contains five annexes:

Annex A (normative) Factory production control

Annex B (normative) Testing for reaction to fire

Annex C (normative) Special conditions to be used for the determination of organic content

Annex D (informative) Additional properties

Annex ZA (informative) Clauses of this European Standard addressing the provisions of the EU Construction

Products Directive

This European standard contains a Bibliography.

This European Standard is one of a series of standards for insulation products used in building equipment and

industrial installations, but this standard may be used in other areas where appropriate.

1 Scope

This European Standard specifies the requirements for factory made expanded perlite and exfoliated vermiculite

products which are used for the thermal insulation of building equipment and industrial installations with an

operating temperature in the range of approximately 0°C to + 1 300°C.

The products are manufactured in the form of boards, pipe sections, segments and prefabricated ware.

This standard describes product characteristics and includes procedures for testing, evaluation of conformity,

marking and labelling.

Products covered by this standard are also used in prefabricated thermal insulation systems and composite panels;

the performance of systems incorporating these products is not covered.

This standard does not specify the required level of a given property that shall be achieved by a product to

demonstrate fitness for purpose in a particular application. The levels required for a given application are to be

found in regulations and invitations to tender.

This standard does not cover products intended to be used for the insulation of building structure.

prEN 15501:2006 (E)

The standard does not cover the following acoustical aspects: direct airborne sound insulation, impact noise index

and sound absorption.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references,

only the edition cited applies. For undated references, the latest edition of the referenced document (including any

amendments) applies.

EN 822, Thermal insulating products for building applications — Determination of length and width.

EN 823, Thermal insulating products for building applications — Determination of thickness.

EN 824, Thermal insulating products for building applications — Determination of squareness.

EN 825, Thermal insulating products for building applications — Determination of flatness.

EN 826, Thermal insulating products for building applications — Determination of compression behaviour.

EN 993-14, Methods of test for dense shaped refractory products. Determination of thermal conductivity by the

hot-wire (cross-array) method.

EN 1094-6, Insulating refractory products — Determination of permanent change in dimensions of shaped products

on heating.

EN 1604, Thermal insulating products for building applications -– Determination of dimensional stability under

specified temperature and humidity conditions.

EN 12086, Thermal insulating products for building applications — Determination of water vapour transmission

properties.

EN 12667, Thermal performance of building materials and products — Determination of thermal resistance by

means of guarded hot plate and heat flow meter methods — Products of high and medium thermal resistance.

EN 12939, Thermal performance of building materials and products — Determination of thermal resistance by

means of guarded hot plate and heat flow meter methods — Thick products of high and medium thermal resistance.

EN 13172:2001, Thermal insulating products — Evaluation of conformity.

EN 13238, Reaction to fire tests for building products — Conditioning procedures and general rules for selection of

substrates.

EN 13467, Thermal insulating products for building equipment and industrial installations — Determination of

dimensions, squareness and linearity of preformed pipe insulation.

EN 13468, Thermal insulating products for building equipment and industrial installations — Determination of trace

quantities of water soluble chloride, fluoride, silicate and sodium ions and pH.

EN 13501-1:2002, Fire classification of construction products and building elements — Part 1: Classification using

test data from reaction to fire test.

EN 13823, Reaction to fire tests for building products — Building products excluding flooring exposed to the

thermal attack by a single burning item.

EN ISO 1182, Reaction to fire tests for building products — Non-combustibility test (ISO 1182:2002).

EN ISO 1716, Reaction to fire tests for building products — Determination of the heat of combustion (ISO

1716:2002).

prEN 15501:2006 (E)

EN ISO 8497, Thermal insulation — Determination of steady-state thermal transmission properties of thermal

insulation for circular pipes (ISO 8497:1994).

prEN ISO 9229, Thermal insulation — Definitions of terms (ISO/DIS 9229:1997).

EN ISO 11925-2, Reaction to fire tests — Ignitability of building products subjected to direct impingement of flame

— Part 2: Single flame source test (ISO 11925-2:2002).

EN ISO 13787, Thermal insulating products for building equipment and industrial installations — Determination of

declared thermal conductivity (ISO 13787:2003).

3 Terms, definitions, symbols, units and abbreviated terms

3.1 Terms and definitions

For the purpose of this European standard, the following terms and definitions apply.

