EN 1482-1:2007

(Main)Fertilizers and liming materials - Sampling and sample preparation - Part 1: Sampling

Fertilizers and liming materials - Sampling and sample preparation - Part 1: Sampling

This European Standard specifies a method for the chromatographic determination of the amount of iron chelated by each of the individual isomers of the chelating agent ortho para EDDHA (o,p-EDDHA) in fertilizers. The method allows the identification of this chelating agent and the determination of the water soluble fraction of iron chelated by this chelating agent. The method is not applicable for the determination of the amount of free chelating agent.

NOTE 1 This method has been shown to be also suitable for the determination of the amount of iron chelated by each of the individual isomers of the chelating agent ortho ortho EDDHA (o,o-EDDHA) in fertilizers.

NOTE 2 o,o-EDDHA and o,p-EDDHA are abbreviations used in this European Standard for the sake of simplicity. For complete names see Annex C.

NOTE 3 The substances o,o-EDDHA and o,p-EDDHA both exist as different stereoisomers. For o,o-EDDHA a meso form and a d/l pair (the racemic isomers) exist, for o,p-EDDHA two different d/l pairs exist. All four stereoisomers are observed separately in this method.

NOTE 4 Currently, an analytically pure standard only exists for o,o-EDDHA. The method for o,p-EDDHA has been developed with an o,p-EDDHA standard containing an uncertain concentration of o,p-EDDHA.

Düngemittel und Calcium-/Magnesium-Bodenverbesserungsmittel - Probenahme und Probenvorbereitung - Teil 1: Probenahme

Dieses Dokument beschreibt und/oder legt Probenahmepläne und Verfahren der repräsentativen Beprobung

von Düngemitteln und Calcium-/Magnesium-Bodenverbesserungsmitteln zur Gewinnung von Proben für

physikalische und chemische Untersuchungen fest.

Es ist anwendbar auf Lieferungen von Düngemitteln oder Calcium-/Magnesium- Bodenverbesserungsmitteln

an Dritte, die sie eigenverantwortlich in kleineren Partien weiterverkaufen, wobei sie dabei der lokalen,

nationalen oder regionalen Gesetzgebung unterliegen. Wenn gesetzliche Regeln es erfordern, muss die

Probenahme in Übereinstimmung mit diesem Dokument erfolgen.

Die in diesem Dokument angegebenen Techniken und Verfahren sind auf alle Düngemittel und

Calcium-/Magnesium-Bodenverbesserungsmittel in Verpackungen und in Behältern bis einschließlich einer

Masse von 1 000 kg und auf alle unverpackten Produkte unter der Voraussetzung anwendbar, dass diese in

Bewegung sind.

Dieses Dokument legt Probenahmeverfahren für flüssige Düngemittel einschließlich Lösungen, dünnflüssige

Schlämme, Suspensionen und flüssige Produkte mit entsprechendem Dampfdruck fest.

ANMERKUNG Der Begriff Düngemittel ist durchgängig in diesem Dokument verwendet worden und schließt, wenn

nicht anders angegeben, Calcium-/Magnesium-Bodenverbesserungsmittel ein.

Dieses Dokument enthält keine vollständigen statistischen Probenahmepläne.

Engrais et amendements minéraux basiques - Echantillonnage et préparation de l'échantillon - Partie 1: Echantillonnage

La présente Norme européenne spécifie les plans et les méthodes d’échantillonnage représentatif d’engrais et d’amendements minéraux basiques pour obtenir des échantillons destinés aux analyses physiques et chimiques, à partir d’emballages et de grands récipients d’une masse jusqu’à 1 000 kg inclus, à partir de produits liquides et d’engrais en vrac à condition que le produit soit en mouvement.

Le présent document s’applique aux livraisons d’engrais ou d’amendements minéraux basiques fournis à une tierce partie pour être revendus sous sa propre responsabilité, en lots plus petits, chacun étant soumis à la législation locale, nationale ou régionale en vigueur. Lorsque la législation l’exige, les échantillons sont prélevés conformément à cette présente Norme européenne.

NOTE Le terme « engrais » est utilisé tout au long de cette présente norme et il convient de le considérer comme incluant les amendements minéraux basiques sauf indication contraire.

La présente norme ne couvre pas les plans d’échantillonnage complets et statistiques.