3.1.1 Terms and definitions as given in prEN ISO 9229

3.1.1.1

expanded perlite

lightweight granular (insulation) material manufactured from naturally occurring volcanic rock expanded by heat to

form a cellular structure

3.1.1.2

exfoliated vermiculite

insulation material which results from expanding or exfoliating a natural micaceous mineral by heating

3.1.1.3

board, slab

rigid or semi-rigid (insulation) product of rectangular shape and cross section in which the thickness is uniform and

substantially smaller than the other dimensions

NOTE Boards are usually thinner than slabs. They may also be supplied in tapered form.

3.1.1.4

pipe section

(insulation) product in the shape of a cylindrical annulus which may be split to facilitate application

3.1.1.5

segment

rigid insulation product for application to large diameter cylindrical or spherical equipment

3.1.1.6

block

(insulation) product generally of rectangular cross section and with a thickness not significantly smaller than the

width

3.1.2 Additional terms and definitions

3.1.2.1

level

given value which is the upper or lower limit of a requirement. The level is given by the declared value of the

characteristic concerned

3.1.2.2

class

combination of two levels of the same property between which the performance shall fall

prEN 15501:2006 (E)

3.1.2.3

prefabricated ware

pieces cut, abraded or otherwise formed

3.1.2.4

production line

assemblage of equipment that produces products in a continuous process. For ITT and FPC, each line is

considered separately

3.1.2.5

production unit

assemblage of equipment that produces products in a discontinuous process. For ITT and FPC, units using the

same process in one factory are considered together (as one production line)

3.2 Symbols, units and abbreviated terms

Symbols and units used in this standard:

b is the width mm

D is the inside diameter mm

i

d is the thickness mm

d is the declared thickness of the product mm

D

∆ε is the relative change in width %

b

∆ε is the relative change in thickness %

d

∆ε is the relative change in length %

l

L is the deviation from linearity mm

l is the length mm

λ is the thermal conductivity W/(m·K)

λ is the declared thermal conductivity W/(m·K)

D

µ is the water vapour diffusion resistance factor —

S is the deviation from squareness for boards on length and width mm/m

b

S is the deviation from squareness for boards on thickness mm

d

S is the deviation from flatness mm

max

σ is the compressive strength kPa

b

σ is the bending strength kPa

m

v is the deviation from squareness for pipe sections mm

ρ is the apparent density kg/m

a

X is the deformation at time t mm

t

Z is the water vapour resistance m h Pa/mg

BS is the symbol of the declared level for bending strength

CL is the symbol of the declared level for soluble chloride ions

F is the symbol of the declared level for soluble fluoride ions

CS(Y) is the symbol of the declared level for compressive strength

CS(10) is the symbol of the declared level for compressive stress at 10 % deformation

L is the symbol of the declared level for linearity

MU is the symbol of the declared value for water vapour diffusion resistance factor

ST(+) is the symbol of the declared level for maximum service temperature

Abbreviated terms used in this standard:

EP is Expanded Perlite

EV is Exfoliated Vermiculite

ITT is Initial Type Test

ML is Manufacturer’s Literature

FPC is Factory Production Control

RtF is Reaction to Fire

prEN 15501:2006 (E)

4 Requirements

4.1 General

Product properties shall be assessed in accordance with clause 5. To conform with this standard, products shall

meet the requirements of 4.2, and the requirements of 4.3 as appropriate.

For FPC, see Table A.1 and Table A.2.

NOTE 1 Information on additional properties is given in annex D.

One test result for a product property is the average of the measured values on the number of test specimens given

in Table 3.

NOTE 2 Apparent density is a useful parameter, among others, for identification but it should not be used as a basis for the

quality assessment of mineral wool products.

Apparent density of boards should be determined in accordance with EN 1602, Thermal insulating products for building

applications – Determination of the apparent density. No mean value of a product should deviate by more than ± 10 15% from

the declared value given in ML.

Apparent density of pipe sections, if voluntarily declared by the manufacturer, will be determined in accordance with EN 13470,

Thermal insulating products for building applications – Determination of the apparent density of preformed pipe insulation. No

mean value of a product should deviate by more than ± 15% from the declared value given in ML.

4.2 For all applications

4.2.1 Thermal conductivity

For flat specimens, thermal conductivity shall be based upon measurements carried out in accordance with EN

12667 or EN 12939 for thick products or EN 993-14 (this test is calibrated against EN 12939). For cylindrical

specimens EN ISO 8497 is used as specified in 5.3.2. The thermal conductivity values shall be declared by the

manufacturer and verified in accordance with EN ISO 13787. They shall be declared by the manufacturer at

reference mean temperatures covering the product service temperature range. The following conditions apply:

the measured values shall be expressed with three significant figures;

the declared thermal conductivity curve shall be given as a limit curve, defined in EN ISO 13787;

the values of the thermal conductivity, λ , shall be rounded upwards to the nearest 0,001 W/(m·K).

D

4.2.2 Dimensions and tolerances

4.2.2.1 Linear dimensions

The length, l, width, b, and thickness, d, of boards and the dimensions of pipe sections and special shapes shall be

respectively determined in accordance with EN 822, EN 823 and EN 13467. No test result shall deviate from the

manufacturer’s declared values.

4.2.2.1 Squareness

Deviation from squareness of boards, S and S , shall be determined in accordance with EN 824 and deviation

b d

from squareness for pipe sections and segments, v in accordance with EN 13467. The deviation from squareness

of boards on length and width, S , shall not exceed the manufacturer’s declared values and the deviation from

b

squareness of boards on thickness, S , shall not exceed the manufacturer’s declared values. For pipe sections and

d

segments the deviation from squareness, ν, shall not exceed the manufacturer’s declared values.

prEN 15501:2006 (E)

4.2.2.2 Flatness

Deviation from flatness, S , shall be determined for boards in accordance with EN 825. The deviation from

max

flatness, S , shall not exceed the manufacturer’s declared values.

max

4.2.2.3 Pipe section linearity

Deviation from linearity, L shall be determined in accordance with EN 13467. The deviation from linearity, L, shall

not exceed the manufacturer’s declared values.

4.2.3 Dimensional stability

Dimensional stability under specified temperature and humidity conditions shall be determined in accordance with

EN 1604. The test shall be carried out after storage for 48 h at (23 ± 2) °C and (90 ± 5) % relative humidity. The

relative changes in length, ∆ε and width, ∆ε shall not exceed the manufacturer’s declared values. The relative

l b

change in thickness, ∆ε shall not exceed the manufacturer’s declared values.

d

4.2.4 Reaction to fire

Reaction to fire classification (Euroclasses) shall be determined in accordance with EN 13501-1.

For products applied on a flat surface or a curved surface with a diameter above 500 mm, EN 13501-1 shall be

used.

If a flat product, which has a classification according to EN 13501-1, is used in a linear application, it does not

require an additional classification.

The product shall be tested according to annex B.

EP/EV Products containing less than 1% organic content are classified without testing as class A1 products.

NOTE For products applied on linear objects or with a diameter below or equal 500 mm, an amendment of EN 13501-

1:2002 is in preparation in accordance with Commission Decision of 26 August 2003 amending Decision 2000/147/EC

implementing Council Directive 89/106/EEC published in the Official Journal L 220, 3.9.2003, p.5.

4.2.5 Durability characteristics

4.2.5.1 General

The appropriate durability characteristics have been considered and are covered in 4.2.5.2, 4.2.5.3 and 4.2.5.4.

4.2.5.2 Durability of reaction to fire against ageing/degradation and high temperature

The reaction to fire performance of EP/EV products does not change with time or when subjected to high

temperature.

4.2.5.3 Durability of thermal resistance against ageing/degradation

The thermal conductivity of EP/EV products does not change with time. This is covered by 4.2.1 thermal

conductivity, 4.2.2 dimensions and tolerances and 4.2.3 dimensional stability or 4.3.2 maximum service

temperature (dimensional stability).

4.2.5.4 Durability of thermal resistance against high temperature

The thermal conductivity of EP/EV products does not change with time at any specific temperature within the

service temperature range. This is covered by 4.3.2 maximum service temperature (dimensional stability).

prEN 15501:2006 (E)

4.3 For specific applications

4.3.1 General

If there is no requirement for a property described in clause 4.3 for a product in use, then that property does not

need to be determined and declared by the manufacturer.

4.3.2 Maximum service temperature

The maximum service temperature, ST(+), for flat products shall be determined in accordance with EN 1094-6.

At the maximum service temperature, ST(+), the relative changes in length ∆ε, and width ∆ε , shall not exceed

l b

2,5%.

The maximum service temperature, ST(+), shall be declared in centigrades in levels with steps of 50 °C.