Gnojila in sredstva za apnjenje - Vzorčenje in priprava vzorcev - 1. del: Vzorčenje

General Information

- Status

- Withdrawn

- Publication Date

- 30-Jan-2007

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 260 - Fertilizers and liming materials

- Drafting Committee

- CEN/TC 260/WG 1 - Sampling

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 18-Dec-2024

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 18-Jan-2023

Frequently Asked Questions

EN 1482-1:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Fertilizers and liming materials - Sampling and sample preparation - Part 1: Sampling". This standard covers: This European Standard specifies a method for the chromatographic determination of the amount of iron chelated by each of the individual isomers of the chelating agent ortho para EDDHA (o,p-EDDHA) in fertilizers. The method allows the identification of this chelating agent and the determination of the water soluble fraction of iron chelated by this chelating agent. The method is not applicable for the determination of the amount of free chelating agent. NOTE 1 This method has been shown to be also suitable for the determination of the amount of iron chelated by each of the individual isomers of the chelating agent ortho ortho EDDHA (o,o-EDDHA) in fertilizers. NOTE 2 o,o-EDDHA and o,p-EDDHA are abbreviations used in this European Standard for the sake of simplicity. For complete names see Annex C. NOTE 3 The substances o,o-EDDHA and o,p-EDDHA both exist as different stereoisomers. For o,o-EDDHA a meso form and a d/l pair (the racemic isomers) exist, for o,p-EDDHA two different d/l pairs exist. All four stereoisomers are observed separately in this method. NOTE 4 Currently, an analytically pure standard only exists for o,o-EDDHA. The method for o,p-EDDHA has been developed with an o,p-EDDHA standard containing an uncertain concentration of o,p-EDDHA.

This European Standard specifies a method for the chromatographic determination of the amount of iron chelated by each of the individual isomers of the chelating agent ortho para EDDHA (o,p-EDDHA) in fertilizers. The method allows the identification of this chelating agent and the determination of the water soluble fraction of iron chelated by this chelating agent. The method is not applicable for the determination of the amount of free chelating agent. NOTE 1 This method has been shown to be also suitable for the determination of the amount of iron chelated by each of the individual isomers of the chelating agent ortho ortho EDDHA (o,o-EDDHA) in fertilizers. NOTE 2 o,o-EDDHA and o,p-EDDHA are abbreviations used in this European Standard for the sake of simplicity. For complete names see Annex C. NOTE 3 The substances o,o-EDDHA and o,p-EDDHA both exist as different stereoisomers. For o,o-EDDHA a meso form and a d/l pair (the racemic isomers) exist, for o,p-EDDHA two different d/l pairs exist. All four stereoisomers are observed separately in this method. NOTE 4 Currently, an analytically pure standard only exists for o,o-EDDHA. The method for o,p-EDDHA has been developed with an o,p-EDDHA standard containing an uncertain concentration of o,p-EDDHA.

EN 1482-1:2007 is classified under the following ICS (International Classification for Standards) categories: 65.080 - Fertilizers. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1482-1:2007 has the following relationships with other standards: It is inter standard links to EN 1482:1996, EN 1482:1996/AC:1996, EN 1482-1:2024. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1482-1:2007 is associated with the following European legislation: EU Directives/Regulations: 2003/2003, 2019/1009; Standardization Mandates: M/335. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 1482-1:2007 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Fertilizers and liming materials - Sampling and sample preparation - Part 1: SamplingEngrais et amendements minéraux basiques - Echantillonnage et préparation de l'échantillon - Partie 1: EchantillonnageDüngemittel und Calcium-/Magnesium-Bodenverbesserungsmittel - Probenahme und Probenvorbereitung - Teil 1: ProbenahmeTa slovenski standard je istoveten z:EN 1482-1:2007SIST EN 1482-1:2007en,fr,de65.080GnojilaFertilizersICS:SIST EN 1482:1998/AC:1998SIST EN 1482:19981DGRPHãþDSLOVENSKI

STANDARDSIST EN 1482-1:200701-september-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1482-1January 2007ICS 65.080Supersedes EN 1482:1996

English VersionFertilizers and liming materials - Sampling and samplepreparation - Part 1: SamplingEngrais et amendements minéraux basiques -Echantillonnage et préparation des échantillons - Partie 1:EchantillonnageDüngemittel und Calcium-/Magnesium-Bodenverbesserungsmittel - Probenahme undProbenvorbereitung - Teil 1: ProbenahmeThis European Standard was approved by CEN on 15 December 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1482-1:2007: E