Table 1 — Levels for maximum service temperatures

Level Requirement

°C

ST(+) 650 ≥ 650

ST(+) 700 ≥ 700

ST(+) 750 ≥ 750

ST(+) 800 ≥ 800

ST(+) 850 ≥ 850

ST(+) 900 ≥ 900

ST(+) 950 ≥ 950

ST(+) 1000 ≥ 1000

ST(+) 1050 ≥ 1050

ST(+) 1100 ≥ 1100

ST(+) 1150 ≥ 1150

ST(+) 1200 ≥ 1200

ST(+) 1250 ≥ 1250

ST(+) 1300 ≥ 1300

prEN 15501:2006 (E)

4.3.3 Compressive strength of flat products

Compressive strength at 10 % deformation shall be determined in accordance with EN 826. No test result shall be

less than the value, given in Table 2, for the declared level.

Table 2 — Levels for compressive strength

Level Requirement

kPa

CS(10)250 ≥ 250

CS(10)500 ≥ 500

CS(10)1000 ≥ 1000

CS(10)2000 ≥ 2000

CS(10)5000 ≥ 5000

CS(10)10000 ≥ 10000

CS(10)15000 ≥ 15000

CS(10)20000 ≥ 20000

CS(10)30000 ≥ 30000

NOTE EN 826 is not applicable to pipe sections.

4.3.4 Water vapour transmission

The water vapour transmission shall be determined in accordance with EN 12086, and declared as the water

vapour diffusion resistance factor, µ.

4.3.5 Trace quantities of water soluble ions and the pH value

Trace quantities of water soluble chloride, fluoride, silicate and sodium ions and the pH value shall be determined,

if required, in accordance with EN 13468. The manufacturer shall declare one or more as appropriate as levels in

mg per kg of product, and the pH value as levels in steps of 0,5.

4.3.6 Release of dangerous substances

NOTE see annex ZA.

5 Test methods

5.1 Sampling

Flat test specimens shall be taken from the same sample and sufficient to cover the needed tests.

Pipe section specimens shall be taken from a sample consisting of at least 3 full size sections.

If this is not possible, the properties of the product shall be measured on the boards from which the product is

fabricated. In all cases dimensions and when relevant squareness and flatness shall be measured on the finished

product.

prEN 15501:2006 (E)

5.2 Conditioning

No special conditioning of the test specimens is needed unless otherwise specified in the test standard. The

outside surface of the test specimens shall be free from dust and water. In case of dispute, the test specimens shall

be stored at (23 ± 2) °C and (50 ± 5) % relative humidity for at least 6 h prior to testing.

5.3 Testing

5.3.1 General

Table 3 gives the dimensions of the test specimens, the minimum number of test specimens required to get one

test result and any specific conditions, which are necessary.

In the case of pipe sections and prefabricated wares cut from boards, the properties shall be determined on the

boards from which they are cut, except dimensions and, where relevant, linearity and squareness.

prEN 15501:2006 (E)

Table 3 — Test methods, test specimens and conditions

Clause Test method Test specimen Minimum Specific

dimensions number of conditions

No Title Flat Cylindrical

(mm) measurements

to get one test

result

4.2.1 Thermal EN 12667 ≥ 300 x 300 x d 1 —

conductivity or

EN 12939 ≥ 300 x 300 x d 1 —

or

EN 993-14 ≥ 230 x 114 x d 1 —

EN ISO 8497 Full-size 1 —

4.2.2 Dimensions and

tolerances

Length and width EN 822 EN 13467 Full-size 1 —

Thickness EN 823 EN 13467 Full-size 1 —

Inside diameter EN 13467 Full-size 1 —

4.2.2.2 Squareness EN 824 EN 13467 Full-size 1 —

4.2.2.3 Flatness EN 825 Full-size 1 —

4.2.2.4 Pipe section EN 13467 Full-size 1 —

linearity

4.2.3 Dimensional EN 1604 Full-size 1 —

stability

500 x 500 x d 3

250 x 250 x d 3

200 x 200 x d 3

4.2.4 Reaction to fire EN 13501-1 Annex B

4.3.2 Maximum service EN 1094-6 EN 1094-6 100 x 100 x d 3 —

temperature

4.3.3 Compressive EN 826 see 6.1 in EN 826 3 —

strength

4.3.4 Water vapour EN 12086 see 6.1 in EN 3 —

transmission 12086

EN 13469 see 6.1 in EN 3 see 6.1 in EN

13469 13469

4.3.5 Trace quantities of EN 13468 — 3

water soluble ions

and the pH value

a a

4.3.6 Release of — — —

dangerous

a

substances

a

Not yet available

5.3.2 Thermal conductivity

For flat test specimens thermal conductivity shall be determined in accordance with EN 12667 or EN 12939 or EN

993-14 (when EN 993-14 is calibrated against EN 12667 or EN 12939). For cylindrical test specimens thermal

conductivity shall be determined in accordance with EN ISO 8497.

prEN 15501:2006 (E)

The tests in accordance with EN ISO 8497 may be replaced by tests in accordance with EN 12667, EN 12939 for

thick products or EN 993-14, provided it has been demonstrated that the results are safe (higher) values.

The thermal conductivity shall be determined for the full temperature range of the product. For FPC see annex A.

The thermal conductivity shall be determined directly at the measured thickness. If this is not possible it shall be

determined by measurements on other thicknesses of the product providing that:

the product is of similar chemical and physical characteristics and is produced on the same production

unit/line;

and it can be demonstrated that the thermal conductivity does not vary more than 10 % over the range of

thicknesses where the calculation is applied.

Where a product is manufactured in a range of thicknesses, and the manufacturer chooses to characterize the

entire range by declaring only one thermal conductivity, the highest thermal conductivity of the range shall be

declared.

In the case of pipe sections, measurements made on two internal diameters of pipe sections at the greatest and

smallest insulation thickness for each of the diameters are deemed to be representative of the total product range.

NOTE Suitable sizes are 48 mm and 194 mm internal diameter.

The guarded hot plate method, EN 12667 or EN 12939 for thick products or EN 993-14, shall be deemed to be a

suitable method for measurements of pipe sections having an internal diameter exceeding 500 mm. Flat slabs shall

be prepared having the same thickness and density as the sections.

In the case of special shapes, flat slabs of suitable thickness size compaction and density shall be prepared.

5.3.3 Maximum service temperature

Maximum service temperature shall be determined in accordance with EN 1094-6 at the declared maximum service

temperature. Specimens for testing the maximum service temperature of pipe sections, segments and special

shapes may be cut from flat boards with the same composition and density as the pipe section or segment product.

5.3.4 Reaction to fire

Tests shall be carried out in accordance with EN 13501-1.

Rules for mounting and fixing are given in annex B.

6 Designation code

A designation code for the product shall be given by the manufacturer. The following shall be included except when

there is no requirement for a property described in 4.3:

The abbreviated term EP/EV

This European Standard number EN xxxxx

Maximum service temperature ST(+)

Compressive strength CS(10)i

Water vapour diffusion resistance factor Mui

Trace quantities of water soluble chloride ions Cli

Trace quantities of water soluble fluoride ions Fi

prEN 15501:2006 (E)

Trace quantities of water soluble silicate ions Sli

Trace quantities of water soluble sodium ions Nai

Level of the pH pHi

where “i” shall be used to indicate the relevant class or level.

The designation code for an EP/EV product is illustrated by the following example:

EP/EV – EN xxxxx – ST(+) 430 – CS(10)500

7 Evaluation of conformity

The manufacturer or his authorised representative shall be responsible for the conformity of his product with the

requirements of this European Standard. The evaluation of conformity shall be carried out in accordance with

EN 13172 and shall be based on initial type testing (ITT), factory production control (FPC) by the manufacturer,

including product assessment and tests on samples taken at the factory.

ITT shall be carried out in accordance with EN 13172 for all characteristics declared except thermal conductivity.

ITT for the thermal conductivity curve shall be carried out in accordance with EN ISO 13787.

For ITT testing of the λ curve and the maximum and minimum service temperatures only one test result is required,

using test specimens from four different production dates.

FPC testing shall be made for the characteristics listed in annex A.

The minimum frequencies of tests in the factory production control shall be in accordance with annex A. When

indirect testing is used, the correlation to direct testing shall be established in accordance with EN 13172.

If a manufacturer decides to group his products, it shall be done in accordance with EN 13172.

The manufacturer or his authorised representative shall make available, in response to a request, a certificate or

declaration of conformity as appropriate.

NOTE For the CE certificate and declaration of conformity, as appropriate, see ZA.2.2.