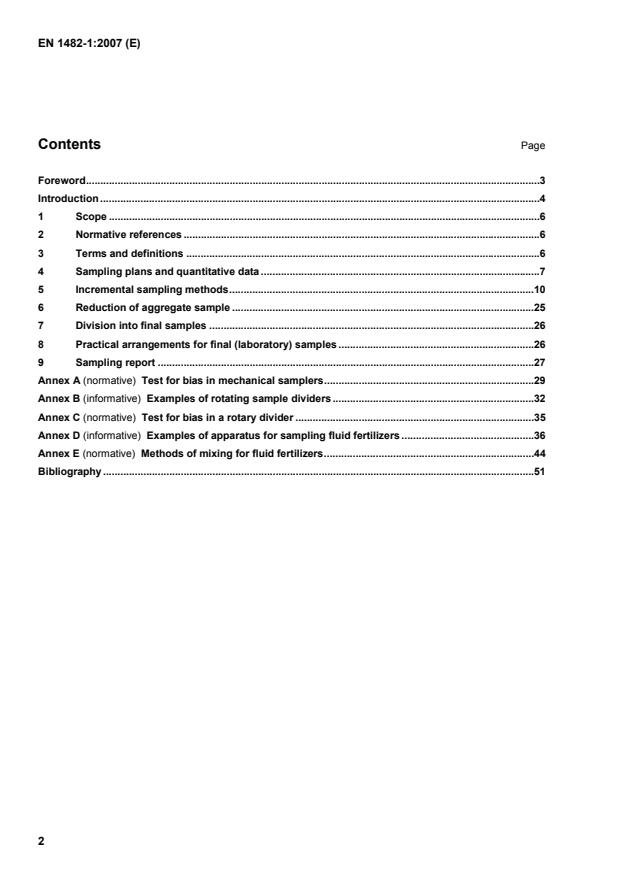

Test for bias in mechanical samplers.29 Annex B (informative)

Examples of rotating sample dividers.32 Annex C (normative)

Test for bias in a rotary divider.35 Annex D (informative)

Examples of apparatus for sampling fluid fertilizers.36 Annex E (normative)

Methods of mixing for fluid fertilizers.44 Bibliography.51

Figure 1 — Schematic diagram of sampling process for solids

Lot size Minimum number of sampling units 4 or fewer packages All packages More than 4 and up to 10 packages 4 More than 10 and up to 400 packages The nearest whole number above the square root of the number of packages present. More than 400 packages 20

4.2.1.3 Product in bulk In the case of product in bulk, the number of sampling units from which incremental samples should be taken depends on the total mass present. The number of sampling units to be sampled should be in accordance with Table 2. Table 2 — Number of sampling units from which incremental samples are to be taken Lot size Minimum number of sampling units 25 t or less 10 More than 25 t and up to 400 t The nearest whole number above the square root of 4 times the number of tonnes present. More than 400 t 40

Divide this time into equal time intervals such that the number of intervals is at least twice the minimum number of sampling units to be sampled in accordance with Table 2 and each sampling unit is not more than 5 t. The time intervals are the sampling units. From these sampling units randomly select the number from which increments are to be taken. Within each of the selected sampling units randomly select a time at which the increment is to be taken. NOTE As there will be some variation in the speed of the belt or the flow in the pipe and the quantity at any one point, it is recommended that the number of sampling units selected is at least 10 % more than the minimum in Table 2. Automatic mechanical samplers normally work at fixed time intervals. In this case the increments are collected over the whole timescale and cannot be regarded as having been taken randomly. For legislative purposes the mechanical sampler shall be operated at the selected random times. 4.2.3 Collection of increments 4.2.3.1 General All incremental samples shall be of approximately the same mass/volume. 4.2.3.2 Solid fertilizer in packages or containers up to and including 50 kg Take one increment from each of the selected packages (sampling units 4.2.2.1), by the use of a divider (5.6 or 5.7) or by the manual method described in 5.8. 4.2.3.3 Product in intermediate bulk containers Collect the relevant number of increments by using the method described in 5.9 and/or 5.10. 4.2.3.4 Solid fertilizer in bulk Collect the relevant number of increments by using one of the methods described in 5.2 to 5.5. 4.2.3.5 Fluid fertilizers Follow the appropriate procedure described in 5.11.

Key 1 sampling cup a direction of sampling cup movement Figure 2 — Method of sampling a free-falling stream

Figure 3 — Example of stream sampling cup 5.5 Solid fertilizer in bulk - Manual sampling method by moving the bulk 5.5.1 General Where the fertilizer to be sampled is in a bulk static heap and is not to be moved at a time or by a method convenient for any of the other methods of sampling described above, then the heap will need to be moved by the sampling official.

sr is the standard deviation for a rotating divider; sf is the standard deviation for a riffle divider. sc is the standard deviation for coning and quartering 5.7.2 Apparatus A riffle divider is a two-way divider without moving parts. It consists of a hopper having two vertical sides and two sloping sides which run the full length of the riffle divider. The hopper feeds a series of at least 12 rectangular slots, each having a width of at least twice the maximum particle size plus 5 mm. Each slot constitutes an opening to a chute; alternate chutes deliver in opposite directions to two receivers. Riffle dividers are commercially available in many sizes ranging from bench size to large floor-mounted models.

Key 1 alternate sections delivered on this side Figure 4 — Riffle sample divider

Key l length of the shovel blade w width of the shovel blade Figure 5 — Example of a shovel 5.9 Sampling from intermediate bulk containers (IBC's) by controlled flow 5.9.1 General This method applies in circumstances where the material is free-flowing and the IBC is not to be reused. Examples would be in a factory where the material can be re-circulated and re-packed or on a farm where the material is about to be used.

Key 1 eye bolts through angle iron. Suspension "U" shackles 10 mm with belting sewn through 2 slotted angle iron reinforcement 3 level of grill and of head of material height line, 100 mm from top of funnel 4 100 mm plywood or appropriate material 5 hinge 6 hinged gate to prevent flow 7 hook and eye to keep gate closed when required Figure 6 — Flow control funnel (top elevation, side elevation, end elevation)

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...