8 Marking and labelling

Products conforming with this standard shall be clearly marked, either on the product or on the label or on the

packaging, with the following information:

product name or other identifying characteristic;

name or identifying mark and address of the manufacturer or their authorised representative in the European

Economic Area;

year of manufacture (the last two digits);

shift or time of production and manufacturing plant or traceability code;

reaction to fire class; specific test conditions shall be indicated with the marking by reference to manufacturer's

literature, where relevant.

declared thermal conductivity; reference to ML, showing thermal conductivity as a function of mean

temperatures given as a table, curve or equation;

declared thickness, if appropriate;

prEN 15501:2006 (E)

designation code as given in clause 6;

type of facing, if any;

declared length and declared width or inside diameter, as appropriate;

number of pieces and area in the package, as appropriate.

NOTE For CE conformity mark see ZA.3.

prEN 15501:2006 (E)

Annex A

(normative)

Factory production control

Table A.1 — Minimum product testing frequencies

a

Clause Minimum testing frequency

No. Title

4.2.1 Thermal conductivity

at the declared temperature range 1 per 2 years

4.2.2 Dimensions and tolerances 1 per production lot

4.2.2.2 Squareness 1 per production lot

4.2.2.3 Flatness 1 per production lot

4.2.2.4 Pipe section linearity 1 per production lot

b

4.2.3 Dimensional stability ITT

4.2.4 Reaction to fire see Table A.2

b

4.3.2 Maximum service temperature ITT

4.3.3 Compressive strength 1 per production lot

b

4.3.4 Water vapour transmission ITT

b

4.3.5 Trace quantities of water soluble ions ITT

c

4.3.6 Release of dangerous substances

a

The minimum testing frequencies, expressed in test results required per period, shall be understood as the minimum for continuous

production for each production unit/line under stable conditions. In the case of pipe sections, it shall be understood as the minimum for

each production batch under stable conditions. In addition to the testing frequencies given above, testing of relevant properties of the

product shall be repeated when changes or modifications are made that are likely to affect the conformity of the product. For mechanical

properties, the testing frequencies are independent of the change of product. In addition, the manufacturer shall establish internal rules for

process adjustments related to these properties when changing the product.

b

ITT, see EN 13172.

c

Frequencies are not given.

prEN 15501:2006 (E)

Table A.2 — Minimum product testing frequencies for the reaction to fire characteristics

a

Clause Minimum testing frequency

c

No. Title Indirect testing

b

Direct testing

4.2.4

Product

Reaction to

fire class

Test method Frequency Test method Frequency

d

A1 prEN 13820 or EN ISO ITT and Check composition 1 per production lot

1182 and indirect testing

EN ISO 1716

(and EN 13823)

A2 EN ISO 1182 or ITT and Check raw material and composition 1 per production lot

EN ISO 1716 indirect testing

and EN 13823

a

The minimum testing frequencies expressed in test results required per period, shall be understood as the minimum for a product or product group for each production unit/line under stable conditions.

In addition to the testing frequencies given above, testing of relevant properties of the product shall be repeated when changes or modifications are made that are likely to affect the conformity of the

product.

b

Direct testing may be conducted either by a third party or by the manufacturer.

c

Indirect testing may be either on the product or on its components, it is only possible in case of product certification.

d

European Decision 96/603/EC : Materials to be considered as reaction to fire class A1 provided for in Decision 94/611/EC without the need for testing (of reaction to fire characteristics).

prEN 15501:2006 (E)

Annex B

(normative)

Testing for reaction to fire

B.1 Scope

This annex gives the basic rules for reaction to fire testing on EP/EV products, including instructions for

mounting and fixing, taking into account the end-use application, flat surface and pipe covering.

Products for the application on pipes with diameters up to 500 mm shall be mounted according to B.4. All

other products shall be tested as flat specimens.

NOTE This annex is necessary for CE marking.

B.2 Product and end use application parameters

The Tables B.1 and B.2 give the parameters which have to be considered when determining a products

reaction to fire performance and the field of application of the test result.

Table B.1 — Product parameters

Standards

Product parameters

EN 13823 EN ISO 11925-2

(Class A1 -D) (Class B - E)

Unfaced products

Thickness X –

Density – –

Chemical composition of product X X

Additional properties for faced products

Type of facings or coatings X X

Thickness/area weight of facing(s) or coatings X X

Type and amount of glue for facing X X

prEN 15501:2006 (E)

Table B.2 — End use application parameters

Standards

Product parameters

EN 13823 EN ISO 11925-2

(Class A1 -D) (Class B - E)

Substrate X X

Air gaps/cavities – –

Joints X –

Size and positioning of the test specimen X –

Product orientation and geometry – –

Fixing of test specimen X –

Exposure to thermal attack X X

Special prefabricated shapes, e.g. elbows, T-pieces, shall be deemed to have the same fire classification as

tested products of the same product group.

B.3 Standardized mounting and fixing

B.3.1 EN ISO 11925-2 (Ignitability)

a) The thickness of the EP/EV product does not influence the test result. Tests shall be performed on

samples with the largest thickness required by the manufacturer for reaction to fire classification. The

result is valid for all thicknesses.

b) The test specimen is mounted in the test apparatus fixed on steel plates or pipes.

B.3.2 EN 13823 (SBI)

Conditioning of the test specimens prior to testing shall follow the rules of EN 13823.

NOTE To prevent any damage of the SBI test equipment, an aluminium foil may be applied to the bottom of the test

specimen as shown in Figure B.1, if agreed with the manufacturer.

prEN 15501:2006 (E)

Key

1 Backing board

2 Test specimen

3 U-profile

4 Burner

5 Aluminium foil

Figure B.1 — Schematic drawing of position of aluminium foil

B.3.2.1 Substrate

The substrate to be used to test flat products as placed on the market is a steel sheet defined in EN 13238, for

pipe insulation testing always steel pipes. Any heat deformation of the metal substrate shall be prevented.

For specific applications of flat products, substrates as defined in EN 13238 (conditioning + substrates) may

be used.

B.3.2.2 Air gaps/cavities

EP/EV products are tested without air gaps/cavity between the test specimen and the substrate. An air gap of

at least 40 mm shall be used between the substrate and the backing board.

B.3.2.3 Joints for flat products

Horizontal or vertical joints shall always be positioned in accordance with 5.2.2.e) of EN 13823, where such

joints are required. The area of each section of the long wing formed as a consequence of the horizontal or

vertical joints shall be filled with full-sized products starting at the uninstalled part which is lowest and nearest

to the corner line between the two wings.

B.3.2.4 Size and positioning of flat test specimen

The size of the test specimens are given in 5.1 of EN 13823. The test specimen shall be cut from the products

including their facings or coatings. Positioning of the test specimens shall meet the following specification:

Products having larger dimensions than the SBI; test specimen shall be cut to size.

Products having smaller dimensions than the SBI; test specimen shall be mounted in such a way that

installation of full size products is started at the bottom corner line between both wings.

The specimens installed on the short wing shall cover (on their thickness) those installed on the long wing

with butt joint, see Figure B.2.

prEN 15501:2006 (E)

The maximum thickness of the test specimen including the substrate that can be installed in the SBI is

200 mm.

Key

1 Substrate

Figure B.2 — Positioning of flat test specimen and substrate in the SBI trolley

B.3.2.5 Fixing of flat test specimen

Products shall be fixed in the SBI in a way that is as close as possible to the method used in end use.

Products can either be mechanically fixed or glued.

A test performed on a product fully glued is equally valid for a product with glue applied in evenly distributed

stripes of dots.

Key

1 Backing boards

2 Substrate

3 Long wing test specimen

4 Short wing test specimen

5 Burner

Figure B.3 — Installation of flat test specimens (top view)

prEN 15501:2006 (E)

Figure B.4 — Positions of fixings of the specimens without joints

Figure B.5 — Positions of fixings of the specimens, with vertical and horizontal joints

To ensure that the vertical joint is always 200 mm from the corner the width of the parts on the large wing shall

be given as “200 + d” and “800 – d”.

B.3.2.6 Exposure to thermal attack

The surface of the product shall be exposed to the burner flame as delivered to the market, with or without

factory applied coatings. Classification results thus obtained are also valid for products where a non-

combustible covering (Euroclass A1) is installed in front of the product in the end use. In case combustible

coverings are installed in front of the product in the end use, extra fire testing and classification are required.

B.4 Additional standardized mounting and fixing conditions for pipe insulation

B.4.1 Dimensions of specimens

Products that can be tested in the SBI are pipe insulation with an inside diameter of 22 mm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...